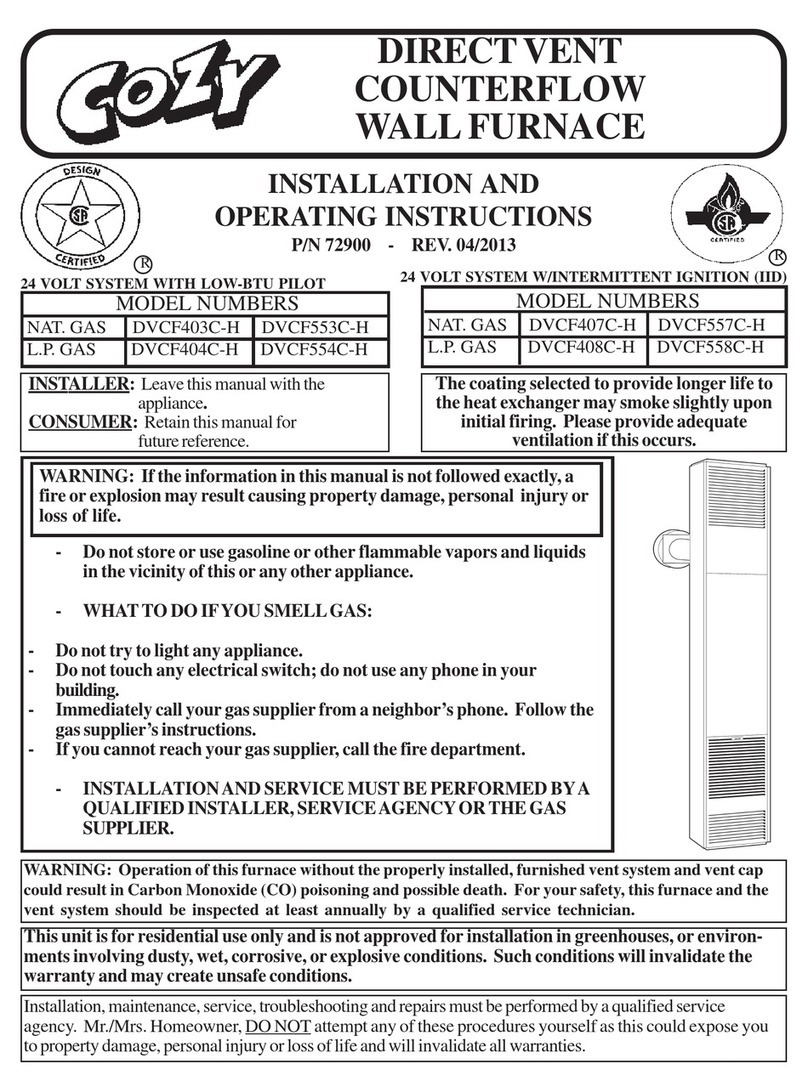

COZY CF557C-H and User manual

Other COZY Wall Furnace manuals

COZY

COZY CF553D-H User manual

COZY

COZY W255G User manual

COZY

COZY CF403D-H User manual

COZY

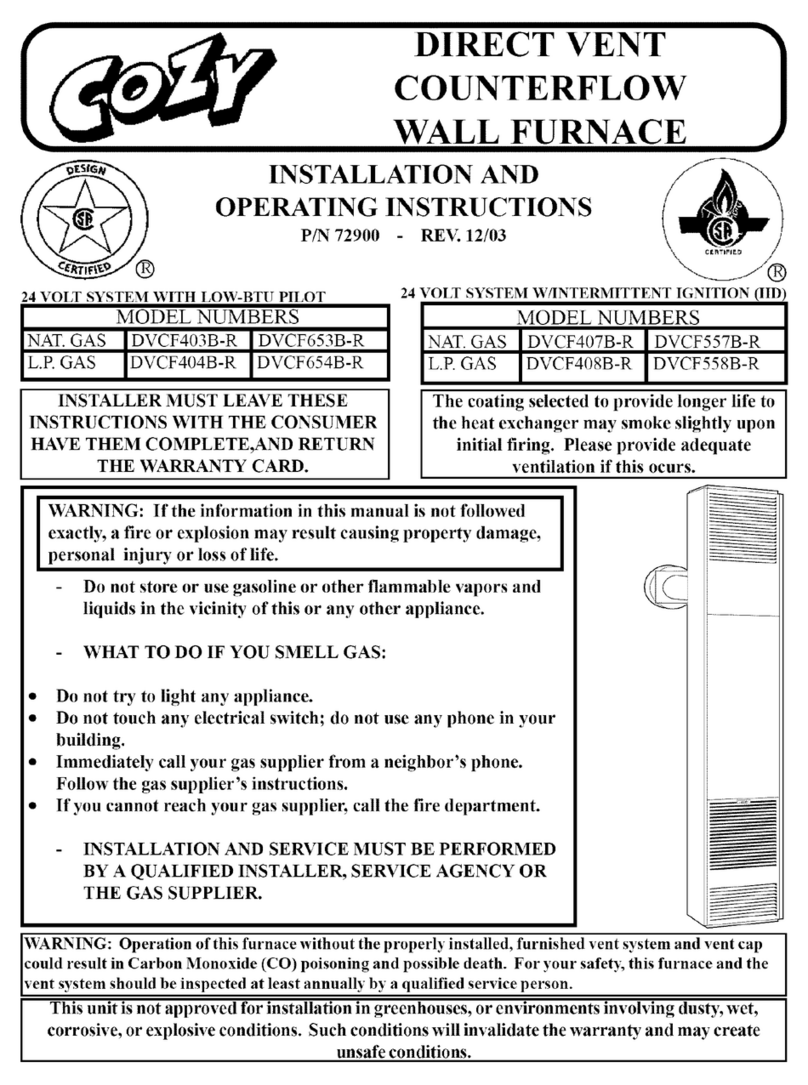

COZY DVCF407B-R and User manual

COZY

COZY DVCF653B-H and User manual

COZY

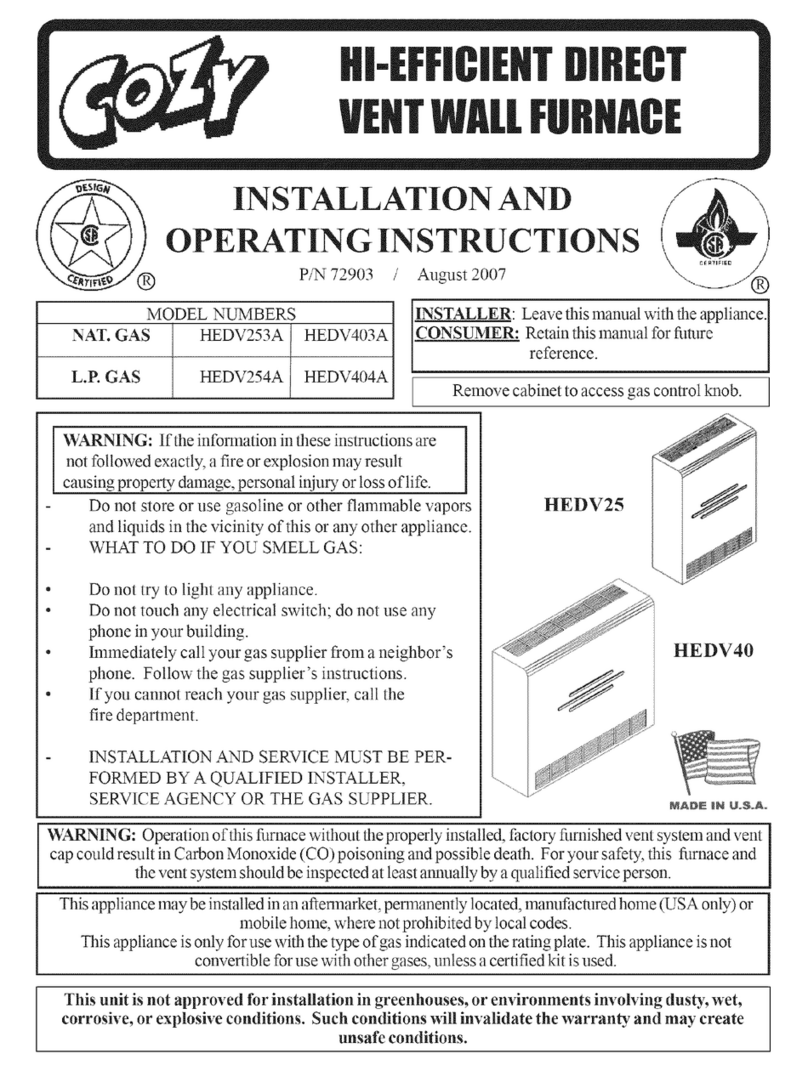

COZY HEDV254A and User manual

COZY

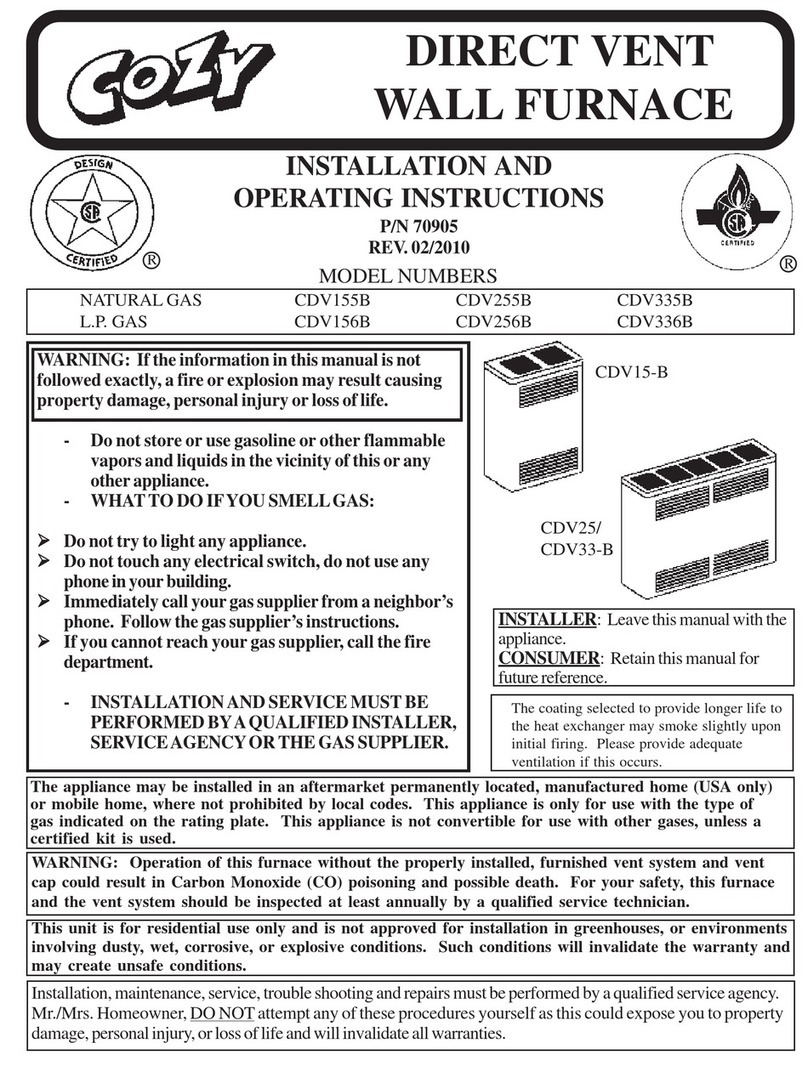

COZY CDV155DPPD User manual

COZY

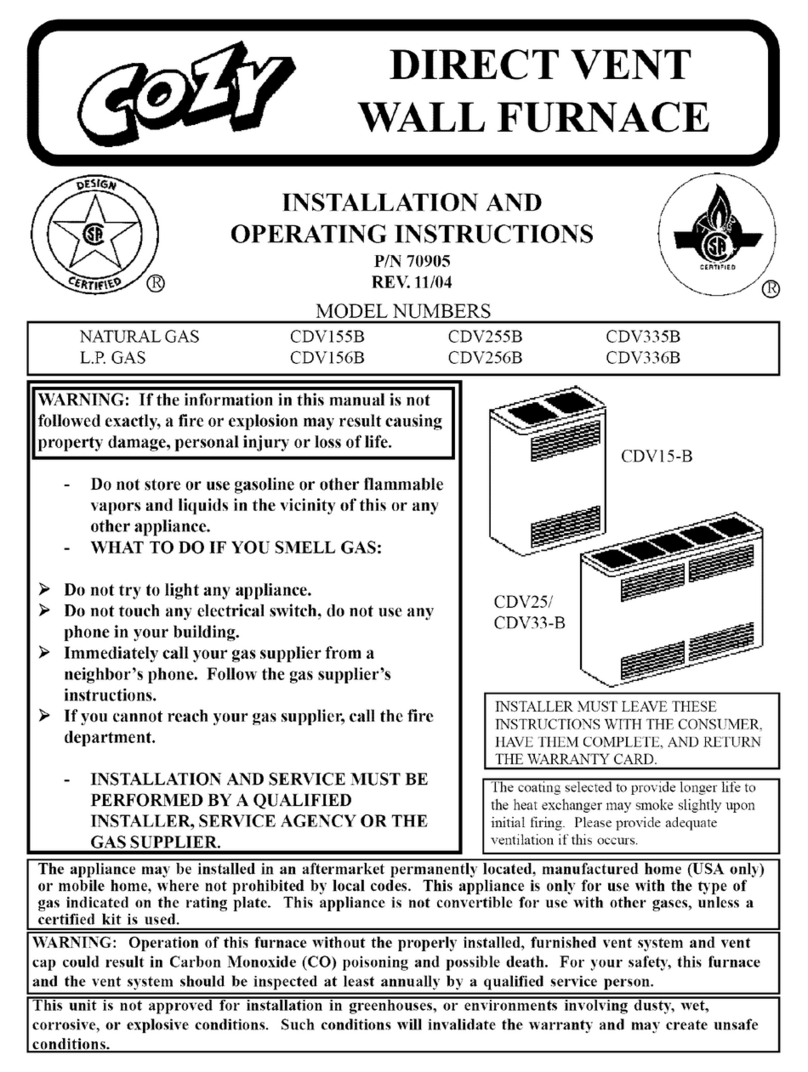

COZY CDV155B and User manual

COZY

COZY CDV335C User manual

COZY

COZY CDV15 User manual

Popular Wall Furnace manuals by other brands

Empire Heating Systems

Empire Heating Systems FAN TYPE VENTED WALL FURNACE FAW-55IP Installation instructions and owner's manual

Braemar

Braemar WF2000 user manual

Empire

Empire FAW40IPXLP-1 Installation instructions and owner's manual

Empire

Empire DV-55IP Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems DV-35-2SG Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems GWT-25-2 SG Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems GWT-25-2 SG Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems DVC55SPPXLP-1 Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems DVC55SPPXLP-2 Installation instructions and owner's manual

Napoleon

Napoleon GDS3700-N Installation and operation instructions

HouseWarmer

HouseWarmer HWDV080DVN-1 owner's manual

Empire Heating Systems

Empire Heating Systems PVS18(N Owner's manual and installation instructions

Empire Heating Systems

Empire Heating Systems DV-25T-1 Installation instructions and owner's manual

Empire Heating Systems

Empire Heating Systems GWT-25 owner's manual

Empire Heating Systems

Empire Heating Systems MV 145 Installation instructions and owner's manual

Longvie

Longvie DV20 owner's manual

Empire

Empire DV-25-2SG Installation instructions and owner's manual

Braemar

Braemar WF2000 installation manual