Page 4

THIS IS A GAS-FIRED, GRAVITY VENTED WALL FURNACE THAT WILL OPERATE SAFELY AND PROVIDE AN EFFICIENT

SOURCE OF HEAT WHEN INSTALLED, OPERATED AND MAINTAINED AS RECOMMENDED IN THESE INSTALLATION

AND OPERATING INSTRUCTIONS. READ THESE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING, SERVICING,

OR USING THE APPLIANCE. IF YOU DO NOT UNDERSTAND ANY PART OF THESE INSTRUCTIONS, CONSULT LOCAL

AUTHORITIES, OTHER QUALIFIED INSTALLERS, SERVICE TECHNICIAN, THE GAS SUPPLIER OR THE MANUFACTURER.

1. The wall furnace should be located near the

center of the house for best heat distribution.

2. Due to high temperatures, the appliance should

be located out of trafc and away from furniture

and draperies.

3. Children and adults should be alerted to the

hazards of high surface temperature and should

stay away to avoid burns or clothing ignition.

4. Young children should be carefully supervised

when they are in the same room as the appliance.

5. Do not place clothing or other ammable material

on or near the appliance. Precautions should be

taken so as not to place furniture, drapes, or

other articles directly in front of grille or lower

access door that would obstruct air openings as

proper air ow is critical to proper operation of

unit.

6. Any safety screen guard or casing front removed

for servicing an appliance must be replaced prior

to operating the appliance.

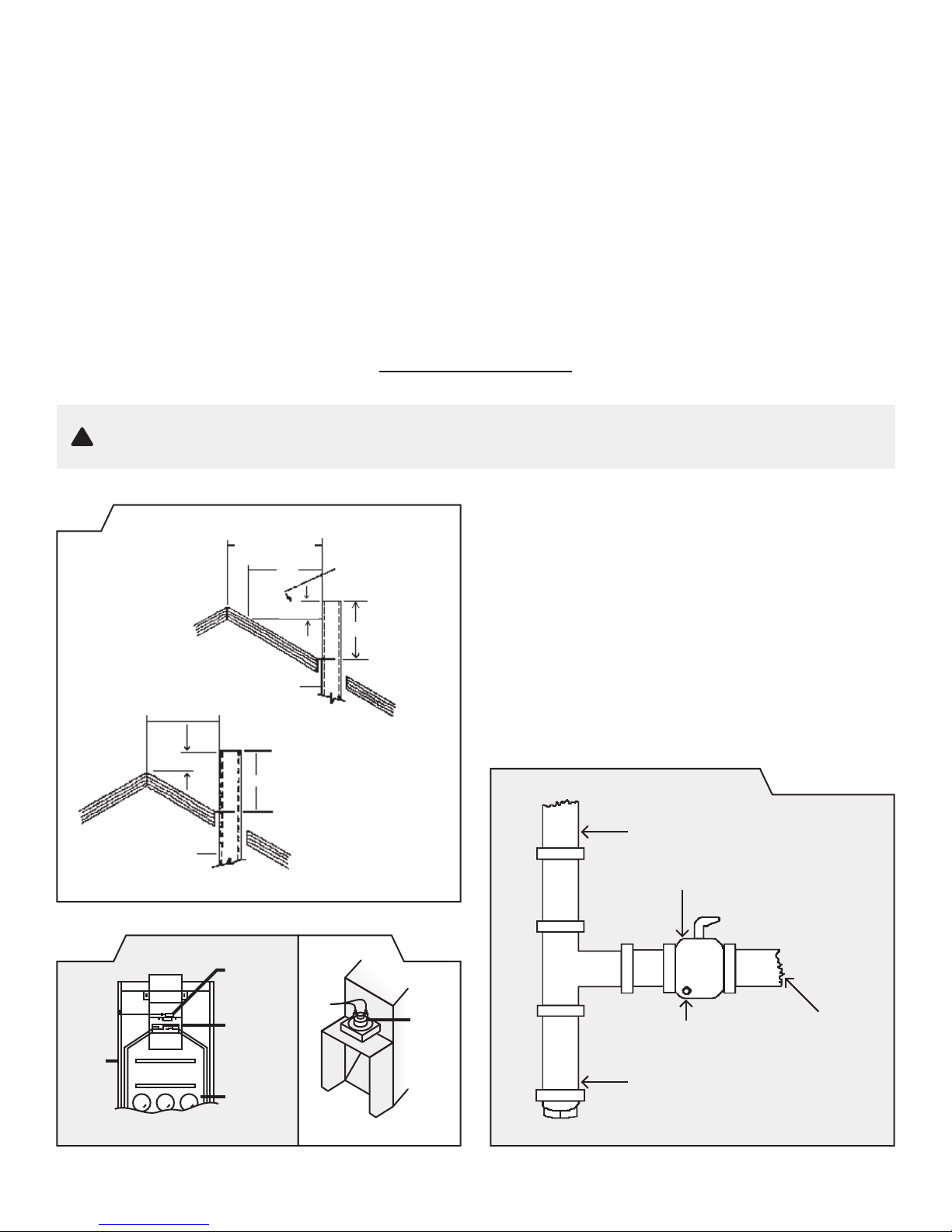

7. Heater must be installed with legs resting on the

2x4 oor sill plate (recessed) or the factory FSK

Kit (ush mount). The header plate shall then

be installed at a height 65-3/4 inches above top

surface of the plate that the heater legs rest on.

This provides the listed 2 inch minimum oor

clearance.

If the area where the heater is installed contains

carpeting, tile, etc., the listed 2 inch minimum

oor clearance must be maintained from the

top surface of these materials. If the heater is

installed DIRECTLY on carpeting, tile or any

combustible material other than wood ooring,

the heater shall be installed on a metal or wood

panel secured to the oor, extending the full

width and depth of the heater.

8. Installation and repair must be done by a

qualied installer or service technician. The wall

furnace must be inspected before use and at

least annually by a qualied service technician.

INTRODUCTION

SAFETY

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or the Natural Gas and Propane Installation

Code, CSA B149.1 and these instructions. Determine that

there is no blockage or restriction, leakage, corrosion and

other deciencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other spaces

of the building.

4. Close replace dampers.

5. Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance

is operating continuously.

7. Test for spillage from draft hood equipped appliances at

the draft hood relief opening after 5 minutes of main burner

operation. Use the ame of a match or candle.

8. If improper venting is observed during any of the above tests,

the venting system must be corrected in accordance with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

Natural Gas and Propane Installation Code, CSA B149.1.

9. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, replace

dampers and any other gas-red burning appliance to their

previous conditions of use.

!WARNING:

CARBON MONOXIDE POISONING HAZARD

Failuretofollowthestepsoutlinedbelowforeachappliance

connectedtotheventingsystembeingplacedintooperation

couldresultincarbonmonoxidepoisoningordeath.