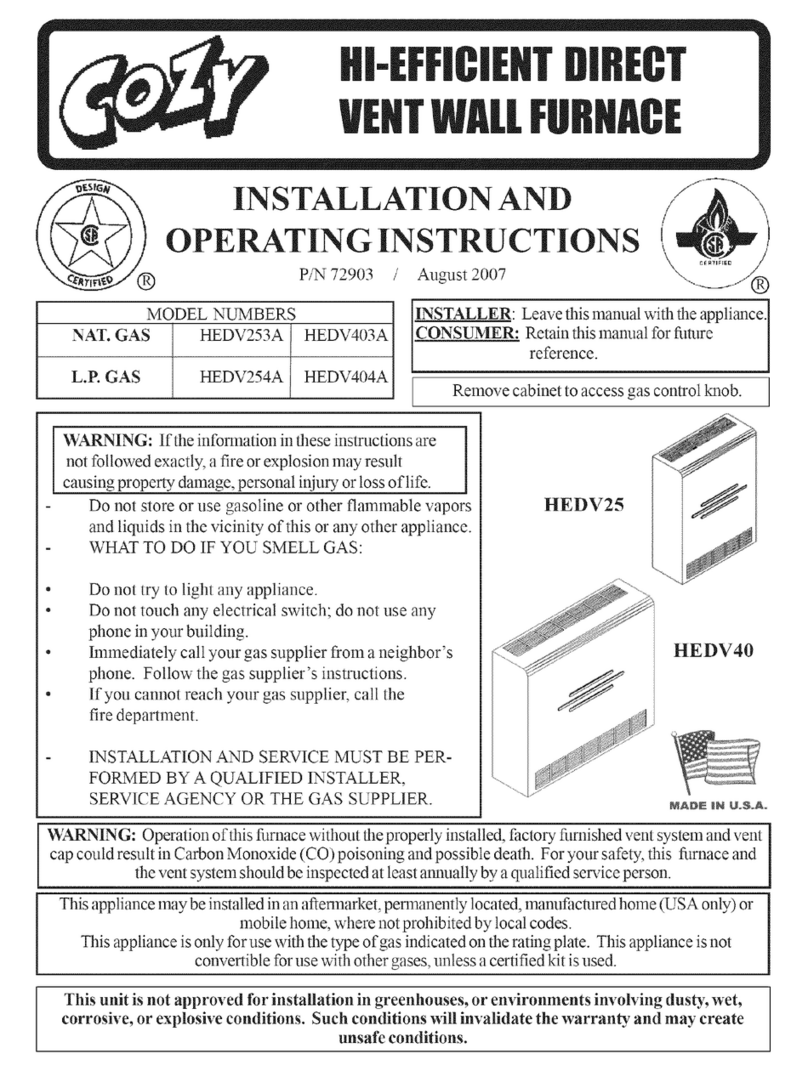

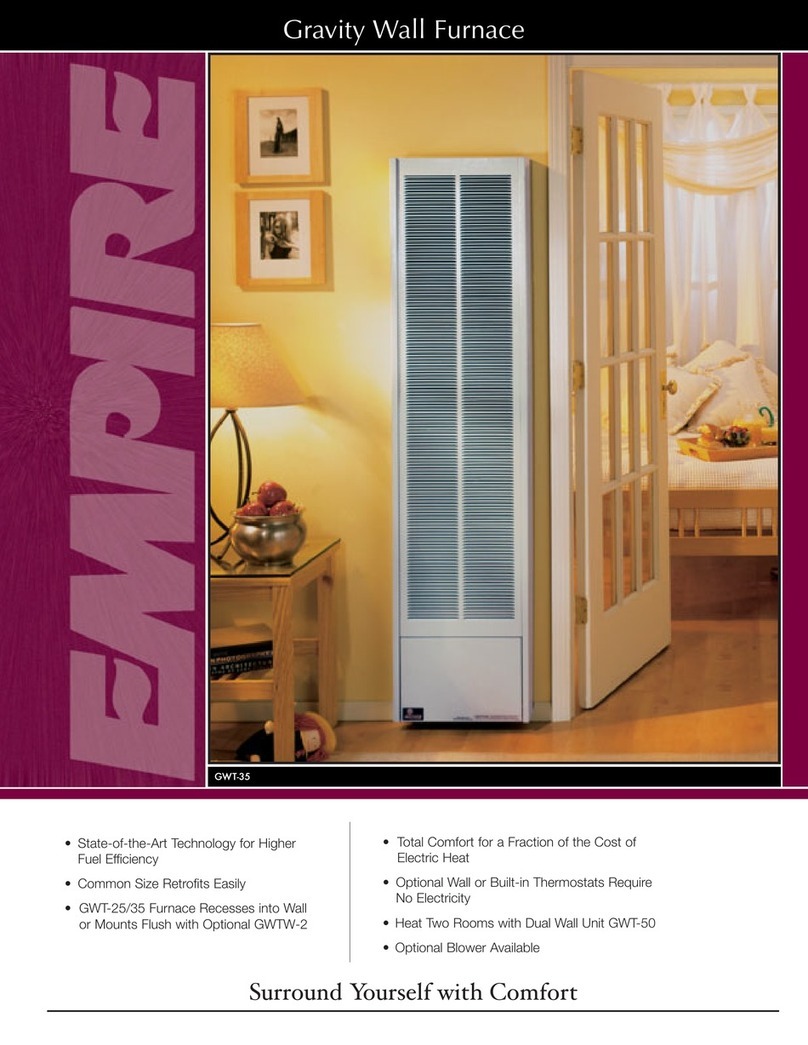

COUNTERFLOW

WALL FURNACE

Installation and Operating Instructions

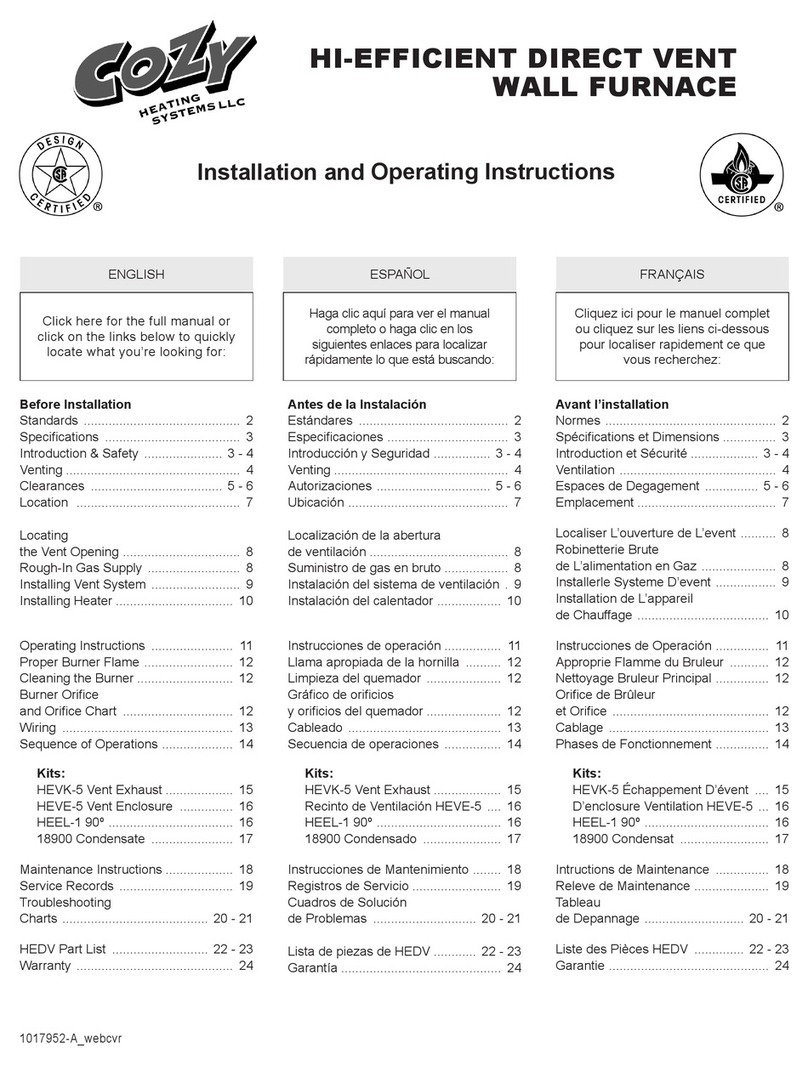

ENGLISH

Click here for the full manual or

click on the links below to quickly

locate what you’re looking for:

ESPAÑOL

Haga clic aquí para ver el manual

completo o haga clic en los

siguientes enlaces para localizar

rápidamente lo que está buscando:

FRANÇAIS

Cliquez ici pour le manuel complet

ou cliquez sur les liens ci-dessous

pour localiser rapidement ce que

vous recherchez:

1018029-A_webcvr

Antes de la Instalación

Estándares .......................................... 2

Especicaciones .................................. 3

Introducción ........................................ 3

Seguridad ............................................ 3

Ventilación ...................................... 4 - 5

Combustion y Ventilacion ............... 6 - 7

Instalación

Ubicaciones ......................................... 8

Instrucciones aproximadas ............. 8 - 9

Instalación .................................. 10 - 11

Controles ........................................... 11

Piloto y oricios .................................. 11

Instrucciones de encendido ........ 12 - 13

Mantenimiento

Llama del quemador apropiado ......... 14

Operación .......................................... 14

Diagrama de cableado del

bloque de terminales ......................... 15

Interruptor de límite auxiliar ............... 15

Instrucciones de mantenimiento ........ 15

Esquemas de cableado ..................... 16

Kits:

14-PEK Kit de extensión..................... 17

406RR-A Kit de registro trasero ......... 18

407RR-A Kit descarga posterior ........ 18

306SR-A y 30SRB-A:

Kits de descarga lateral ..................... 19

Cuadros de solución de

problemas ....................................20 - 23

CF - Lista de piezas .................... 24 - 27

Garantía ............................................. 28

Antes de la Instalación

Estándares .......................................... 2

Caractéristiques et Dimensions ........... 3

Introduction ......................................... 3

Règles de Sécurité .............................. 3

Ventilation ....................................... 4 - 5

Aire de Combustion et Ventilacion .. 6 - 7

Installation

Emplacements ..................................... 8

Instructions approximatives ............ 8 - 9

Installation .................................. 10 - 11

Commandes ...................................... 11

Veilleuse et L’Orices ........................ 11

Instructions D’allumage .............. 12 - 13

Entretien

Flamme Appropriée Du Brûleur ......... 14

Fonctionnement ................................. 14

Diagramme de Câblage

du Bloc de Bornes ............................. 15

Commutateur Auxiliaire de Seuil ....... 15

Instructions D’entretien ...................... 15

Schéma de Câblage .......................... 16

Kits:

14-PEK Kit D’extension Bouchon....... 17

406RR-A D’enregistrement Arrière .... 18

407RR-A Jeu Avec

Enregistrement Arrière ....................... 18

306SR-A y 30SRB-A:

Kits du décharge latérale ................... 19

Tableau de Dépannage ...............20 - 23

CF - Liste des pièces .................. 24 - 27

Garantie ............................................. 28

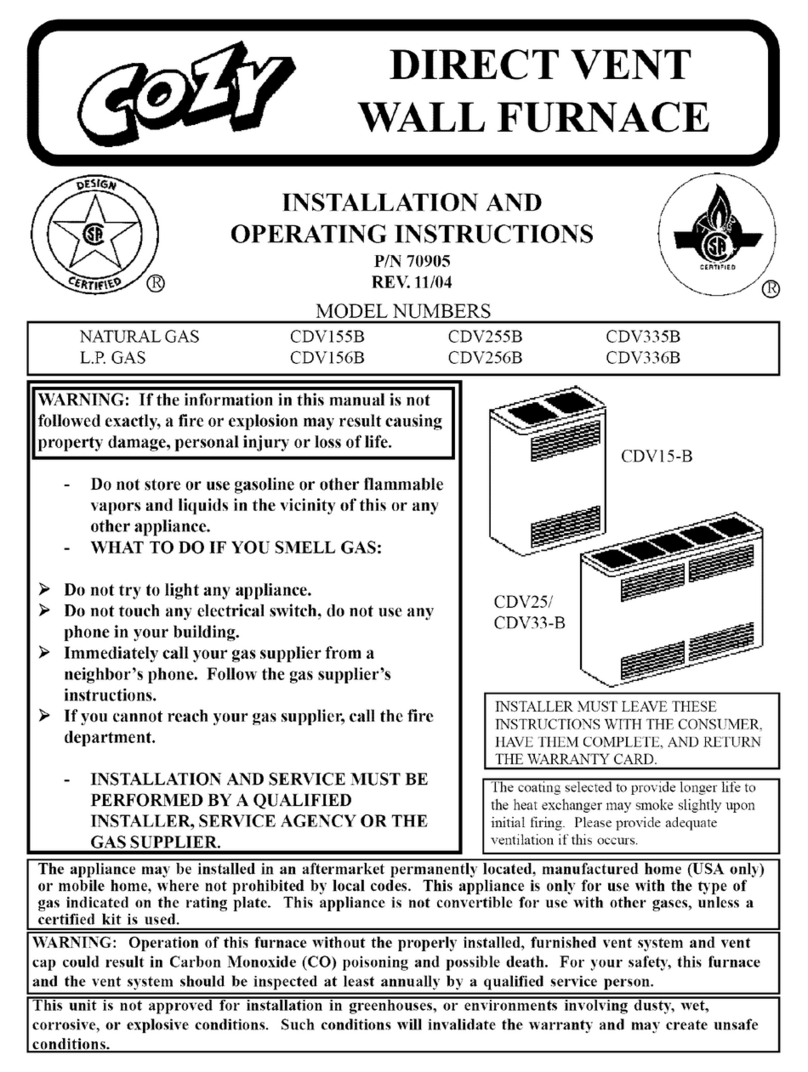

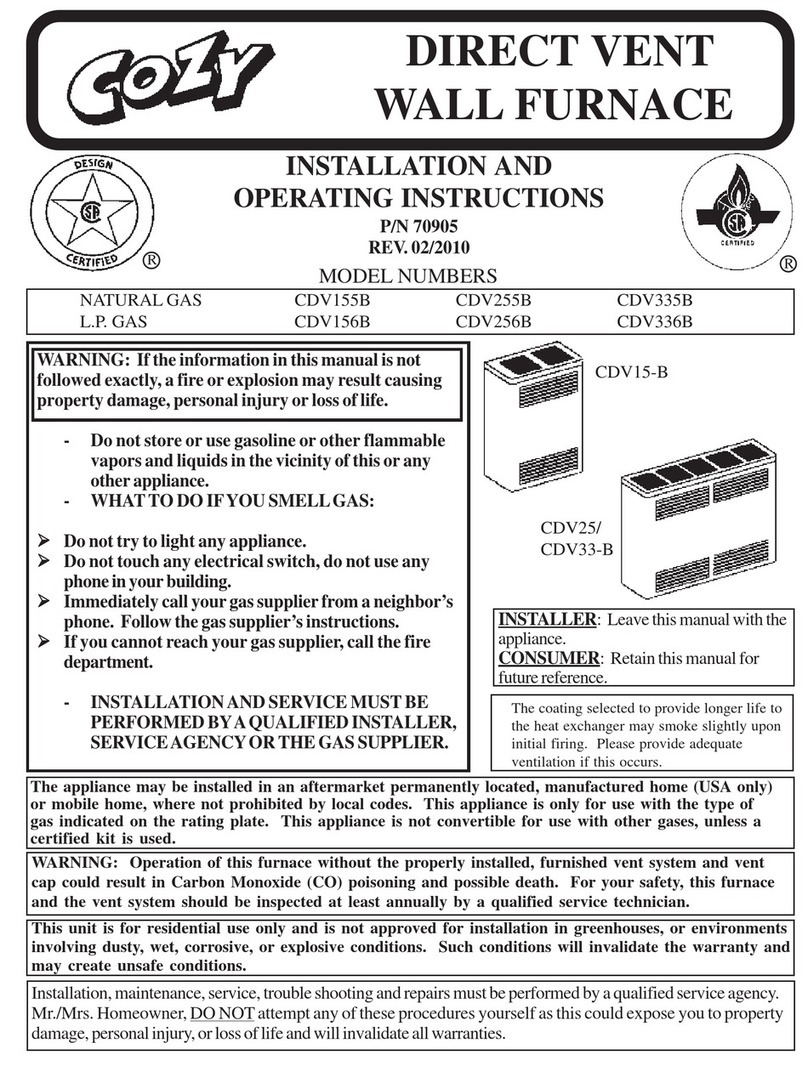

Before Installation

Standards ............................................ 2

Specications ...................................... 3

Introduction ......................................... 3

Safety .................................................. 3

Venting ............................................ 4 - 5

Combustion & Ventilation ............... 6 - 7

Installation

Locations ............................................. 8

Rough-In Instructions ..................... 8 - 9

Installing ..................................... 10 - 11

Controls ............................................. 11

Pilot & Orices ................................... 11

Lighting Instructions .................... 12 - 13

Maintenance

Proper Burner Flame ......................... 14

Operation ........................................... 14

Terminal Block Wiring Diagram ......... 15

Auxiliary Limit Switch ......................... 15

Maintenance Instructions ................... 15

Wiring Schematics ............................. 16

Kits:

14-PEK Extension Kit ........................ 17

406RR-A Rear Register Kit ............... 18

407RR-A Rear Discharge Kit ............ 18

306SR-A and 30SRB-A:

Side Discharge Kits .......................... 19

Troubleshooting Charts .............. 20 - 23

CF Part List ................................. 24 - 27

Warranty ............................................ 28