LOCATE VENT OPENING

After the location of the heater has been determined, the

opening for the vent pipe should be cut. If the heater is to be

recessed, cut out opening for heater between studs on the

interior wall and cut out the floor plate between the studs, so

heater will set flat on floor as all dimensions are given from

a finished floor. The height of the cut out for a 40,000 BTU

model is 78-5/8”, for the 55,000 models the cut out height is

87-5/16”. NOTE: This dimension may be increased to allow

moreroom for installation and making the wiringconnection,

then refinished.

Next, cut out a 9-1/4” opening in exterior wall for the vent

tubes to pass through. The center of opening for the 40,000

BTU furnace is 59”, the center for opening for 55,000 BTU

furnace is 68-1/2”. See Figure 5, on Page 6.

If the heater is to be surfaced mounted, cut out 9-1/4” opening

through the interior and exterior wall. The center of cut out

willbe59”for40,000BTUand68-1/2”for55,000BTUmodels.

Be sure both cutouts are level with each other.

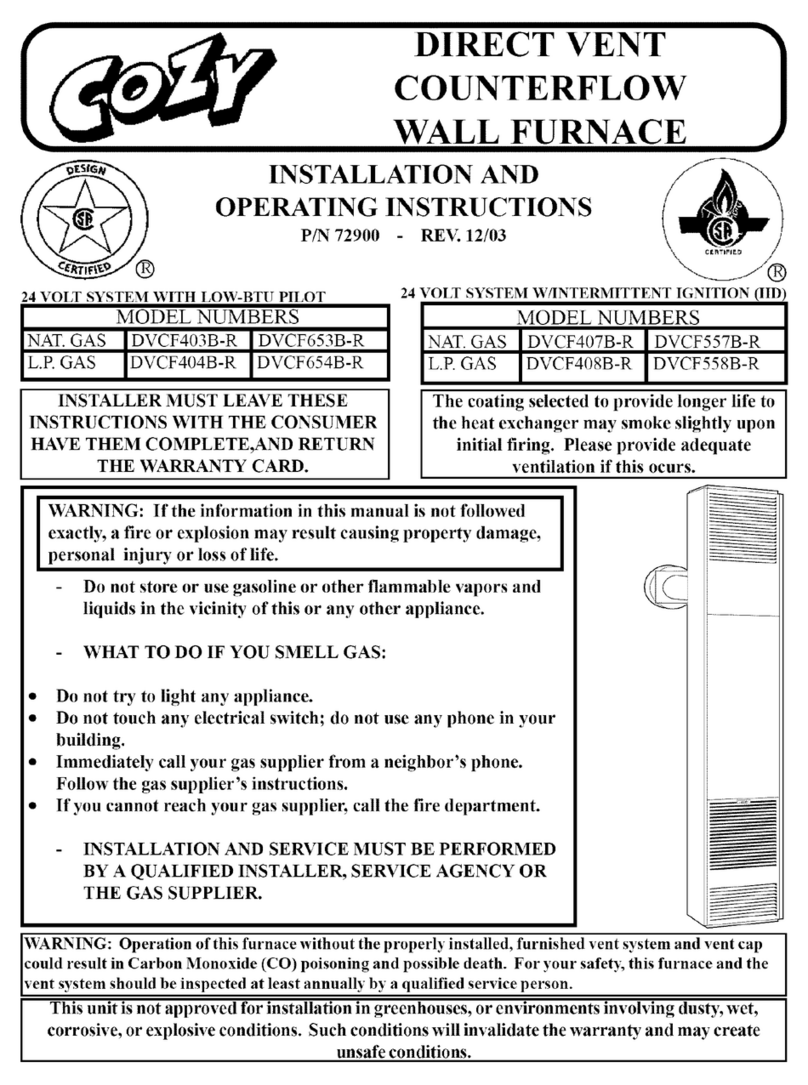

INSTALLING THE FURNACE

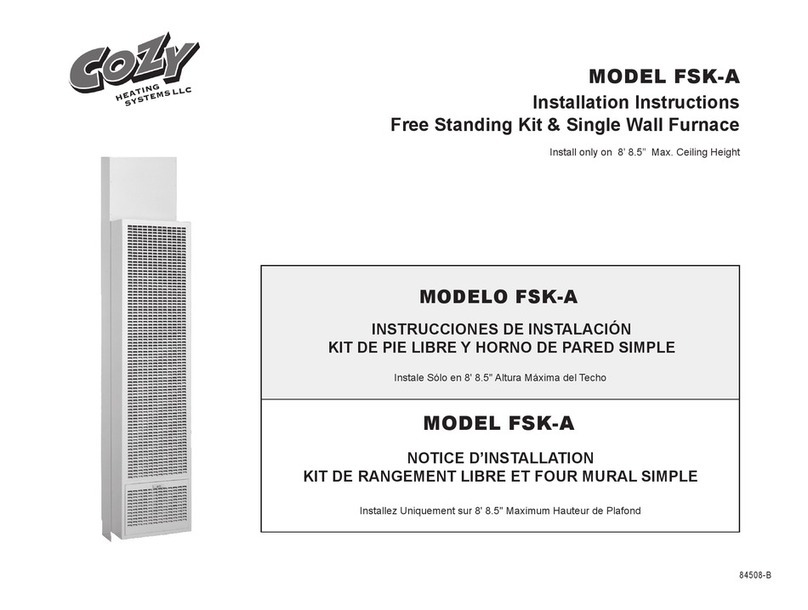

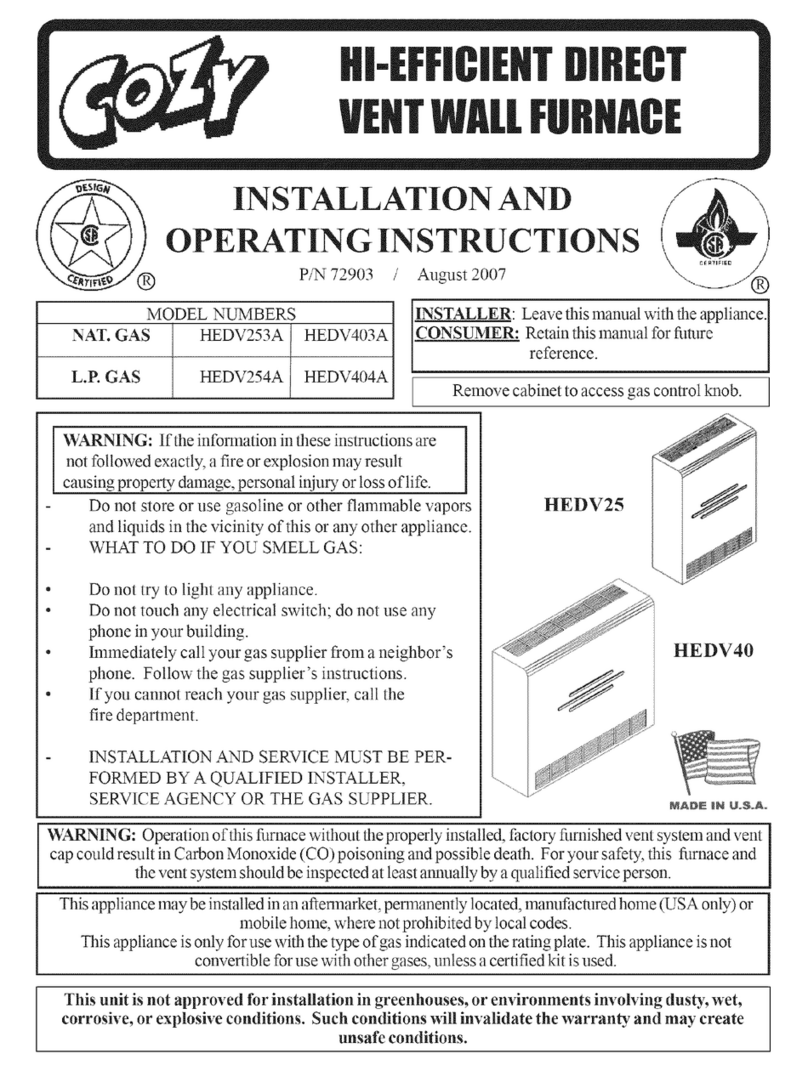

Thevent systemsupplied withthis furnacewill accommodate

walls ¾” (when recessed) up to 12” thick. Use only the

exhaust tube, air intake tube and vent cap supplied with

heater. Do not attempt to lengthen the exhaust or air intake

tubes, this could cause an imbalance in the heater resulting

in poor performance and pilot outage (See Figure 6).

Measure exact distance “X” between surface on which back

of cabinet will rest (inside of recessed cavity or face of wall

when freestanding) and the outside wall surface (see Figure

6).

Inlet Air Tube “A” – Measuring from gasketed surface,

mark and cut pipe same as dimension “X”. Remove any

burrs.

Vent Exhaust Tube “B” – Measuring from gasketed

surface, mark and cut pipe 1-3/4” greater than dimension

“X”. Remove any burrs.

Fasten vent exhaust tube “B” to heat exchanger collar and

Inlet Air Tube “A” to flange on back of furnace using 16 #

3/8 screws (“C”) provided. Be sure gaskets are in place and

not damaged. Anytime the vent pipes are removed check

and replace gaskets (if necessary). Failure to replace missing

or damaged gaskets may expose homeowner to life

threatening conditions.

Secure furnace in place using 2 holes provided in bottom of

casing. NOTE: Make sure both tubes are centered in cut

out. Slide the vent cap onto the pipes extending from the

back of the furnace. A rotating or twisting motion will ease

this installation. Secure vent cap and vent cap spacer plate

to wall causing the vent tubes to have a slight downward

pitch. This will prevent water from entering. Anchors (not

provided) may be required. Caulk around vent cap spacer

plate with caulking provided. NOTE: Some framing may

be necessary to provide a flat surface against the vent cap

spacer plate and to prevent rain from entering the wall

opening.

GASCONNECTION

Make the gas connection between the manual shut off valve

and the furnace gas control valve with approved ½”

connectors. Compounds used on threaded joints of gas

piping shall be approved for use with L.P. gas. The gas

lines must be checked for leaks by the installer with soapy

water or liquid detergent, never use an open flame. If

connections are not exposed, a pressure test must be run.

Be sure to disconnect the gas supply line from the appliance

valve before pressure testing. The manifold pressure is

pre-set at the factory and should be 3.5” w.c. for Natural

Gas and 10” w.c. for L.P. Gas. The minimum inlet pressure

for Natural Gas is 4.5” w.c. and 11” w.c. for L.P. Gas, “for

purpose of input adjustment”. The maximum inlet pressure

should never exceed 7.0” w.c. on Natural Gas or 14” w.c.

on L.P. Gas.

THERMOSTAT INSTALLATION

Follow the instructions included with the thermostat. Select

alocation for the thermostat on an inside wall approximately

5 feet above the floor where it won’t be affected by heat or

cold sources such as direct sunlight, televisions, fireplaces,

hidden hot or cold water pipes, drafts, etc., and a minimum

of 4’from the heater. The thermostat must never be placed

in an adjacent room. Connect thermostat wires to

thermostat and mount to wall. Run wire to furnace and

make connections to thermostat wires coming out of top of

furnace. Use insulated staples (provided) to secure wire to

wall.

OPERATION

This heater is equipped with a slow opening gas control. On

a call for heat the gas valve does not snap-open to full

manifold pressure, but opens with a gradual increase to

normal manifold pressure. The time lapse from the call for

heat to normal operating pressure is two to five seconds.

The slow open feature assures a safe, less noisy ignition.

After the heat exchanger has warmed sufficiently, the fan

will automatically come on to efficiently transfer the heat

into the room. NOTE: The 40,000 BTU models have a one

speed and the 55,000 BTU models have a two-speed

automatic fan.

Vent

Cap Vent Cap

Spacer

Plate

Heat

Exchanger

Collar

FIGURE6

Page 7