1018028-B Page 8

INSTALLATION

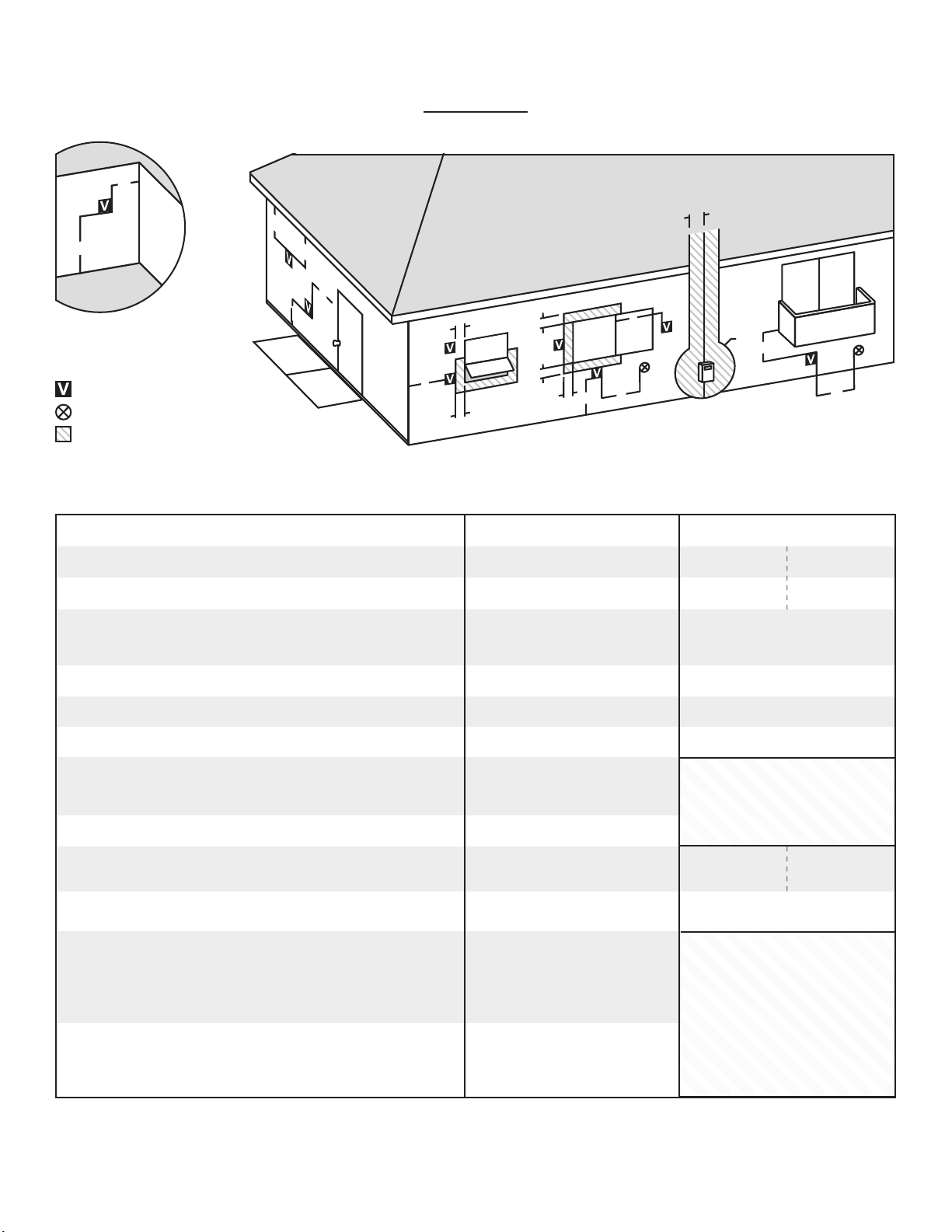

LOCATE VENT OPENING

After the location of the heater has been determined, the opening

for the vent pipe should be cut. If the heater is to be recessed, cut

for a 40,000 BTU model is 78-5/8”, for the 55,000 models the cut out

NOTE: This dimension may be increased to allow

more room for installation and making the wiring connection, then

renished.

pass through. The center of opening for the 40,000 BTU furnace is

See

Figure 5, on Page 6.

If the heater is to be surfaced mounted, cut out 9-1/4” opening

INSTALLING THE FURNACE

the exhaust or air intake tubes, this could cause an imbalance in the

heater resulting in poor performance and pilot outage (See Figure 6).

(see Figure 6).

GAS CONNECTION

must be run. Be sure to disconnect the gas supply line from the

appliance valve before pressure testing. The manifold pressure is

THERMOSTAT INSTALLATION

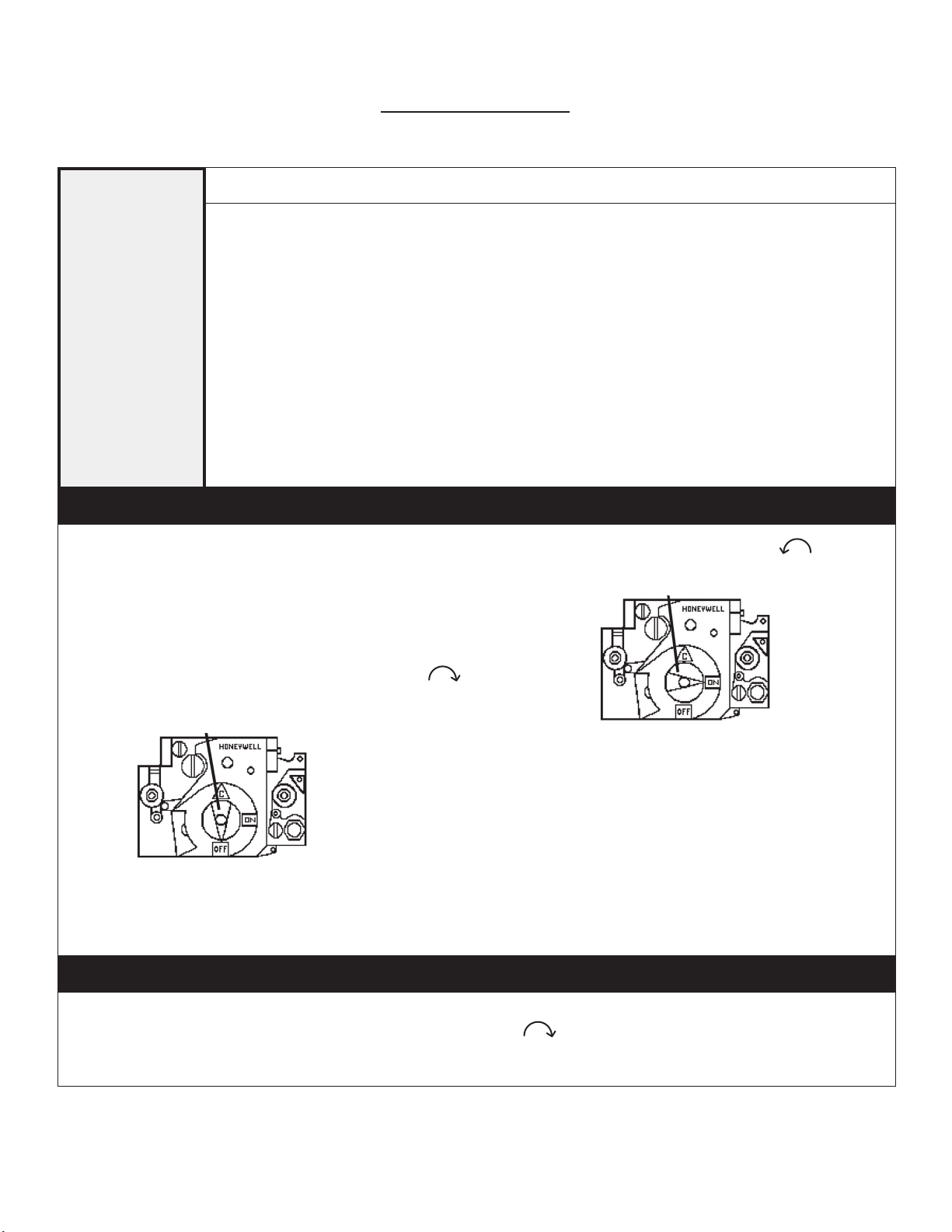

OPERATION

for heat the gas valve does not snap-open to full manifold pressure,

ignition.

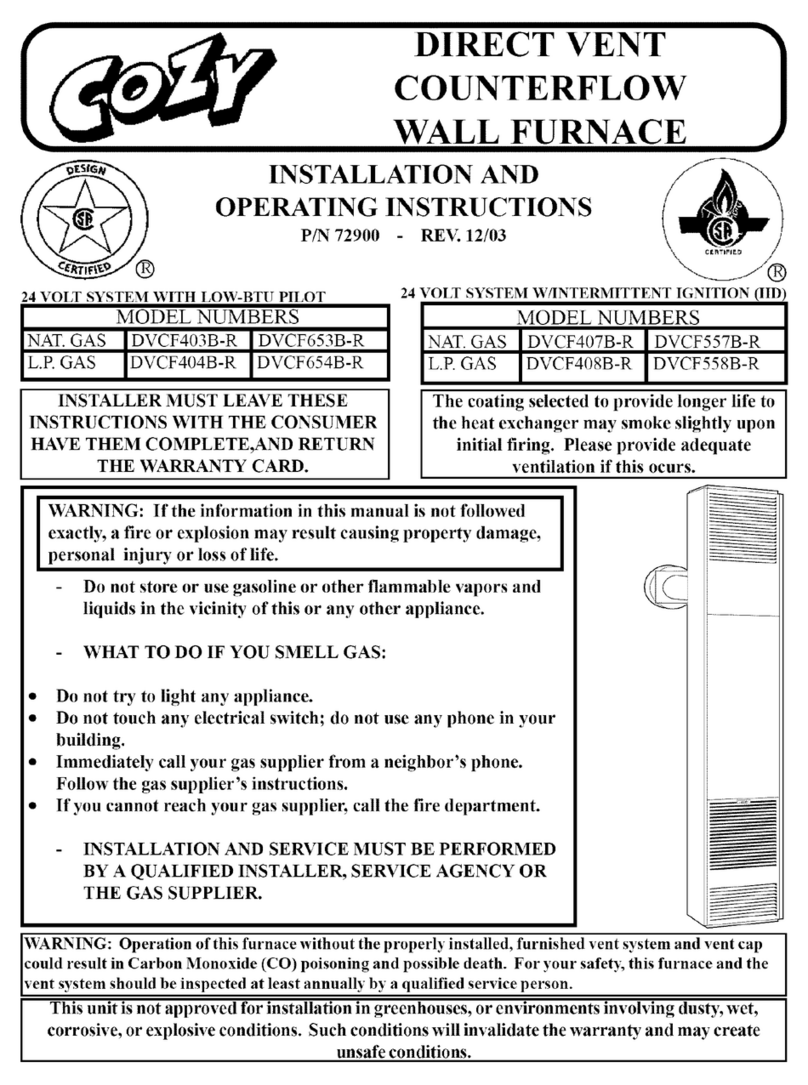

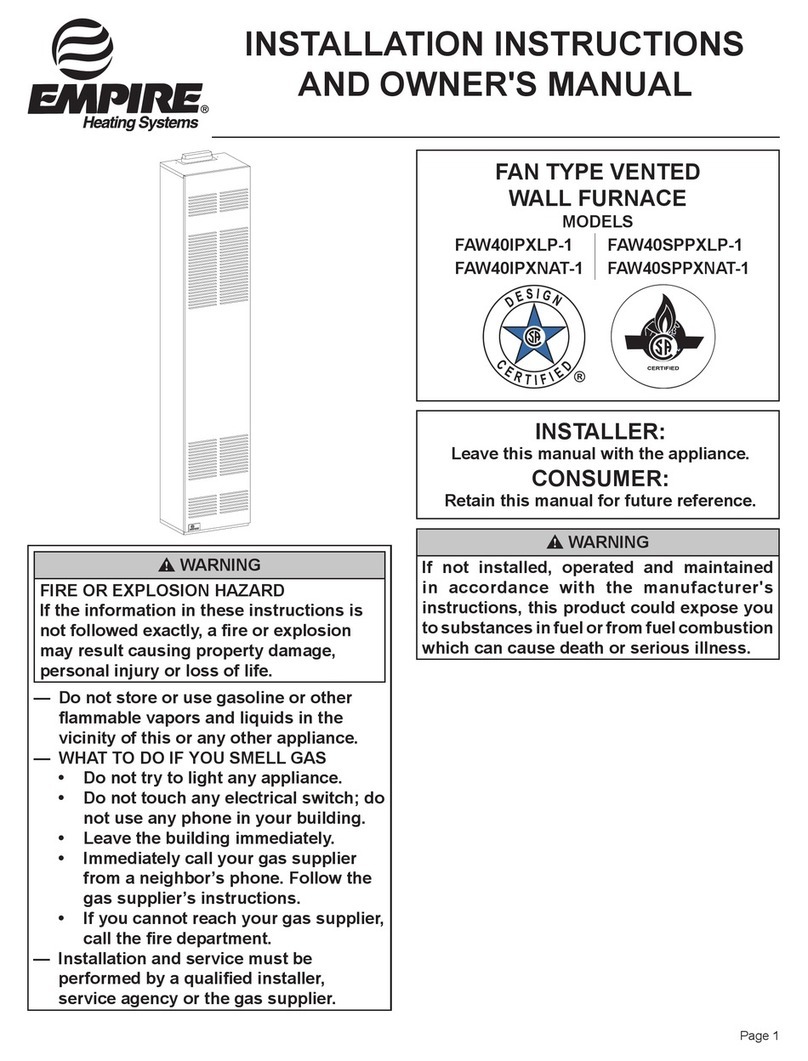

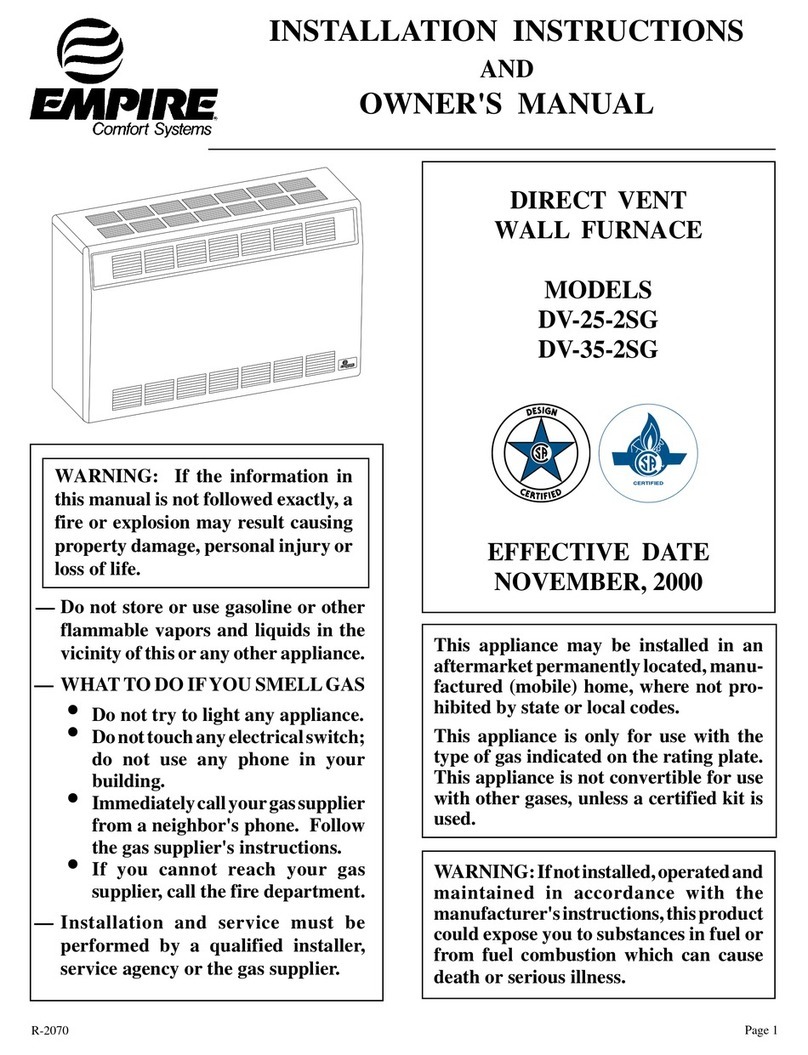

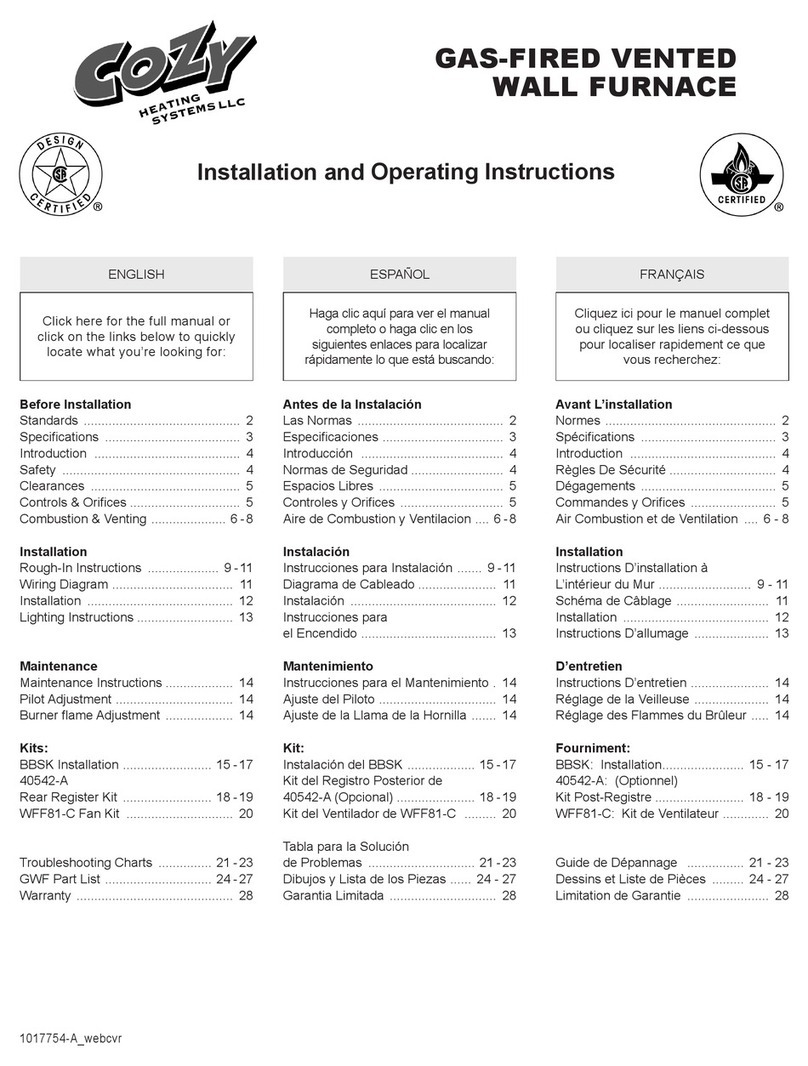

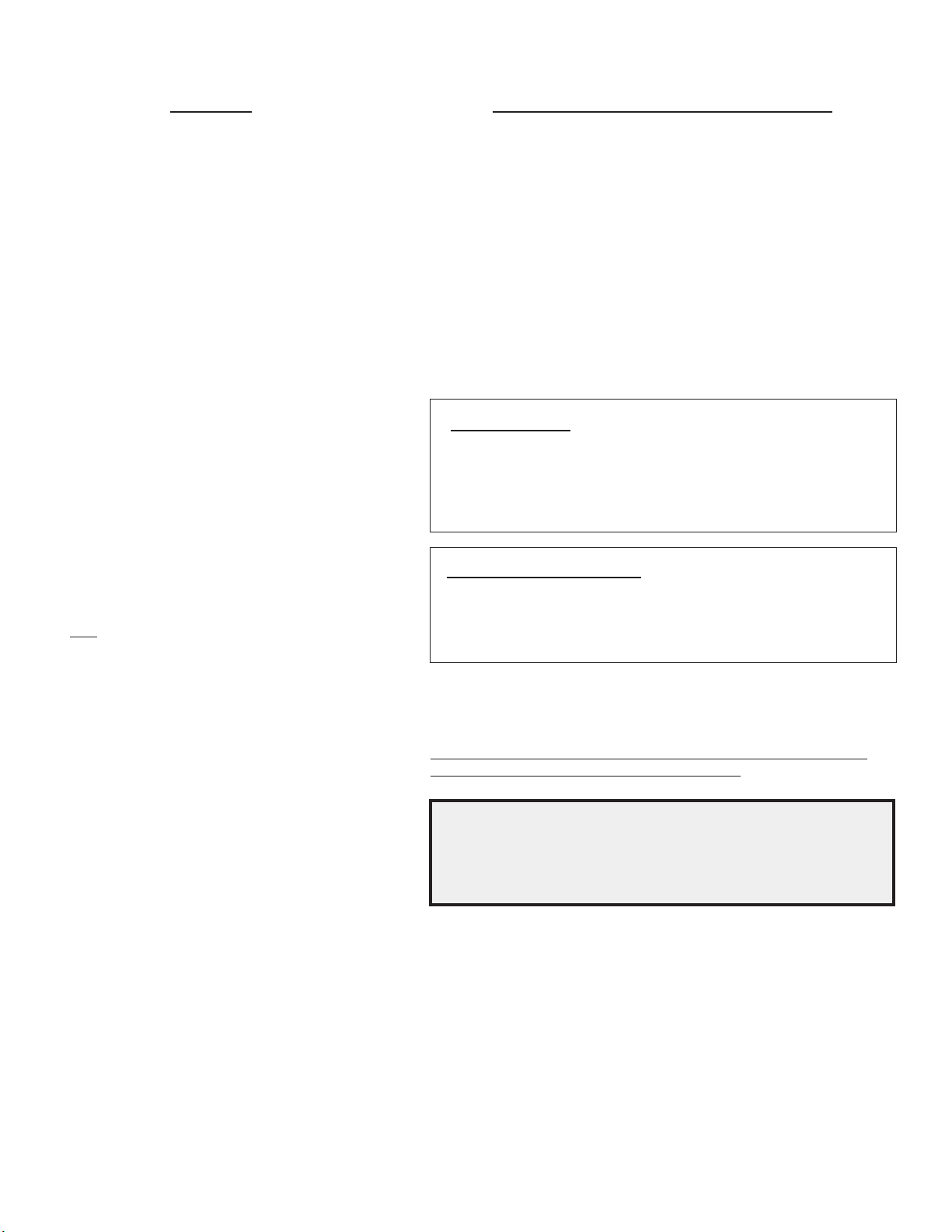

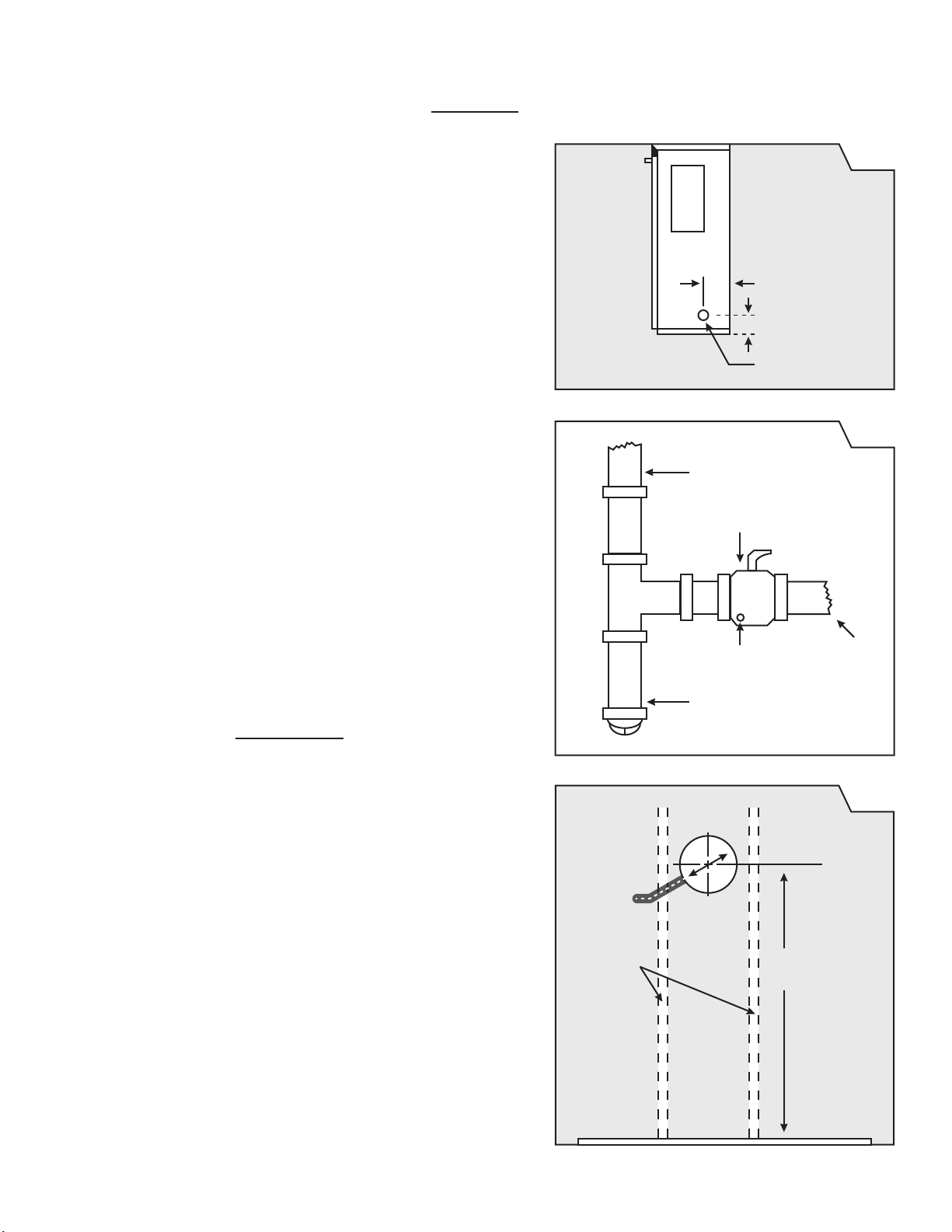

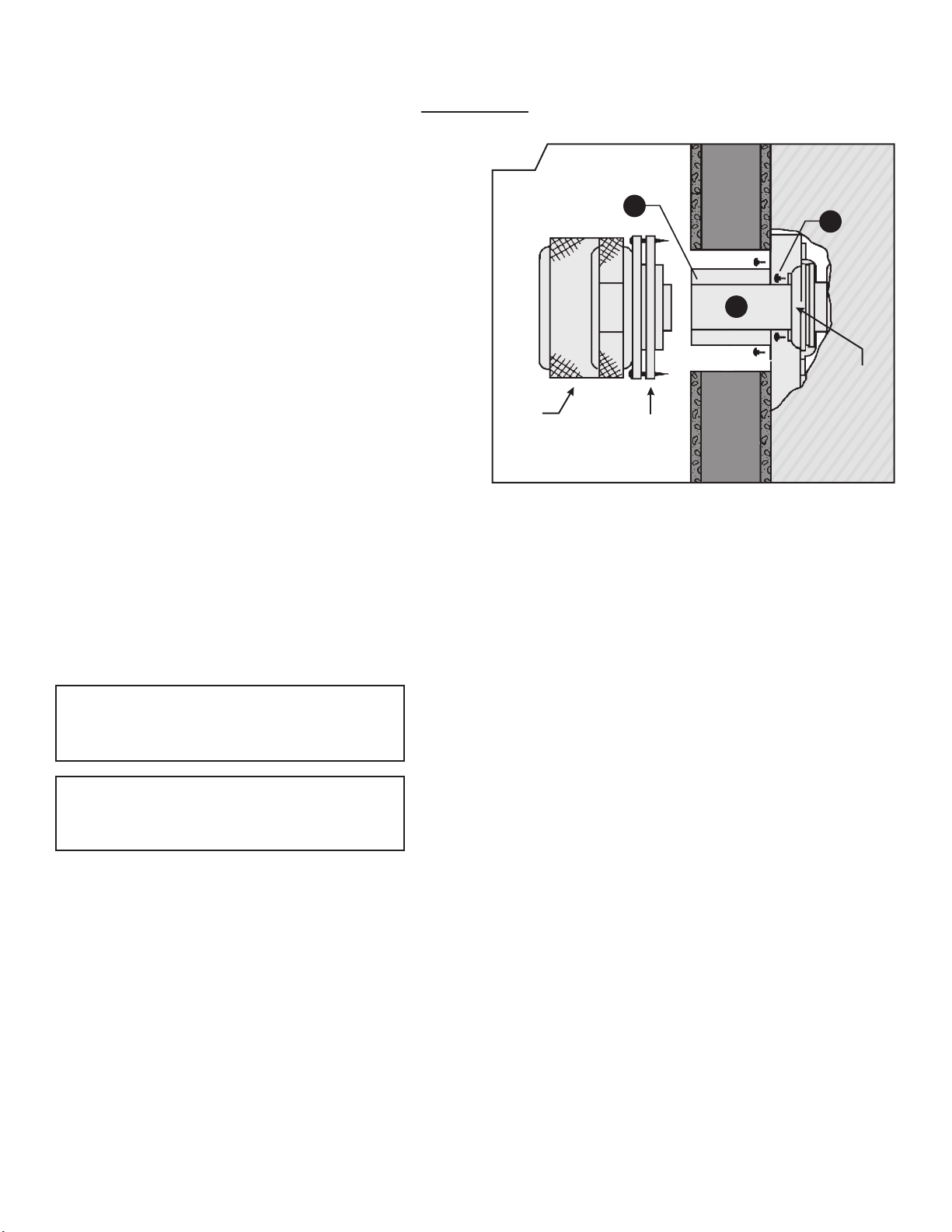

INLET AIR TUBE “A” – Measuring from gasketed

surface, mark and cut pipe same as dimension “X”.

VENT EXHAUST TUBE “B” – Measuring from

gasketed surface, mark and cut pipe 1-3/4” greater

Fasten vent exhaust tube “B” to heat exchanger collar and Inlet Air

provided. Be sure gaskets are in place and not damaged. Anytime

the vent pipes are removed check and replace gaskets (if necessary).

Failure to replace missing or damaged gaskets may expose

Secure furnace in place using 2 holes provided in bottom of casing.

NOTE: Make sure both tubes are centered in cut out. Slide the vent

cap onto the pipes extending from the back of the furnace. A rotating

or twisting motion will ease this installation. Secure vent cap and

caulking provided.

NOTE: Some framing may be necessary to provide a at surface

against the vent cap spacer plate and to prevent rain from entering

the wall opening.

Vent

Cap Vent Cap

Spacer Plate

WALL

“

X

”

OUTSIDE INSIDE

A

C

B

Heat

Exchange

Collar