13

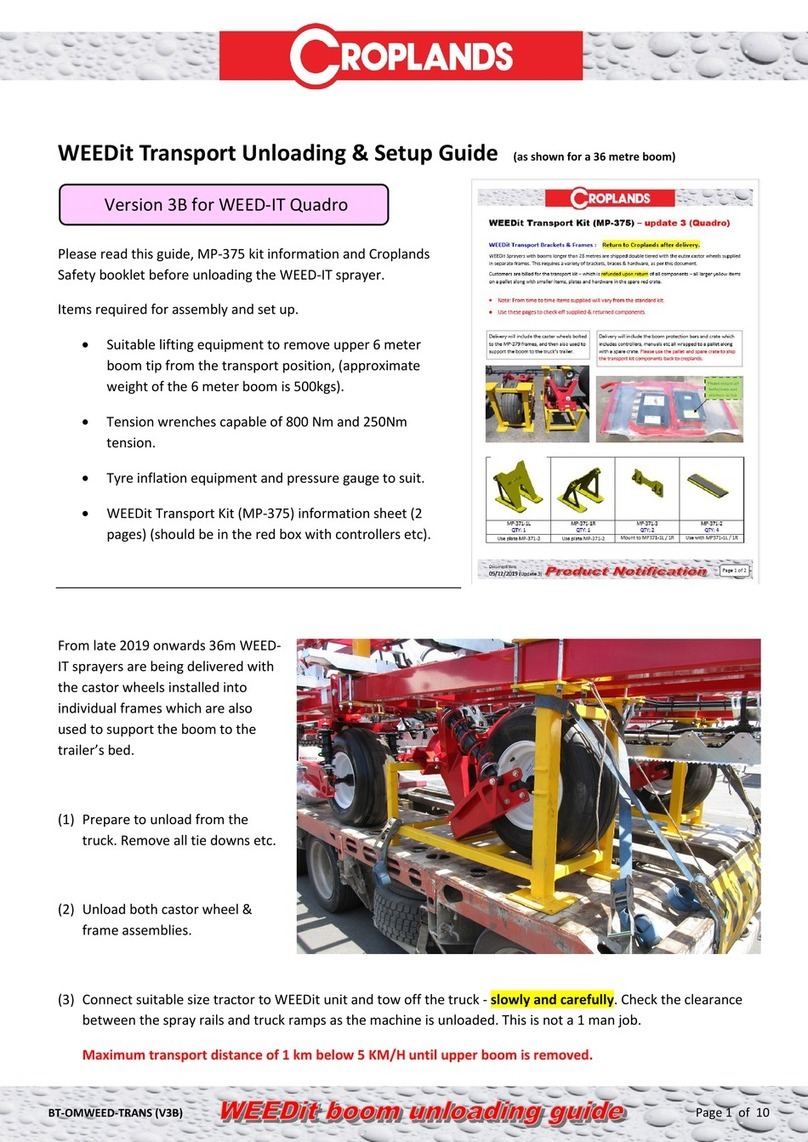

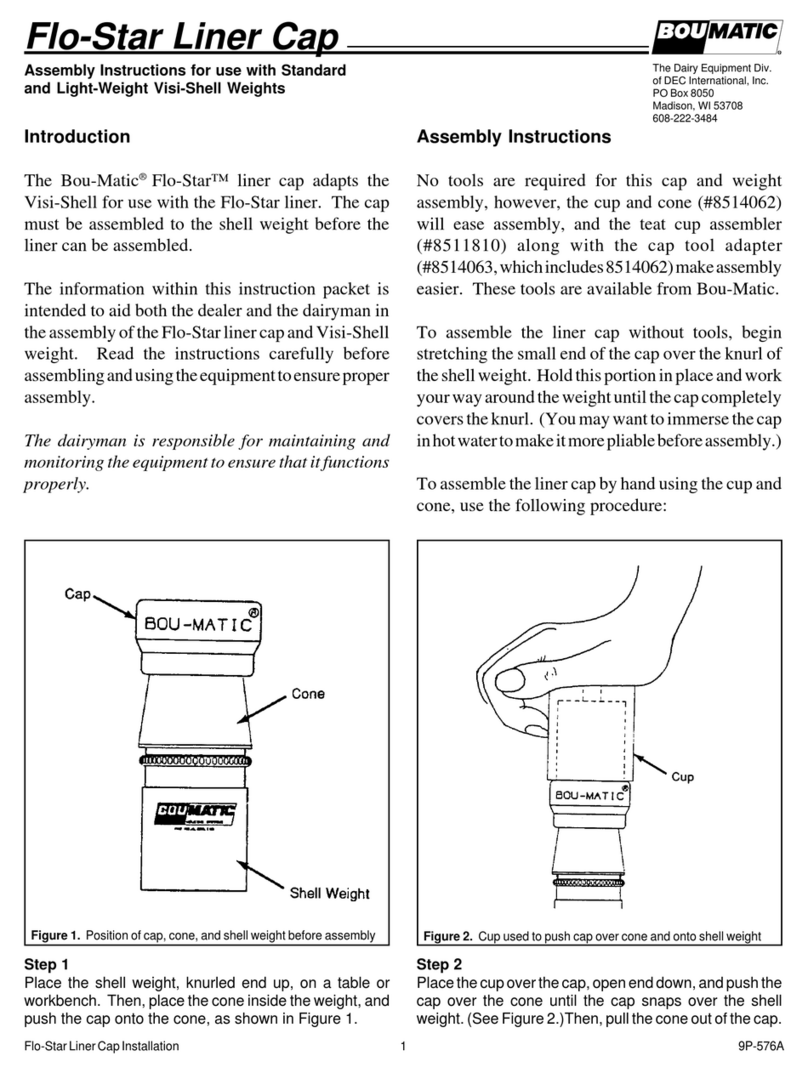

Before operating, please read the Boom

Parking Quick Start Guide, BT-OMWEED-

QSG-B (version 3), as shown here.

Carry out the set up and pre-delivery of the machine using

the supplied manuals for the WEEDit system and blanket

spray line (if equipped) using the supplied manuals.

WEEDit – Boom Parking, Quick Start Guide (v3), to suit the 4 + 5 switchbox.

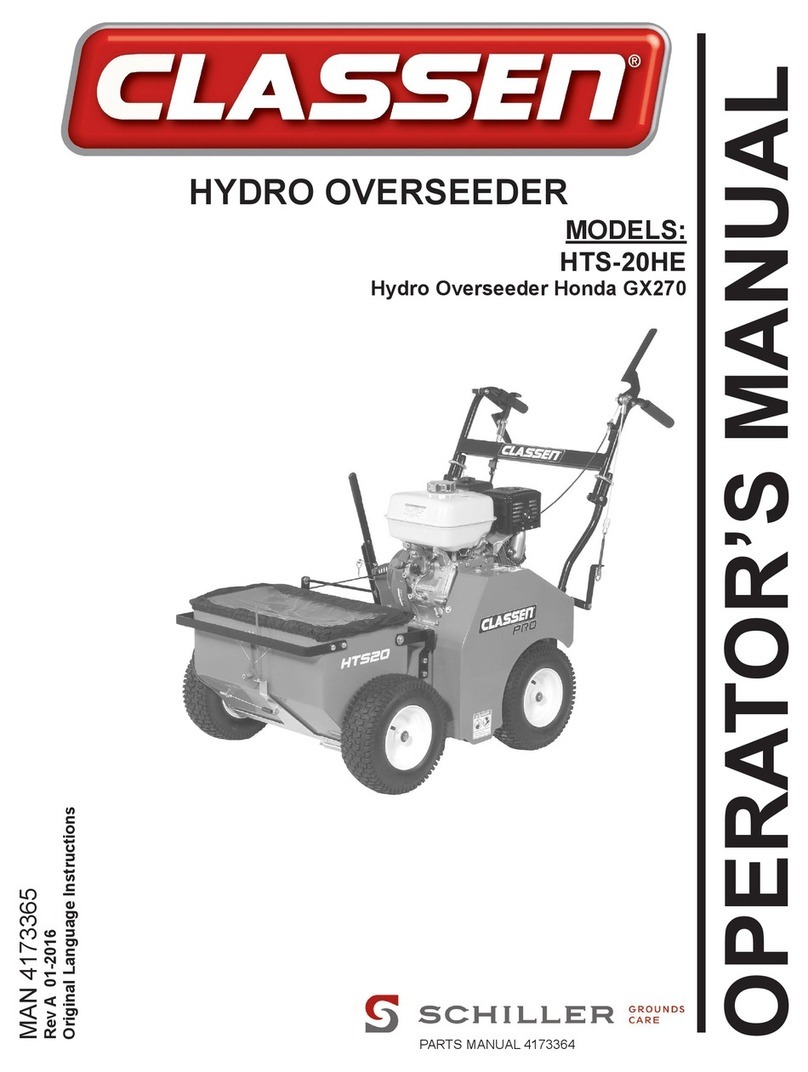

It’s vital that the correct

parking procedures are

followed.

Failure to follow these

guidelines may result in

damage to the sprayer.

Perform all folding

operations on flat ground.

LH and RH Fence-line switching is via

the same switchbox. Down is OFF.

TO OPEN THE WEEDit BOOM, ready to spray >>>

1. Hold the LATCH ARMS switch DOWN to set the latches to the Lock position.Check the locking

rams are retracted.

2. Fully extended both stay arms. Hold the FOLD ARM switch to the DOWN position until both

sides are fully extended.

3. Set the BOOM STEER WHEELS switch to PART FOLD, this will only allow the boom wheels

to rotate ½ of their travel.

4. Drive forwards slowly below 5 KM/H. While moving forward, hold both the LH WHEEL &RH WHEEL

switches DOWN, this will allow the booms to move approximately out half way

•It will take approximately take 10 ~ 30 metres of travel to accomplish

this, depending on the soil conditions.

•Set the BOOM WHEELS switch back to the LOCK position.

Rotate the main wheels back to the original position, so they are in-line with the

boom. Hold both the LH WHEEL & RH WHEEL switches to the UP position until done.

BT-OMWEED-QSG-B WEEDit Boom Parking: Quick Start Guide (v3) Page 2of 2

5. Reverse slowly until the booms arms have opened all the way

and the fold arms have latched into the locks.

•If one side latches before the other side use the wheel

switch to rotate the wheel to the field position to prevent

the wheels from bulldozing.

•It may take around 10 metres of travel to accomplish this,

depending on the soil conditions.

•Do not continue to reverse with wheels in this position.

•Double check that both stay arms are docked & locked.

6. Rotate both main wheels “outwards” 90 degrees, to now point forwards in the

direction of spray travel. Hold both the LH WHEEL & RH WHEEL switches to the DOWN

position, and at the same time slowly move forwards until done (a few seconds).

7. Spray mode:Set the BOOM WHEELS switch to SPRAY position.

This will allow the boom wheels to float when turning. Go spraying.

TO FOLD THE WEEDit BOOM >>> All folding operations should be on flat ground

1. Lock the wheels (facing direction of travel). Set the BOOM WHEEL switch to LOCK .

2. Unlock the arms. Move the LATCH ARMS switch UP to UNLOCK.

3. Drive forwards slowly below 5 KM/H. While moving forward, hold both the LH WHEEL &RH WHEEL

switches UP, this will move the wheels into the transport position (in line with

the boom). Travel forwards slowly until both booms are trailed behind the sprayer.

4. Fold in both stay arms. Hold the FOLD ARM switch to the IN position until both sides are fully

retracted. Only fold the arms in when the booms are fully folded together to

avoid damage to mudguards.

5. Set up the machine for safe transport (also see Transport, unloading & setup guide). Remain in “Lock”.

NOTE

Never operate the boom when

the wheels are at right angles

to the direction of travel.

NOTE

Be very careful to follow the (manual)

instructions for setting up the boom stay arms

(it’s a little counter intuitive and easy to get

wrong if not following instructions).