BT-OMPEG7STD-A

4

SECTION 1

IMPORTANT INFORMATION

FOREWORD

Croplands Equipment is a subsidiary of Nufarm Australia

Ltd and operates as Croplands Equipment Pty Ltd in Australia

and Croplands Equipment Ltd in New Zealand. Croplands

are a leading manufacturer and supplier of spraying

equipment.

This operator’s manual covers the Croplands’ Micro Power

Pack, as supplied with Quantum Mist / Smart Sprayers.

Manufactured to a high standard for use in Agriculture

and Horticulture, every effort has been made to include

all information needed for the correct use of your Micro

Power Pack.

ABOUT THIS MANUAL

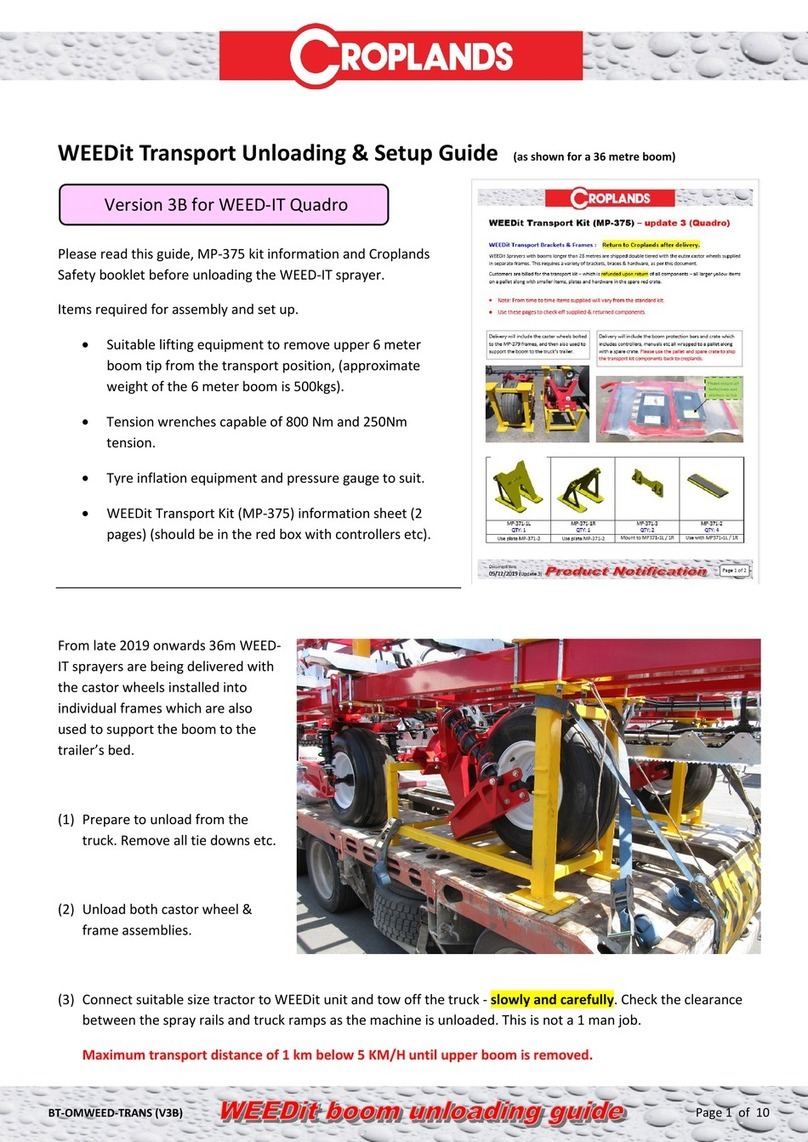

This manual provides assembly, setting up, operating and

maintenance instructions for the Croplands Pegasus 7000

Standard, broadacre sprayer.

Some features explained in this manual may not be installed

on your sprayer.

Please pass on this manual with the sprayer at the time of resale

for usage by the new owner.

This manual, BT-OMPEG7STD-A - Rev 1, was published in

May 2020.

Check online as there maybe more recent revisions of this

manual.

TERMINOLOGY

These terms/symbols used throughout

this manual:

NOTE to convey useful operating

information.

CAUTION to highlight potential injury

or machinery damage.

WARNING

to stress potential dangers

and the importance of

personal safety.

DANGER probability of death or serious

injury if accident occurs.

BEFORE OPERATING YOUR SPRAYER

1. Before attempting to use your sprayer, make sure

you read all Operator Manuals for this sprayer

including but not limited to:

• This Operator’s Manual

• Quick Start Guide, Part No. BT-PEG7STD-QS1

• Croplands Safety Part No. GP-SAFE-A

• Croplands BA7000 Operators Manual (if applicable)

• Pentair Hypro Series 9316, or equivalent,

Instruction Manual

• Arag Visio

Read and understand this Operators’ Manual before

operating the sprayer.

and properly understand:

• All Safety Issues.

• Assembly & Installation instructions.

• Calibration of the sprayer.

• Sprayer Operation.

• Sprayer Maintenance.

2. Read and follow instructions on chemical

manufacturers’ labels.

3. Always wear applicable protective clothing.

DANGER

!

Probability of a death or serious

injury if accident occurs

WARNING

!

To stress potential dangers and the

importance of personal safety.

CAUTION

!

To highlight potential injury or

machinery damage.

NOTE

To convey useful operating information.