1.3 Pegasus BT-POM 1212 - Rev 3

Important Information

General Description &

Specications

Tank

4000, 5000 or 6000 litre polyethylene

tank with hinged lid, lling strainer, top/

bottom ll point, large sump with drain,

dual agitators, direct chemical induction

& tank rinsing jet. Calibrated sight gauge

tted. UV and chemical resistant nish.

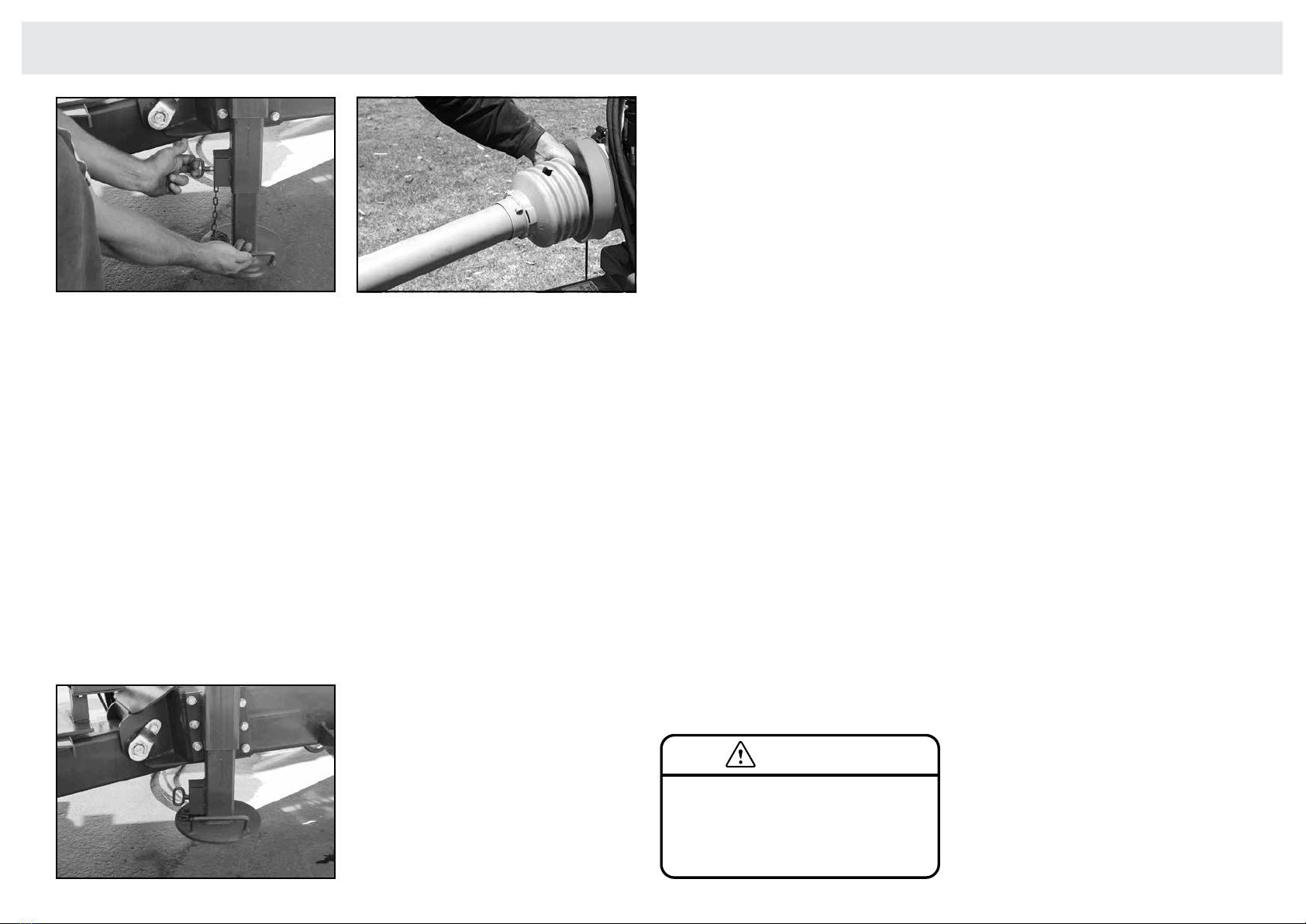

Chassis

Strong, fabricated wide-rail chassis, fully

welded for maximum strength. Standard

with solid xed-width axle. Adjustable-

height drawbar hitch with cast swivel eye

and heavy duty jack-stand. Optional air

suspension axle and/or adjustable track

axle, 2.1 – 3 metres.

Wheels & tyres

18.4 x 38” on 4000 & 5000 litre models;

20.8 x 42” on 6000 litre models;

Mudguards optional (all models).

Mudaps optional (all models).

General Specications

6000 litre Pegasus with 20.8 x 42 single wheels.

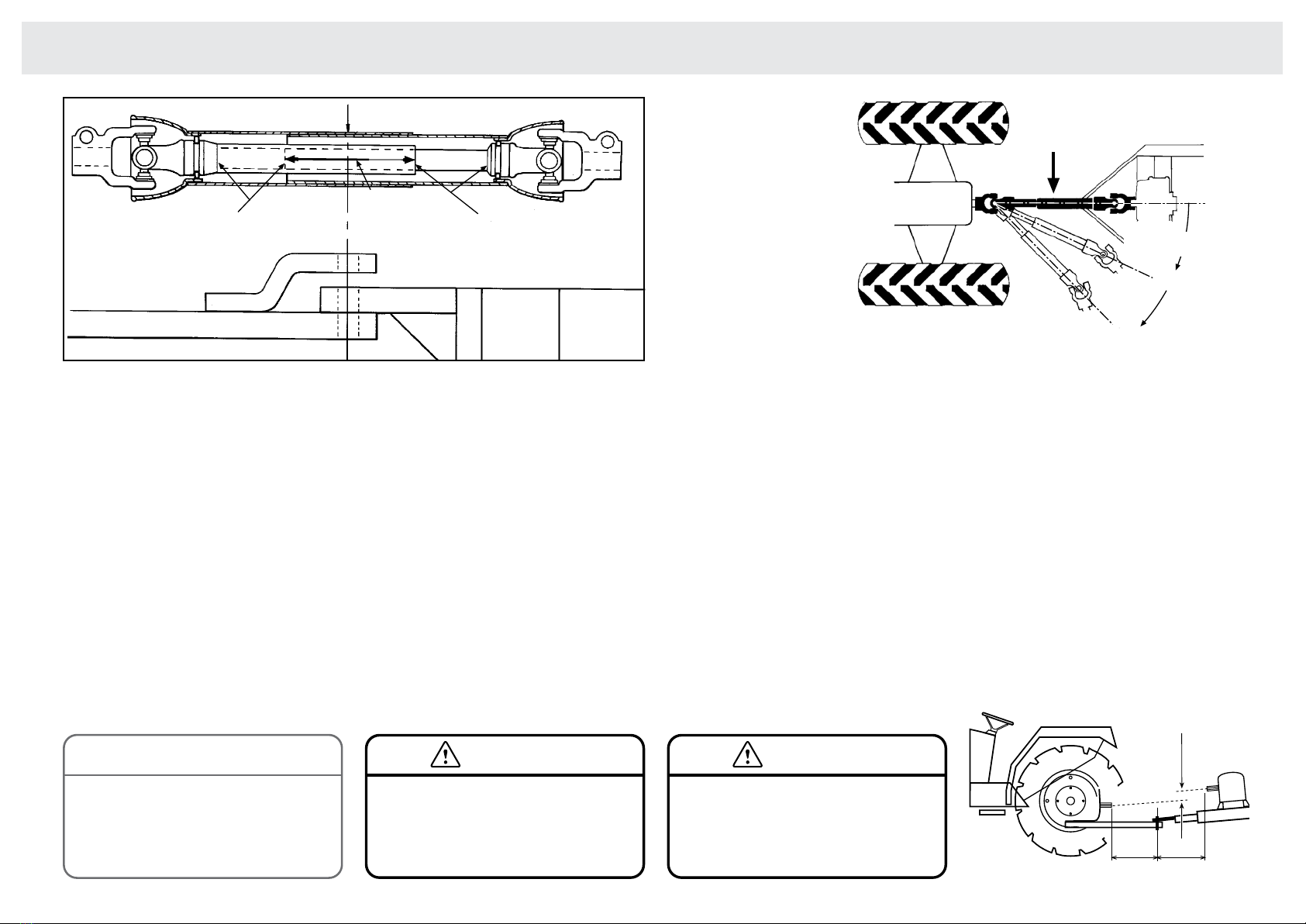

Pump

AR positive displacement oil-bath four

diaphragm pump, chemical resistant,

rated to 20 bar. Normal operating range

1 – 8 bar. Standard 185 l/min output (at

zero pressure), optional 250 & 280 l/min

pumps available. PTO drive standard,

hydraulic optional.

Filtration

Five ltration points: Basket (18 mesh),

Filling lter (32 mesh), Suction lter (50

mesh), Pressure lter (100 mesh), Nozzle

lters (50 or 100 mesh).

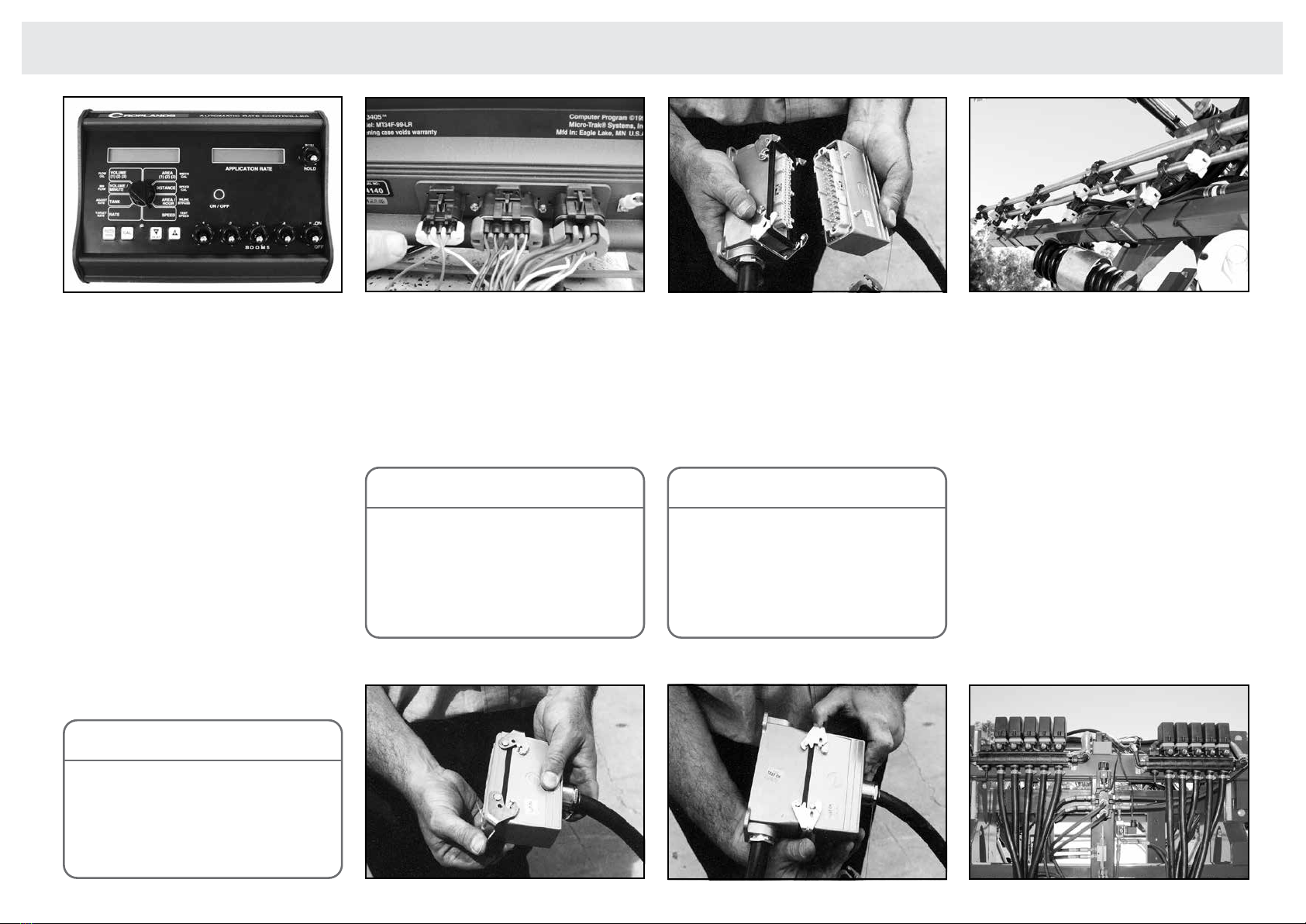

Controller & boom valves

MT3405 Microtrak fully automatic

controller tted. Three electric (motorized)

boom section valves are tted as standard

(4, 5 or 7 optional), dump & servo tted,

Polmac rapid-check owmeter with in-cab

console with switches, showing spray rate

and other functions. Optional BA7000 or

ZYNX X20 system for dual line operation.

Boom & Lift

24, 28, 30, 33 & 36 metre booms are

options (model dependent). The boom is

constructed of high quality steel in a lattice

design. Finish is in epoxy-coat paint for

chemical resistance. Outer boom wings

are tted with self-returning breakaways.

The centre boom section acts as a self-

leveler, with adjustment for anti-yaw.

Boom liquid tubing is stainless steel, with

single non-drip nozzles tted as standard.

Dual lines or triplex nozzle bodies are

optional. Boom folds hydraulically, and a

wing-lift version is offered on all models.

The parallelogram height adjuster has a

2000mm lift (2.5 metre from ground), and

is equipped with hydraulic accumulator

for boom suspension. Automatic hydraulic

boom levelling available with ZYNX X20

system controller

Agitation

Dual supa-ow agitators are tted. Pump

bypass also aids agitation & mixing.

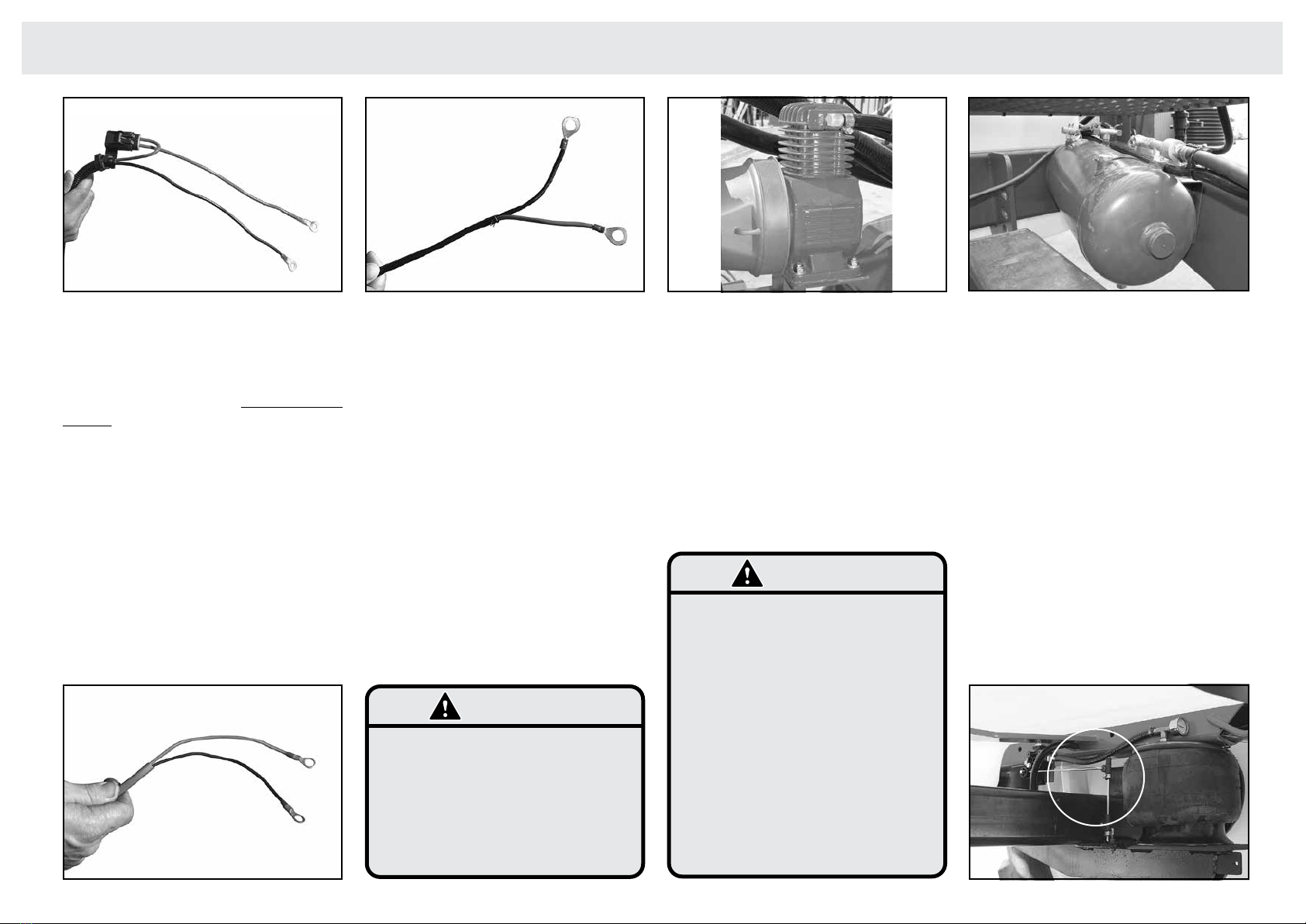

Foam Marker (if tted)

An air-compressor runs off the pump, and

feeds the air-tank, which in turn operates

the optional high-capacity Outback Foam

Marker, which has in-cab controls. A 130

litre foam concentrate tank is tted.

Chemical handling

Integrated chemical mixer/induction unit

is tted with a drop-leg device. Options

include a chemical suction probe, enviro-

transfer kit and a Dosmatic injection kit.

A 30 litre hand-wash tank is also tted

for safety.

Flushing & controls

A 340 litre ushing tank is tted, operated

from the easy-to use control panel, located

on the left hand side of the sprayer.

Options

Hydraulic pump drive, 250 or 280 l/min

pump upgrade, 4/5/7 boom sections,

dual lines, axle width adjustment kit, air-

ride axle kit, mudguards and mudaps,

BA7000 controller, Induction probe,

enviro-transfer kit, lling owmeter, foam

marker and/or GPS Guidance system,

left & right wing-lift, independent outer

wing fold kit, manual or electric fence-line

nozzles, larger wheels and tyres.

Machine specications are subject to change without

prior notication.