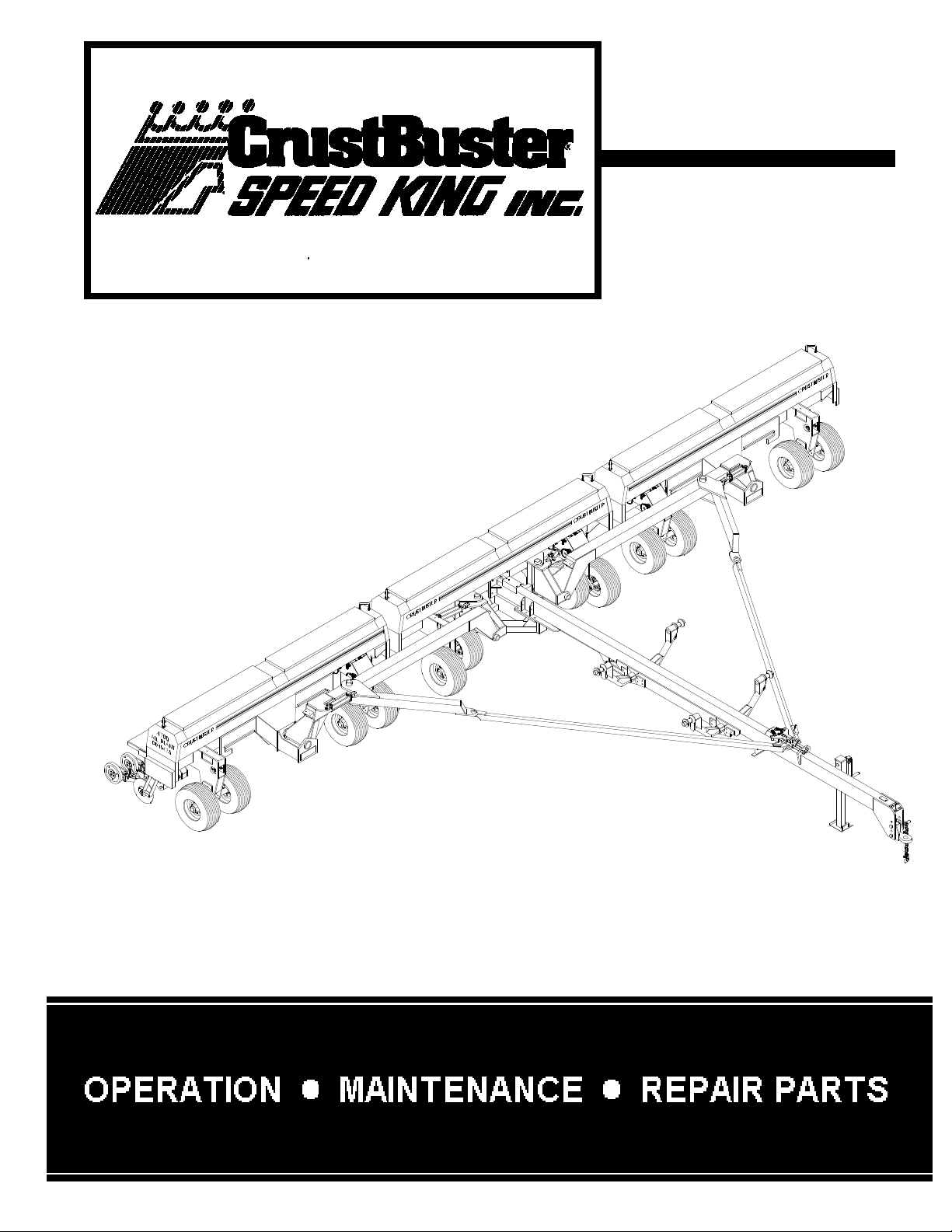

CrustBuster 4740 User manual

4740 Drill

OWNER'S MANUAL

# 606483 - 2009

Identification

Your CrustBuster® drill is identified by a Serial Number and Model Number.

Record these numbers in the spaces provided in this manual and refer to them

when ordering parts or requesting service.

Serial Number Model Number

Warranty

WARRANTY: In addition to the implied warranties of fitness and of merchantability,

CrustBuster®/Speed King, Inc. warrants new products sold by it to be free from defects in

workmanship and material for a period of 12 months, from the date of delivery to the first user

customer. Warranty on purchased parts (cylinder, blades, bearings, shanks, etc.) will be the

same as that offered by the appropriate manufacturer of these parts.

EXCLUSIONS: No warranty of any kind is made by CrustBuster®/Speed King, Inc. with regard

to new products which have been subject to operation in excess of recommended capacities,

misuse, abuse, negligence, or accident, or have been altered or repaired in any manner not

authorized byCrustBuster®/Speed King, Inc. CrustBuster®/Speed King, Inc. is constantly striving

to improve its products. Changes in design and improvement will be made whenever

CrustBuster®/Speed King, Inc. believes the efficiency of its products will be improved thereby,

but without incurring any obligation to incorporate such improvements in any products which have

been shipped or are in service. No obligation exists for compensation of unauthorized repairs or

modifications without prior approval. And in no event will CrustBuster®/Speed King, Inc. be liable

for consequential damages, such as but not limited to: downtime, delayed or late tillage or

planting, etc.

WARRANTY REGISTRATION: This warranty is not valid unless registered with

CrustBuster®/Speed King, Inc. within 10 days from the date of purchase. It is the sole

responsibility of the selling retail dealer to fill out the registration forms and see that they are

properly filed with CrustBuster®/Speed King, Inc.

WARRANTY PROCEDURE: Should any part fail to conform with this warranty,

CrustBuster®/Speed King, Inc. will repair or replace the part or parts which do not conform. If a

part is defective, take it to your authorized CrustBuster® Farm Equipment Dealer immediately,

along with your warranty registration, and complete the proper forms requesting a warranty

adjustment. Our representative will pick up the part to be returned to the factory for examination.

If the customer (first user) requests that a new part be substituted for the old part, a new part will

be charged to the dealer who will in turn charge the customer. If the part is found by us to be

defective, a credit for the part will be given to the dealer to be passed on to the customer. If the

dealer or customer wishes to repair the part, this will be done only if authorized by

CrustBuster®/Speed King, Inc. This warranty procedure is in addition to all remedies authorized

by law.

CRUSTBUSTER®/SPEED KING, INC.

Box 1438

Dodge City, KS 67801

Specifications are subject to change without notice. ® is a registered trademark of CrustBuster/Speed King, Inc.

1

Table of Contents

Identification and Warranty . . . . . . . . . . . . . . .

. Inside Front Cover

Specifications ........................ 1

Safety ............................ 2-8

TransportingDrill...................... 9

Folding and Unfolding Drill . . . . . . . . . . . . . 10

Field Operating Checklist . . . . . . . . . . . . . . 10

Field Operation:

Operating Speed . . . . . . . . . . . . . . . . 11

Adjustment Procedure . . . . . . . . . . . . 11

LevelingDrill .................... 11

All Plant Drill:

Opener and Toolbar Adjustment . . . . . 11

Setting Down Pressure . . . . . . . . . . . . 12

Weighting ...................... 12

Setting Seed Depth . . . . . . . . . . . 12-13

Minimum Tillage Conditions . . . . . . . . 13

Conventional Field Conditions . . . . . . 13

No-Till Conditions . . . . . . . . . . . . . . . . 13

Min-Till Drill:

Setting Down Pressure . . . . . . . . . . . . 14

Down Pressure Spring . . . . . . . . . . . . 14

Setting Seed Depth . . . . . . . . . . . . . . 14

Presswheel Adjustment and

Tool Bar Rotation . . . . . . . . . . . . . . 15

Lubrication and Service . . . . . . . . . . . . . . 16

Scraper Adjustment . . . . . . . . . . . . . . . . 16

Blade Gap Adjustment . . . . . . . . . . . . . . 17

Tandem Wheel Drive Clutch . . . . . . . . . . 17

Calibration / Drilling Rates . . . . . . . . . . . . . . 18

Sprocket Box Operation . . . . . . . . . . . . . . . 18

Seed Cup Adjustments and Service . . . . . . 19

Sprocket Locations . . . . . . . . . . . . . . . . 20-21

Meter Man Acreage Counter . . . . . . . . . . . . 22

Sprocket Box Adjustment . . . . . . . . . . . . . . 22

Seed Rate Charts . . . . . . . . . . . . . . . . . 23-30

Illustrations and Repair Parts:

Center Drive . . . . . . . . . . . . . . . . . . . 32-33

Wing Drive . . . . . . . . . . . . . . . . . . . . 34-37

Gearbox . . . . . . . . . . . . . . . . . . . . . . 38-41

Clutch Lever Assembly . . . . . . . . . . . 39-41

Center Frame Section . . . . . . . . . . . . . . . 42

Drive End Bracket & Bearing . . . . . . . . . 43

Tandem Axle . . . . . . . . . . . . . . . . . . . . . . 43

Drive Plate w/Hub . . . . . . . . . . . . . . . . . . 44

8 Bolt Hub . . . . . . . . . . . . . . . . . . . . . . . . 44

Center Clutch Assembly . . . . . . . . . . . . . 45

Center Drive Sprocket . . . . . . . . . . . . . . . 45

Throw-out Clutch Half . . . . . . . . . . . . . . . 45

Drive Clutch Sprocket . . . . . . . . . . . . . . . 45

Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-Point Hitch Option & Pin . . . . . . . . . . . 47

Wing Carrier Adjustment . . . . . . . . . . . . . 47

Wing Frame Sections . . . . . . . . . . . . . . . 48

Clutch Assembly . . . . . . . . . . . . . . . . . . . 49

Spindle & Hub Assembly . . . . . . . . . . . . . 49

6 Bolt Hub . . . . . . . . . . . . . . . . . . . . . . . . 49

Meter Man Acre Counter . . . . . . . . . . . . . 49

Fold and Pull Bar . . . . . . . . . . . . . . . 50-52

Grain Box . . . . . . . . . . . . . . . . . . . . . 54-55

Tool Bars . . . . . . . . . . . . . . . . . . . . . 56-57

Cylinder Depth Control Lock . . . . . . . . . . 57

All Plant Opener Assembly . . . . . . . . 58-59

Min-Till Opener Assembly . . . . . . . . . 60-61

All Plant Opener Blades . . . . . . . . . . . . . 62

Min-Till Opener Blades . . . . . . . . . . . . . . 63

Presswheel Assemblies . . . . . . . . . . 64-67

Feed Tubes . . . . . . . . . . . . . . . . . . . . . . . 68

Hydraulics . . . . . . . . . . . . . . . . . . . . . 69-73

Markers . . . . . . . . . . . . . . . . . . . . . . . 74-80

Lighting System . . . . . . . . . . . . . . . . . . . 81

Shaft & Bin Monitor . . . . . . . . . . . . . . . . . 82

Harrow . . . . . . . . . . . . . . . . . . . . . . . 83-86

Fertilizer . . . . . . . . . . . . . . . . . . . . . 87-102

Troubleshooting . . . . . . . . . . . . . . . . . . 103

Specifications

Size & Number Weight w/ Weight w/

Spacing Openers Min-till Openers All Plant Openers Min. HP

40' x 7½" 63 23,105 lbs. 24,050 lbs. 180

40' x 10" 48 21,222 lbs. 21,912 lbs. 180

40' x 15" 32 20,762 lbs. 21,242 lbs. 180

(Opener offset center)

40' x 15" 31 20,686 lbs. 21,151 lbs. 180

2

BE A SAFE OPERATOR

BY THINKING BEFORE ACTING

AND

BY READING

YOUR OWNER'S MANUAL

Avoid Accidents

Most accidents, whether they occur in

industry, on the farm, at home, or on the

highway, are caused by the failure of some

individual to follow simple and fundamental

safety rules or precautions. For this reason

most accidents can be prevented by recog-

nizing the real cause and doing something

about it before the accident occurs.

———————

Regardless of the care used in the design

and construction of any type of equipment,

there are many conditions that cannot be

completely safeguarded against without

interfering with reasonable accessibility and

efficient operation.

A CAREFUL OPERATOR

is the Best Insurance Against an Accident.

The complete observance of one simple

rule would prevent many thousands

of serious injuries each year.

That rule is:

Never Attempt to

Clean, Oil, or Adjust

A Machine While It Is In Motion.

To Our Customers

The following pages and illustrations are

printed to help supply you with the knowledge

to better operate and service your new

CrustBuster equipment.

We are proud to have you as a customer

and feel you will be proud to be a

CrustBuster owner.

Any piece of equipment needs, and must

have, a certain amount of service and main-

tenance to keep it in top running condition.

We have attempted to cover all the adjust-

ments required to fit most conditions; how-

ever, there may be times when special care

must be taken to fit a condition.

Study this owner's manual carefully and

become acquainted with all the adjustments

and operating procedures before attempting

to operate your new equipment. Remember,

it is a machine and has been designed and

tested to do an efficient job in most operating

conditions and will perform in relation to the

services it receives.

If special attention is required for some

condition, ask your CrustBuster dealer; he

will be glad to help and answer any questions

on operations and service of your new ma-

chine.

TAKE TIME FOR SAFETY

3

Safety

RECOGNIZE SAFETY INFORMATION

UNDERSTAND SIGNAL WORDS

FOLLOW SAFETY INSTRUCTIONS

4

Safety

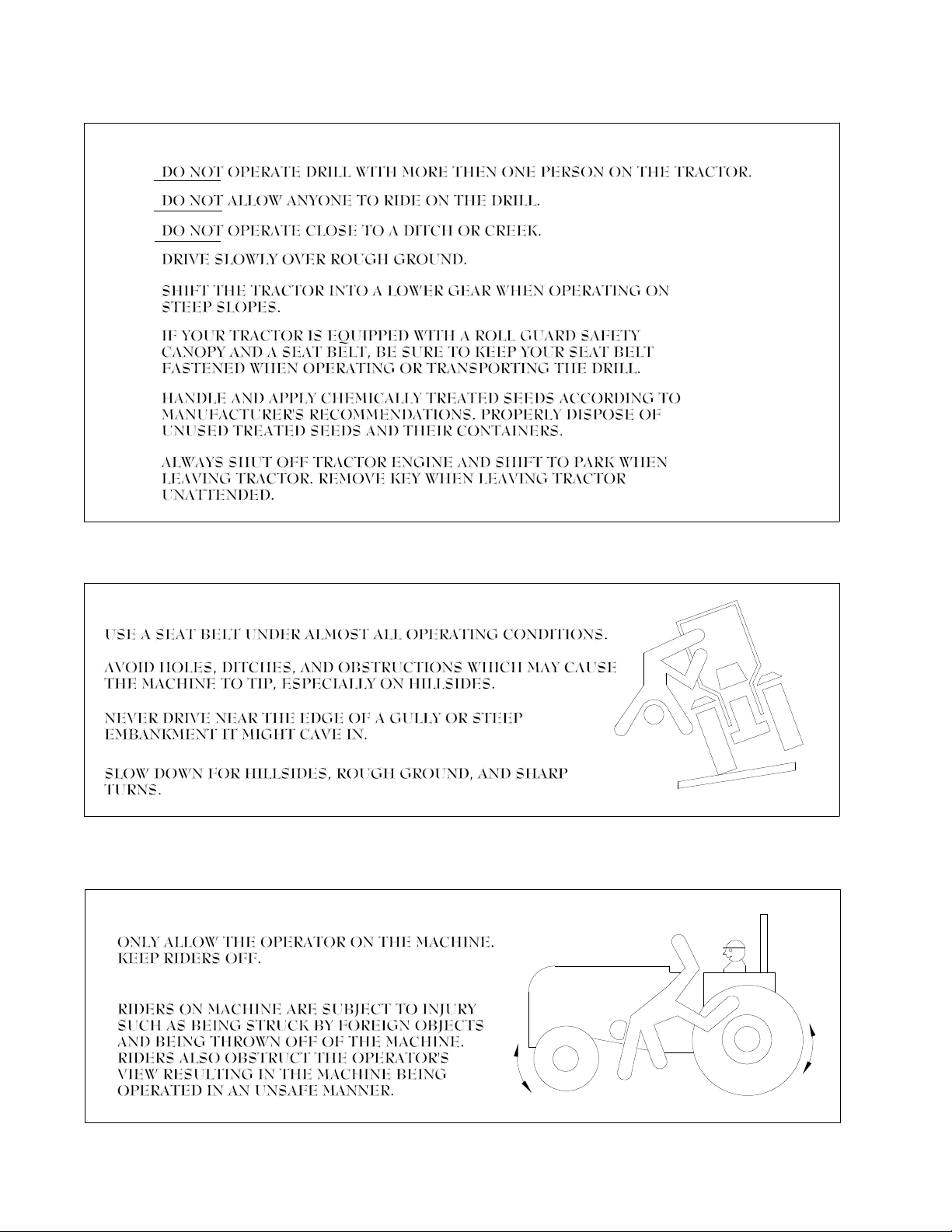

OPERATE SAFELY

AVOID TIP-OVERS

KEEP RIDERS OFF MACHINE

5

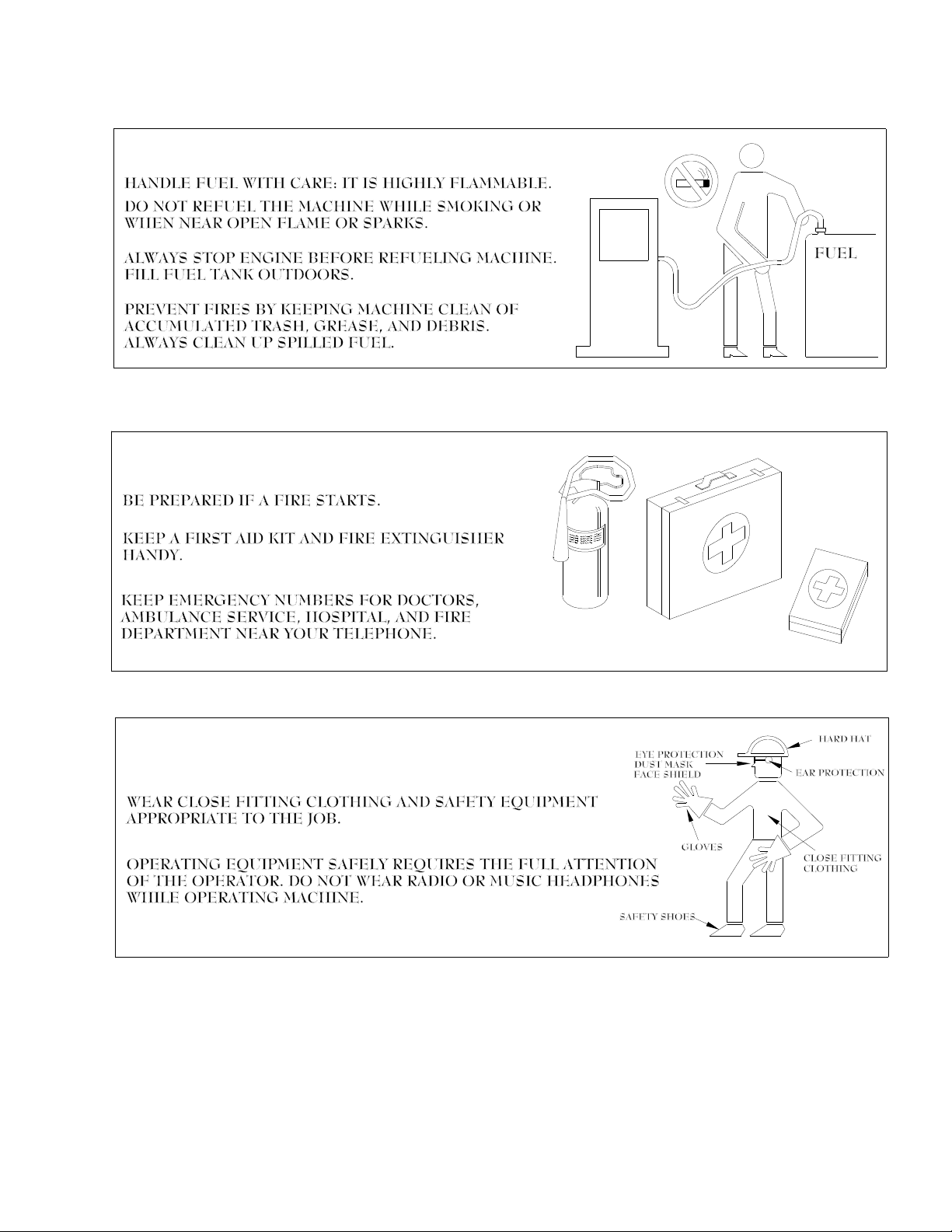

Safety

HANDLE FUEL SAFELY - AVOID FIRES

PREPARE FOR EMERGENCIES

WEAR PROTECTIVE CLOTHING

6

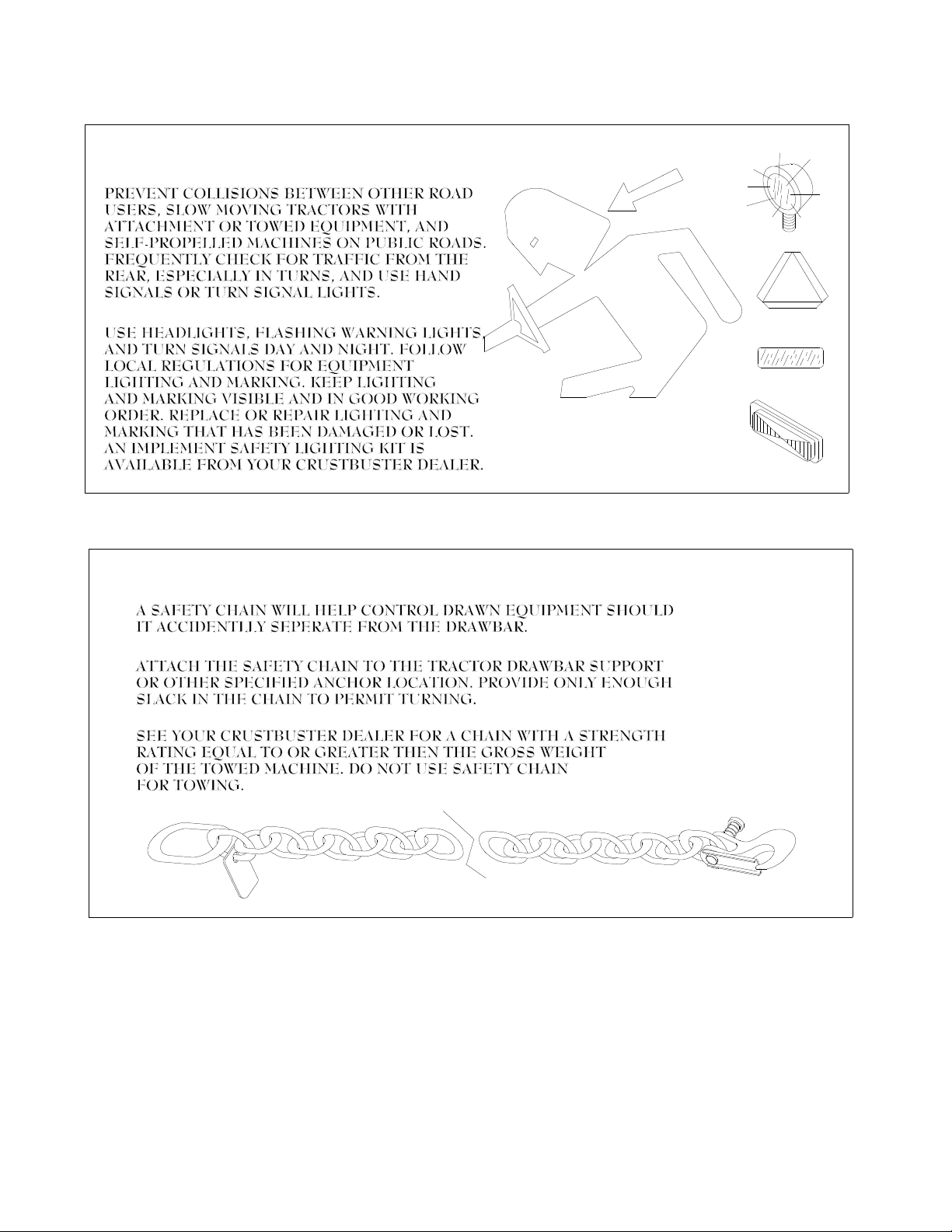

Safety

USE SAFETY LIGHTS AND DEVICES

USE A SAFETY CHAIN

7

Safety

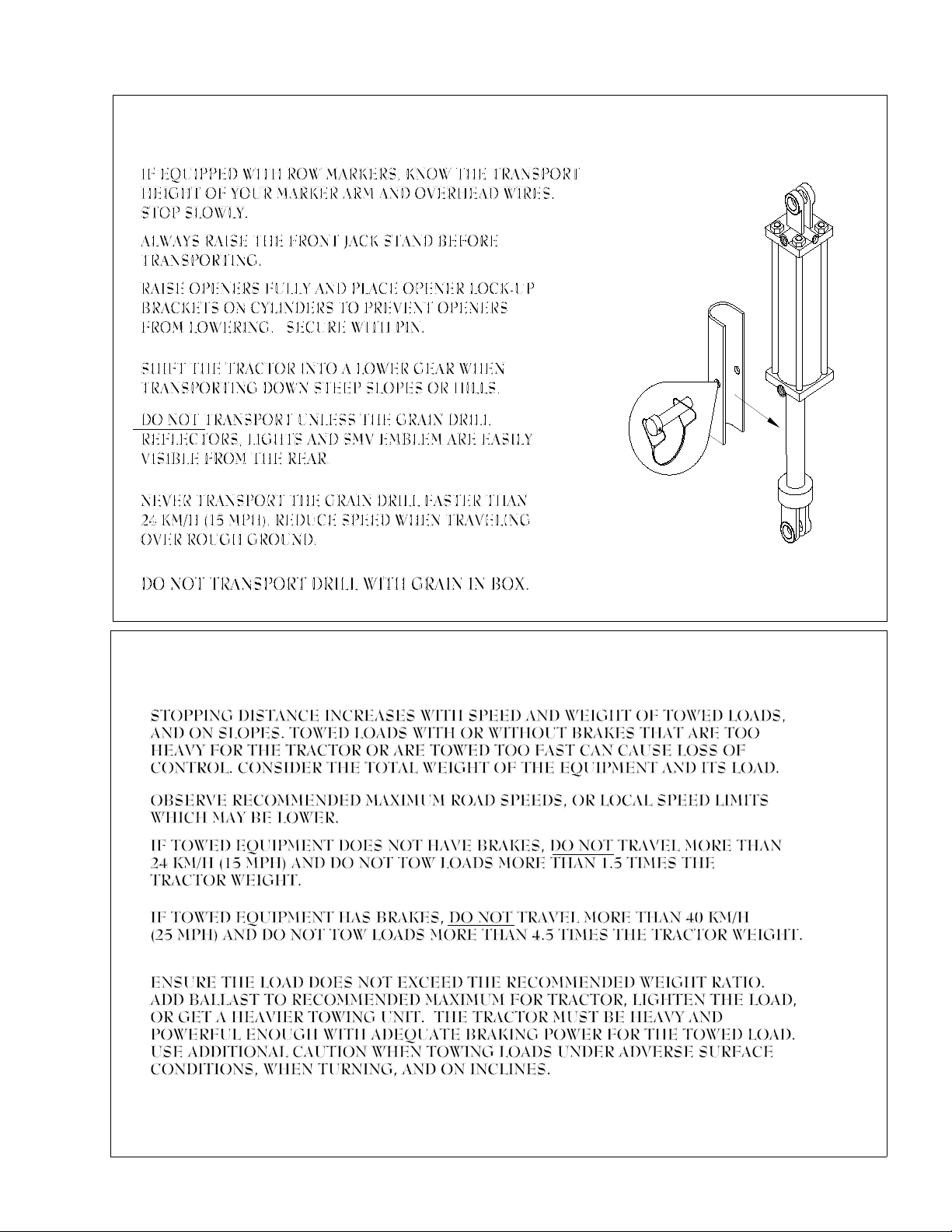

TRANSPORT SAFELY

TOW LOADS SAFELY

8

Safety

PRACTICE SAFE MAINTENANCE

AVOID HIGH-PRESSURE FLUIDS

CHARGE ROW MARKER

HYDRAULIC SYSTEM

9

Before Unfolding and Operating This Equipment ---

Read and understand this owner's manual.

Transport & Safety Instructions

F

When transporting drill, be aware you are towing a 24,000 lb. load with up to 6,550 lb. empty

hitch weight.

Tow width - 16' Tow length - 34'

Take appropriate precautions in stopping, turning, etc. DO NOT EXCEED 15 MPH.

Grain boxes are to be empty in transport to avoid exceeding the capacity of the 4740

drill center towing tires.

Follow tire manufacturer's recommendations regarding inflation for towing.

(Goodyear farm implement tire for highway and agriculture usage)

Mfg stated capacity @ 90 PSI = 4870 lb.

4740 Drill load per tow tire empty boxes = 4387 lb.

4740 Drill load per tow tire full boxes = 5600 lb.

F

Use a minimum hitch pin of 1" with lock nut to towing vehicle. DO NOT use a hairpin or wire

to secure hitch pin. Make sure adequate safety chains are in place.

F

NEVER use an unsecured pin in draw bar.

F

Before transporting, make sure transport locks are in place on the wing carrier arms located

under the hitch and on tool bar lift cylinders.

F

Lug bolts should be checked prior to towing, after 1 mile of transport, within the next 20 miles

and periodically thereafter. Check hubs for excess heating.

F

Make sure center section drive wheel throw-out pin is disengaged when transporting

F

Make sure 3-point linkages are raised completely to clear hitch.

F

If your tractor does not already have a lighting receptacle, install one. Always plug in the drill

lighting system to a correctly wired tractor and USE for transport safety. Wiring should be

extended into tow tractor for turn and stop light.

F

Connect the 7 pin lighting plug to the tractor receptacle and use at all times. Confirm the

correct lights are operating if your tractor is not wired by industry standard code. Standard 7

pin receptacles are available through your dealer, local truck supply stores, and auto parts

facilities.

F

Before operating hydraulics, remove all transport locks or damage to drill will result.

F

Never have more than 391 lbs. per section on the walkboards without drill securely attached

to tractor or towing vehicle.

CAUTION: Your drill weighs more than the towing vehicle. The drill is NOT

equipped with brakes. EXERCISE EXTREME CAUTION ! Maximum

allowable speed - 15 mph.

NEVER ALLOW ANYONE TO RIDE THE DRILL!

10

Fold and Unfold Instructions

F

Folding or unfolding of drill should be done on nearly level ground with the tractor transmission

in neutral.

F

When drill is plumbed with markers, the manual selector valve located at rear and top of hitch

will have to be shifted from marker to fold system.

F

During the fold and unfold operation, be sure to stay clear of pull bar slides located at front top

of hitch.

F

Check that all wing carrier cylinder locks are removed.

F

Lower wings by rotating wing carrier arms down out of hooks on front of wing frames. Be sure

wing carrier arms are clear of wing frames before unfolding. Unfolding is complete when pull

bar slides are pulled back against stop, and locked in place by automatic locks located at front

top of hitch. When folding, automatic locks will release pull bar slides.

F

Be sure wing carrier arms are lowered to clear wing frames when folding.

F

When pull bars come together against bumpers, and rollers on wing carrier arms are centered

under guides on wing frames, drill is completely folded. Wings can now be raised.

F

Be sure rollers are securely in hooks on wing frames.

F

Install cylinder locks on wing carrier lift cylinders.

F

Drill is now ready for transport. USE GOOD JUDGEMENT AND SAFE OPERATING

PROCEDURES WHEN TRANSPORTING.

Field Operating Checklist

____ Remove ALL transport locks.

____ Inflate tires to recommended air pressure.

____ Lubrication as required.

____ Seed shafts turned manually to check for obstructions and improper chain alignment on drive

sprockets.

____ Correct sprocket selection and slot width for seed type and size.

____ Calibration as required for accuracy.

____ Drill adjusted at hitch for level field operation.

____ Cylinder stop set for proper toolbar rotation (Initial setting recommended - 1").

Both cylinders for each bar are set equally to avoid twisting tool bar.

____ Down pressure set for soil conditions.

____ Acre meter reset.

____ Lower drill while moving forward to avoid plugging openers.

____ Check seed depth and adjust accordingly.

____ Allow no riders.

____ After approximately 10 hours, check tool bar bolts, wheel bolts, presswheel swivel bolts, etc..

Make sure they are tight.

Other manuals for 4740

1

Other CrustBuster Farm Equipment manuals

CrustBuster

CrustBuster Speed King Drive Over- Pit User manual

CrustBuster

CrustBuster 3200 User manual

CrustBuster

CrustBuster Speed King Seed Tote 4 Box User manual

CrustBuster

CrustBuster Speed King 10" BeltVeyor User manual

CrustBuster

CrustBuster Seed Tender 160 User manual

CrustBuster

CrustBuster COTTON MODULE BUILDER User manual

CrustBuster

CrustBuster 1325 User manual

CrustBuster

CrustBuster 4740 User manual

CrustBuster

CrustBuster 4000 Series Use and care manual

CrustBuster

CrustBuster DrillMaster User manual