- 3 -

1. INTRODUCTION.......................................................................................................................................................... 5

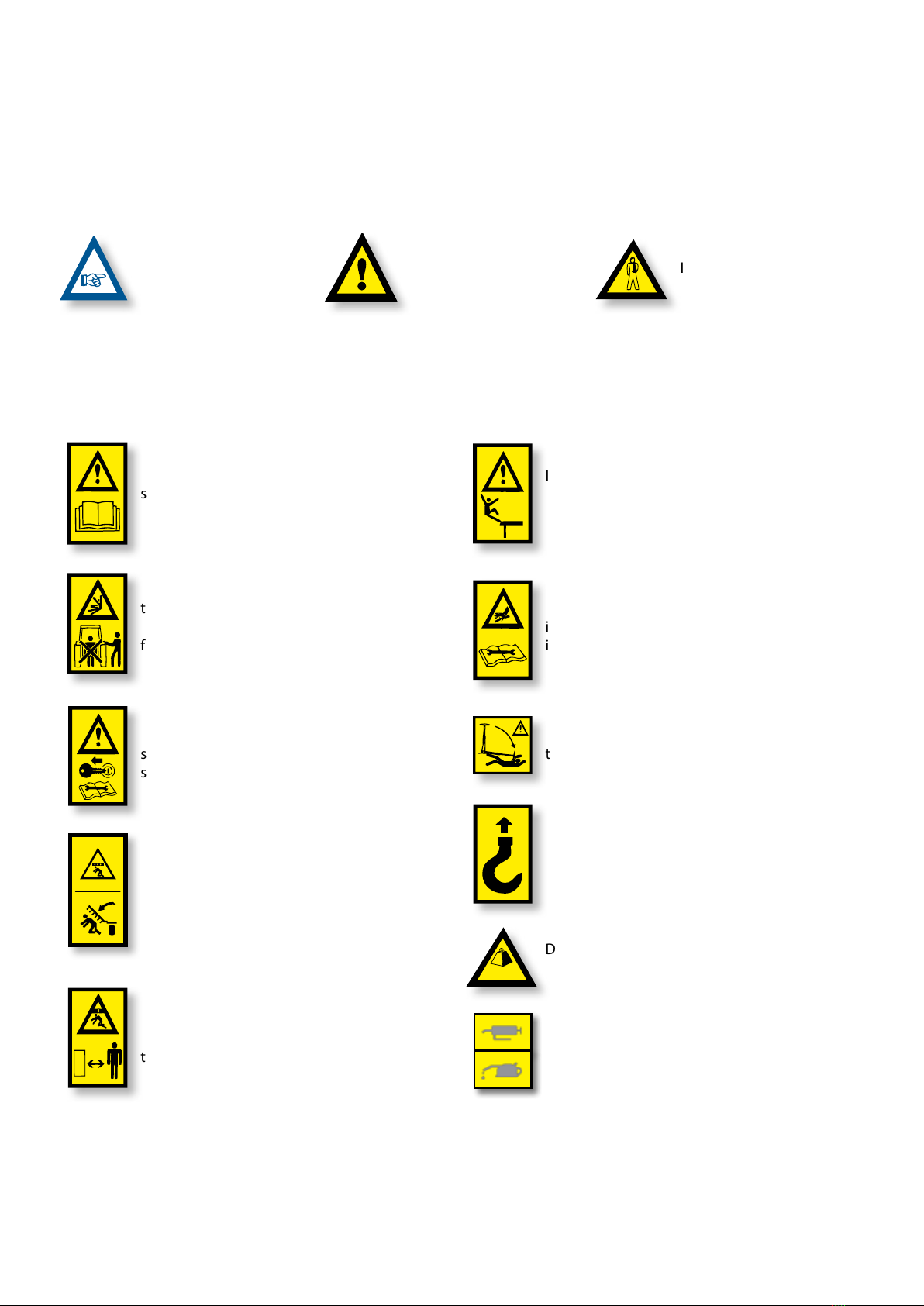

2. SAFETY INSTRUCTIONS ............................................................................................................................................. 6

2.1 SAFETY SYMBOLS........................................................................................................................................................................ 6

2.2 GENERAL SAFETY INSTRUCTIONS ........................................................................................................................................... 7

2.3 LOADING AND UNLOADING INSTRUCTIONS......................................................................................................................... 7

3. GENERAL DESCRIPTION............................................................................................................................................. 8

3.1 OVERVIEW OF THE MACHINE .................................................................................................................................................... 8

3.1.1 PLANTER SOWING UNIT.................................................................................................................................................. 10

3.1.2 SEEDER SOWING UNIT.................................................................................................................................................... 10

3.2 TECHNICAL CHARACTERISTICS (PLANTER).......................................................................................................................... 11

3.3 TECHNICAL CHARACTERISTICS (SEEDER)............................................................................................................................. 12

3.4 MACHINE IDENTIFICATION...................................................................................................................................................... 13

3.5 USE ACCORDING TO DESIGN................................................................................................................................................... 13

4. ESSENTIAL SOWING CONCEPTS................................................................................................................................14

4.1 TERRAIN....................................................................................................................................................................................... 14

4.2 SEEDS........................................................................................................................................................................................... 14

4.3 DEPTH.......................................................................................................................................................................................... 14

5. START-UP...................................................................................................................................................................15

5.1 HITCHING THE PLANTER TO THE TRACTOR.......................................................................................................................... 15

5.2 ELECTRICAL CONNECTIONS.................................................................................................................................................... 17

5.2.1 INDICATOR LIGHTS.......................................................................................................................................................... 17

5.2.2 ISOBUS............................................................................................................................................................................... 17

5.2.3 HYDRAULIC CONTROL AND WORK LIGHTS ............................................................................................................... 17

5.3 HYDRAULIC CONNECTIONS .................................................................................................................................................... 18

5.4 TRANSPORT POSITION ............................................................................................................................................................. 19

5.5 FILLING AND EMPTYING THE HOPPERS................................................................................................................................ 20

5.5.1 SEED HOPPERS (SEE PLANTER) ..................................................................................................................................... 21

5.5.2 CENTRAL HOPPERS......................................................................................................................................................... 21

5.5.3 CENTRAL HOPPERS FOR MICRO-GRANULAR PRODUCTS....................................................................................... 24

5.6 SUPPORT FEET............................................................................................................................................................................ 25

5.6.1 MAIN SUPPORT FOOT ..................................................................................................................................................... 26

5.6.2 SOWING EQUIPMENT SUPPORT FEET ......................................................................................................................... 27

5.7 PARKING...................................................................................................................................................................................... 27

5.8 AFTER WORKING WITH THE MACHINE.................................................................................................................................. 28

6. PLANTER MODEL ADJUSTMENTS ............................................................................................................................ 29

6.1 PLANTING DISTANCE BETWEEN SEEDS................................................................................................................................. 31

6.1.1 MECHANICAL TRANSMISSION....................................................................................................................................... 31

6.1.2 ELECTRICAL TRANSMISSION - ISOBUS ........................................................................................................................ 38

6.2 REPLACING THE SEED DISC..................................................................................................................................................... 38

6.3 FACTORS THAT AFFECT SEED QUALITY ................................................................................................................................ 39

6.3.1 ADJUSTING THE SELECTOR ........................................................................................................................................... 39

6.3.2 ADJUSTING THE SEED EJECTOR ................................................................................................................................... 40

6.3.3 DISTRIBUTOR SEED INLET ............................................................................................................................................. 41

6.4 SUCTION SYSTEM - FAN ........................................................................................................................................................... 43

6.5 DISABLING A SOWING UNIT....................................................................................................................................................44

6.5.1 DISABLING THE TRANSMISSION...................................................................................................................................44

6.5.2 LIFTING THE UNIT............................................................................................................................................................ 45

6.6 PLANTING DEPTH......................................................................................................................................................................46

6.7 PROSEM K SCRAPERS................................................................................................................................................................ 47

6.8 UNIT PRESSURE ON THE GROUND......................................................................................................................................... 47

6.9 CLOSING THE FURROW.............................................................................................................................................................48

6.9.1 WORKING WIDTH OF THE WHEEL................................................................................................................................. 49

6.9.2 PRESSURE ON THE SEED ................................................................................................................................................ 49

6.9.3 CASTER ANGLE................................................................................................................................................................. 50

TABLE OF CONTENTS