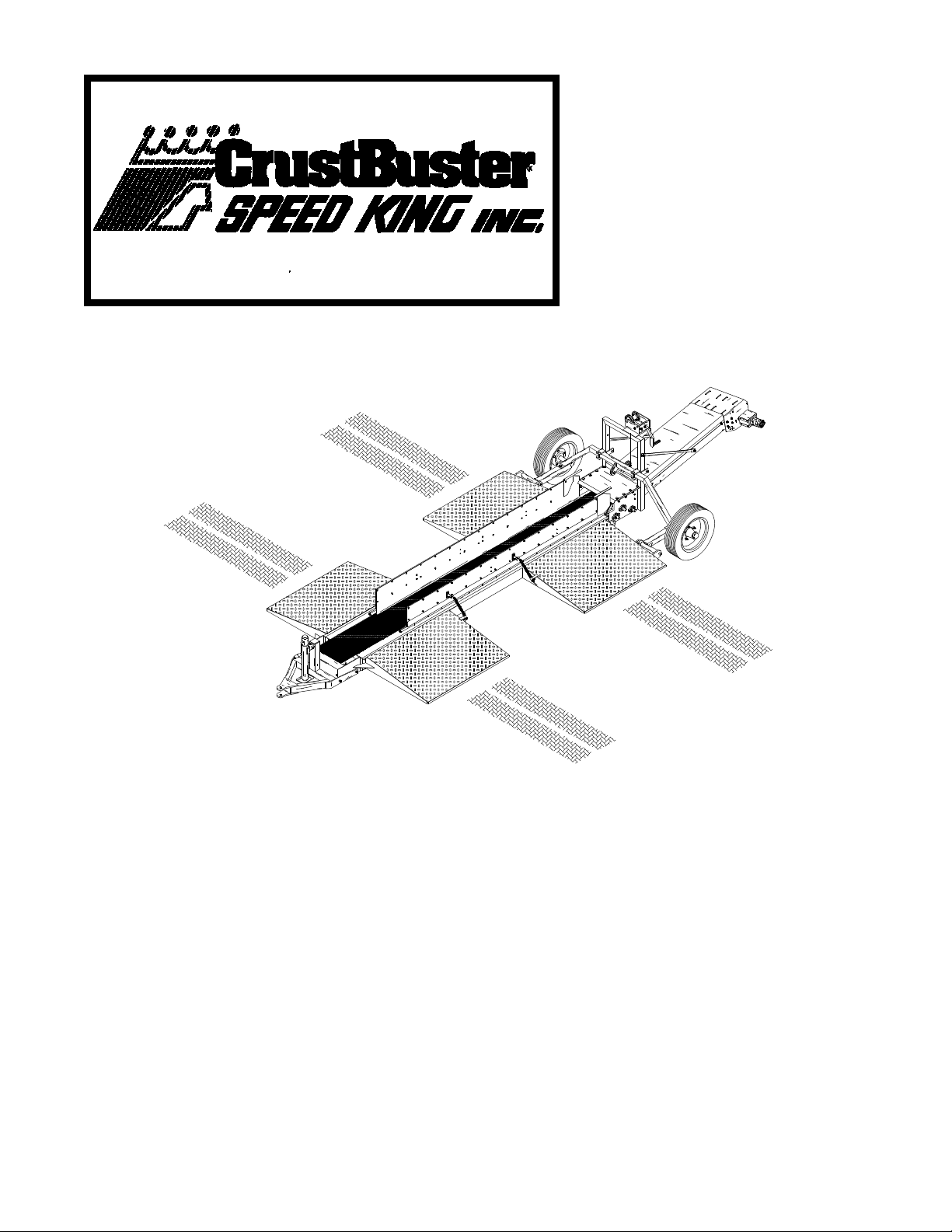

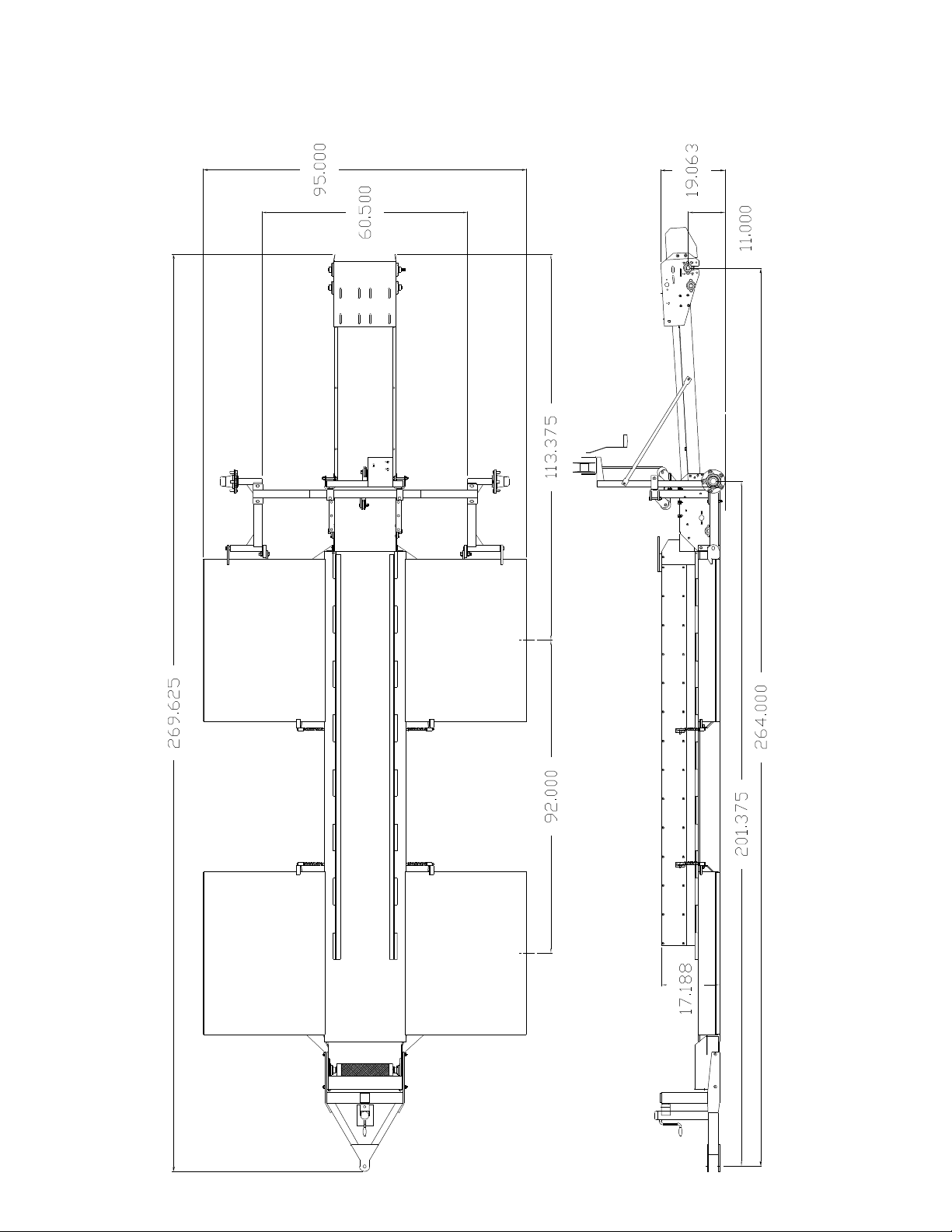

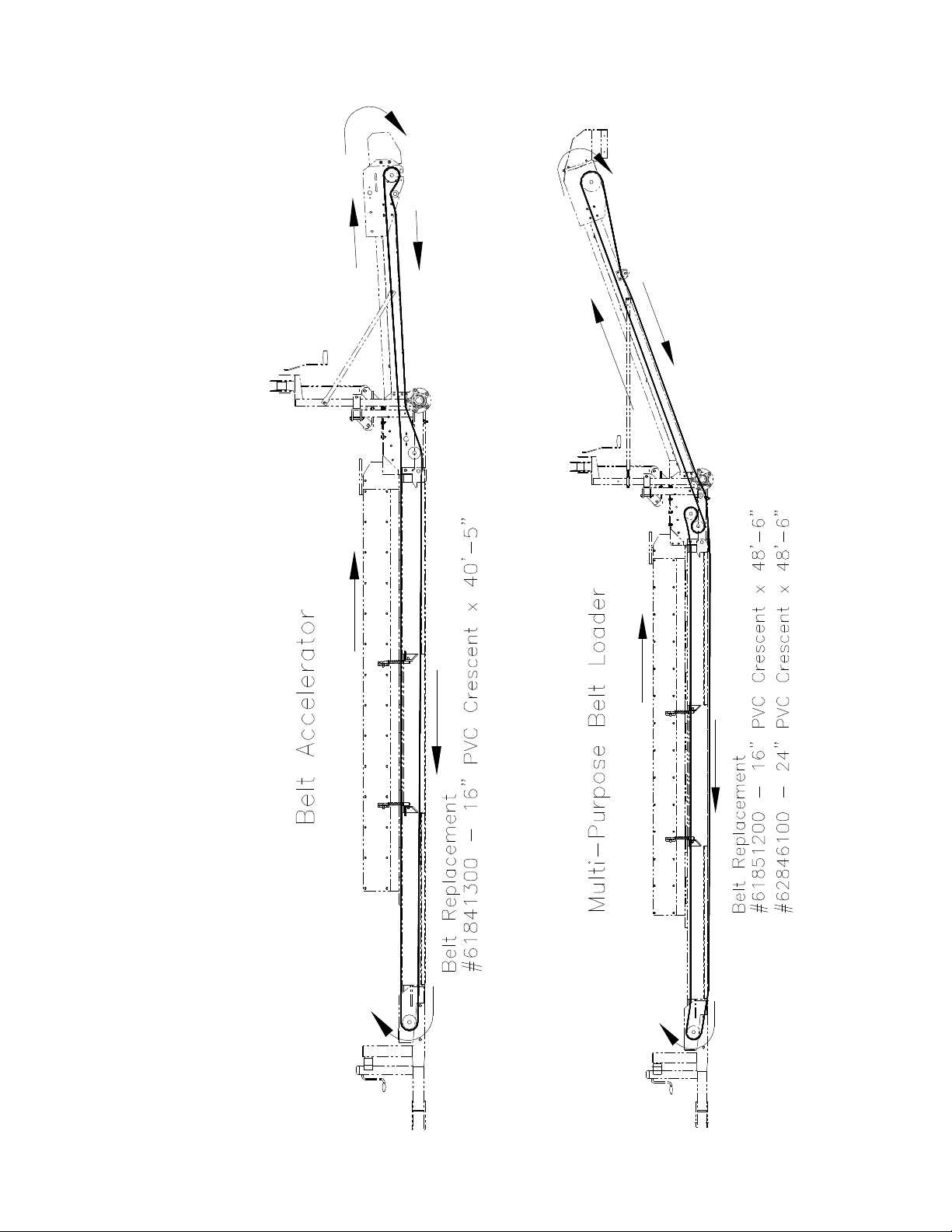

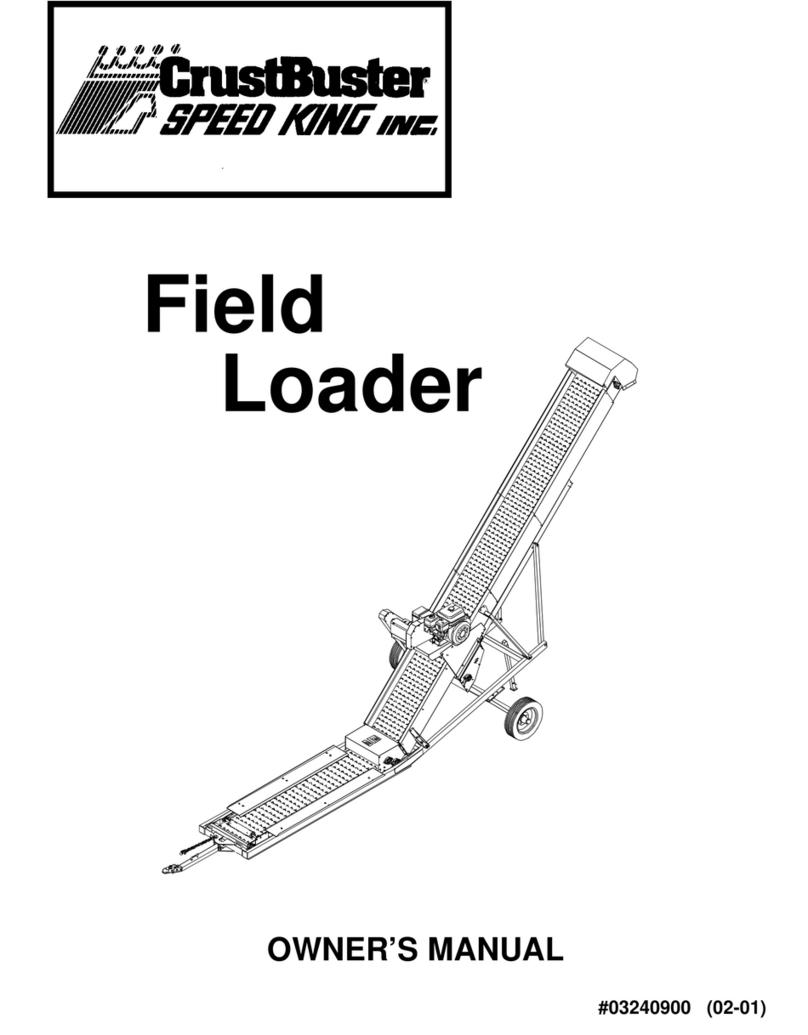

CrustBuster Speed King Drive Over- Pit User manual

Other manuals for Speed King Drive Over- Pit

1

Table of contents

Other CrustBuster Farm Equipment manuals

CrustBuster

CrustBuster 4740 User manual

CrustBuster

CrustBuster COTTON MODULE BUILDER User manual

CrustBuster

CrustBuster Speed King 10" BeltVeyor User manual

CrustBuster

CrustBuster Super 20XL User manual

CrustBuster

CrustBuster 3200 User manual

CrustBuster

CrustBuster 4740 User manual

CrustBuster

CrustBuster Speed King Seed Tote 4 Box User manual

CrustBuster

CrustBuster 4000 Series Use and care manual

CrustBuster

CrustBuster Speed King User manual

CrustBuster

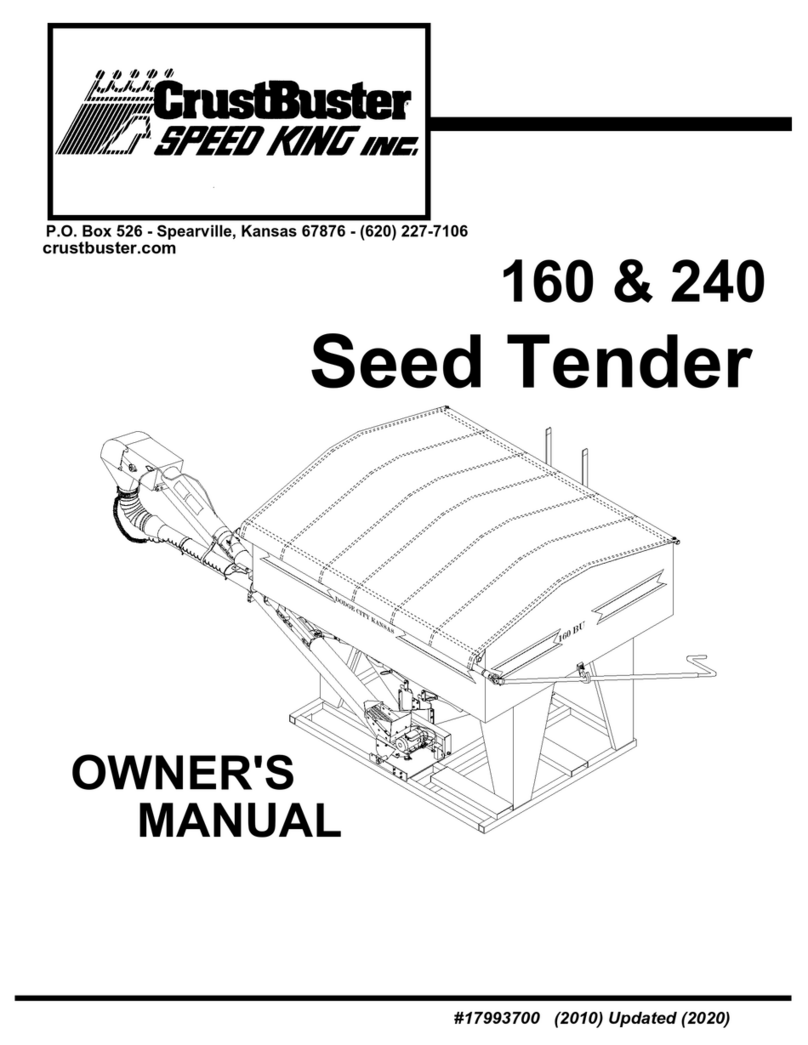

CrustBuster Seed Tender 160 User manual

Popular Farm Equipment manuals by other brands

Redexim

Redexim RINK DS 3800 Operating Instructions and Spare Parts Book

Amazone

Amazone Grasshopper SmartCut operating manual

Dhollandia

Dhollandia DH-RMH 44 installation manual

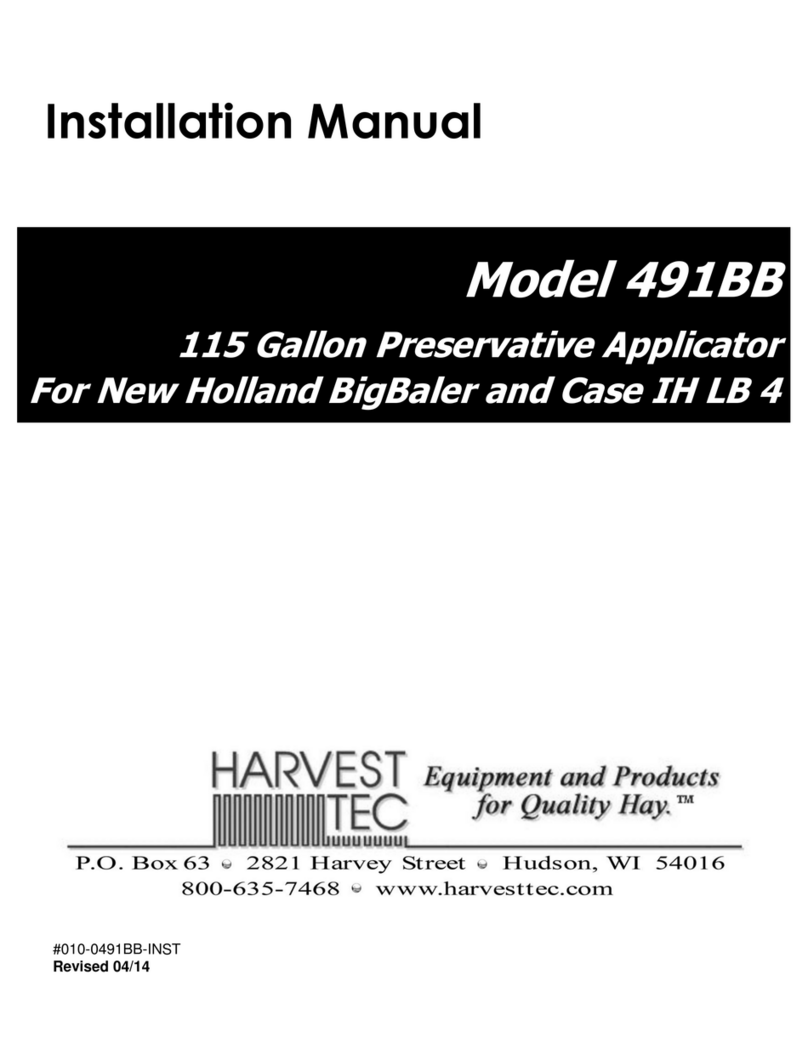

Harvest TEC

Harvest TEC 491BB installation manual

Teagle

Teagle Tomahawk 404M Instruction book

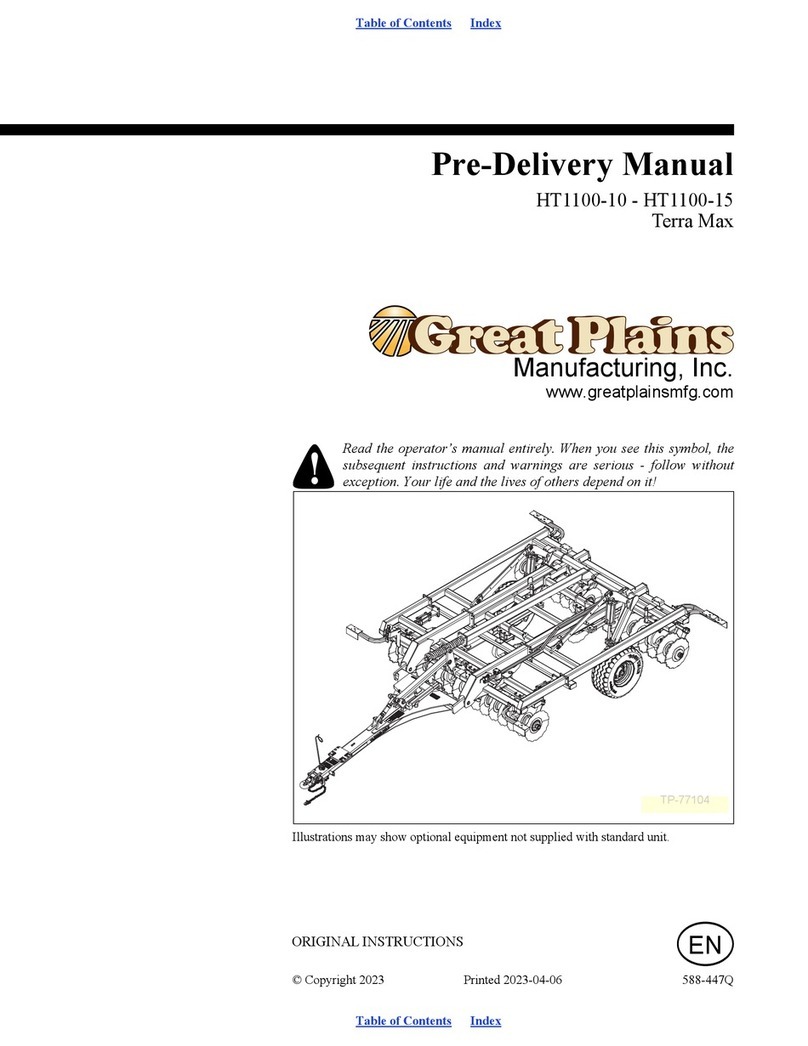

GREAT PLAINS

GREAT PLAINS Terra Max HT1100-10 Predelivery Manual