CrustBuster 4000 Series Use and care manual

4000 SERIES

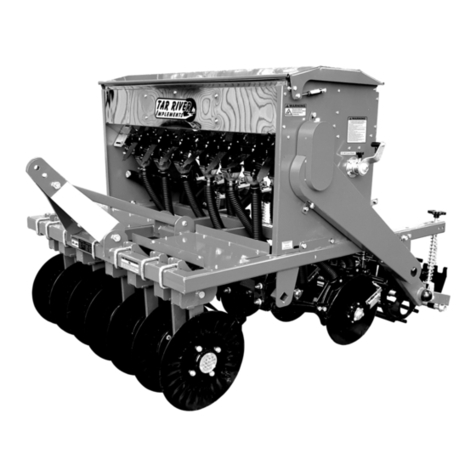

ALL PLANT & MIN-TILL DRILL

OWNER'S MANUAL

(4-01) #604694

Identification

Your CrustBuster® drill is identified by a Serial Number and Model Number. Record these numbers

in the spaces provided in this manual and refer to them when ordering parts or requesting service.

Serial Number Model Number

Warranty

WARRANTY: In addition to the implied warranties of fitness and of merchantability,

CrustBuster®/Speed King, Inc. warrants new products sold by it to be free from defects in

workmanship and material for a period of 12 months, from the date of delivery to the first user

customer. Warranty on purchased parts (cylinder, blades, bearings, shanks, etc.) will be the same

as that offered by the appropriate manufacturer of these parts.

EXCLUSIONS: No warranty of any kind is made by CrustBuster®/Speed King, Inc. with regard

to new products which have been subject to operation in excess of recommended capacities,

misuse, abuse, negligence, or accident, or have been altered or repaired in any manner not

authorized by CrustBuster®/Speed King, Inc. CrustBuster®/Speed King, Inc. is constantly striving

to improve its products. Changes in design and improvement will be made whenever

CrustBuster®/Speed King, Inc. believes the efficiency of its products will be improved thereby, but

without incurring any obligation to incorporate such improvements in any products which have

been shipped or are in service. No obligation exists for compensation of unauthorized repairs or

modifications without prior approval. And in no event will CrustBuster®/Speed King, Inc. be liable

for consequential damages, such as but not limited to: downtime, delayed or late tillage or

planting, etc.

WARRANTY REGISTRATION: This warranty is not valid unless registered with

CrustBuster®/Speed King, Inc. within 10 days from the date of purchase. It is the sole

responsibility of the selling retail dealer to fill out the registration forms and see that they are

properly filed with CrustBuster®/Speed King, Inc.

WARRANTY PROCEDURE: Should any part fail to conform with this warranty,

CrustBuster®/Speed King, Inc. will repair or replace the part or parts which do not conform. If a

part is defective, take it to your authorized CrustBuster® Farm Equipment Dealer immediately,

along with your warranty registration, and complete the proper forms requesting a warranty

adjustment. Our representative will pick up the part to be returned to the factory for examination.

If the customer (first user) requests that a new part be substituted for the old part, a new part will

be charged to the dealer who will in turn charge the customer. If the part is found by us to be

defective, a credit for the part will be given to the dealer to be passed on to the customer. If the

dealer or customer wishes to repair the part, this will be done only if authorized by

CrustBuster®/Speed King, Inc. This warranty procedure is in addition to all remedies authorized

by law.

CRUSTBUSTER®/SPEED KING, INC.

Box 1438

Dodge City, KS 67801

Specifications are subject to change without notice. ® is a registered trademark of CrustBuster/Speed King, Inc.

Table of Contents

Introduction

Identification & Warranty . . . . . . . . . Inside Cover

Safety ................................2-8

OperatingCautions ...................... 9

Field Operating Checklist . . . . . . . . . . . . . . . . . . 9

Lubrication and Operating

Lubrication, Maintenance, and Service . . . . . . 10

Transporting ........................... 11

Folding & Unfolding . . . . . . . . . . . . . . . . . . . . . 11

Leveling .............................. 11

Wobble Slot Seed Cup Adjustments . . . . . . . . 12

Chain Tension on Drive Shaft . . . . . . . . . . . . . 12

Meter Man Acreage Counter . . . . . . . . . . . . . . 13

Sprocket Box Adjustment . . . . . . . . . . . . . . . . . 13

Field Operation

OperatingSpeed ....................... 14

Adjustment Procedures . . . . . . . . . . . . . . . . . . 14

Scraper Adjustments . . . . . . . . . . . . . . . . . . . . 14

Blade Gap Adjustment . . . . . . . . . . . . . . . . . . . 14

All Plant Settings . . . . . . . . . . . . . . . . . . . . . 15-17

Min Till Settings . . . . . . . . . . . . . . . . . . . . . . 18-19

Calibration and Drilling Rates

Calibration ............................ 20

Sprocket Box Operation . . . . . . . . . . . . . . . . . . 20

Sprocket Locations . . . . . . . . . . . . . . . . . . . . . . 21

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . 22-29

Repair Parts

Hitch ................................. 30

Tongue ............................... 31

Wing Sections

4025 / 4030 ..................... 32-33

4020 ............................44-45

Tool Bars

4025 / 4030 All Plant ................. 34

4020 All Plant ...................... 35

4025 / 4030 Min Till ................. 36

Slide Fold & Pull Bar . . . . . . . . . . . . . . . . . . . . . 37

Grain Box

4025 / 4030 ......................38-39

4020 ............................40-41

Drives

4025 / 4030 ......................42-43

4020 ............................44-45

Gear Boxes

4025 / 4030 ......................46-49

4020 ............................50-57

Repair Parts - Cont.

Opener Assemblies & Blades

All Plant Opener . . . . . . . . . . . . . . . . . . 54-55

All Plant Blades . . . . . . . . . . . . . . . . . . . . . 58

Min Till Opener . . . . . . . . . . . . . . . . . . . 56-57

Min Till Blades . . . . . . . . . . . . . . . . . . . . . 59

Feed Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Clutch Lever Assemblies . . . . . . . . . . . . . . . . . 61

Bearing Bracket Assemblies . . . . . . . . . . . . . . 61

Hub Assemblies . . . . . . . . . . . . . . . . . . . . . . . . 62

Clutch Assemblies . . . . . . . . . . . . . . . . . . . . 63-64

Presswheel Assemblies . . . . . . . . . . . . . . . . 64-67

Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . 68-69

Markers

4025 / 4030 . . . . . . . . . . . . . . . . . . . . . . 70-71

Tri-Fold..........................72-74

4020 .............................. 75

Marker Blade Assembly . . . . . . . . . . . . . . . 76

Marker Cylinder . . . . . . . . . . . . . . . . . . . . . 76

Valve Bracket Assembly . . . . . . . . . . . . . . 77

Hydraulics

4020 -Triple . . . . . . . . . . . . . . 78-79

4025 -Triple . . . . . . . . . . . . . . 80-81

4030 -Triple . . . . . . . . . . . . . . 82-83

4020 -Triple w/Markers . . . . . . 84-85

4025 -Triple w/Markers . . . . . . 86-87

4030 -Triple w/Markers . . . . . . 88-89

4020 / 4025 -Double w/Markers . . . . 90-91

4030 -Double w/Markers . . . . 92-93

Spring Tine Harrow . . . . . . . . . . . . . . . . . . . . . 94

Harrow Layouts

4020 x 7½" . . . . . . . . . . . . . . . . . . . . . . 95

4020 x 8" . . . . . . . . . . . . . . . . . . . . . . 96

4020 x 10" . . . . . . . . . . . . . . . . . . . . . . 97

4025 x 7½" . . . . . . . . . . . . . . . . . . . . . . 98

4025 x 8" . . . . . . . . . . . . . . . . . . . . . . 99

4025 x 10" . . . . . . . . . . . . . . . . . . . . . 100

4030 x 7½" . . . . . . . . . . . . . . . . . . . . . 101

4030 x 8" . . . . . . . . . . . . . . . . . . . . . 102

4030 x 10" . . . . . . . . . . . . . . . . . . . . . 103

Lighting System . . . . . . . . . . . . . . . . . . . . . . . 104

Fertilizer Unit

Settings, Cleaning, & Storage . . . . . . 106-107

Sprocket Locations . . . . . . . . . . . . . . . . . 108

Fertilizer Seed Rate Chart . . . . . . . . . . . . 109

Drive ........................110-111

Bearing Bracket Assemblies . . . . . . . . . . 111

Gear Boxes . . . . . . . . . . . . . . . . . . . . 112-115

Chain Tightening Instructions . . . . 115

Box Assembly . . . . . . . . . . . . . . . . . . 116-117

Box Bottom Assemblies . . . . . . . . . . . 118-119

Drive Clutch Assembly . . . . . . . . . . . . . . . 119

Feed Tubes . . . . . . . . . . . . . . . . . . . . . . . 120

Troubleshooting

.................... 121

2

BE A SAFE OPERATOR

BY THINKING BEFORE ACTING

AND

BY READING

YOUR OWNER'S MANUAL

Avoid Accidents

Most accidents, whether they occur in

industry, on the farm, at home, or on the

highway, are caused by the failure of some

individual to follow simple and fundamental

safety rules or precautions. For this reason

most accidents can be prevented by recog-

nizing the real cause and doing something

about it before the accident occurs.

———————

Regardless of the care used in the design

and construction of any type of equipment,

there are many conditions that cannot be

completely safeguarded against without

interfering with reasonable accessibility and

efficient operation.

A CAREFUL OPERATOR

is the Best Insurance Against an Accident.

The complete observance of one simple

rule would prevent many thousands

of serious injuries each year.

That rule is:

Never Attempt to

Clean, Oil, or Adjust

A Machine While It Is In Motion.

To Our Customers

The following pages and illustrations are

printed to help supply you with the knowledge

to better operate and service your new

CrustBuster equipment.

We are proud to have you as a customer

and feel you will be proud to be a

CrustBuster owner.

Any piece of equipment needs, and must

have, a certain amount of service and main-

tenance to keep it in top running condition.

We have attempted to cover all the adjust-

ments required to fit most conditions; how-

ever, there may be times when special care

must be taken to fit a condition.

Study this owner's manual carefully and

become acquainted with all the adjustments

and operating procedures before attempting

to operate your new equipment. Remember,

it is a machine and has been designed and

tested to do an efficient job in most operating

conditions and will perform in relation to the

services it receives.

If special attention is required for some

condition, ask your CrustBuster dealer; he

will be glad to help and answer any questions

on operations and service of your new ma-

chine.

TAKE TIME FOR SAFETY

3

Safety

4

Safety

5

Safety

6

Safety

7

Safety

8

Safety

9

Before Operating This Equipment

Read and understand this owner's manual.

Secure implement to tractor drawbar with as large a hitch pin as allowed. A

large bolt with locking nut or castle nut is recommended. Do not use a hairpin or

wire to secure hitch pin. Residue may catch and remove these devices.

CAUTION!

During the unfolding sequence, drill becomes tail

heavy. Do Not stand over tongue during or after un-

folding.

Remove tongue cylinder transport lock strap before

attempting to operate.

Field Operating Checklist

G

Tires at recommended air pressure (44 PSI).

G

Lubrication as required.

G

Seed shafts turned manually to check for obstructions and improper chain

alignment on drive sprockets.

G

Correct sprocket selection and slot width for seed type and size.

G

Calibration as required for accuracy.

G

Drill adjusted for level field operation.

G

Down pressure set for soil conditions.

G

Record starting number on acre meter.

G

Lower drill while moving forward to avoid plugging openers.

G

Drill opener rockershaft fully raised before folding.

G

Check seed depth and adjust accordingly.

G

Allow no riders.

10

Lubrication, Maintenance, and Service

Lubrication and Maintenance

Proper maintenance will extend the life of your drill and

give you years of excellent performance. Refer to the

illustrations below for lubrication requirements. Use a

high quality grease in pivot points and bearings. On

greaseable sealed bearings, be careful not to over-

grease and destroy the dirt seal. Pay attention to

recommended intervals. Oil chains with a light chain

lube. A light penetrating oil should be used on seed

cups initially and at the end of each season. Clean

cups with air pressure or vacuum before applying

penetrating oil.

Do Not Attempt To Service

Your Drill While

It Is In Motion!

11

Clutch Maintenance

CAUTION!

At the start of a new drilling season, or anytime the

drill is going to be used, especially if the drill has

been stored out in the weather all winter long, make sure the

clutch drive is not frozen up. Failure to do this will result in

damage to the clutch assembly.

To make sure the clutch is not frozen up, tighten up the clutch

bolts. This should free the disc torque limiter. If not, use a knife

to free the torque limiter from one or the other. Reset clutch

back to where it was. Do Not use any oil or penetrating oil of

any kind.

Transport Instructions

Before Attempting to Operate Tongue

Cylinder,

Remove Transport Lock Strap.

The clevis or mono hitch will stay level on the 4000 Drill, making

it very easy to hook to the tractor. Attach the hoses to the

hydraulic ports on your tractor and operate the tongue up or

down to align with the tractor drawbar. Once the hitch pin or

large bolt is in place, extend the tongue cylinder fully to raise the

front of the drill. Raise the support stand before moving the drill.

Folding and Unfolding Drill

Always Raise Openers Completely

Before Folding Drill!

Fold Procedure Should Be Done On Nearly Level Ground

With The Tractor Transmission In Neutral.

When drill is plumbed with manual hydraulic selector valves,

change valve handle to change hydraulic flow to the fold

cylinders.

To Unfold:

1. Lower front of drill tongue with tongue cylinder fully retracted

and be sure the wing carrier arms will release from the wing

carrier brackets.

2. Hold hydraulic pressure on fold cylinder until wings are in

position.

To Fold:

1. Raise openers completely out of ground to full up position.

2. Lower front of drill tongue to allow wing carrier arms to clear

the wing carrier brackets.

3. Hold hydraulic pressure on fold cylinder until wings are in

position.

4. Extend tongue cylinder fully for maximum road clearance.

Leveling

It is important that your drill be set level front to back during

field operation. Seeding rate and opener travel will be affected

if it is not. The tongue cylinder is equipped with a number scale

for your convenience. When you are sure the drill is level,

remember the number that is relative to the tongue cylinder

position. After transporting to and from the farmstead or field, it

will be easy to return to level. You should re-check the drill

especially if field conditions are different.

12

Wobble Slot Seed Cup Adjustments and Service

The wobble slot seed cups should be checked against

the slot gauge initially and anytime service has been

performed on the seed shaft or individual seed cups.

Refer to the drawing below for proper adjustment if

repairs have been made.

To verify that all seed cups are set the same on the shaft,

start with all cups fully closed. A slight crack between the

cup halves would be considered normal tolerance. If any

individual cup is not "zeroed out," open the slot width

using the adjusting handle, loosen allen set screws and

adjust to equal others on shaft.

To determine if the gauge is reflecting the correct seed

cup slot width, open the seed cups using the adjusting

handle. Notice that wobble slot halves are positioned

differently on the hex shaft. Identify a cup that will accept

a piece of ½" keystock or other measuring device com-

fortably and give solid contact against each half. It may

be necessary to turn the hex shaft slightly to position the

particular seed cup correctly. Close the slot width firmly

against the measuring device. At the cup next to the

wobble slot adjusting handle, position the

gauge to equal the slot width you have just measured

with the keystock by loosening with a screwdriver and

sliding in or out.

Before removing the keystock, make certain the bearing

located on the adjustment lever is securely running

between the shaft bushings. Adjusting bushings must

be set screwed tightly to shaft with zero to 1/64" toler-

ance between the bushing and bearing. Excess toler-

ance in this area will allow the seed shaft to float from

right to left, thus opening and closing wobble slot and

varying the seed rate.

Small changes in rate can be made by opening or

closing slot width. To close the slot width with grain in

the box, close the slot down a maximum of 1/8" and

then rotate the shaft one turn to clear the slot. Repeat

this process until the desired slot width is selected.

Seeding rate is affected by seed size, seed treat-

ments, foreign material, and test weight. Refer to

seed rate charts as guidelines for desired seeding

rates.

Chain Tension on Drive Shaft

When making sprocket changes to the seed shaft, tighten

chain to leave approximately 1/2" of flex. The final sprocket

must allow the hex shaft to slide within the sprocket when the

adjusting lever is moved. If the chain is too tight, bowing and

binding of box end will occur making seed cup

adjustment difficult. Lightly lubricate the shaft

where the sprocket will slide. DO NOT

OVERTIGHTEN CHAIN.

13

Spacing 20' 25' 30'

6" .00307 .00369

7 ½" .00212 .00246 .00294

8" .00191 .00224 .00271

10" .00152 .00177 .00212

Meter Man Acreage Counter

(Option)

Calibration

Use the formulas below to determine your implement

calibration factor or refer to the predetermined factors

listed when using CrustBuster drills.

DT = Distance traveled with one counter shaft rotation

(when using two magnets, divide DT by 2).

WW = Working Width of implement (in inches).

WW x DT/2 = Calibration factor

6272640

NOTE: Whenever a gear change is made on the shaft

being monitored, you will need to enter a new calibration

factor.

Entering Calibration Factor

1. Depress ON/C

2. Round off factor to 5 digits

3. Enter factor (remember decimal point)

4. Depress + key

5. Depress = key

6. Depress decimal point (screen display 0)

CrustBuster Drill

Meter Man Factors by Model

4000 Drills

Sprocket Box Adjustment

The sprocket box design will enable the operator to set

a wobble slot width once for a given seed size and

change rates by changing the speed of the seed shaft.

Choose a range of seeding rates that you wish to

operate in, set the slot width as indicated by the chart

and simply change knob position with the slide handle to

select seed rate.

A narrow slot width will produce more even distribution

and spacing in the row.

For round seeds, the ideal slot width can be determined

by measuring seed size. To attain singular file flow of

seeds from the wobble slot seed cup, the slot width

should be greater than one and one half (1 ½) times the

average seed size, but less than two (2) times the

average size.

Ideal Slot Width = Greater than (>) 1½ times seed size

Less than (<) 2 times seed size

To determine average seed size, lay out 20-30 seeds in

single file, each seed touching each other. A short piece

of angle iron can help align the seeds evenly. Measure

distance from end to end with a ruler. Divide that

measurement by the number of seeds to equal the

average seed size. Multiply average seed size times 1½

to find the minimum width. Multiply average seed size

times 2 to find the maximum width. The slot width

should be ideal when set between these values.

Example: 30 seeds measure 9 inches.

9 " divided by 30 seeds = .30"

.30" times 1.5 = .45" .30 times 2 = .60"

Ideal slot width is greater than .45", less than .60"

Ideal slot width = ½"

Refer to seed chart ½" column as a starting point for

setting final seed rate.

To change position, move throw-out lever toward the

rear to disengage the chain from the lower sprocket.

Pull the spring loaded collar outward with two fingers

and slide side to side to the desired gear position. Pull

throw-out lever forward to re-engage the chain.

Sprocket Box

14

Field Operation

Recommended Operating Speed

Operating speeds of 4-7 mph will provide optimum

results from your Min-Till and All Plant drill. Conven-

tional field conditions can warrant speeds in the

upper end of the range. High levels of "tough"

residue due to morning dew or recent moisture,

rough field conditions, rocky fields, or hard ground

may require lower speeds for adequate performance.

Recommended Adjustment Pro-

cedure

Setting your drill requires adjustments be made in a

particular order to ensure the opener will work

properly. You will find it much easier to set the drill

if adjustments are made in the following order:

1. Level the drill

2. Set toolbar rotation

3. Set down pressure

4. Set seed depth

Scraper Adjustment

Opener blade inside scrapers are spring loaded and

require no adjustment. To replace the scraper

blades, remove the rear lock nut and slide both

blades from the stem. Assemble with new blades

and replace onto stem being careful not to over

tighten lock nut.

NOTE: Do not over tighten lock nut. Be sure

scrapers move freely. Failure to do so will

result in damage to scrapers and proper

operation of scrapers. All Plant

Opener

SPRING LOADED SCRAPER

Blade Gap Adjustment

Offset blade designs form better seed furrows and

penetrate and cut in tougher planting conditions. If

using the ALL PLANT opener, as the blades wear

Blade Gap Adjustment -

(cont'd.)

the gap between blades will increase. Removing each

blade from the opener bracket allows the operator to

take shim washers from behind the bearing and re-

adjust the blade gap for better performance. Shim

washers that are removed must then be placed on

outside of blade to maintain length of bolt. Maintain a

3/16" clearance between blades, measuring at the

pinch point. Inadequate clearance will increase wear on

the inside of the lead blade and mean quicker replace-

ment. The lead blade changes sides on the opener on

each half of the drill. The right blade on ALL PLANT

openers is installed with a right hand threaded bolt.

The left blade is installed with a left hand threaded bolt.

If the MIN-TILL opener is used, the offset design is

achieved by using a 15" leading blade and a 13" trailing

blade. One bolt and lock nut secures both blades in

the proper angle by tightening the bearing races

against the opener bracket. Be sure to hold the bolt as

the nut is removed or replaced. The bolt is bent to the

proper angle for the blades to meet at the front pinch

point. Since it is mounted with one bolt, the MIN-TILL

opener blades require no gap at the pinch point. Shim

washers may be needed to achieve this. When

tightening blades, rotate the bent bolt until bearing

races are flat and flush against beveled surface of

opener blade bracket.

ALL PLANT opener shown

LEAD

BLADE

PINCH

POINT

3/16" GAP

15

TOOL BAR LIFT CYLINDER SET

AT RECOMMENDED SETTING.

CYLINDER RETRACTED WITH

DEPTH SCREW STOP

TURNED OUT 1". THIS

MAKES CYLINDER LENGTH

FROM PIN HOLE TO PIN

HOLE 21¼" AS SHOWN.

NOTE: SET BOTH

CYLINDERS PER TOOL

BAR THE SAME TO

PREVENT TWISTING OF

TOOL BAR.

4025 & 4030

Weight Brackets

4020

Weight Brackets

If you have purchased a Min-Till Drill, the operation procedures continue on page 18.

All Plant Drill

Opener / Tool Bar Adjustments

The All Plant units are attached to a 4x4 bar that is

rotated by two cylinders on each section of the drill.

Each cylinder uses a screw adjustable depth stop on

the cylinder rod. The adjustable depth stop should be

set to rotate the 4x4 bar square to the 7x7 frame in all

conditions.

After the drill is leveled, rotation of the toolbar must be

set. Using the screw adjustable stop on the lift cylin-

der, adjust rotation of the toolbar with the screw adjust-

ment turned out 1" for an initial recommended setting.

Adjustment range of the presswheel depth quadrant

will be affected if the toolbar does not rotate far enough

or goes beyond perpendicular. If the toolbar

is not set correctly, the opener travel

range will not allow for penetration into

low areas or provide clearance when

meeting obstructions.

Check that both tool bar lift cylinders on

each section are set the same. DAMAGE

TO TOOL BAR WILL RESULT IF THEY

ARE NOT SET THE SAME.

Additional Weighting /

Weight Brackets

When operating the All Plant drill in hard ground

conditions, it will be necessary to add weight to the

frame. This can be achieved two different ways.

Optional weight bars are available to place into the 7 x

7 main frame. Simply remove the bolted step caps and

slide as many as six weight bars into the frame. (Refer

to Figure shown at right.)

16

All Plant Drill

Setting Down Pressure

The parallel linkage opener design assures the opera-

tor the opener blades and presswheel operate on the

same level throughout the range of up and down travel.

Due to the location of the down pressure spring, the

pressure applied to the opener remains relatively

constant in the entire range of travel. Changing the

spring position from the first (top) notch to the last

(bottom) notch provides 4 different levels of force.

Each notch represents approximately these amounts

of down pressure: . .

Notch 1 (top) 140# Notch 3 . . . 400#

Notch 2 . . . 275# Notch 4 . . . 525#

It may be necessary to add ballast to the drill in the

third or fourth notch. In order that all the opener

springs are able to achieve the down pressure se-

lected, the total weight of the drill must equal that

amount of pressure times the number of row units on

the drill. The parallel linkage arms should have a "live

working action" during field operation. Setting the drill

for too much down pressure without adequate weight

will reduce the ability of the opener to flex and give

good performance.

To determine the correct amount of down pressure,

begin with the unit set in the lightest setting and the

presswheel adjusted all the way up (or deepest set-

ting). Put the openers in the ground and pull forward

50-100 feet. Stop and check opener penetration. If

the opener is not penetrating to the depth you wish to

plant, rotate toolbar upwards until clear of the ground,

and add one more notch of down pressure. Repeat

the process until the opener will penetrate to at least

the depth you wish to plant.

LIGHT

HEAVY

Down Pressure Spring

Replacement

(Refer to drawing on page 17 in Conventional Field

Conditions section.)

If a down pressure spring breaks, the remaining portion

of the spring is easily removed. With the drill raised,

release the spring top latch and pull outward on the

entire spring top assembly as though changing from

notch to notch. Rotate the spring top assembly ¼" turn

while raising the unit to "parallel" position. Push the

lower portion forward to force the spring pivot pin out of

the welded cradles on either side of the linkage. A tab

prevents accidental loss of the down pressure spring.

Remove the cast plug and install in the new spring.

Replace the spring top assembly, raise the row unit to

"parallel" position and pull the lower portion of the

spring into place.

Setting Seed Depth

Depth settings are achieved by moving the depth

quadrant to affect the presswheel relationship to the

opener. Changes are made by pulling the spring-

loaded pin handle and moving the quadrant up or down

with the hand slot. LOWERING the quadrant will set

seed depth shallow --RAISING the quadrant will set

seed depth deeper. Irregular seed placement can be

caused by excessive field speed, residue hairpinning,

rocky conditions, and cloddy or wet soil conditions.

On the side plates holding the depth quadrant are two

holes for the spring loaded pin. If you move the

quadrant one hole without changing the pin location in

the side plate, you will change depth approximately ½".

Smaller ¼" adjustments can be made by alternately

moving the pin from front to back in the side plate

when moving the quadrant plate.

FRONT HOLE

BACK HOLE

17

All Plant Drill

Setting Seed Depth -

(cont.)

DEEP

SHALLOW

Minimum Tillage Conditions

The most challenging condition is often presented

when a high level of residue is present in a "loose" soil

environment. The opener blades will not cut residue

cleanly and can often have a tendency to push or

"bulldoze" residue ahead of the opener discs.

For minimum tillage operations, the lightest spring (top

notch) is recommended. Firming the ground using a

culti-packer or similar tool can aid in packing the

residue for better cutting and blade penetration with

less hairpinning.

The All Plant drill will work well in minimum tillage

conditions if a "stale seedbed" is created. Soil worked

at an earlier date, and allowed to firm and crust over

can give the opener more resistance, allow for better

cutting action, and create a firmer seed furrow. The

first or second notch will usually provide enough down

pressure to penetrate the soil.

Conventional Field Conditions

For tilled field conditions, the lightest spring setting (top

notch) is recommended. More weight will be trans-

ferred to the carrying wheels of the drill when the

toolbar is rotated. Behind tractor and drill tires it may

be necessary to adjust individual row units for extra

down pressure or different depth setting. Setting the

drill in conventional tillage will

be easier if the tillage trips are

kept shallow (2" - 4").

If the first notch presents too

much down pressure, the down

pressure spring assembly can

be removed. With the spring

assembly removed, the ef-

fective down pressure of the

opener is approximately

60#.

With the openers rotated

clear of the ground, release the

latches on the spring top assem-

blies. With the spring top ears

between the parallel arms, raise

the opener halfway and push

the bottom of the spring

and spring pin forward

out of the cradles.

No-Till Conditions

No-till presents many different conditions. Residue

level and condition, previous tillage strips (ridges, plow

dead furrows), soil type, soil moisture and rocky

conditions all increase the demands on the no-till drill.

Many variables and conditions not removed by tillage

trips require greater attention to settings and speed. In

some circumstances, it may be desirable to drill at a

slight angle to existing rows. This will also randomize

the opener disc wear and extend the maintenance

interval for new blades.

As a general rule, less than ideal conditions will require

slower speeds, to reduce hairpinning, improve opener

penetration and residue cutting, reduce rock damage,

and maintain good furrow formation and seed place-

ment.

It is recommended you set the drill beginning with light

down pressures and work your way up to heavier

settings. If the presswheel presses firmly on the seed

slot and control depth evenly, it is unnecessary to add

more pressure. When increased down pressure does

not improve penetration, or carrying wheels lose

ground contact (and seed drive shaft stops), begin

adding ballast with weight bars.

18

Min-Till Drill

Setting Down Pressure

Opener pressure setting is easy and allows separate

settings for tire compaction areas to different soil

conditions from field to field. Ratchet mechanism

allows you to turn the pressure up or down. The locking

key rolls up or down the notch gauge and locks to your

desired setting from 140# to 250# per opener.

Notch 1 . . 140#

Notch 2 . . . 190#

Notch 3 . . 210#

Notch 4 . . 230#

Notch 5 . . 250#

Down Pressure Spring

Adjustment

Row units that run in wheel tracks can be set with

heavier down pressure to assure solid presswheel

action. The following will help in changing spring

pressure.

1. Rotate the tool bar to raise the opener. Fold up the

walkboard to give good access to the front of the

opener.

2. Using ratchet type wrench, roll locking key up or

down notch gauge to desired setting.

Setting Seed Depth

Understanding the tool bar operation and parallel

linkage design will make setting the drill much easier.

Refer to the drawing on the next page.

Rotating the rockershaft DOWN

sets seed depth more SHALLOW.

Each tool bar is controlled by a hydraulic cylinder within

each wheel arm. An adjustable depth stop sets the

travel of the cylinder which in turn determines how

much the tool bar rotates.

Set depth stop in middle position as a starting point.

To set deeper seed depth, screw the depth stop out

and lengthen the cylinder travel. The opener and

presswheel relationship controls the depth of seed.

When lowering the openers, be sure the tool bar is

in the full down position and the cylinder is re-

tracted against the depth stop. The parallel linkage

must be "set" to achieve the desired down pres-

sure and depth control.

Individual presswheels may be set to correct for wheel

track compaction. Usually, these will only need to be

adjusted once if the same tractor is pulling the drill the

entire season. At the rear of the opener, a cam rotation

bracket holds the single presswheel arm. Turn the cam

toward the "D" or "S" to achieve the desired depth

control.

LOWERING the presswheel

will set seed depth more SHALLOW.

DEEP

SHALLOW

This manual suits for next models

3

Table of contents

Other CrustBuster Farm Equipment manuals

CrustBuster

CrustBuster Speed King User manual

CrustBuster

CrustBuster DrillMaster User manual

CrustBuster

CrustBuster Speed King Drive Over- Pit User manual

CrustBuster

CrustBuster 4740 User manual

CrustBuster

CrustBuster 4750 Drill User manual

CrustBuster

CrustBuster COTTON MODULE BUILDER User manual

CrustBuster

CrustBuster Super 20XL User manual

CrustBuster

CrustBuster Speed King 10" BeltVeyor User manual

CrustBuster

CrustBuster Seed Tender 160 User manual

CrustBuster

CrustBuster 4600 Series User manual