Version 2 / 09.22

6

4. Safety instructions

These assembly instructions must be read and understood before starting work in order to ensure safe handling of the Cargo Hybrid. The

safety instructions must be observed! if you disregard the safety instructions, you endanger yourself and others. All components of the

Cargo Hybrid, especially safety devices, must be correctly assembled to ensure proper operation.

Before assembly, check the Cargo Hybrid and all components for damage.

Do not assemble the Cargo Hybrid or components if these show signs of cracks, deformations or colour changes.

Do not bend damaged components straight again.

Replace damaged components immediately.

Do not use components if damage to them is apparent or suspected.

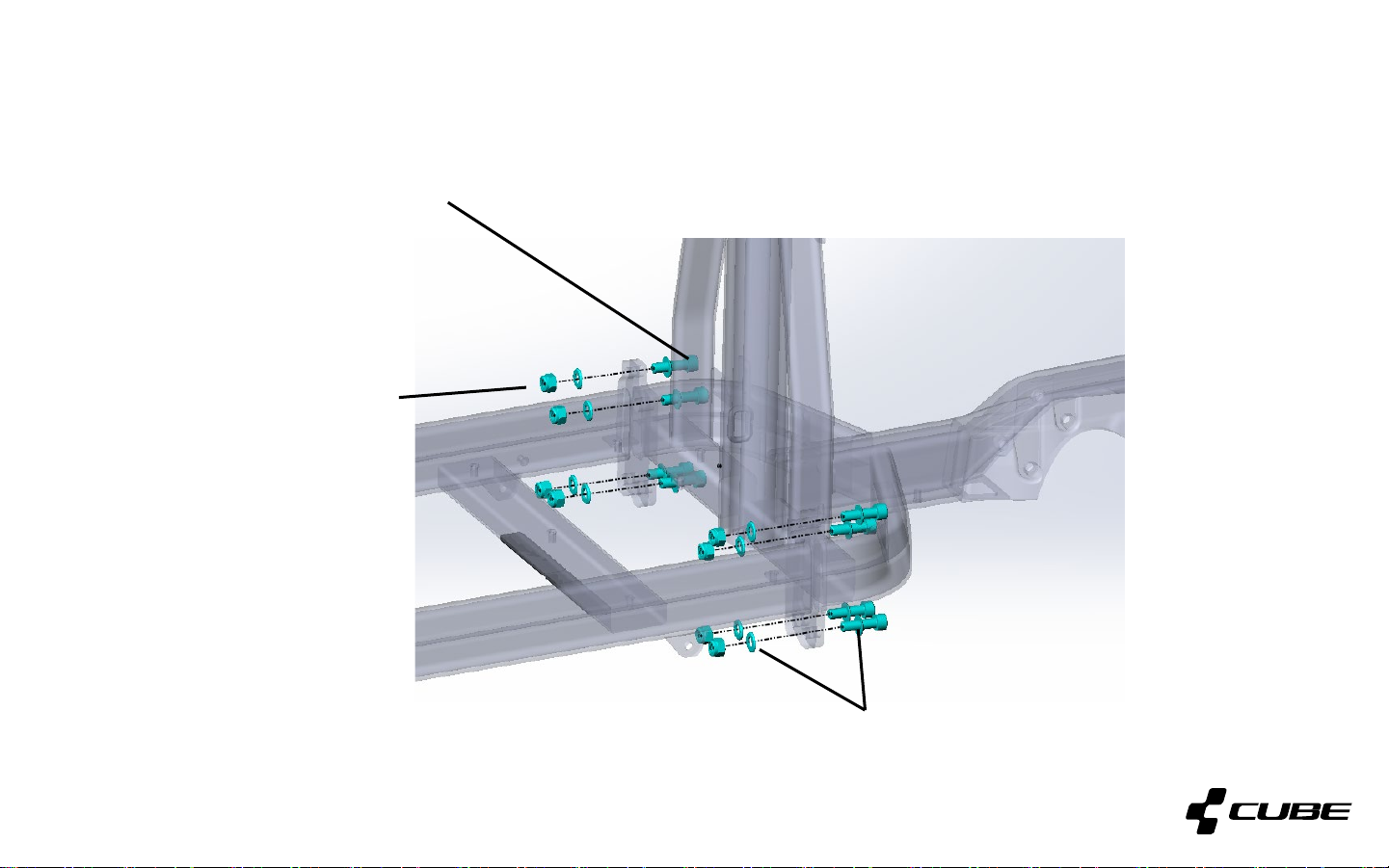

Observe the specified assembly sequence of screws, nuts and washers.

Only use the connectors supplied. Replacement screws or nuts must be of the appropriate standard, size and strength class.

Tighten screw connections with the correct torques.

Conversions, unauthorised changes to the Cargo Hybrid or the components as well as the use of non-approved parts are prohibited.

The applicable national and international safety, health and work regulations must always be observed.

The immediate surroundings must be free of easily flammable substances and other combustible materials.

Always secure the Cargo Hybrid against unintentional switching on.

The power supply must be disconnected before carrying out any assembly steps on the product.

Always wear the appropriate protective equipment during installation.

After assembly has been completed, carry out a thorough check and functional test of the Cargo Hybrid and the components. Inadequate

assembly and inspection can result in serious injury.

Never change the design or condition of the Cargo Hybrid or components without consulting the manufacturer. Incorrect changes can

considerably impair the functionality of the Cargo Hybrid and lead to serious injuries.