iii

Curtis 1244 Manual, Rev. E

CONTENTS

1. OVERVIEW ...........................................................................................1

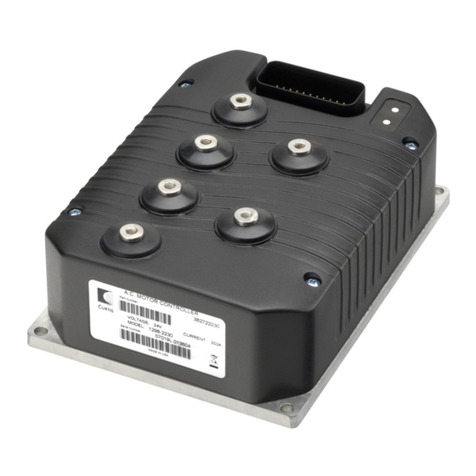

2. INSTALLATION AND WIRING.........................................................4

Mounting the Controller ..................................................................4

Connections: Low Current ..............................................................6

Connections: High Current .............................................................7

Wiring: Controller...........................................................................8

Wiring: rottle.............................................................................10

5kΩ–0, 2-wire resistive throttle (“Type 1”) ..............................11

0–5V, current source, 3-wire pot, and electronic

single-ended throttles (“Type 2”) .....................................12

0–5kΩ, 2-wire resistive throttle (“Type 3”) ..............................15

0–5V and 3-wire pot wigwag-style throttles (“Type 4”)............15

CAN-Nodes throttle (“Type 5”) ..............................................16

Wiring: Fault Outputs ...................................................................16

Wiring: Contactor Drivers.............................................................16

Wiring: Pedal Switch .....................................................................19

Wiring: Hour Meter ......................................................................19

Wiring: CAN Bus Interface ...........................................................19

Wiring: Emergency Reverse ...........................................................19

Contactor, Switches, and Other Hardware......................................21

3. PROGRAMMABLE PARAMETERS ..................................................23

Acceleration Parameters ..................................................................26

Acceleration Rate, M1–M4......................................................26

Braking Rate, M1–M4 ............................................................26

Deceleration Rate ....................................................................26

Quick Start..............................................................................26

Taper Rate ...............................................................................27

Speed Parameters ............................................................................27

Maximum Speed, M1–M4 ......................................................27

Creep Speed, M1–M4 .............................................................27

Regen Speed ............................................................................27

rottle Parameters.........................................................................28

Control Mode..........................................................................28

rottle Type ...........................................................................29

rottle Deadband ..................................................................30

rottle Max ...........................................................................32

rottle Map, M1–M4............................................................34

rottle Braking Percent, M1–M4........................................... 36

Current Limit Parameters ...............................................................36

Drive Current Limit, M1–M4................................................. 36

Braking Current Limit, M1–M4..............................................36

Minimum Field Current Limit ................................................36

Maximum Field Current Limit ................................................37

Restraint..................................................................................37

Emergency Reverse Current Limit ...........................................38

Current Ratio ..........................................................................38

CONTENTS