TABLE OF CONTENTS

1Introduction............................................................................................ 6

1.1 Safety Notes and Symbols....................................................................... 7

1.2 Intended Use............................................................................................ 8

1.3 Reasonably foreseeable misuse.............................................................. 8

1.4 Continuing Documentation....................................................................... 9

2Safety.................................................................................................... 10

2.1 Qualification of Specialists..................................................................... 10

2.2 Safety of the Work Environment ............................................................ 10

2.3 Safe Handling of the Spray Guns........................................................... 10

2.4 Grounding.............................................................................................. 11

2.5 Material and Air Hoses........................................................................... 11

2.6 Cleaning................................................................................................. 12

2.7 Handling of Liquids, Paints and Enamels............................................... 12

3Transportation and Storage................................................................ 13

3.1 Transportation........................................................................................ 13

3.2 Storage.................................................................................................. 13

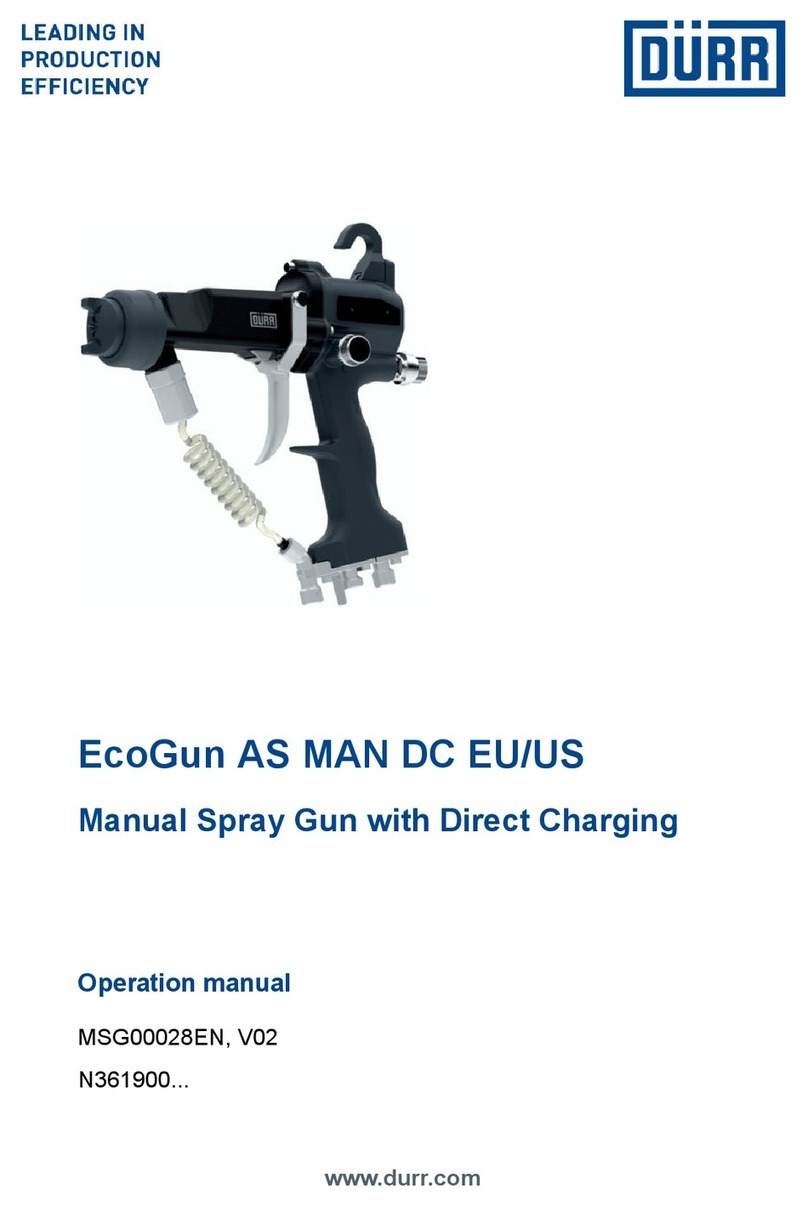

4Description of Function....................................................................... 14

5Commissioning.................................................................................... 15

6Operation.............................................................................................. 16

6.1 Operational Checks ............................................................................... 16

6.2 Air connection........................................................................................ 16

6.3 Material connection................................................................................ 16

6.4 Operation of the high pressure spray gun.............................................. 17

6.5 Flat jet regulation ................................................................................... 17

6.6 Trigger forces......................................................................................... 17

6.7 Round jet regulation............................................................................... 18

6.8 Adjustment of atomization air cap.......................................................... 18

6.9 Spray Gun guidance.............................................................................. 20

6.10 Filter selection........................................................................................ 21

6.11 Adjustment of pre-air.............................................................................. 21