OperatingManual ©DürrSystemsAG

MCD00011EN

L058709070

EcoGun Cleaner M Compiled : Vicentini

Release 10 Checked : Messina

Date 07.09.2017 Approved : Roncarati

3

TABLE OF CONTENTS

1 Introduction....................................................................................... 05

1.1 How to Use this Document................................................................. 05

1.2 Terminology........................................................................................ 05

1.3 Explanations on the Safety Notes and Symbols................................. 06

2 Technical Data.................................................................................. 08

2.1 Range of Application and Intended Use............................................. 08

2.2 Key Data............................................................................................. 09

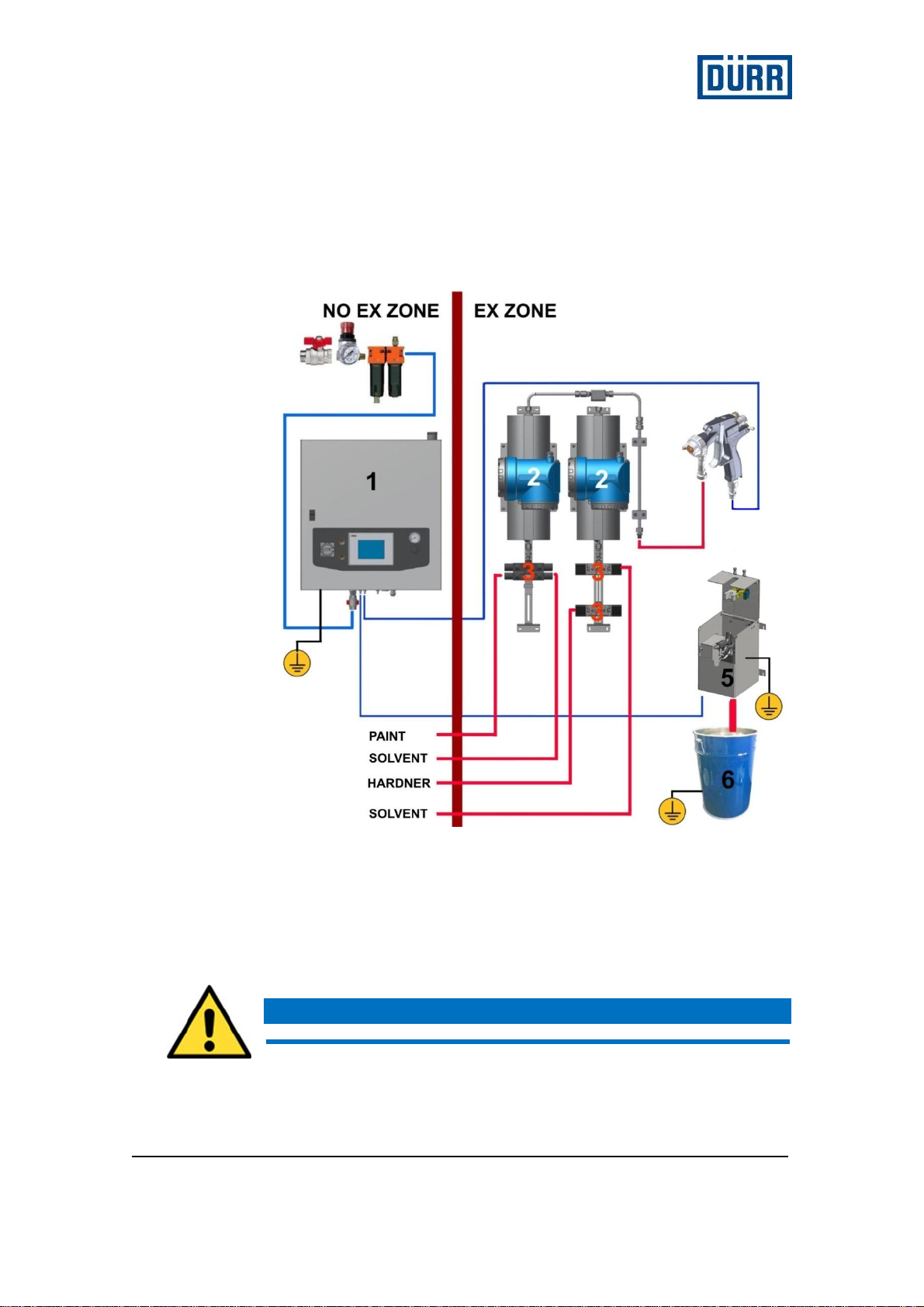

2.3 Determination of the Ex Zones........................................................... 10

2.5 Continuing Documents....................................................................... 11

3 Safety12

3.1 Addressees for this Manual................................................................ 12

3.2 Use of Tools in Ex Zones ................................................................... 13

3.3 Basic Information on our Safety Notes............................................... 14

3.4 Troubleshooting Instructions .............................................................. 14

3.5 Special Safety Notes.......................................................................... 14

3.6 Plate data........................................................................................... 16

4 Transport and Storage..................................................................... 17

4.1 Transport............................................................................................ 17

4.2 Storage............................................................................................... 17

5 Design and Function........................................................................ 18

5.1 General Description............................................................................ 18

5.2 Operating system............................................................................... 18

5.3 Design of the Modules........................................................................ 20

6 Assembly instruction....................................................................... 21

6.1 Installation.......................................................................................... 21

6.2 Collecting dirty solvent........................................................................ 22

6.3 Ground connection............................................................................. 23

6.3.1 EcoGun CleanerM........................................................................................ 23

6.3.2 box collecting dirty solvent............................................................................ 23

6.3.3 flammable fluids ........................................................................................... 23

6.4 Pneumatic connections ...................................................................... 24

6.5 Trigger Height Adjustment.................................................................. 25

7 Commissioning................................................................................. 27

7.1 Staring................................................................................................ 27