4 | © Danfoss | DHS-SRMT/SI | 2017.01 73691490 / VI.HU.D2.02

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respec

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

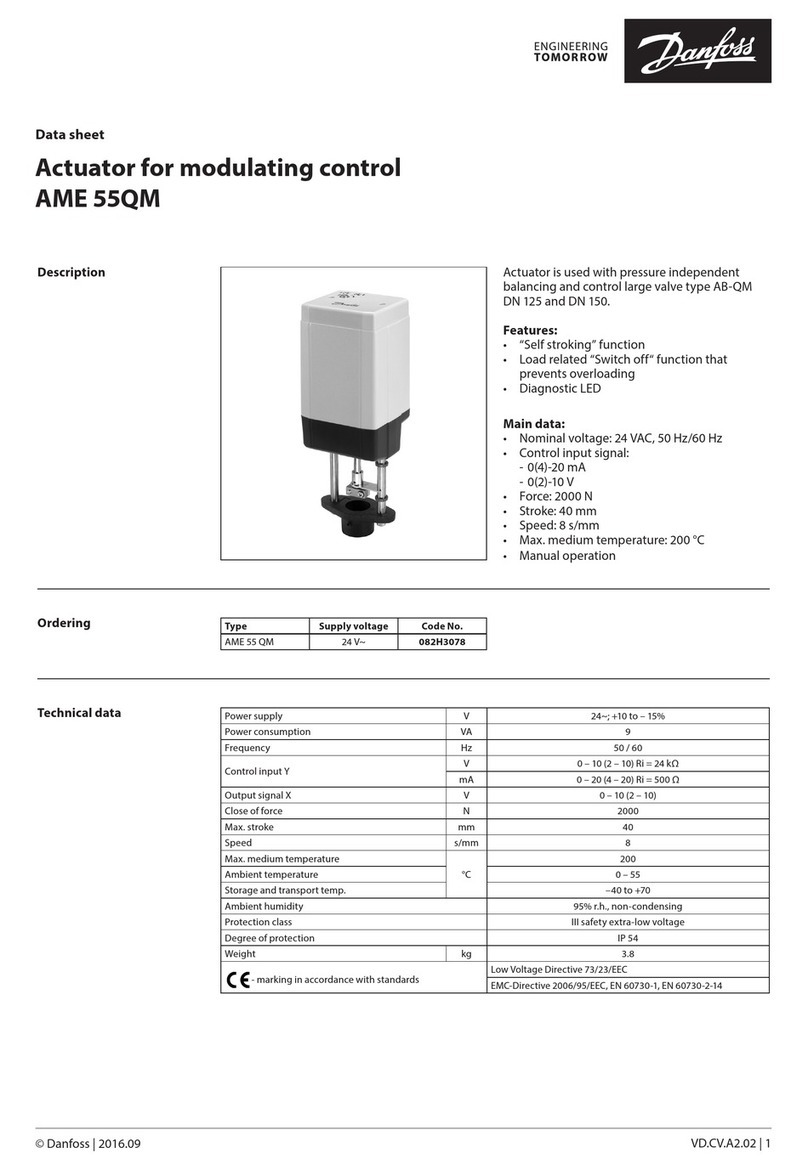

AME 110 NLX

ENGLISH

Safety Note

To avoid injury of persons and

damages to the device, it is absolutely

necessary to read and observe these

instructions carefully.

Necessary assembly, start-up, and maintenance

work must be performed by qualified and

authorized personnel only.

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before the

power supply is fully switched off.

Disposal instruction

This product should be dismantled

and its components sorted, if possible,

in various groups before recycling or

disposal.

Always follow the local disposal regulations.

AC 24 V

Connect via safety isolating

transformer.

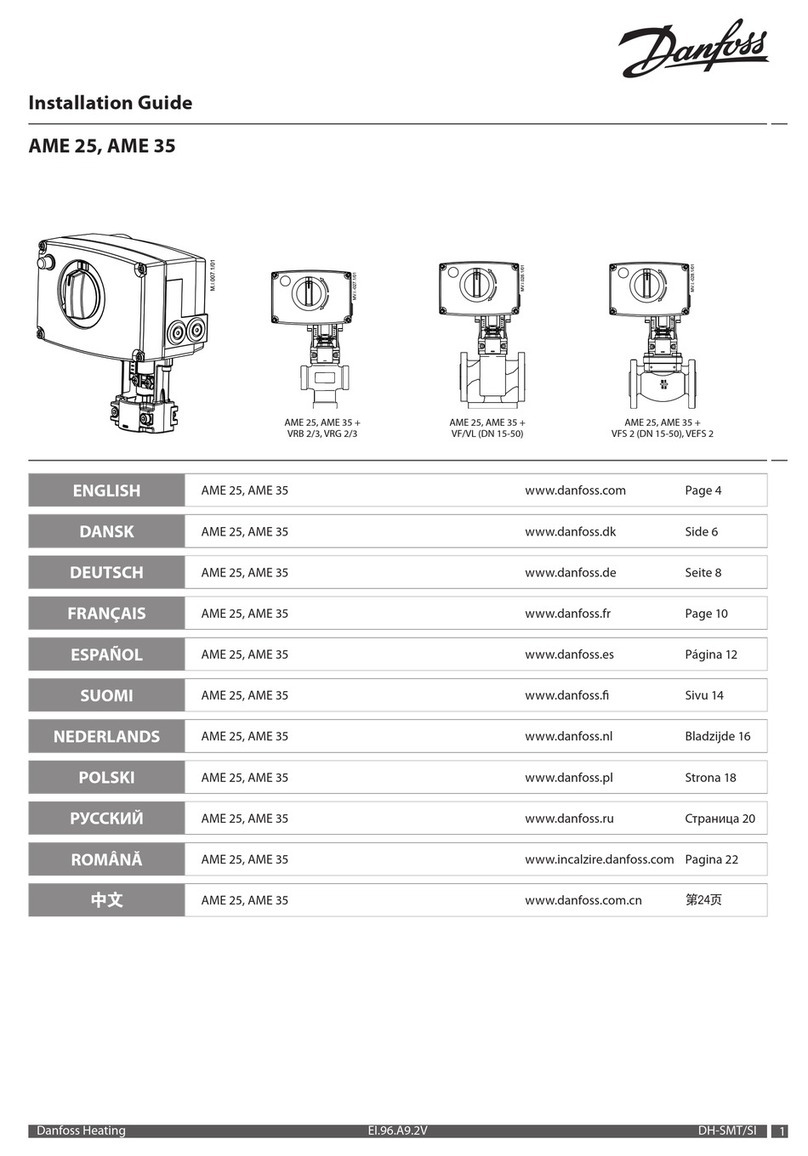

Mounting ❶

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

The actuator is fixed to the valve body by means

of a ribbed nut which requires no tools for

mounting. The ribbed nut should be tightened

by hand.

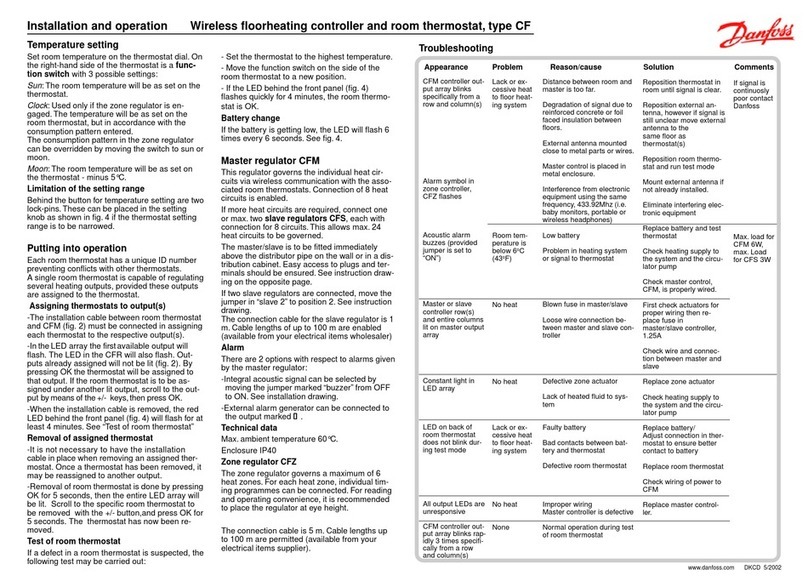

Wiring ❷

Do not touch anything on the PCB!

Switch off the power line before wiring

the actuator! Lethal voltage!

Wire the actuator according to the wiring

diagram.

Auto sleep mode

1. If actuator AME 110 NLX is charged by 24 V

supply voltage and if it is not installed on AB-

QM valve, it will stop in lower position and

switch off all LED indicators after 5 minutes

2. It is mandatory to drive the spindle of the

actuator to upper position before it will be

installed on

AB-QM valve (please refer to manual

override drawings)!

3. Auto sleep mode switches back to learning

mode by pressing RESET button or by

cycling power supply.

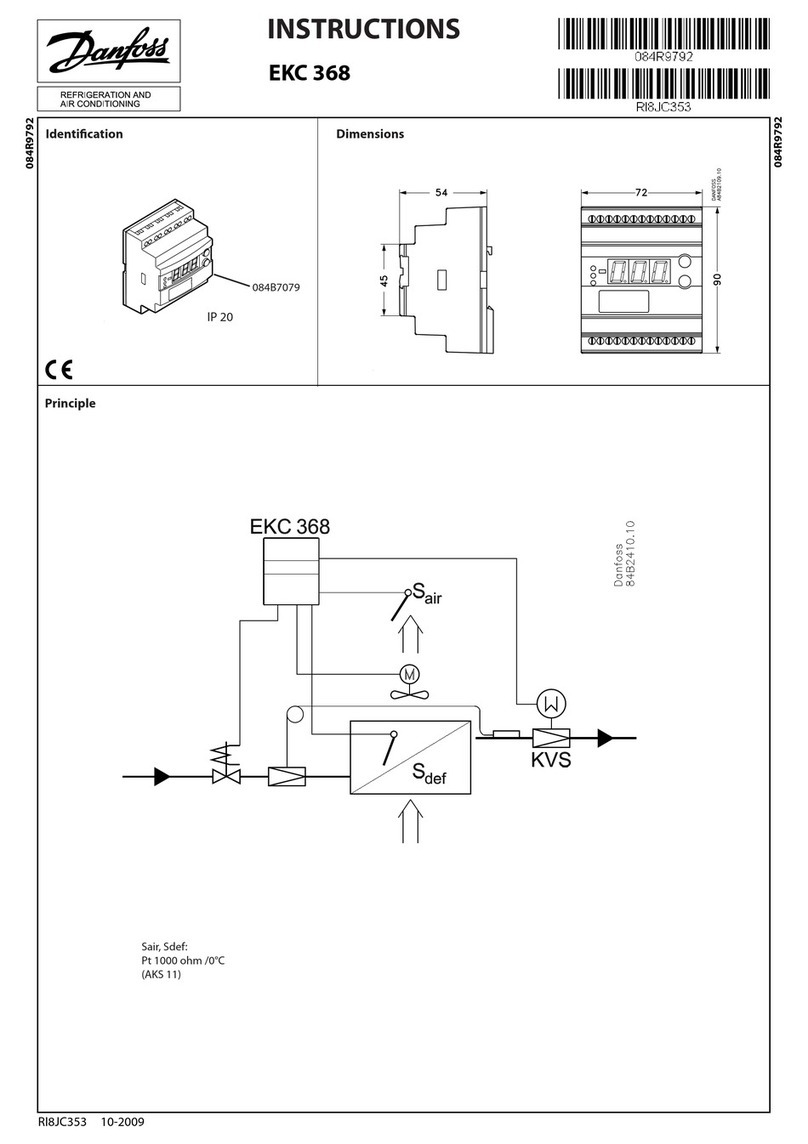

Installation ❸

1. Check the valve neck. The actuator should be

in stem up position (factory setting). Ensure

that the actuator is mounted securely on the

valve body

2. Wire the actuator according to the

wiring diagram.

3 The direction of stem movement can be

observed on the position indicator ❸①.

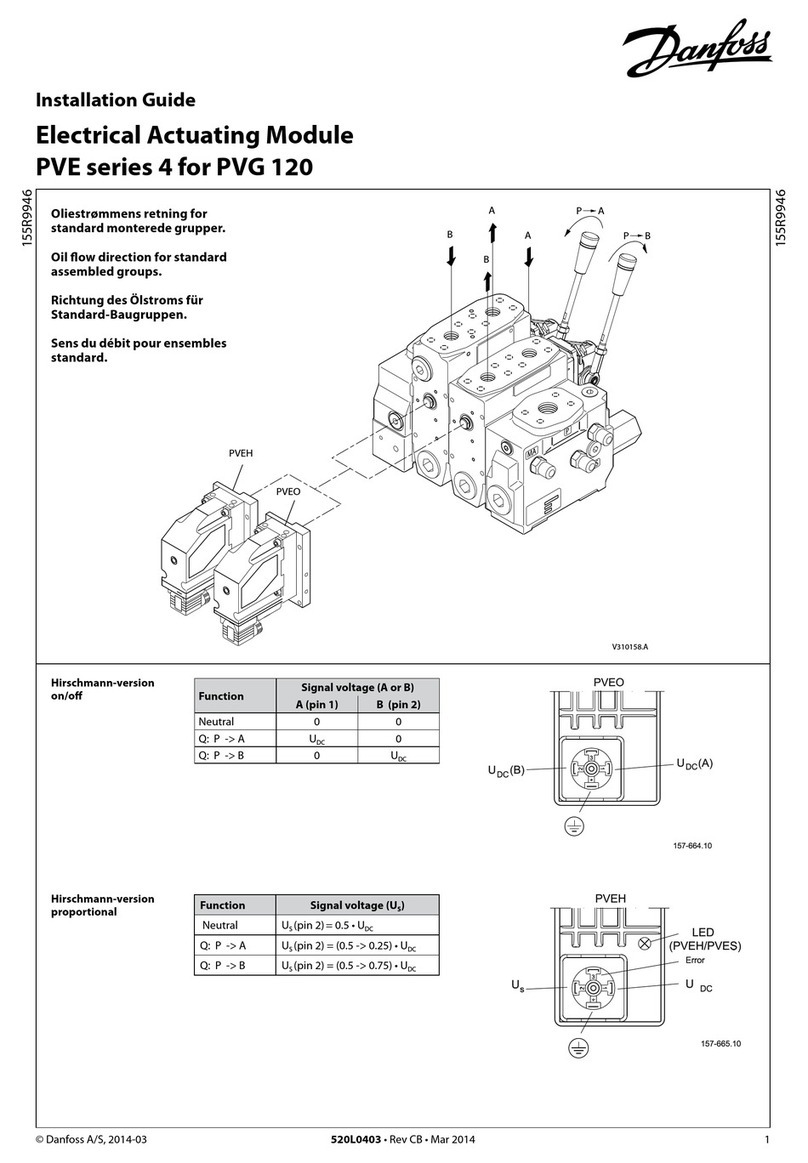

DIP switch settings and reset button ❹

1) DIP switches ❹④

Factory settings:

ALL switches (except SW 1 which is in ON

position) are in OFF position!

NOTE:

All combinations of DIP switches are allowed.

All functions that are selected are added

consecutively.

SW 1: 0/2 - Input signal range selector

If set to OFF position, the input signal is in the

range from 2-10 V (voltage input) or from 4-20

mA (current input). If set to ON position, the

input signal is in the range from 0-10 V (voltage

input) or from

0-20 mA (current input).

SW 2 : D/I - Direct or inverse acting selector

If set to OFF position, the actuator is direct

acting (stem contracts as voltage increases). If

the actuator is set to ON position, the actuator

is inverse acting (stem extracts as voltage

increases).

SW 3: ---/Seq - Normal or sequential mode

selector

If set to OFF position, the actuator is working

in range 0(2)-10 V or 0(4)-20 mA. If set to ON

position, the actuator is working in sequential

range:

0(2)-5 (6) V or

(0(4)-10 (12) mA) or

(5(6)-10 V) or

(10(12)-20 mA).

SW 4: 0-5 V/5-10 V - Input signal range in

sequential mode

If set to OFF position, the actuator is working in

sequential range 0(2)-5 (6) V or 0(4)-10 (12) mA.

If set to ON position, the actuator is working in

sequential range; 5(6)-10 V or 10(12)-20 mA.

SW 5: LIN/LOG - Linear or equal percentage

flow through valve selector

If set to ON position, the flow through the valve

is equal percentage to the control signal.

If set to OFF position, the valve position is linear

acc. to the control signal.

SW 6: ---/ASTK - Anti-blocking function

Exercises the valve to avoid blocking in periods

when the heating/cooling is off.

If set to ON position (ASTK), the valve motion is

switched on. The actuator opens and closes the

valve every 7 days.

If set to OFF position (---), function is disabled.

SW 7: U/I - Input signal type selector

If set to OFF position, voltage input is selected. If

set to ON position, current input is selected.

Reset button ❹③

The reset button will cause the actuator to go

through a self stroking cycle (press it for 2 s).

Manual override ❺

(for service purposes only)

Do not manually operate the drive if

power is connected!

- Remove cover ❺①

- Press and hold the button (on the bottom

side of the actuator) ❺② during manual

override ❺③

- Replace cover ❺④

- Install actuator on valve ❺⑤

Remark:

A ‘click’ sound after energising the actuator

indicates that the gear wheel has jumped into

normal position.

Function test

The light emitting diodes (LEDs)

❹① (green - direction indicator),

❹② (red - reset and normal mode indicator)

indicate whether the actuator is in operation or

not, the operating status, and failures, if any.

Red LED:

• No light

- no operation or no power supply

• Constant light

- normal operation

• Flashing light (1 Hz)

- self-adjusting mode

• Flashing light (~ 3 Hz):

- power supply too low

- initial self-adjusting time too short due to

too short valve strokes

- failure during self calibration

Green LED:

• Spindle extracts (green led diode blinking

once per sec.)

• Spindle retracting (green LED on)

• Actuator reached set-point acc. to Y signal

(LED off).

Dimensions ❻

Part Name

部件名称

Hazardous Substances Table/有害物质含量表

Lead (Pb)

铅(Pb)

Mercury (Hg)

汞(Hg)

Cadmium (Cd)

镉(Cd)

Hexavalent Chromium (Cr(VI))

六价铬 (Cr(VI))

Polybrominated biphenyls (PBB)

多溴联苯 (PBB)

Polybrominated diphenyl ethers (PBDE)

多溴二苯醚 (PBDE)

Connecting nut/

连接螺母 X O O O O O

O: Indicates that this hazardous substance contained in all of the homogeneous material for this part is below the limit requirement in GB/T 26572;

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X: Indicates that this hazardous substance contained in at least one of the homogeneous material for this part is above the limit requirementw in GB/T 26572;

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规定的限量要求。