ESBE 3-WAY VALVE

INSTALLATION INSTRUCTIONS

Pipe the Valve into the System

• ESBE 3-way valves can be piped for either 3-way Mixing or 3-way Diverting applications

• 3-way Mixing: 2 inputs, 1 output • 3-way Diverting: 1 input, 2 outputs

• The System port, or the port on the valve which will deliver the mixed water to the

system, must never be the center port.

• Install the valve so the actuator (if so equipped) will not be below the valve (ie.

facing the floor).

Orient the Valve Face Plate

• The face plate can be turned over and rotated to match your piping configuration.

For technical support or additional product information, contact:

Danfoss Inc.

7941 Corporate Drive

Baltimore, MD USA 21236

Telephone: (433) 512 - 0266

Fax: (443) 512 - 0270

www.na.heating.danfoss.com

Danfoss Inc.

6711 Mississauga Road · Suite 410

Mississauga, ON, L5N 2W3 Canada

Telephone: (905) 285 - 2050

Fax: (905) 285 - 2055

www.na.heating.danfoss.com

3-WAY MIXING – Two temperature inputs, one blended output

A) B)

C) D)

Art.nr. 98140081 Ritn.nr 3285 Utg PC6

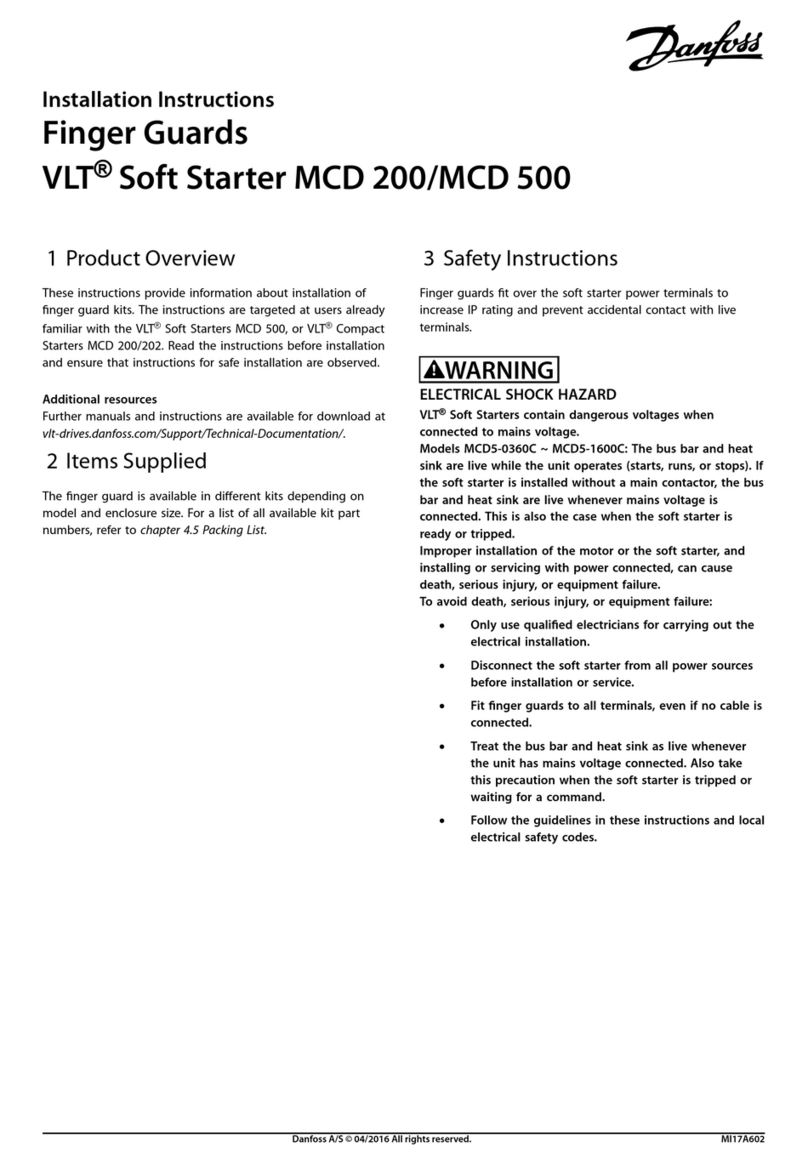

Wiring: 91M, 92M, 92-2M and 93M for “Floating” Signals (see ). For ESBE

92P and 92K2 actuators, refer to the actuator’s installation instructions.

Warning: Always turn off all electrical power before removing or servicing

the actuator.

– The actuator is powered using a 24VAC transformer, 3VA minimum.

– Remove the four cover screws and lift the cover off the actuator.

– Remove one (or two) of the wiring knockouts and install one (or two) of the

“conduit fittings”. All wires must go through these fittings.

– Attach the “common” from the control (or transformer) to terminal “N”.

– Connect the control output for clockwise rotation to “Upper terminal L1”, and

connect the control output for counterclockwise rotation to “Lower terminal L1”

Auxiliary Switch

–ESBE 91M, 92M, 92-2M and 93M actuators include one fully adjustable

auxiliary switch. The wiring should be connected as shown in . To set the

switching position, turn the cam (see ).

Reinstall the cover and secure it, before turning on the power.

Adjusting the Degree of Rotation

– ESBE 90 series actuators do not require adjustment when used with ESBE

valves. However if the actuator is used for an application that requires a differ-

ent degree of rotation, the middle and lower cams can be adjusted to provide

between 30° and 180° of rotation. For access to the cams, the cam operating the

aux switch must be removed. See . Always turn off all power before adjust-

ments are made.

Test: Test the valve rotation to ensure the valve is allowed to fully open and

fully close. Rotations of 30° to 180° are possible via middle and lower cams for

applications that require them. For access, aux. switch cam must be removed.

10

0

10

0

0

10

0

10

4 1