2 DKRCC.PI.CD0.F1.22 / 520H6076 © Danfoss A/S (AC-MCI / jmn), 2012-12

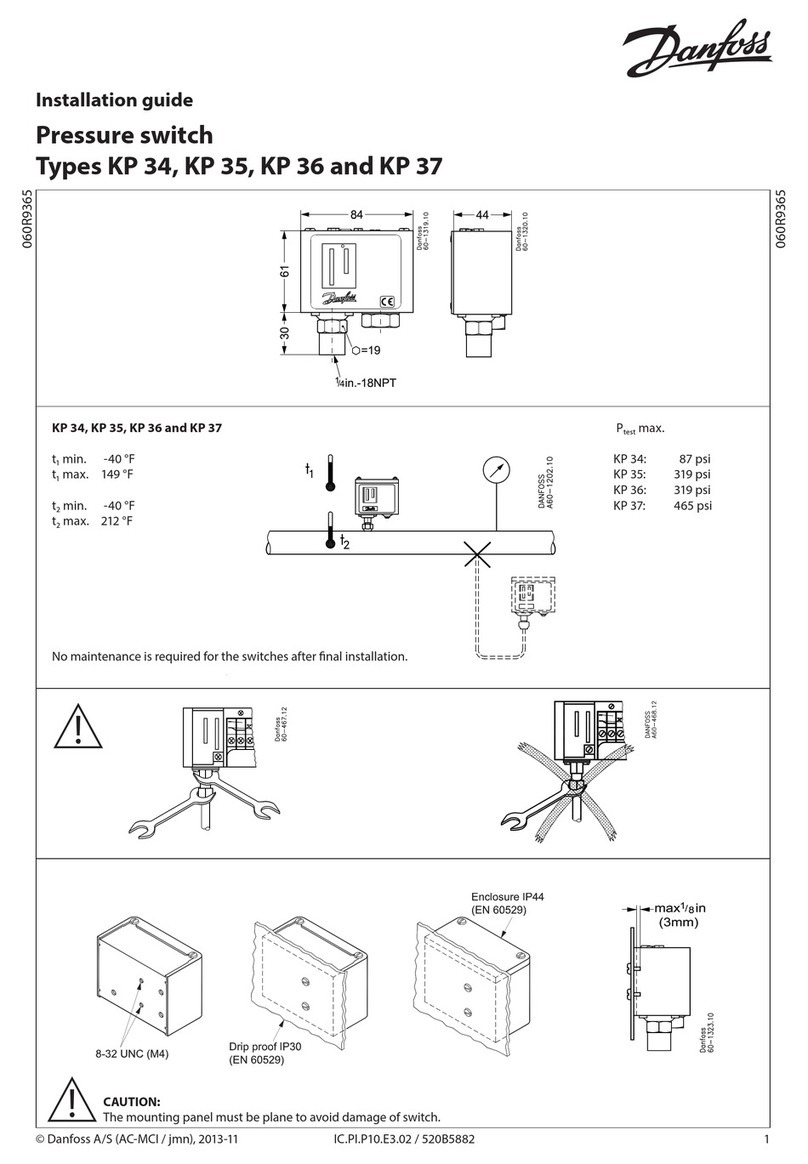

Mount the KPU pressure control on a bracket

or on a completely at surface.

Mounting to an uneven surface might cause

improper control operation.

For bracket mounting use only the 10-32x3/16

screws provided with the control. If other screws

are used function of the pressure control might be

disturbed (they may not protrude into the control

more than 1/8in.).

Use only the mounting holes provided;

no other holes are to be added to the control

IMPORTANT:

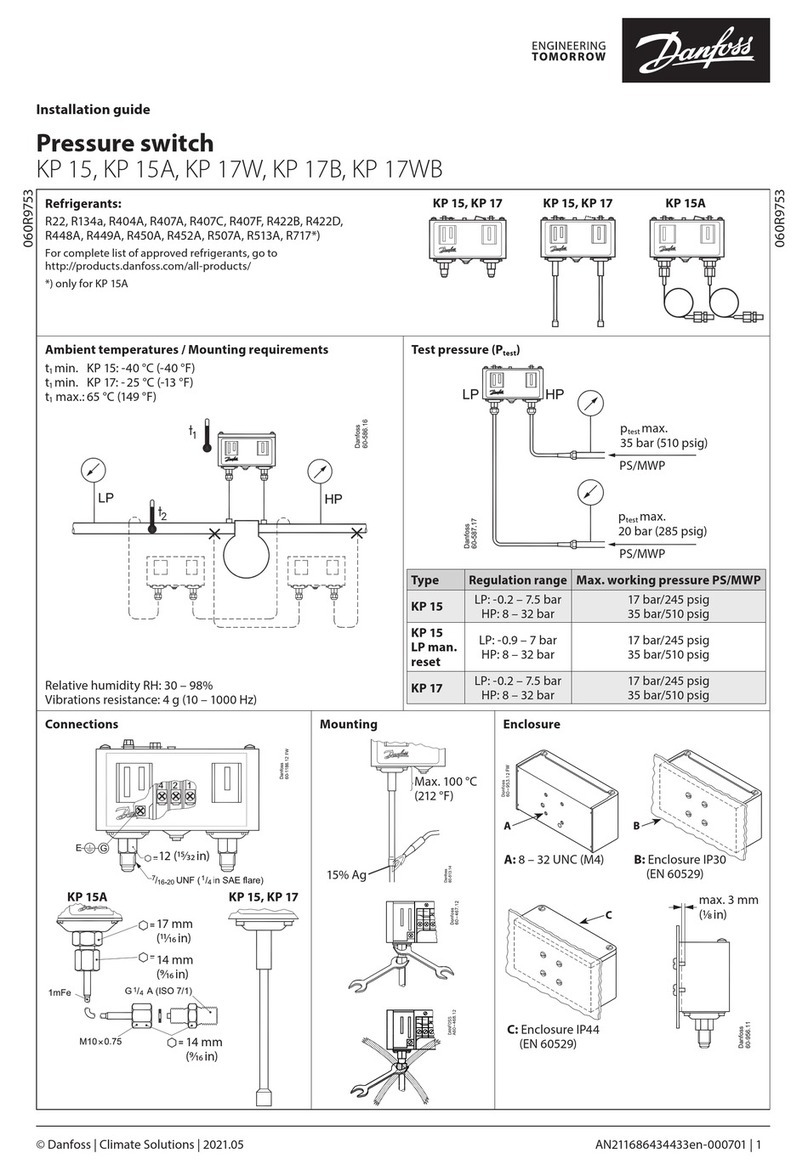

Pressure pulsations in the refrigeration system

reduce life time of the bellows and might

disturb switch function. Pressure pulsations

should always be eectively damped e.g.

by connection the pressure controls to the

refrigeration system through a capillary tube.

Screws for bracket

mounting

Mounting holes

for at surfaces

1. Ensure self-draining of the capillary tube

to minimize clogging.

2. Coil excess capillary tube into smooth, circular coils

(approximately 3 in. diameter). The coiled tube should

be securely fastened in order to prevent possible

damage due to vibration.

3. Leave a little slack in the capillary tube as it helps

to damp mechanical vibrations.

4. Avoid sharp bends as well as re-bending of the capillary

tube on the same point as it weakens the material,

increasing the risk of crack.

5. Never allow for contact between the capillary tube

and sharp or abrasive objects as during vibrations

the tube could be damaged due to friction.

6. Purge the piping before connecting pressure controls.

7. Always use two wrenches

tightening the are nut on

the pressure control.

One wrench should support

the connector while

the second wrench

is used to tighten the nut.

8. Do not over tighten are nuts as it may damage the

threadscausing leaks.

9. Protect the capillary tube from damage

caused by vibrations from compressor:

– when the control unit is mounted directly on the

compressor, the capillary must be secured to the

compressor so that everything vibrates as a whole.

– when the control is mounted remote from the

compressor, make the pressure connections away

from the compressor.

– when the control is mounted remote from the

compressor and the pressure connections have to be

on the compressor, then damping coils must be used

between the compressor and the pressure control.

NOTE:

After installing the pressure control, evacuate

the plant in accordance with applicable EPA

and other regulations, to remove air, moisture,

and other contaminants.

Recommendations for capillary tube and are connections:

Wiring CAUTION:

Disconnect power supply before wiring connections

are made or service to avoid possible electrical shock

or damage to equipment. Do never touch live parts

with your ngers or with any tool.

NOTE:

All wiring should conform to the National Electrical

Code and local regulations. Use copper wire only.

Use terminal screws furnished in the contact block.

Do not exceed tightening torque 20 lb. in (2.3 Nm).

Do not exceed electrical ratings for the control.

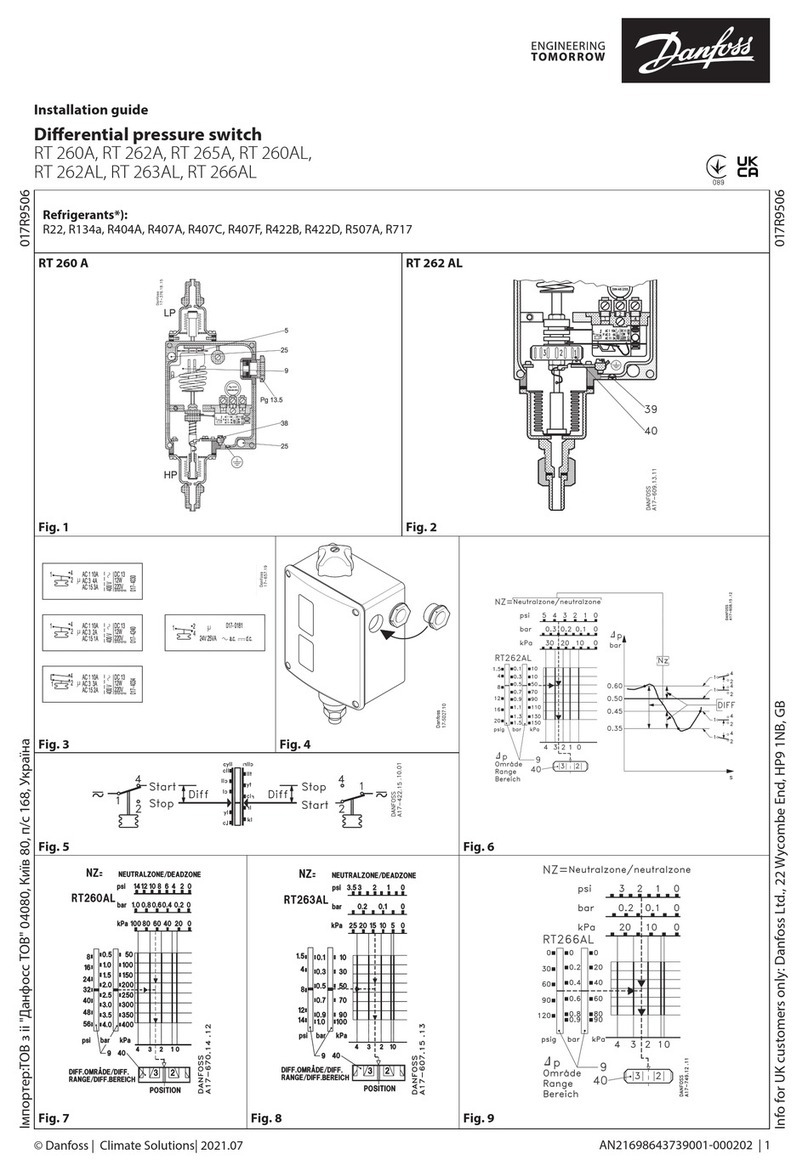

Electrical ratings according to UL regulations

European electrical ratings according to EN 60947

120 V a.c. 24 FLA, 144 LRA – make only

240 V a.c. 24 FLA, 144 LRA – make only

240 V d.c. 12 W pilot duty

The terminal block as well as grounding screw

are accessible after dismounting of the front cover.

AC1 AC3 AC15 LR DC13

16 A 16 A 10 A 112 A 12 W

400 V 220 V