2

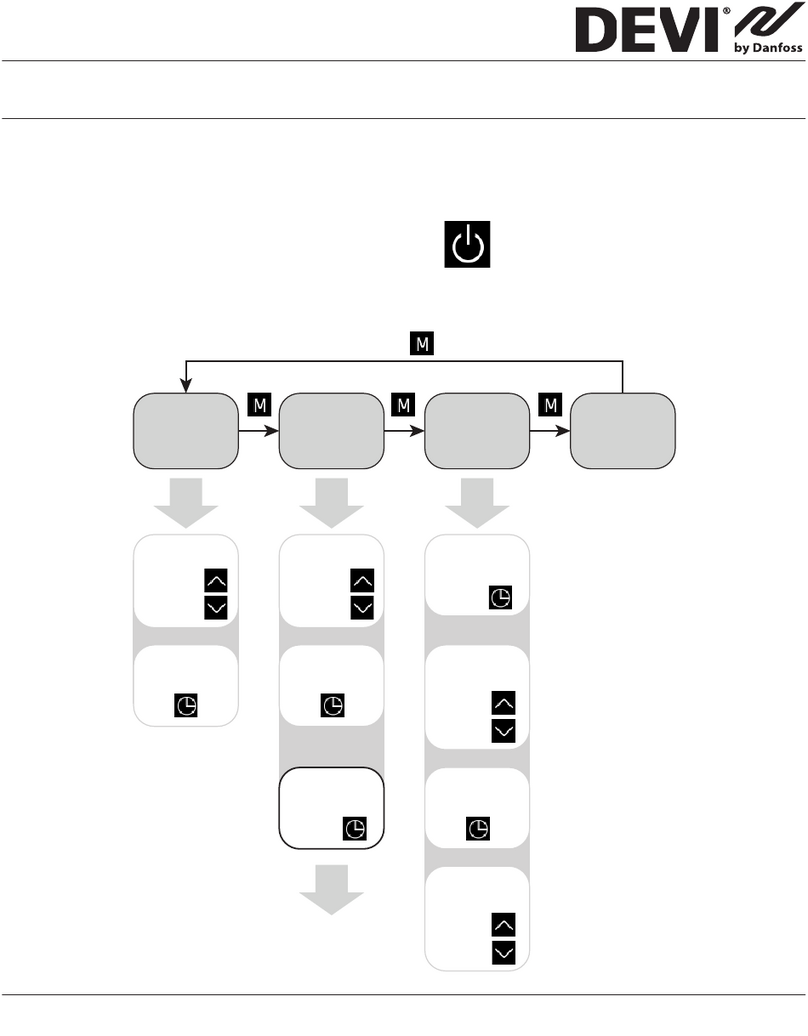

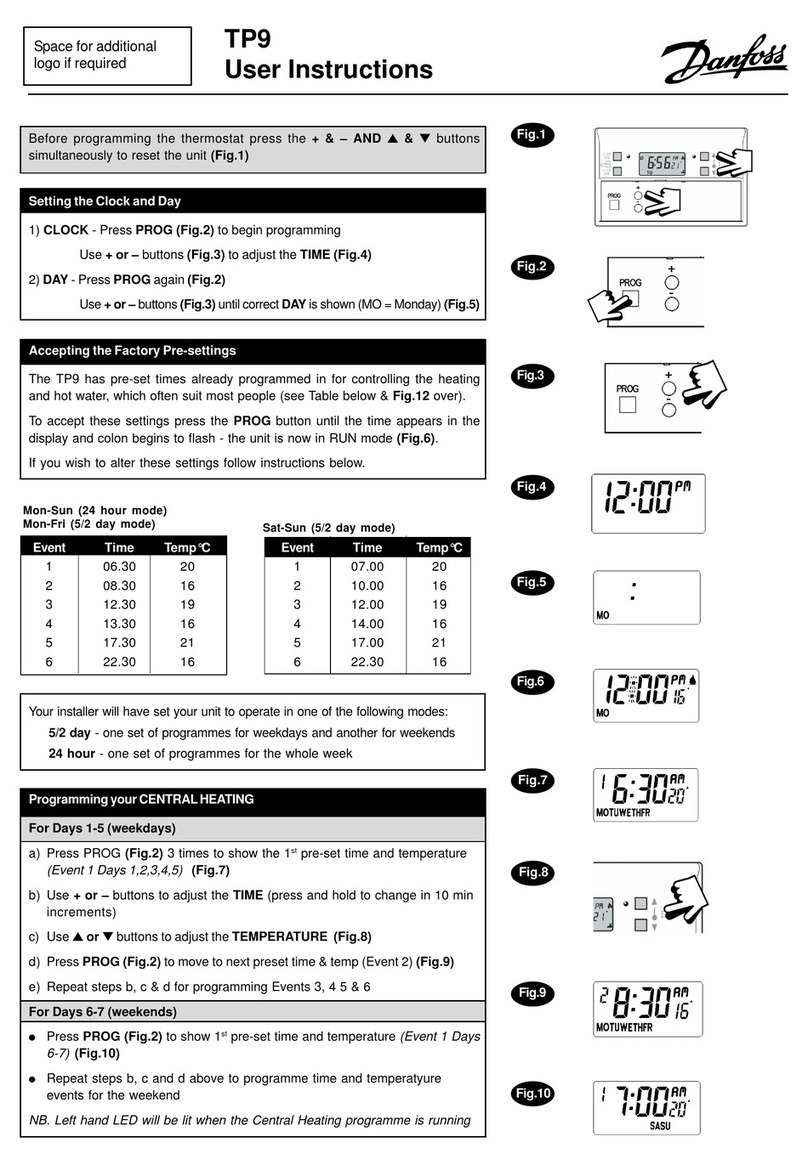

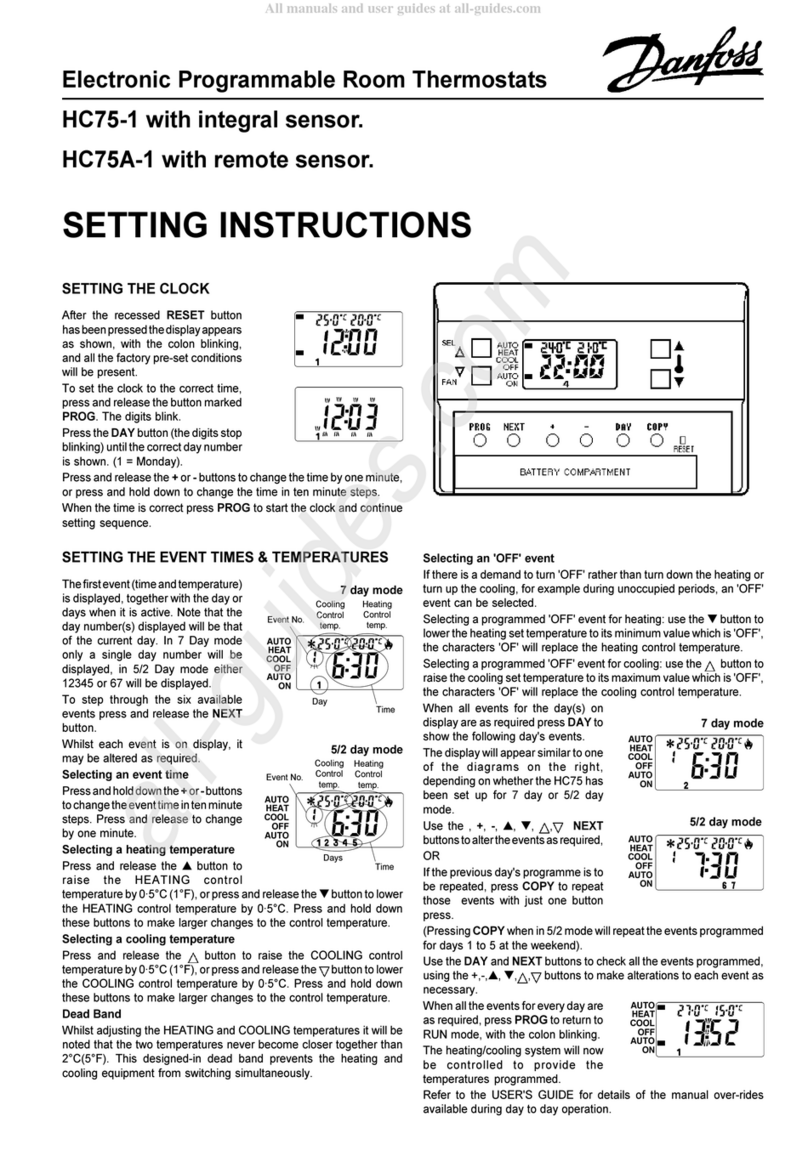

Fig. 4 Factory pre-set

DIL switch

settings.

7 day

OSC OFF

ON/OFF

Chrono 3

5/2 day

OSC ON

CHRONO

Chrono 6

TP75 Installation

The unit (and remote sensor when used) must be installed by a

competent electrician and the installation should conform to IEE

Wiring Regulations.

The electronics and relay switching circuits are powered by two AA

size alkaline batteries however mains electricity control circuits

connected to this unit should be wired through a full disconnect in

accordance with BS EN60730-1 i.e. one which provides an air gap of

at least 3mm in both poles of the mains e.g. a 13amp plug and

unswitched socket or a switched fused outlet with neon; either fitted

with a 2 amp (max.) fuse.

Fixing

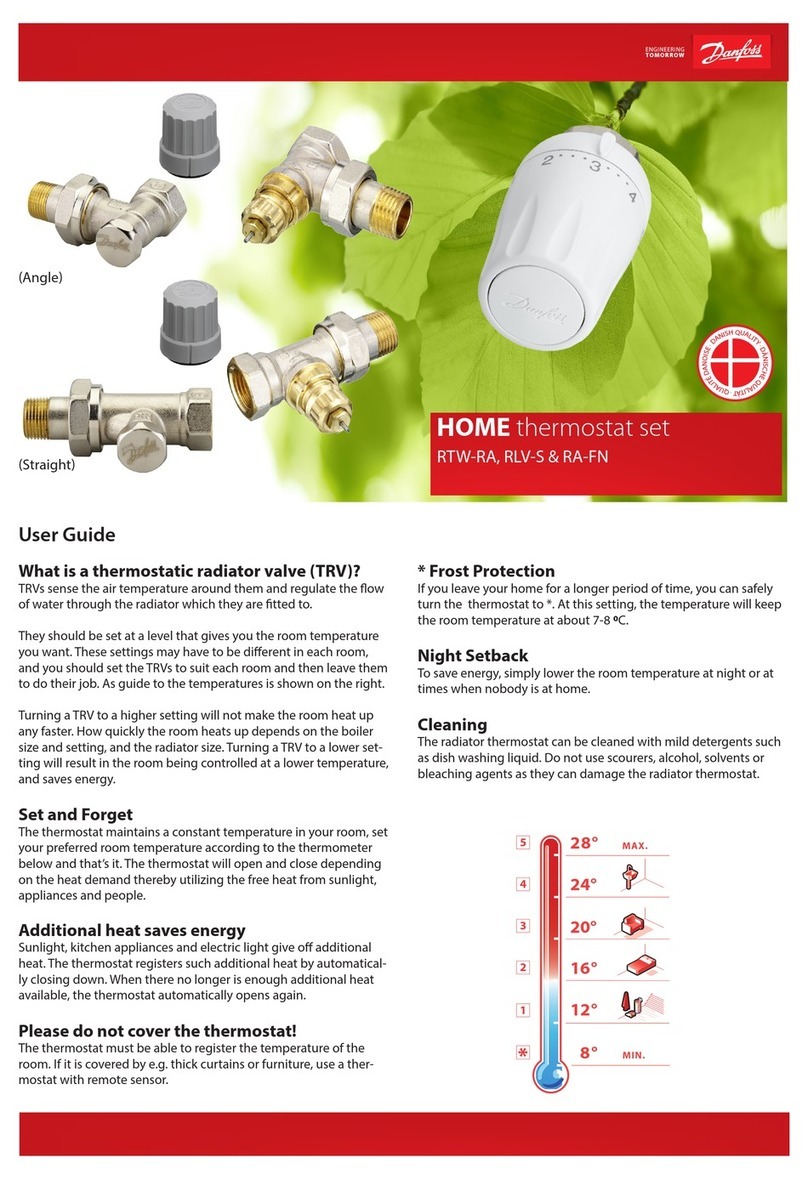

Fig. 2 TP75 or TS2 location

1a. TP75 Select the desired fixing position. (This should

adhere to normal room thermostat practice, see Fig. 2).

1b. TP75A Select the desired fixing position for the TS2

remote sensor. (This should adhere to normal room thermostat

practice, see Fig. 2). Select the desired fixing position for the

TP75A. 1·0mm²solid copper cable should be used to connect

the TP2 to the TP75A. Note that

a) the cable length should not exceed 50 metres,

b) to avoid electrical interference the cable should not be run

parallel in close proximity to other cables carrying mains

electricity, and where necessary the cable should cross

over mains cabling at right angles.

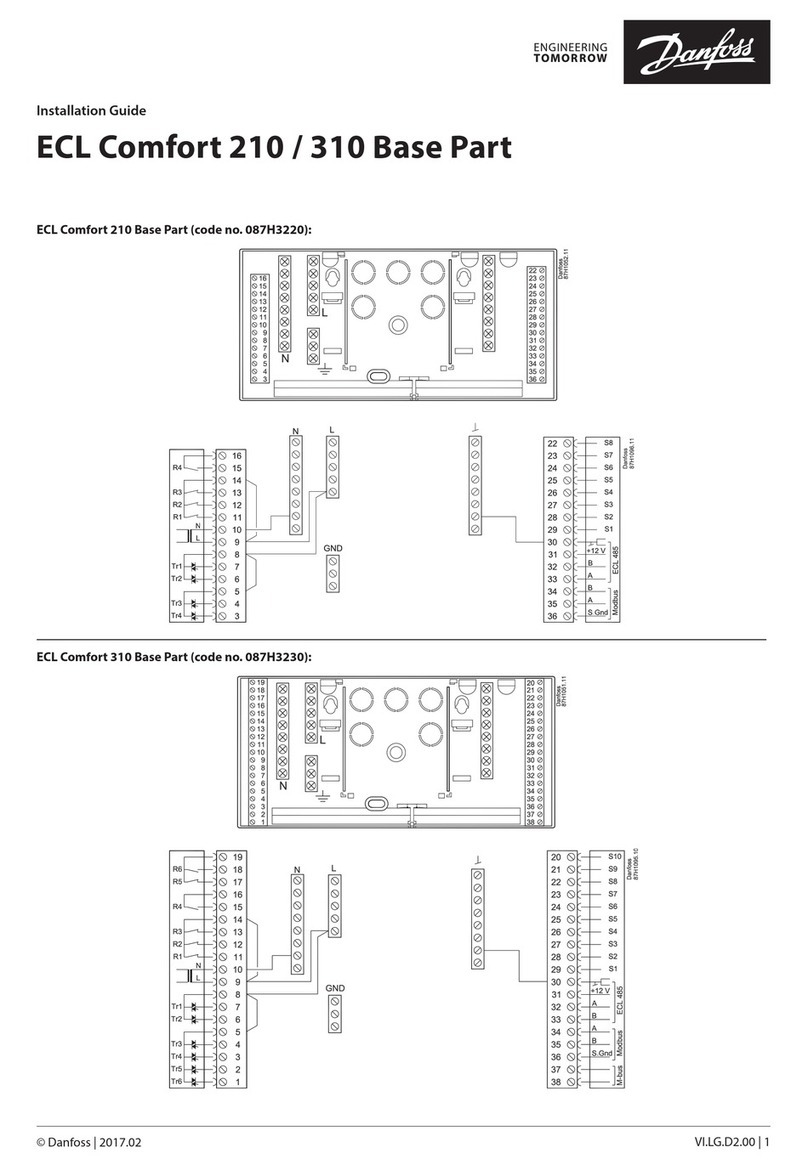

Fig. 3 Wallplate fixing clearances.

2. Whenfixingtheheatingcontrollerwallplatenotethattheterminals

areat the topand the verticalcentre lineofthe heatingcontroller

is at the right hand edge of the terminal 4 recess. Observe the

clearance required for fitting and removal, Fig. 3.

3. Fix the wallplate to the wall or plaster box as required.

4. Makethe wiringconnections forthe systemcontrol circuits,(and

remote sensor when used).

5. Surfacecables canonly enterfrom belowthe unit.If mountedon

aplasterbox cablescanenterfromtherearthroughtheaperture

in the wallplate.

6. These models do not require an earth connection. However, an

earth terminal is provided on the wallplate to ensure earth

continuity for the connections to the heating plant. (A neutral

looping terminal is also provided.)

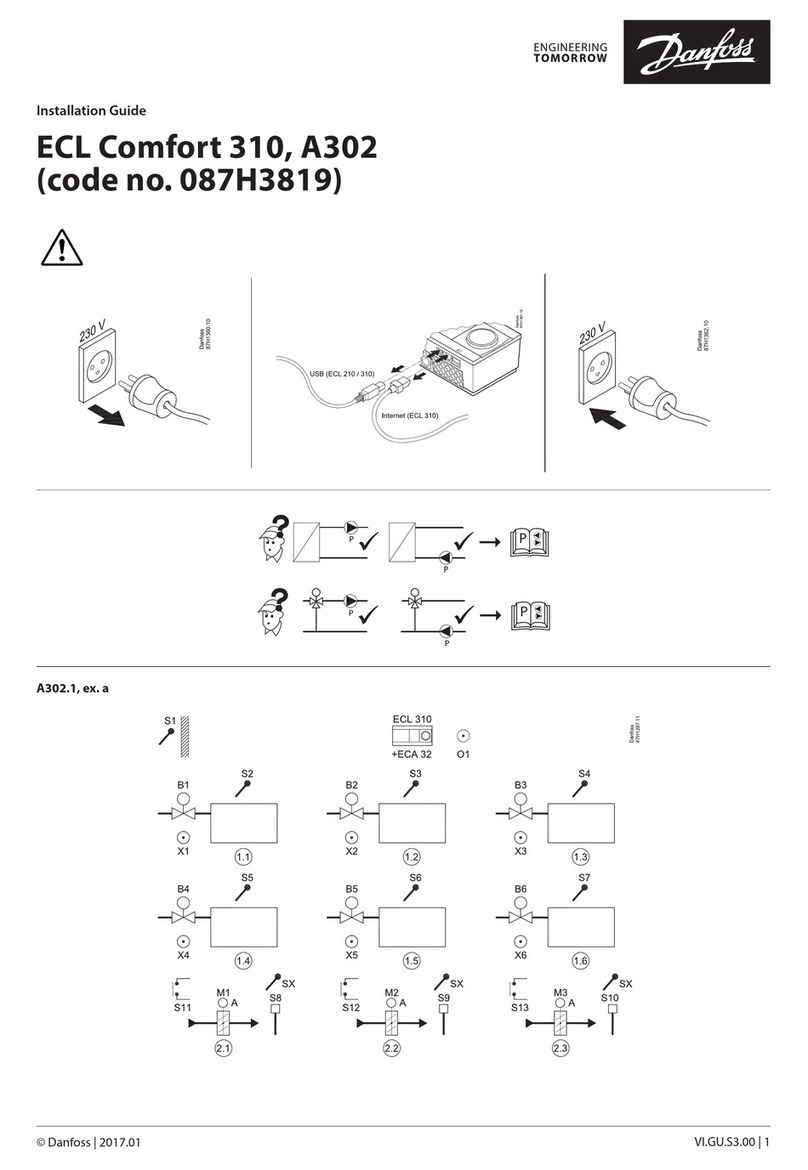

7. The diagrams on the next page show typical wiring circuit's with

which the units may be used, together with terminal to terminal

wiring information for use with the WB12 Wiring Box included

with Heatshare and Heatplan Control Packs.

8. Clear all dust and debris from the area.

9. Before fixing the unit on to its wallplate, ensure that the four DIL

switches on the rear of the unit (see Fig. 4) have been moved to

the required settings; the choices are:-

Switch No. 1- 5/2 DAY or 7 DAY.

When the switch is in the 7 DAY position each day may be

programmed with different switching times and temperatures.

Placing the switch in the 5/2 DAY position enables Monday to

Friday to be programmed with one set of switching times and

temperatures and Saturday and Sunday to be programmed with

a different set.

Switch No. 2 - OSC ON or OSC OFF

This is used to enable or disable the optimum start control (OSC)

function for event 1. To cater for different types of building

construction with differing fabric constants there are four start-

up curves from which to choose (see the diagram over the

page). These curves dictate how long before event 1 the heating

equipment will be switched on. The selectable start-up durations

are 0:00 0:30 1:00 1:30 or 2:00 (2 hours). (Selecting 0

effectively disables the function).

Once initiated the difference between the space temperature

and the event 1 temperature is used to generate a pre-heat

period proportional to the OSC period selected. The closer the

space temperature is to the event 1 temperature the shorter the

pre-heat period. Refer to the earlier section on Optimum Start

Control for more detail.

It is recommended that the initial setting of the OSC is 30

minutes. See the section on post-commissioning.

Switch No. 3 - CHRONO or ON/OFF

With this switch set to ON/OFF the TP75 will act as a conventional

room thermostat switching the heating plant to maintain the

programmed temperature. When set to CHRONO the control

function selected by switch No. 4 is enabled.

IMPORTANT. For systems with motorised zone valves ON/OFF

mode is recommended.

Switch No. - Chrono 6 or Chrono 3

This switch configures the TP75 to control different forms of

heating system typically as follows:

Use Chrono 3 for high thermal inertia systems e.g. floor

standing cast iron boilers.

Use Chrono 6 for low thermal inertia systems e.g. low water

content boilers and combi. boilers.

See the earlier section on Chrono-proportional Control for more

detail.

10. Position the slots in the top surface of the module over the lugs

atthetopofthewallplate,andhingedownwardsuntilthemodule

is pressed fully against the wallplate. Tighten the two screws

from below to fix the module to the wallplate.

11. Before setting the programmes the unit and circuits should be

checked. Refer to the following Commissioning Instructions.

30mm

minimum

Wall or Plaster bo

mounting holes

Aperture for rear

cable entry

Knockouts for

bottom cable

entry

Outline of unit

Terminals

C/L

N &

looping

terminals

Clearance for

screwdriver

access