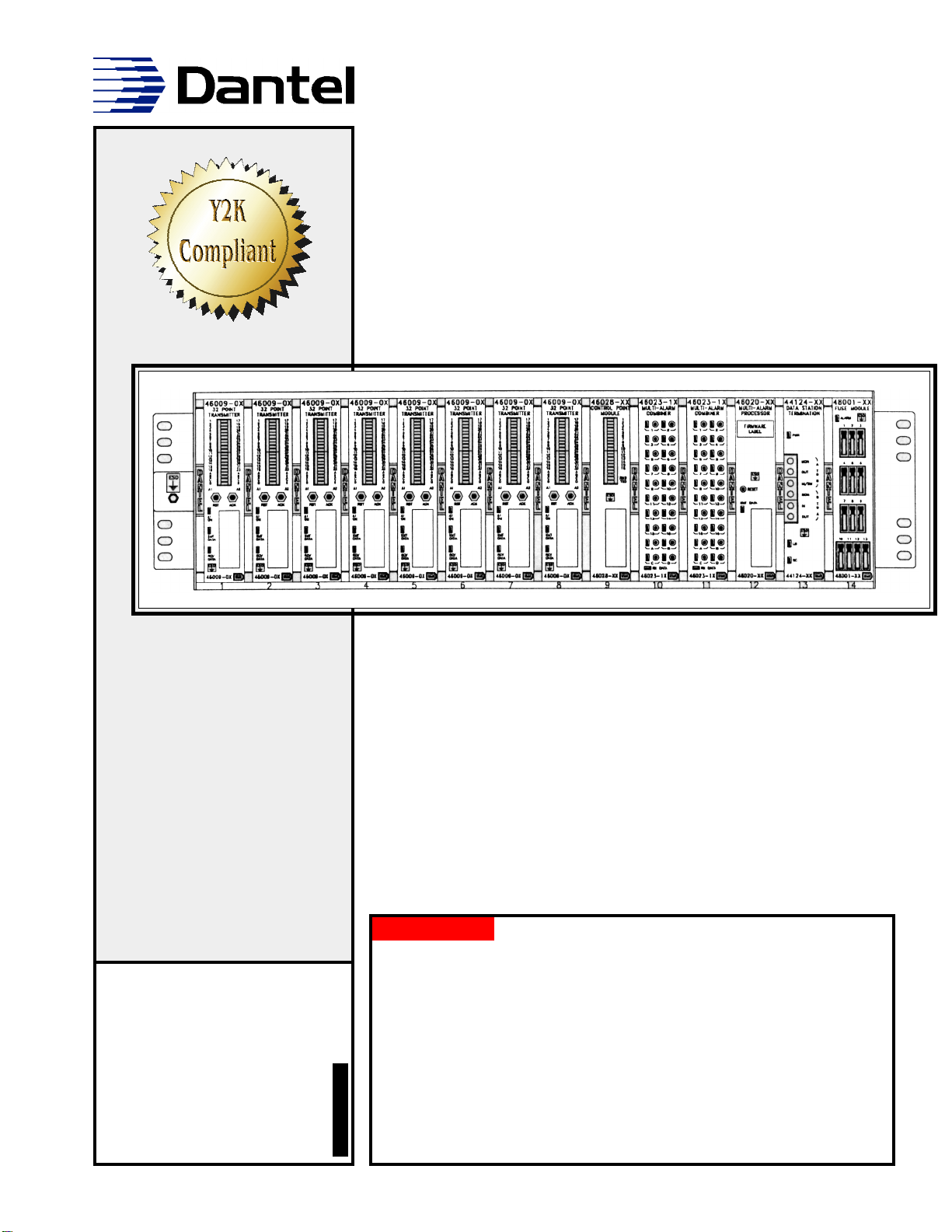

Dantel 05202 User manual

CAUTION

•Install or remove modules from the shelf only when the power is off.

If you install a module in the shelf with the power on, the internal

circuitry may suffer damage and the product warranty will be void.

•Remove and install circuit boards only in a static-safe environment

(use antistatic wrist straps, smocks, footwear, etc.).

•Keep circuit boards in their antistatic bags when they are not in use.

•Do not ship or store circuit boards near strong electrostatic, electromag-

netic, magnetic, or radioactive fields.

•For more complete information on electrostatic discharge safety

precautions, refer to BellcoreTM Technical Reference # TR-NWT-000870.

Copyright 1999 by Dantel, Inc. • Dantel is a registered trademark of Dantel, Inc. • ISO 9001 Registered

Printed in the U.S.A.

INSTALLATION & OPERATION MANUAL

05202-0299 <90-00046>

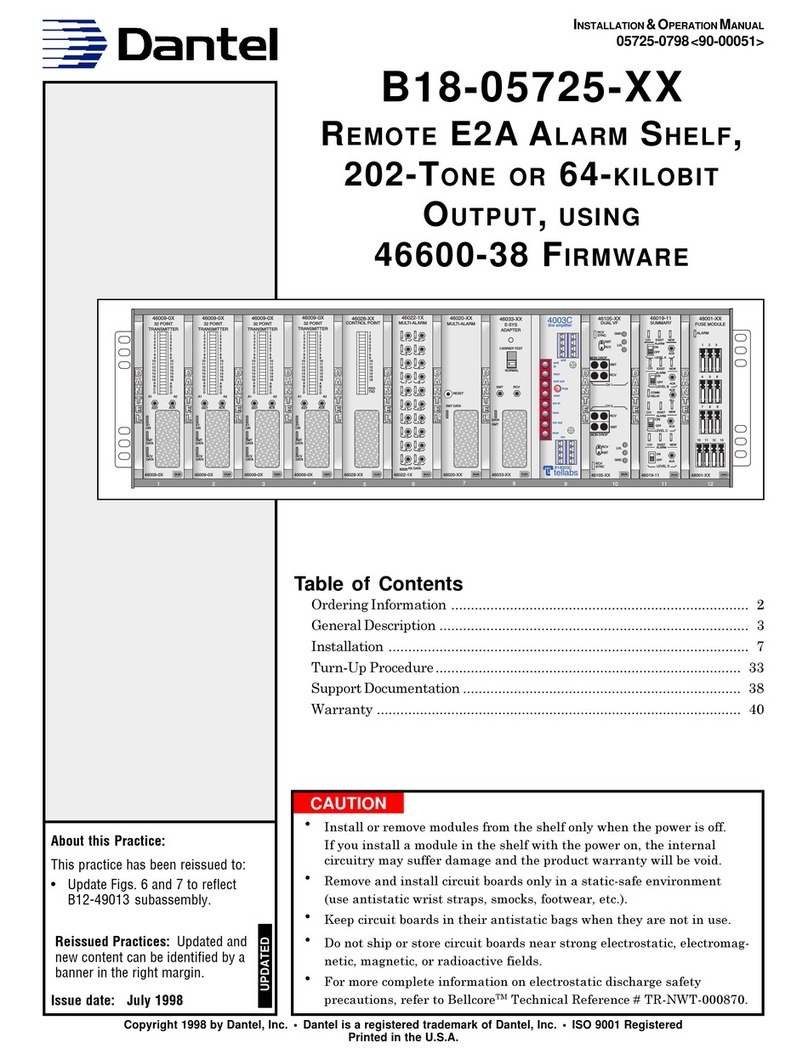

05202

SMALL CENTRAL OFFICE

MASTER ALARM SYSTEM

About this Practice:

This practice has been reissued to:

• Update to reflect Y2K compliance.

Issue date: February 1999

Reissued Practices: Updated and

new content can be identified by a

banner in the right margin.

UPDATED

Table of Contents

Ordering Information ........................................................................... 2

Introduction .......................................................................................... 3

Application Information ....................................................................... 5

Installation............................................................................................ 7

Support Documentation ..................................................................... 43

Warranty ............................................................................................. 46

PAGE 2 05202-0299 <90-00046>

ORDERING INFORMATION

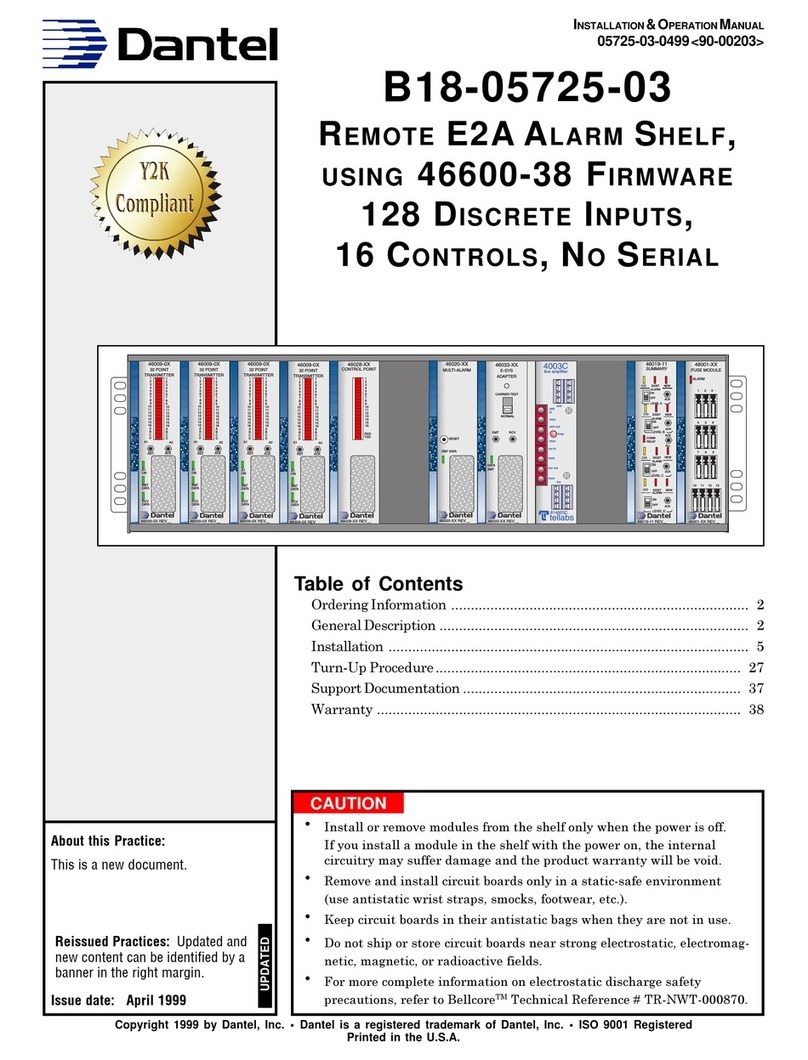

The DJ05202 drawings provide information for ordering the

various components of the Small Central Office Master

Assembly. All the above options include a 256K Status Monitor

w/ keyboard, 41071 Alarm Display Unit, and 3 Terminal Block

Assemblies.

NOTE: This section lists the different options available for this product. To order any of the avail-

able options, contact Dantel Inside Sales through our toll-free number, 1-800-432-6835.

OPTION NUMBER FEATURES

A18-05202-30 256 Discrete Alarm Points, 16 Control Points, 15 TBOS Ports, Writing Shelf

A18-05202-31 128 Discrete Alarm Points, 16 Control Points, 15 TBOS Ports, Writing Shelf

A18-05202-32 128 Discrete Alarm Points, 16 Control Points, 7 TBOS Ports, Writing Shelf

A18-05202-33 96 Discrete Alarm Points, 16 Control Points, 7 TBOS Ports, Writing Shelf

A18-05202-34 160 Discrete Alarm Points, 16 Control Points, 7 TBOS Ports, Writing Shelf

A18-05202-35 256 Discrete Alarm Points, 16 Control Points, 15 TBOS Ports

05202-0299 <90-00046> PAGE 3

INTRODUCTION

This system manual provides information on how to order,

install, and operate the Small Central Office Master Alarm

Assembly. The manual is divided into three main sections, as

outlined below.

Application

A brief description is provided of how the shelf operates and

interfaces with external equipment.

Installation

Follow this section for step-by-step details on installing the

equipment. This section is divided into five parts: equipment

mounting, wiring, switch and strap settings for modules,

turn-up procedure and troubleshooting. The turn-up procedure

provides instructions for getting the system operating.

Support Documentation

This section consists of individual practices on the different

components of the system. The practices provide in-depth

information on the operation of the system components, func-

tional schematics, and technical specifications. The operating

instructions in the practices will provide a useful reference to

the user who needs more details than given in the turn-up

procedure in the Installation section.

PAGE 4 05202-0299 <90-00046>

INTRODUCTION

05202-0299 <90-00046> PAGE 5

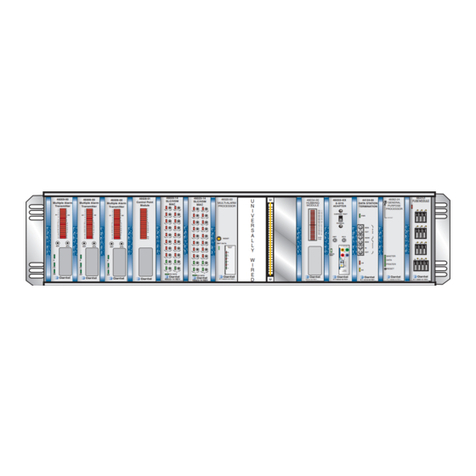

APPLICATION INFORMATION

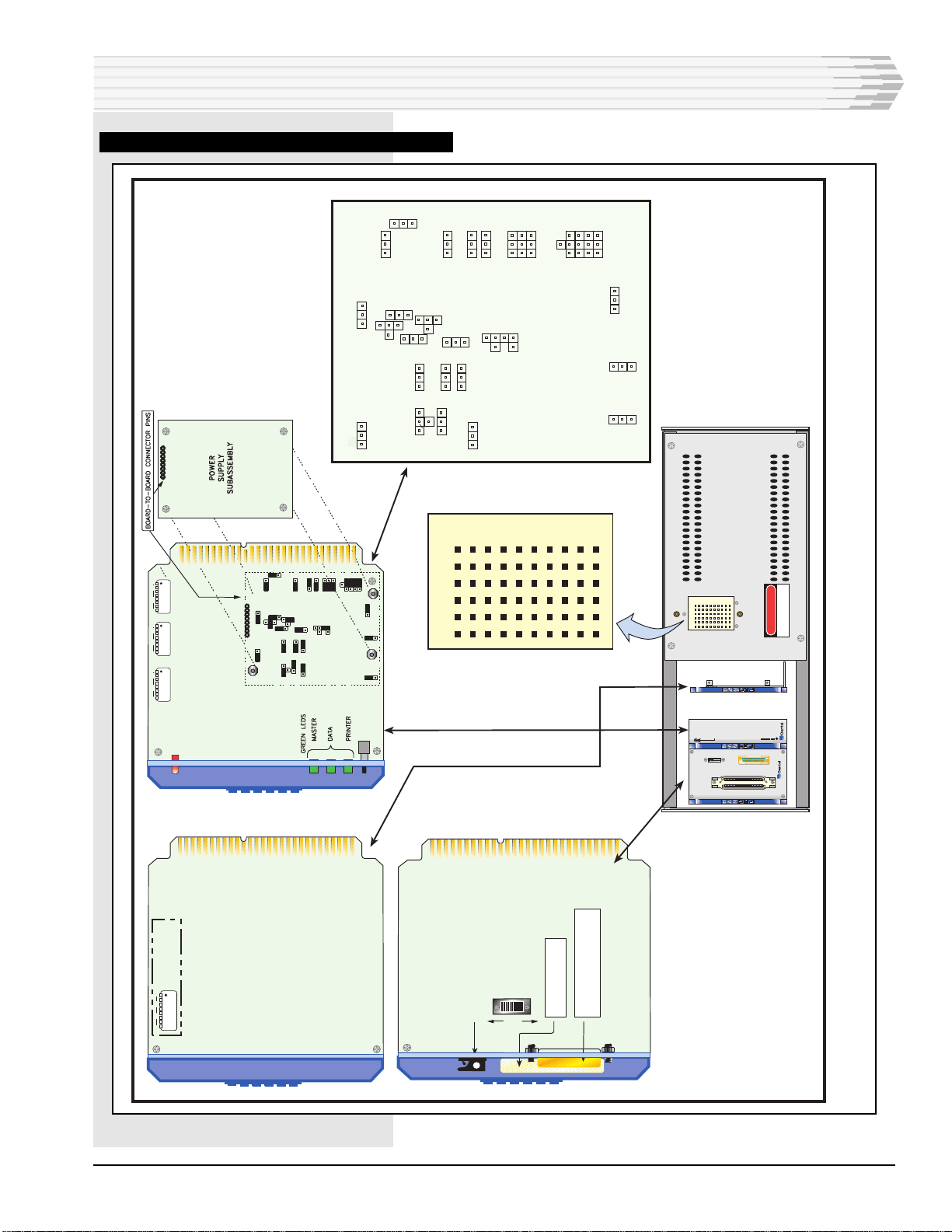

For a functional schematic of the Small Central Office Master

Alarm System Shelf, refer to sheet 2 of the DJ05202 drawing

that follows this page.

Operation of the shelf is controlled by 46020 Multiple Alarm

Processor (MAP) in slot 12. The MAP polls for alarms and issues

commands to operate control points through the Smart MACs in

slots 10 and 11. The 46009 Multiple Alarm Transmitters (MATs)

in slots 1 through 8 accept ground inputs. The 46028 Control

Point Module (CPM) in slot 9 has normally-open relays for

operating controls.

Alarms received by the MAP are reported locally to the 46001

Status Monitor and 41071 Alarm Display Unit.

The MAP also communicates with the alarm center through the

44124 Data Station Termination module is slot 13.

The MAP and Status Monitor require a database to operate.

These databases are configured using a computer running

T/Shell software and downloaded to the modules from the

computer.

The Fuse Module provides fused power to each slot of the shelf.

PAGE 6 05202-0299 <90-00046>

APPLICATION INFORMATION

05202-0299 <90-00046> PAGE 7

INSTALLATION

This section consists of five parts, as explained below.

EQUIPMENT MOUNTING

♦41060 Writing Shelf

♦41071 Alarm Display Unit

♦46001 Status Monitor

♦05202 Equipment Shelf

WIRING

♦A18-05202-XX Block Diagram

♦DT-05202-30 Master Alarm System Interconnection draw-

ings

SWITCH AND STRAP SETTINGS

♦44124-00 Data Channel Termination Module

♦46001-03 Status Monitor

♦46009-02 Multiple Alarm Transmitter

♦46020-41 Multiple Alarm Processor

NOTE: This shelf is Y2K compliant if it is equipped with a

D11-46020-41 or later Multiple Alarm Processor

♦46023-14 Smart Multiple Alarm Combiner

♦46028-01 Control Point Module

♦49008-00 Current Loop Subassembly

♦49013-00 Tone Modem Subassembly

TURN-UP PROCEDURE

TROUBLESHOOTING

UPDATED

PAGE 8 05202-0299 <90-00046>

INSTALLATION

05202-0299 <90-00046> PAGE 9

EQUIPMENT MOUNTING

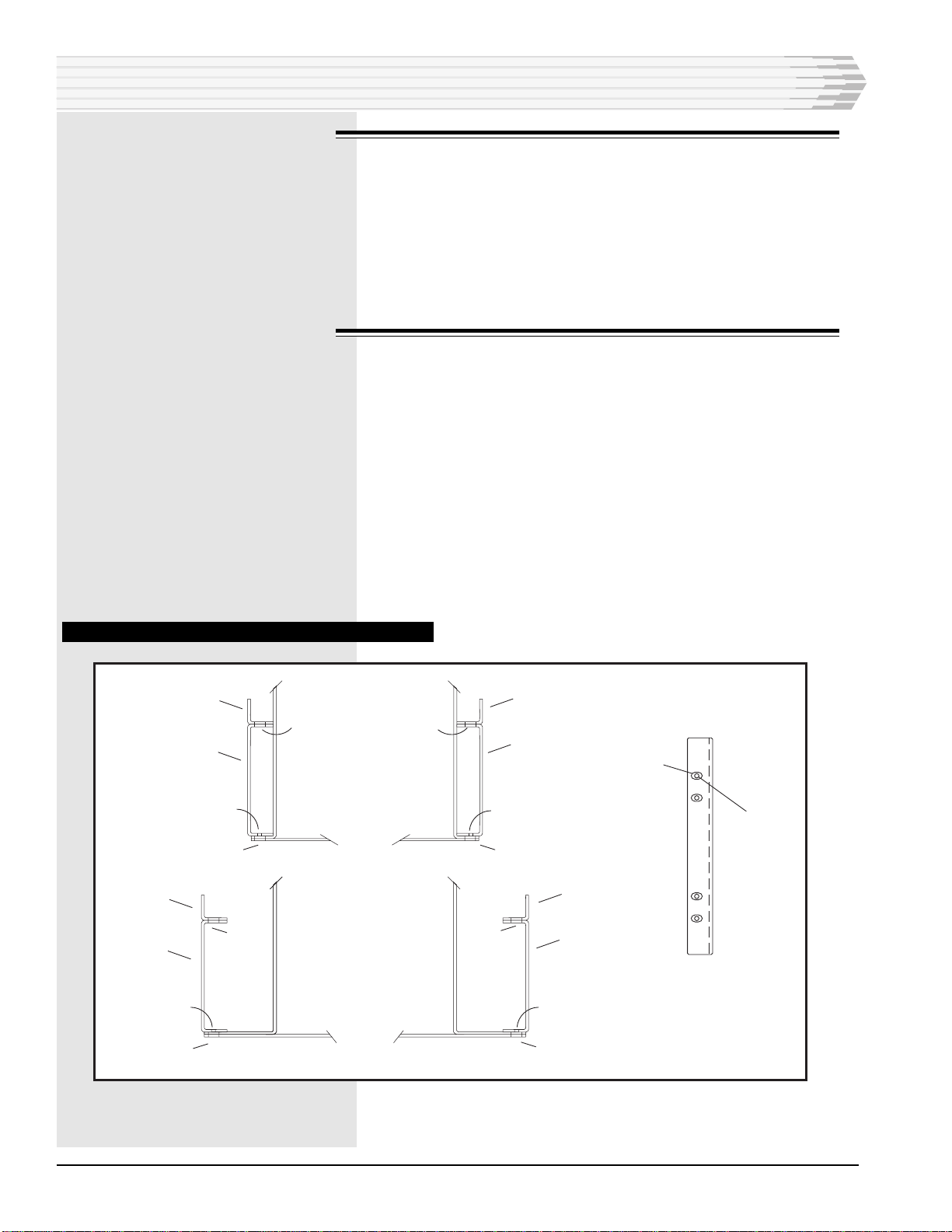

41060 WRITING SHELF

Tools Required

♦Phillips Screwdriver

1. The 41060 can be mounted three ways. Refer to Fig. 1. For maxi-

mum stability, the double mounted projection is recommended.

Units come with brackets in the flush mount position. Additional

brackets are included for double mounting.

2. If not mounting flush, remove the slides from the shelf to reposition

the brackets. Fully extend the slide to access the slide mounting

screws from the outside of the shelf. Remove the front bracket

mounting screws by lining them up with the holes in the slide.

Make sure that the bracket positions match the rack before reat-

taching the slides to the shelf.

FIG. 1 - MOUNTING CONFIGURATIONS, 41060 WRITING SHELF

DOUBLE MOUNTED

PROJECTION

(Recommended)

FLUSH MOUNTED

SINGLE MOUNTED

PROJECTION

INSTALLATION

PAGE 10 05202-0299 <90-00046>

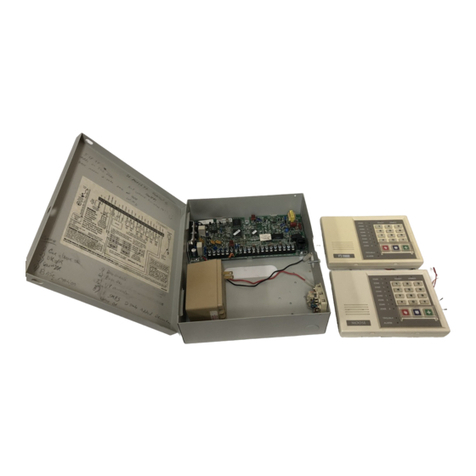

41071 ALARM DISPLAY UNIT

1. Mount the light display box using the two mounting holes on the

rear or left side. Use #6 hardware (not provided).

2. Remove the cover from the remote switch unit and mount as re-

quired using the two mounting holes on the rear. Use #6 hardware

(not provided).

3. Refer to the 41071 practice for information on wiring this unit.

46001 STATUS MONITOR

1. Verify that the equipment rack has at least 8 3/4 inches of vertical

clearance (five rack units) to mount the 46001. Mount the 46001 by

placing it in position in the equipment rack and then installing the

bolts shipped with the unit. If extension brackets were ordered,

they must be installed on the equipment rack prior to mounting the

Status Monitor. Refer to Fig. 2.

2. Mount the brackets to the equipment rack using the slotted holes,

with the base located away from the Status Monitor. Mount the

Status Monitor to the brackets using the threaded holes.

3. Install the ESD studs.

FIG. 2 - MOUNTING BRACKET, 46001 STATUS MONITOR

TOP VIEW

19" STATUS MONITOR

SLOTTED

HOLE

SLOTTED

HOLE

EQUIPMENT RACK

MOUNTING BRACKET

THREADED FLANGE

HOLES

EQUIPMENT RACK

MOUNTING BRACKET

THREADED FLANGE

HOLES

EQUIPMENT RACK

MOUNTING BRACKET

THREADED FLANGE

HOLES

SLOTTED

HOLE

EQUIPMENT RACK

MOUNTING BRACKET

THREADED FLANGE

HOLES

SLOTTED

HOLE

SLOTTED

HOLE

SLOTTED

HOLE

SLOTTED

HOLE

SLOTTED

HOLE

THREADED FLANGE

HOLES

SLOTTED

HOLE

TOP VIEW

23" STATUS MONITOR

INSTALLATION

05202-0299 <90-00046> PAGE 11

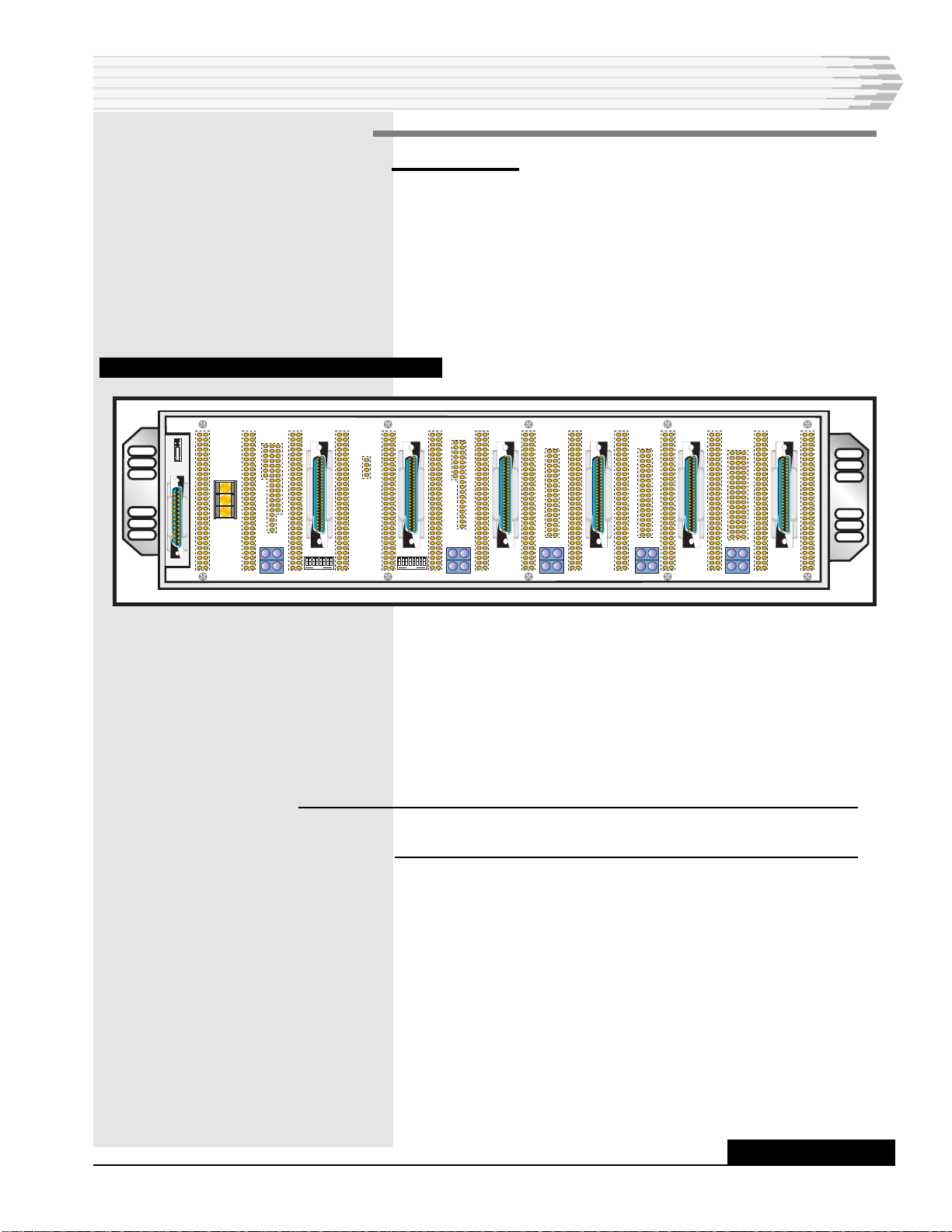

05202 EQUIPMTENT SHELF

Tools Required:

♦Ohmmeter

♦Phillips screwdriver

1. Visually inspect shelf for obvious damage.

2. Use ohmmeter to check for a short across power input at B (-DC)

and (GND) at the left end of the rear of the shelf (refer to Fig. 3).

FIG. 3 - REAR VIEW OF 05202 EQUIPMENT SHELF

If the shelf is damaged or the power is shorted, the faulty unit is

to be replaced and returned to the factory. For repairs and

emergency replacements, obtain a “Return Material Authoriza-

tion” (RMA) number by calling 1-800-4DANTEL

(1-800-432-6835) and asking for the Customer Return Represen-

tative.

NOTE: To avoid further damage, use the original shipping materials

when returning the shelf.

To ensure expedient processing for your order, provide a pur-

chase order number and shipping and billing information when

requesting an RMA number. Also, when the units are returned

to Dantel, include a description of the failure symptoms for each

unit returned.

Send returned materials to:

Dantel, Inc.

2991 N. Argyle Ave.

Fresno, CA 93727-1388

INSTALLATION

CONTINUED . . .

B

-Batt

Gnd

OPEN OPEN

PAGE 12 05202-0299 <90-00046>

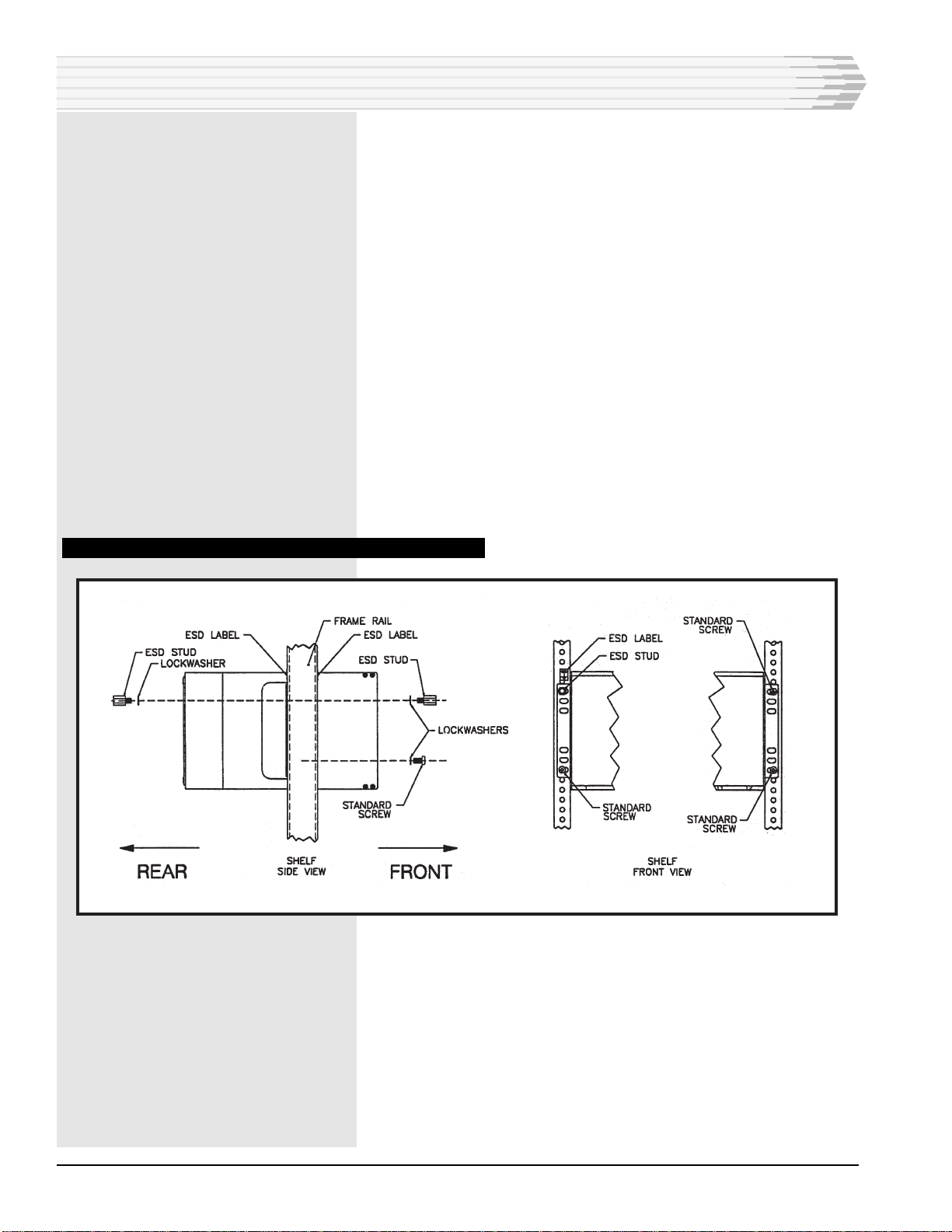

3. With a Phillips screwdriver, mount the shelf in an equipment rack

using the screws and lockwashers supplied in a bag attached to the

side of the shelf.

Mounting hardware is supplied in a bag attached to the side of

the shelf. Refer to Figure 4.

Facing the frame rail, place the equipment shelf in the rack in

the desired location. Secure with three Phillips-head screws and

lockwashers - two on the right side, top and bottom, and one on

the lower left side.

4. Install one ESD stud, with lockwasher, in the upper left location.

5. Secure all fasteners tightly, ensuring proper grounding between

ESD stud and frame rail.

6. Place ESD label next to the ESD stud.

7. From the rear of the bay, install the other ESD stud and

lockwasher into the frame rail next to the equipment shelf. Secure

tightly, ensuring proper grounding of the ESD stud. Place ESD

label next to the ESD stud.

FIG. 4 - MOUNTING CONFIGURATION, 41075 400-TYPE MOUNTING

INSTALLATION

05202-0299 <90-00046> PAGE 13

WIRING

Wire the Small Central Office Master Alarm System to external

equipment as required. Use the A18-05202-XX and DT-05202-30

drawings as references for making connections to the Dantel

equipment.

INSTALLATION

PAGE 14 05202-0299 <90-00046>

INSTALLATION

05202-0299 <90-00046> PAGE 15

SWITCH AND STRAP SETTINGS

44124 DATA STATION TERMINATION MODULE

Refer to Fig. 6. Recommended switch settings:

S1-1 through S1-8 All OFF

S2 - place in G Position

S3 - place in L position

S4 - place in NOR position

S5 - place in N position

S6 - place in 600 position

S7-1 through S7-8 All OFF

S8-1 through S8-5 All ON (OUT)

S9 - place in BYP position

S10 - place in 4W position

S11-1 through S11-8 All OFF

S12-1 place in 4 position

S12-2 place in ON (unmarked) position

S12-3 place in OFF (disable) position

S12-4 and S12-5 OFF

S13 - place in L position

NOTE: For details about the switch settings, refer to the 44124 Data

Station Termination Module Practice.

FIG. 6 - SWITCH LOCATIONS, 44124 MODUJLE

INSTALLATION

G

L

S2S1

G

L

S3

R

N

S5 S4

NOR

SXT

SC

S6

150 600 1200

S7

HT BW

OUT

IN

S8

S10

4W2W

EQR

S9

BYP

S11

S12

L

S13

G

ON

ON

.1

ON

DTD

81620

MLB

OPEN

12481248

OPEN

NL 1 2 4 8

OPEN

4

.1.2.4.8 1.5 3 6 12

OPEN

.2.4.8 1.5 3 6 12

OPEN

PAGE 16 05202-0299 <90-00046>

46001 STATUS MONITOR

Refer to Fig. 7. Recommended switch and strap settings:

Power Supply and Relay Card

S1 - DOWN (Global)

This switch sets the audible alarm relays to operate on

GLOBAL alarms.

CRT Control Card

S1-1 through S1-8 UP (OFF)

This switch sets the CRT card data rate to 9600 baud.

NOTE: This setting must match the data rate of the GPP printer port.

General Purpose Processor

S1-1 through S1-6 All UP (OFF)

S1-7 and S1-8 DOWN (ON)

S2-1 through S2-8 All UP (OFF)

S3-1 through S3-8 All UP (OFF)

See Fig. 8 for factory strap settings

These switches set the data rate for the master and printer

ports for 9600 baud. The address for the Status Monitor is 1.

Also the switches are set so that neither Global or Local alarms

can be masked.

The data rate for the data port defaults to 1200 baud. The data

rate can be changed to 9600 baud using printer syntax com-

mands.

NOTE: For additional information regarding this and other printer

ssyntax commands, or for further details about switch settings,

refer to the 46001 Status Monitor Practice.

INSTALLATION

05202-0299 <90-00046> PAGE 17

FIG. 7 - BOARD LAYOUT, 46001 STATUS MOLNITOR

INSTALLATION

FEDCBA 1

2

3

4

5

6

7

8

9

10

FEDCBA1

2

3

4

5

6

7

8

9

10

DANGER

HIGH VOLTAGE

POWER SUPPLY

A11-46068-00

F1

J4

J3

TB-1

46062-03

GENERAL

PURPOSE

PROCESSOR

B11-46062-03

MASTER

DATA

PRINTER

RESET

LOW BAT.

STATUS

MONITOR

SUBASSEMBLY

LOW BATTERY

INDICATOR

81

OFF

81

OFF

81

OFF

SW 1 SW 2 SW 3

DOWN = ON

GPP CARD

81

OFF

DIP SWITCH S1

CRT

CONTROLLER

CARD

(B80-00345-00)

FUSE

G/L SWITCH

GLOBAL

J5 DB25 CONNECTOR

(TO PERSONAL COMPUTER)

J3 CONNECTOR

(TO CRT HOUSING)

LOCAL

POWER

SUPPLY

&

RELAY CARD

K3

B1

J2

U1 R2

S2

P2

G2

V2

M1

N1

W1

AA2

Q3

L2

A1

E2

C1

D2

EE1

DD1

I1

X1

X2

Z1

BB1

CC2 T1

H2

F2

PAGE 18 05202-0299 <90-00046>

The GPP Module has been strapped at the factory for RS-232

communications on both the master and data ports. To change

or verify the strap positions the power supply subassembly

board must be removed from the module. This is accomplished

by the following steps:

1. Remove power from the 46001 (if not already removed).

2. Remove the GPP card from the rear of the 46001.

3. Refer to Fig. 8. Carefully remove the power supply subassembly,

exposing the straps located on the main circuit board below the

subassembly.

4. Verify the strapping and make changes as required.

NOTE: Refer to the 46001 Status Monitor Practice for additional

information.

5. Reinstall the power supply subassembly board, insuring that each

pin of the board to board connector is in the proper position. Rein-

stall the module into the 46001 housing.

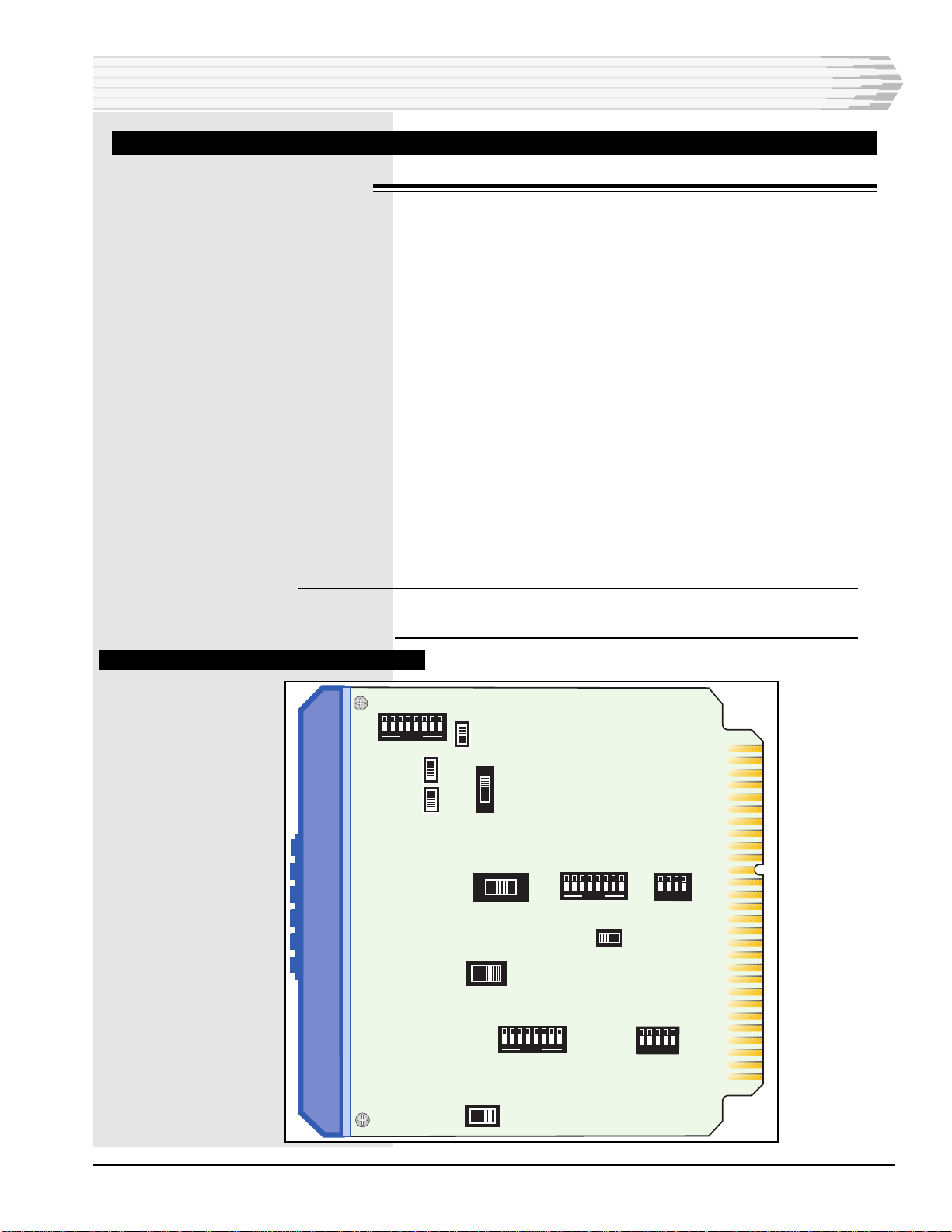

FIG. 8 - SWITCH AND STRAP LOCATIONS, 46062

INSTALLATION

LOW BATTERY

INDICATOR

81

OFF

81

OFF

81

OFF

05202-0299 <90-00046> PAGE 19

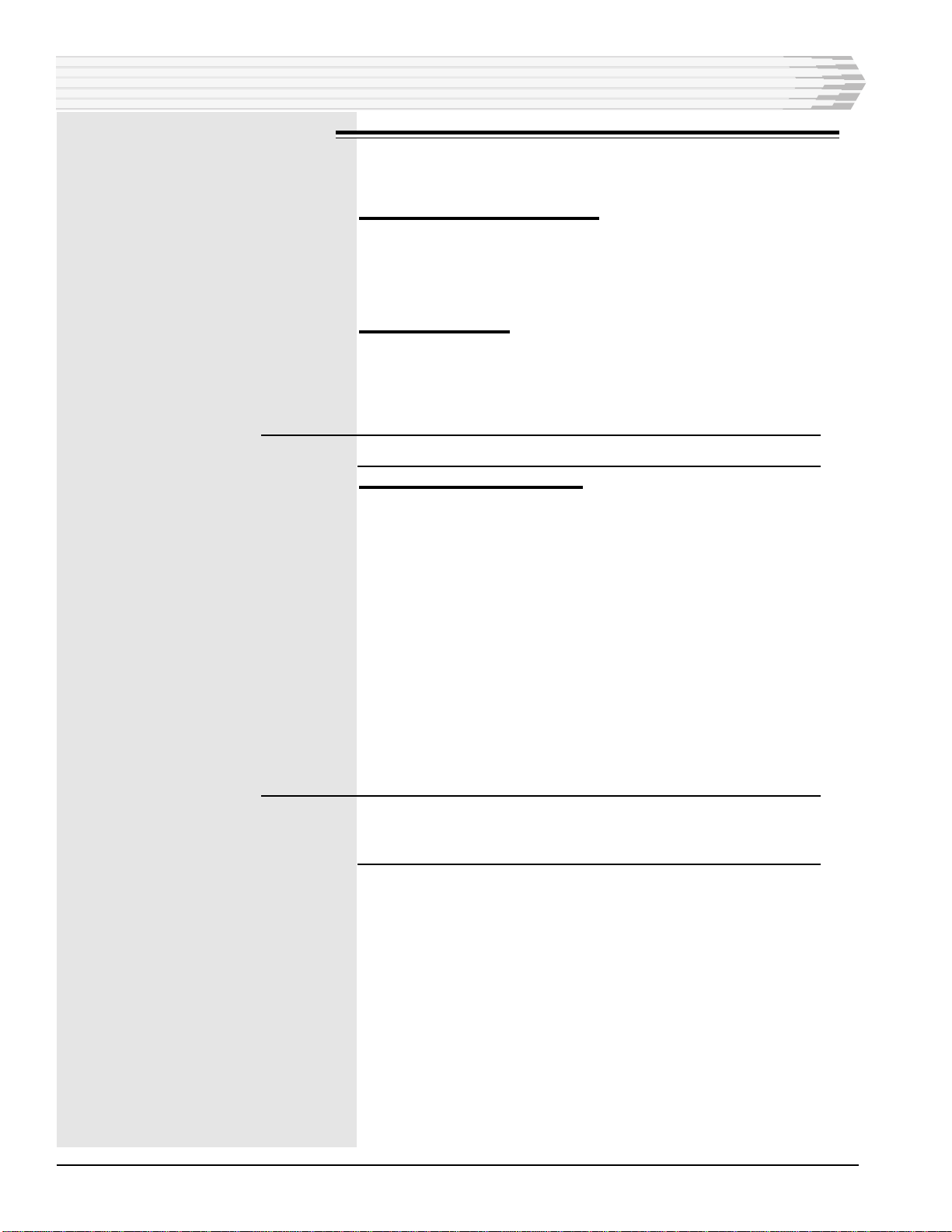

46009 MULTIPLE ALARM TRANSMITTER

Recommended switch and strap settings:

NOTE:Switch settings are the same for all MATs unless specified

otherwise. Refer to Fig. 9 for switch locations and Fig. 10 for

addresses.

S3 - All UP (OFF)

S4 - 1 and 2 UP (OFF)

S4 - 3, 4, and 5 DOWN (ON)

S4 - 6, 7, and 8 UP (OFF)

S5 - See Figure 10

S6 - All UP (OFF)

S301 - 1 DOWN (ON) and 2 UP (OFF)

A/B mini-jumper - A position

These switches set the data rate for the MATs at 1200 baud and

the protocol for DCM. The address is 1 for the MAT in slot 1;

3 for the MAT in slot 2; 5 for the MAT in slot 3 and so on.

NOTE: For additional details about the switch and strap settings,

refer to the 46009 Multiple Alarm Transmitter Practice in the

Appendix.

INSTALLATION

PAGE 20 05202-0299 <90-00046>

113

1

4

J5 J4

SUBASSEMBLY

MOUNTING

AREA

S5

12345678

S4

12345678

S3

8

1234567

MEMORY BOARD SUBASSEMBLY

MOUNTS ON MAIN BOARD OVER S6

21

S301

4 3 2 1

S6

AB

FIG. 9 - SWITCH AND STRAP LOCATIONS, 46009 MODULE

INSTALLATION

This manual suits for next models

6

Table of contents

Other Dantel Security System manuals

Dantel

Dantel 46022-20 User manual

Dantel

Dantel A23-41073-00 User manual

Dantel

Dantel A23-41073 User manual

Dantel

Dantel 46022-12 User manual

Dantel

Dantel B23-41070 User manual

Dantel

Dantel B23-41071 User manual

Dantel

Dantel 46131 User manual

Dantel

Dantel 46022-30 User manual

Dantel

Dantel B18-05725-03 User manual

Dantel

Dantel B15-00459-02 User manual