Dantel A18-05791 Series User manual

This manual suits for next models

2

Table of contents

Other Dantel Security System manuals

Dantel

Dantel 46022-12 User manual

Dantel

Dantel 46022-20 User manual

Dantel

Dantel B23-41071 User manual

Dantel

Dantel 46022-30 User manual

Dantel

Dantel B18-05725-03 User manual

Dantel

Dantel B15-00459-02 User manual

Dantel

Dantel RemoteMaster 46132-41 User manual

Dantel

Dantel A18-05775 Series User manual

Dantel

Dantel 05202 User manual

Dantel

Dantel A23-41073-00 User manual

Popular Security System manuals by other brands

Se-Kure Controls

Se-Kure Controls SK-800KME Series installation instructions

ADT

ADT 3G Cellular Medical Alert System Quick installation guide

ORANGE

ORANGE Live Button user guide

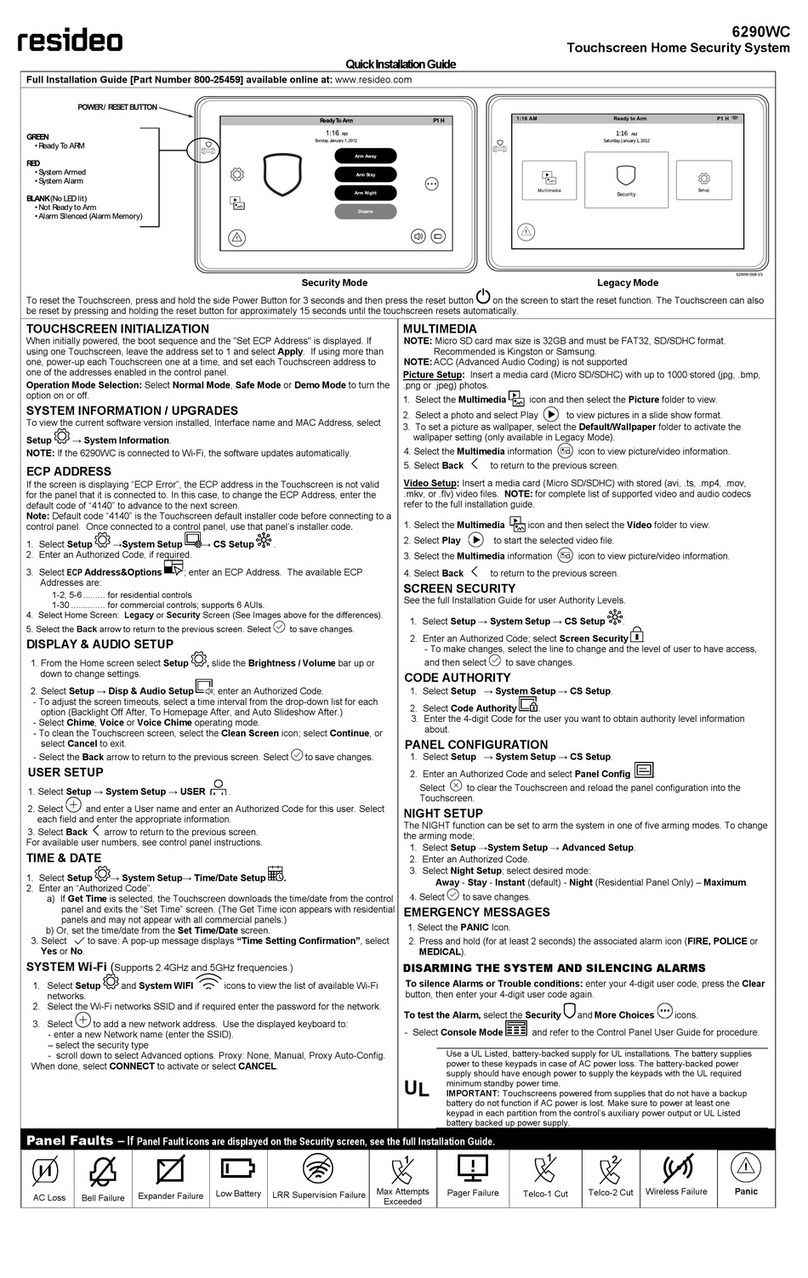

resideo

resideo 6290WC Quick installation guide

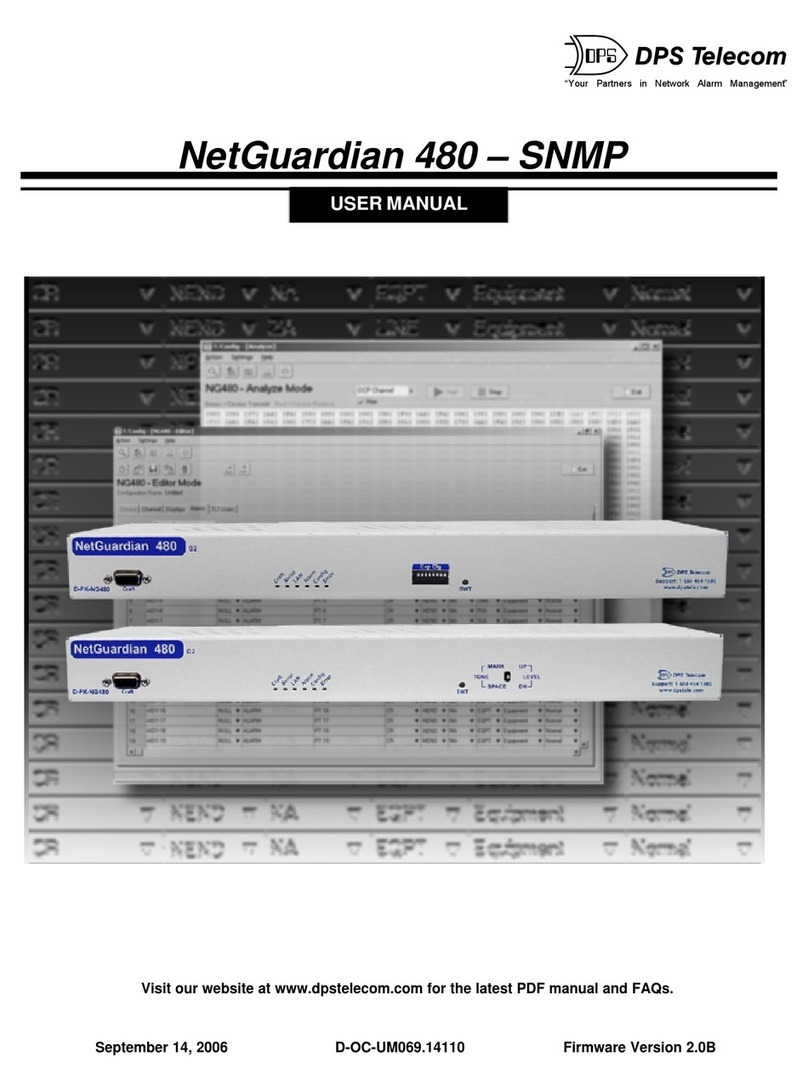

DPS Telecom

DPS Telecom NetGuardian 480 user manual

Wavetronix

Wavetronix Click 513 quick start guide

Bulldog Security

Bulldog Security DELUXE 200B installation manual

Seneca

Seneca MyALARM2-3 installation manual

Whelen Engineering Company

Whelen Engineering Company 2004B installation guide

ChinaPST

ChinaPST PST-OFS04 user manual

DAS

DAS Smart DL-300 Operator's manual

Deckma Hamburg

Deckma Hamburg OMD-2005 instruction manual

Generac Power Systems

Generac Power Systems 21-light owner's manual

POSIFLEX

POSIFLEX SD200 Series user manual

Extel

Extel WESV 82500 Installation and user guide

Security-Center

Security-Center FU2938 installation guide

First Alert

First Alert FA160C user manual

American Dynamics

American Dynamics Intellex Digital Recorder Quick setup guide