SK00-9662-EI-103-00

VII

Contents

BEFORE USING THIS PRODUCTS........................................ II

SAFETY SYMBOL MARKS............................................... II

SAFETY PRECAUTIONS................................................III

REVSION HISTORY................................................... VI

CONTENTS..........................................................VII

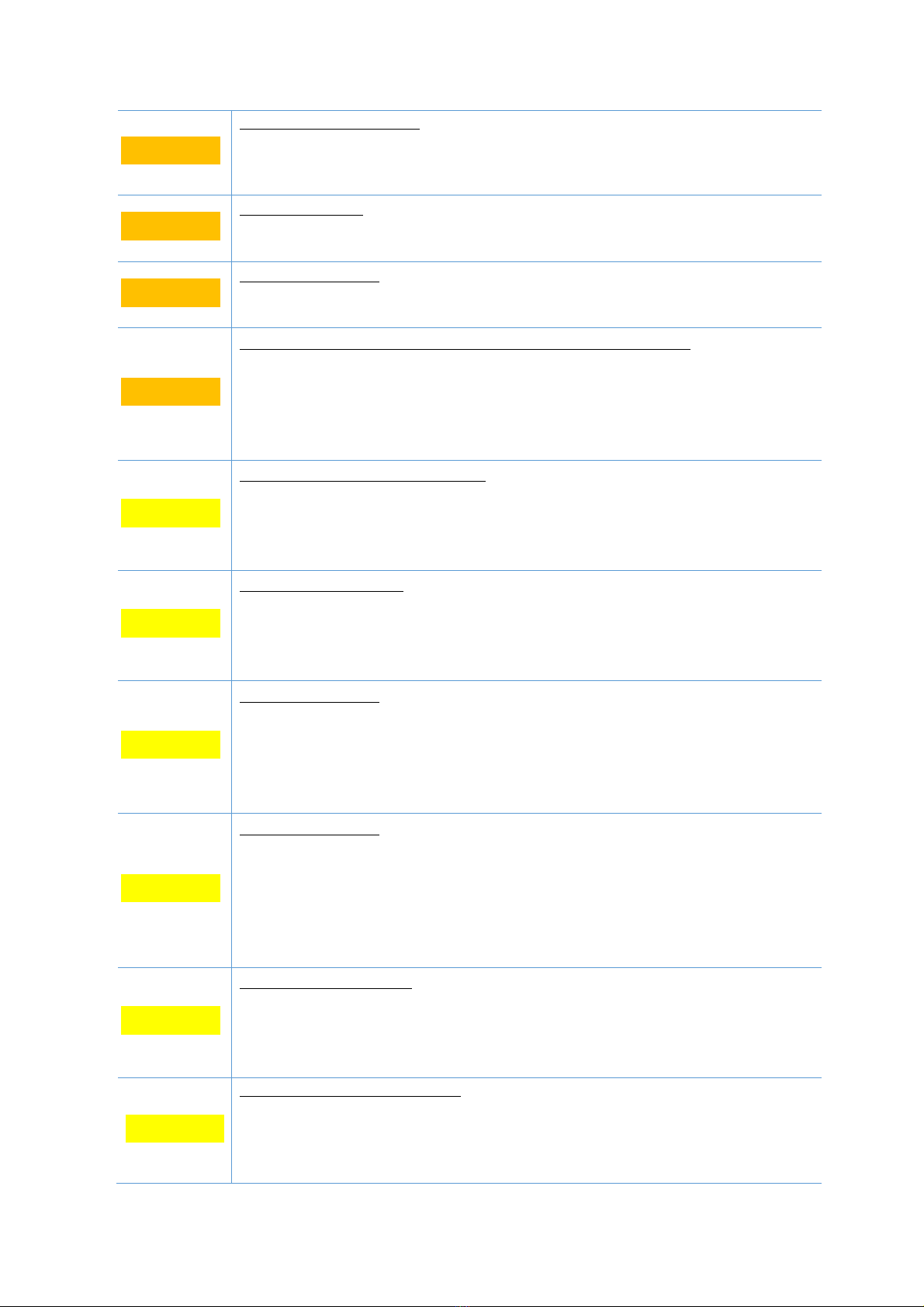

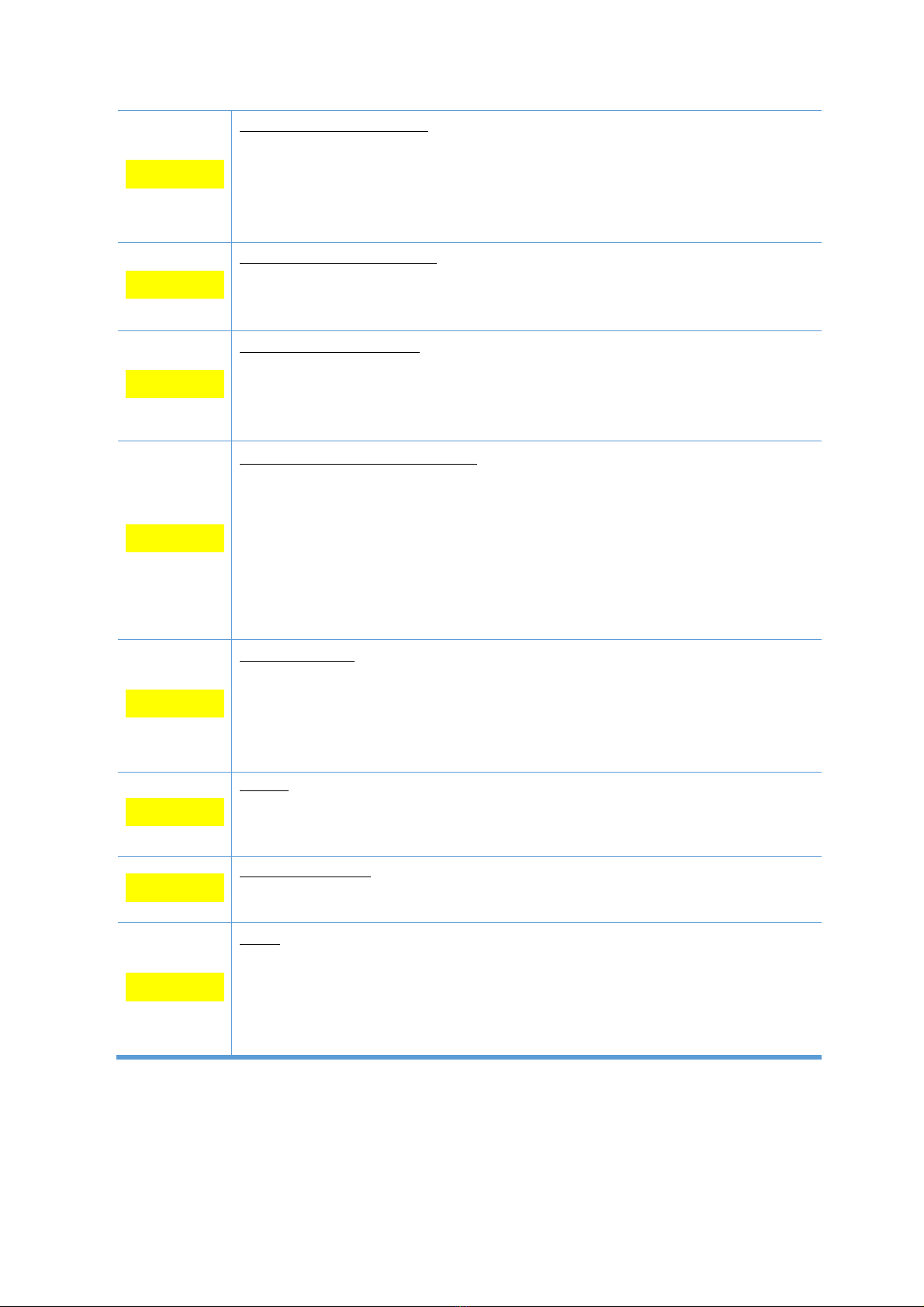

1. SPECIFICATION ....................... 1

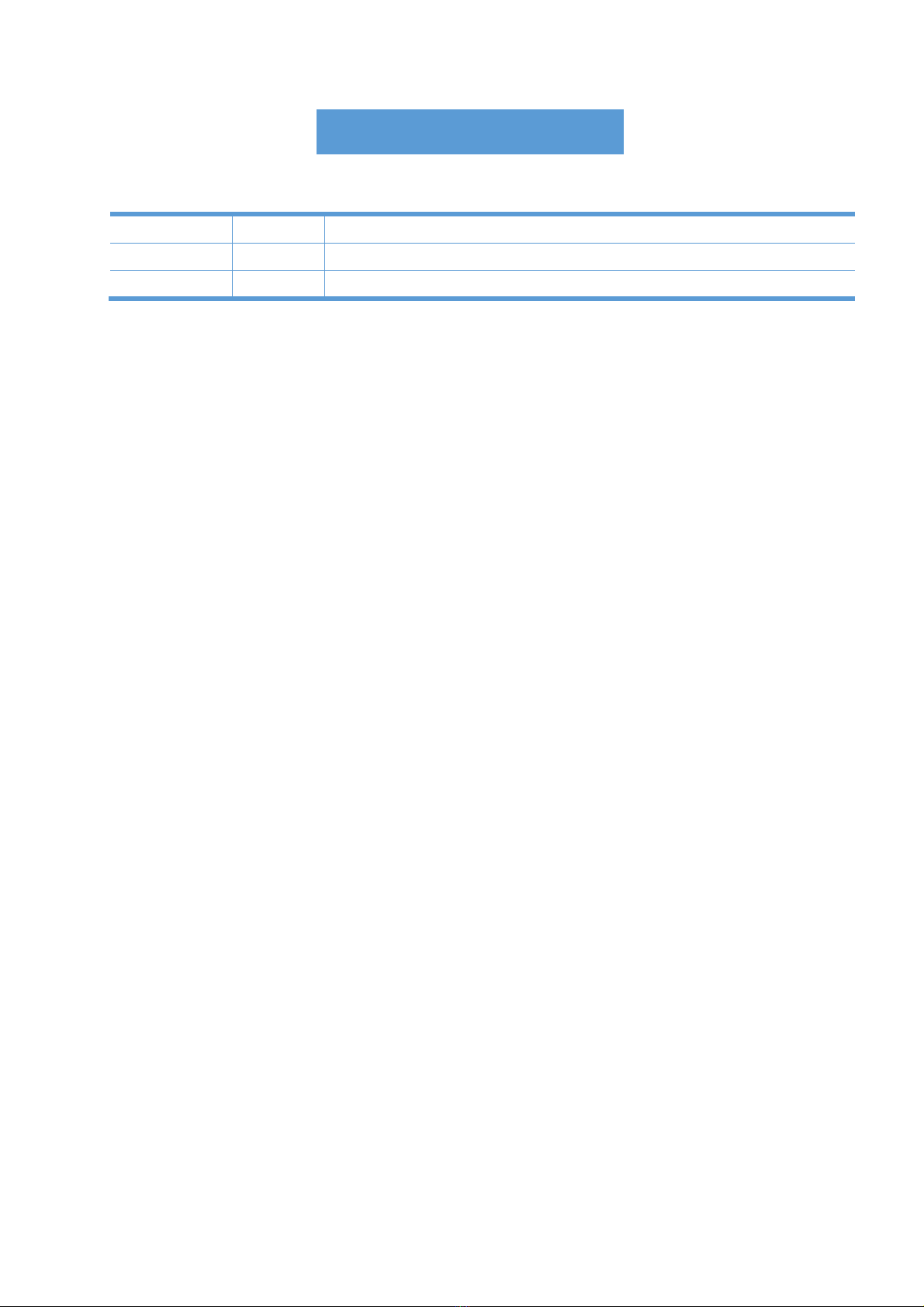

1.1. UNPACKING AND QUANTITY CHECK.......... 1

Included items .............. 1

Items that need to be ordered

separately .......................... 1

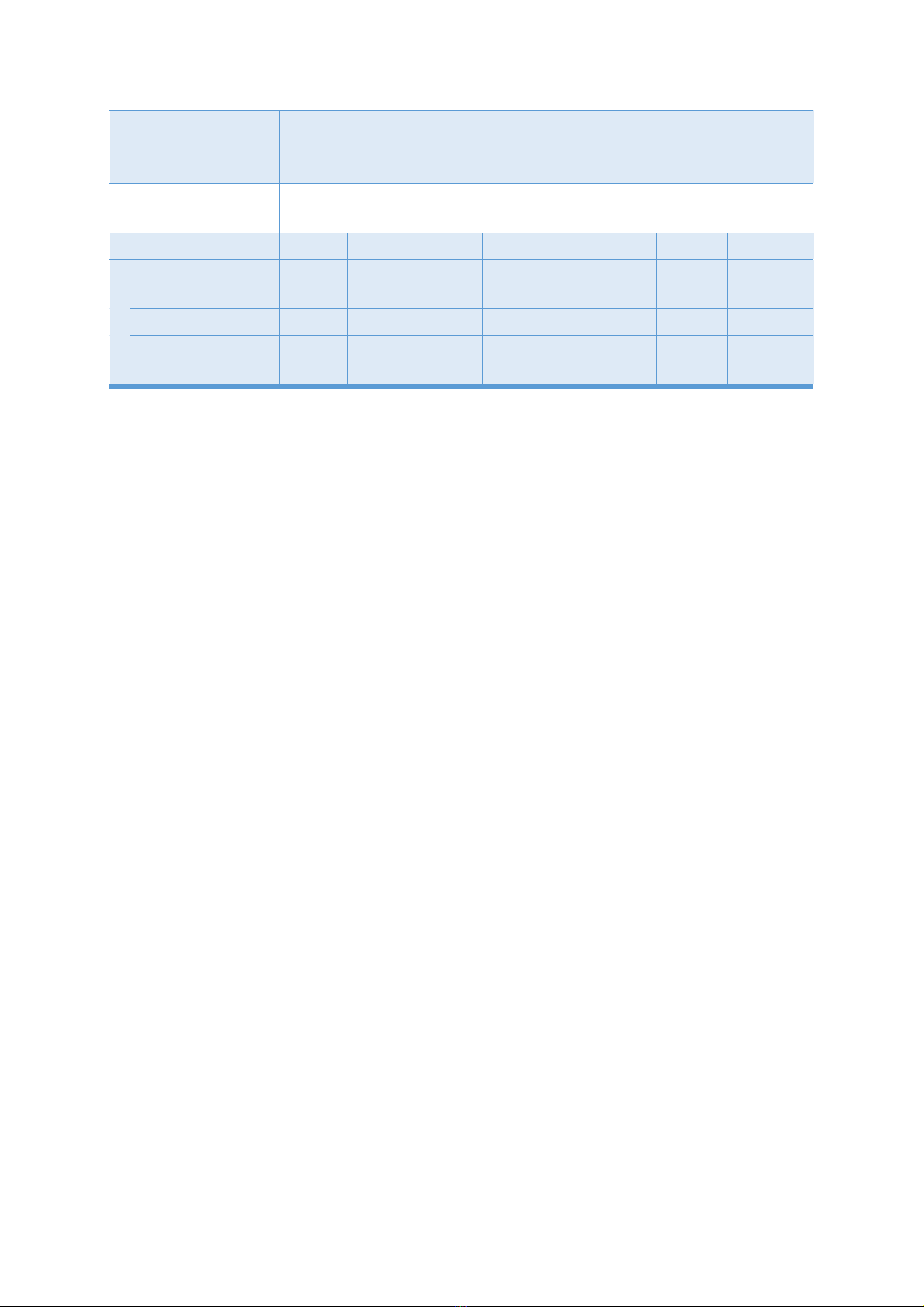

1.2. SWU10-U STANDARD SPECIFICATIONS ...... 2

2. HANDLING PRECAUTIONS ................ 4

2.1. PRECAUTIONS ON OPERATING ENVIRONMENT ... 4

2.2. PRECAUTIONS ON POWER SUPPLY........... 5

2.3. PRECAUTIONS ON INSTALLATION OF THIS UNIT 5

2.4. PRECAUTION ON USAGE ................. 7

2.5. CHECK ITEMS IMMEDIATELY AFTER THE START OF

USE ................................ 7

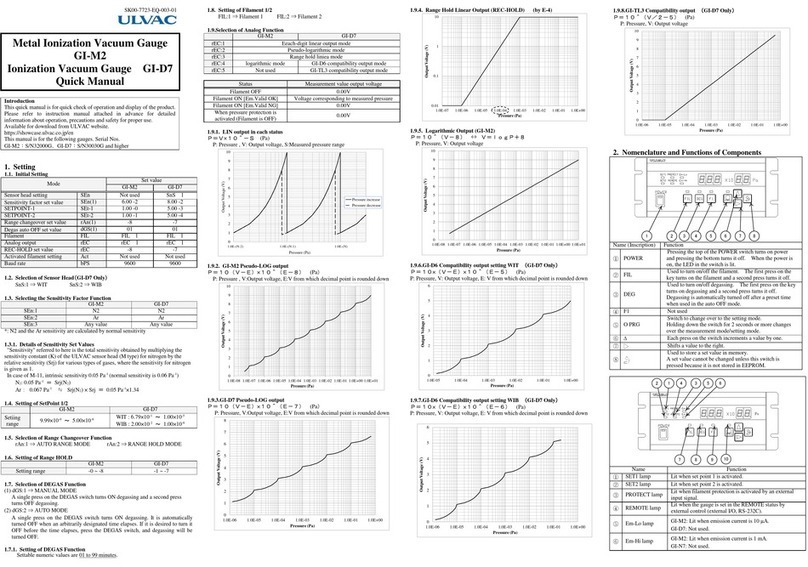

3. NAME OF EACH PART AND EXPLANATION OF

FUNCTION................................. 8

3.1. SWU10-U ......................... 8

4. ZERO POINT ADJUSTMENT AND ATMOSPHERIC

PRESSURE ADJUSTMENT...................... 9

4.1. ADJUSTING METHOD ................... 9

Zero point adjustment ....... 9

Atmospheric pressure

adjustment .......................... 9

4.2. ADJUSTMENT CLEAR .................. 10

4.3. MEMORY FUNCTION ................... 10

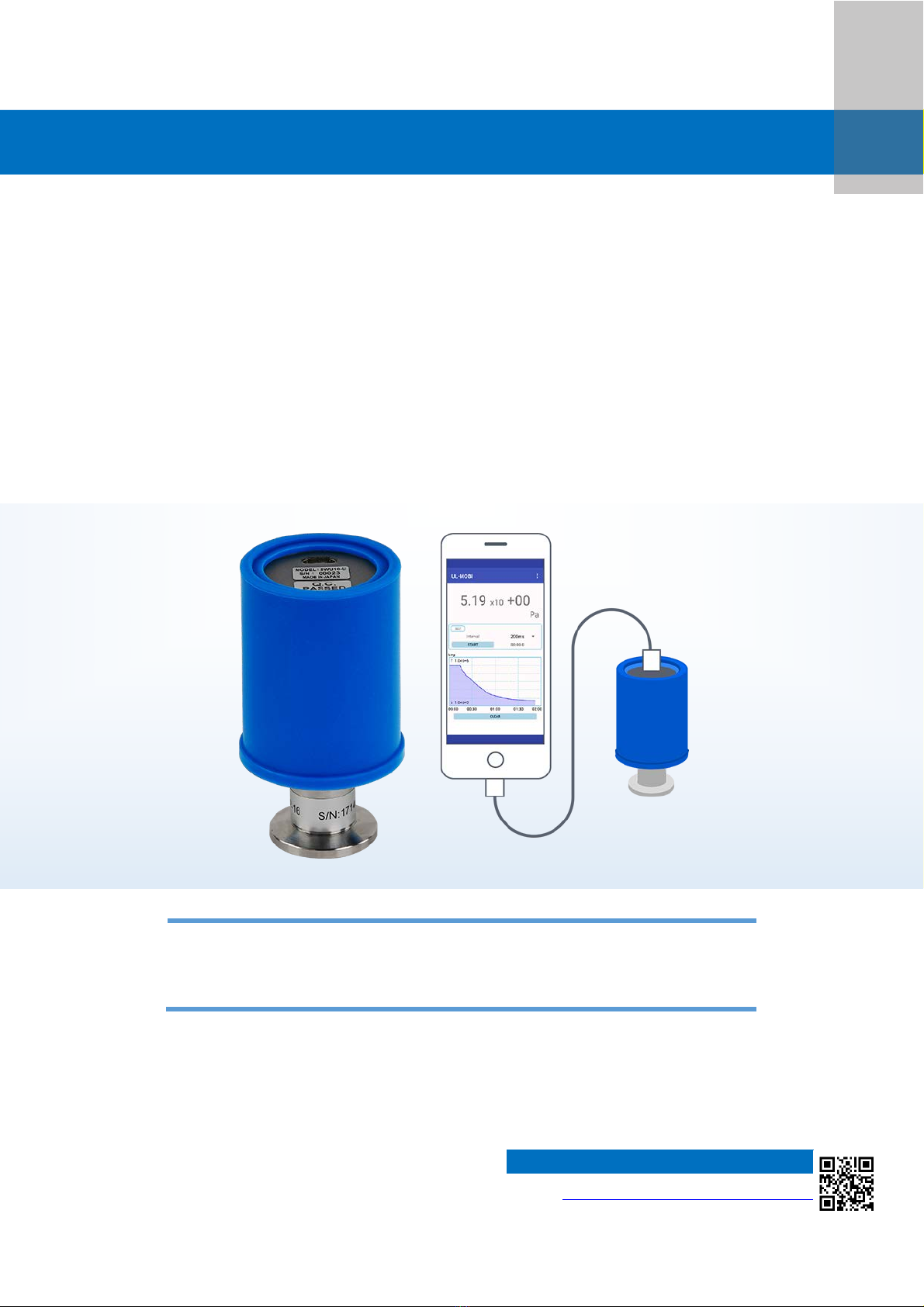

5. HOW TO USE UL-MOBI ................. 11

5.1. FUNCTION......................... 11

5.2. UL-MOBI FOR ANDROID .............. 12

Usage condition ............ 12

Download/install ........... 12

How to use ................. 13

5.3. UL-MOBI FOR WINDOWS .............. 15

Usage condition ............ 15

Download/install ........... 16

How to use ................. 16

5.4. STATUS COMMENT ................... 19

6. TROUBLESHOOTING .................... 20

6.1. TROUBLESHOOTING ................... 20

7. TECHNICAL REPORT ................... 22

7.1. GAS SPECIE/HUMIDITY DEPENDENCE ........22

7.2. ZERO POINT ADJUSTMENT AND ATMOSPHERIC

PRESSURE ADJUSTMENT .......................23

7.3. SCHEDULED ADJUSTMENT ................24

8. WARRANTY ............................25

9. EC DECLARATION OF CONFORMITY ........27

10. UK DECLARATION OF CONFORMITY ......28

11. CERTIFICATE OF DECONTAMINATION ....29

12. DRAWINGS ..........................30

12.1. SWU10-U DIMENSIONS ..............30

12.2. SWU10-U DIMENSIONS ..............31