22750 DryLoc pH/ORP Sensor Electronics

Caution / Warning / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of Signet products.

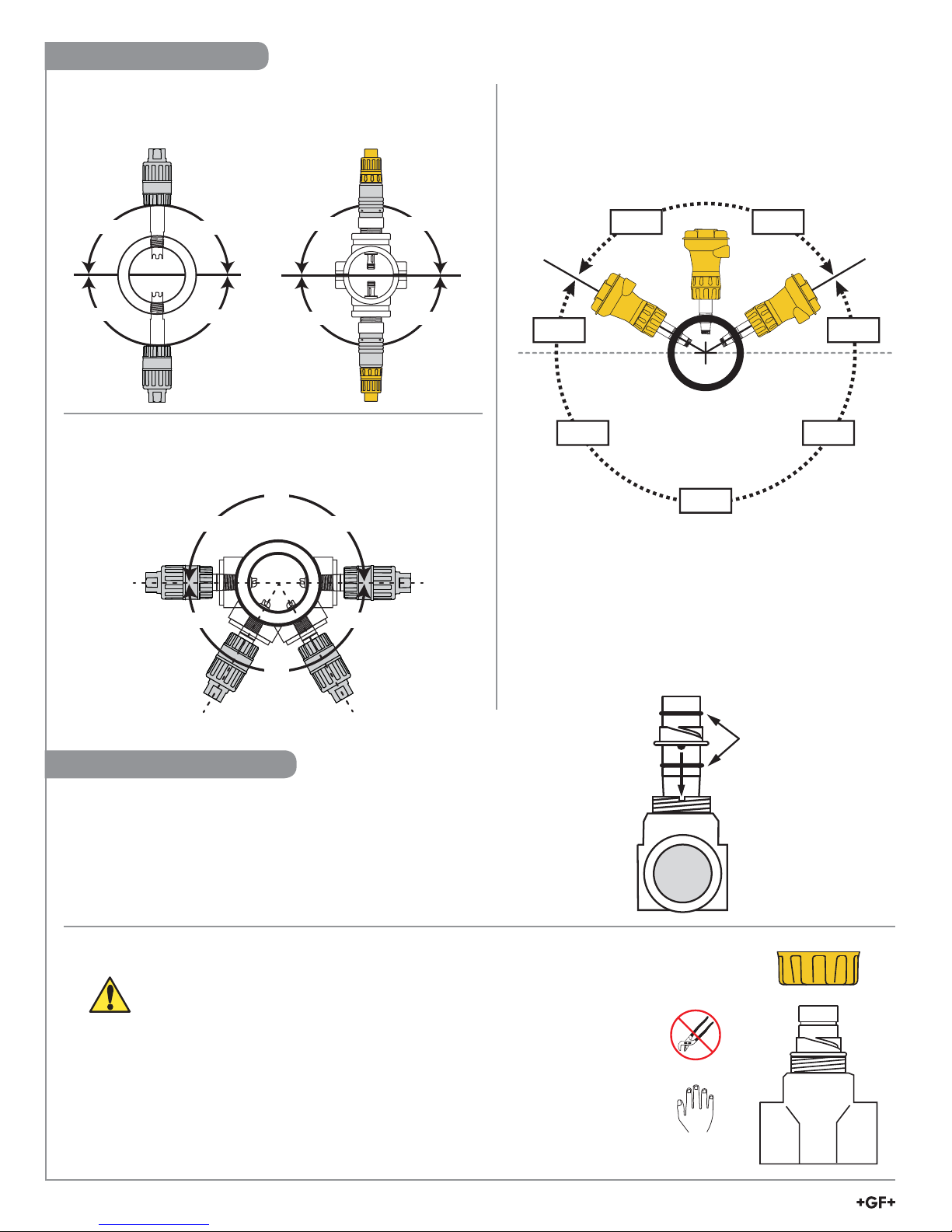

Pressurized System Warning

Sensor may be under pressure, take caution to vent

system prior to installation or removal. Failure to do so

may result in equipment damage and/or serious injury.

Hand Tighten Only

Overtightening may permanently damage product threads

and lead to failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.

Note / Technical Notes

Highlights additional information or detailed procedure.

Safety Information

Refer to your local Georg Fischer Sales office for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales office or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature, chemical poisoning, dry-out) or

mishandling (e.g. broken glass, damaged membrane, freezing

and/or extreme temperatures).

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now register

online in one of the following ways:

• Visit our website www.gfsignet.com. Under Service and

Support click on Product Registration Form

• If this is a pdf manual (digital copy), click here

General

Compatible Electrodes......... Signet DryLoc Electrodes

(PT1000 or 3K Balco temperature

sensor versions for pH)

Operational Range 2750...... 0.00 to 14.00 pH, ±2000 mV ORP,

0 °C to 85 °C (32 °F to 185 °F)

Response Time (includes electrode response):

pH ..................................... <6 s for 95% of change

ORP.................................. application dependent

pH Temp T90 ................... 200 s (2724 and 2734)

132 s (2726 and 2736)

438 s (2756-WT)

Materials

In-line:

2750-1, 2750-2, 2750-7..... PBT (thermal plastic polyester)

Submersible:

2750-3, 2750-4.................. CPVC

Cable for 2750-3, 2750-4, 2750-7:

•5 m (15 ft) 3-conductor shielded, 22 AWG

•May be extended up to 305 m (1000 ft) with current output

• May be extended up to 305 m (1000 ft) with (S3L) output

Shipping Weight

2750-1, 2750-2...................... 0.75 kg (1.75 lb)

2750-3, 2750-4, 2750-7 ........ 0.64 kg (1.4 lb)

Environmental

Ambient Temp...................... 0 °C to 85 °C (32 °F to 185 °F)

Storage Temp. ..................... -20 °C to 85 °C (-4 °F to 185 °F)

Relative Humidity ................. 95% max, non-condensing

Immunity............................... EN50082-2

Emissions............................. EN50081-1

Enclosure Rating

In-line:

2750-1, 2750-2

, 2750-7

.... NEMA 4X/IP65

(with electrode connected)

Submersible:

2750-3, 2750-4 ................. NEMA 6P/IP68

(with electrode and watertight

extension pipe connected)

Electrical

Input Impedance .................. >1011 Ω

Input response time ............. 500 ms

Temperature drift.................. ±0.002 pH per ºC,

±0.1 mV ORP per ºC

Input resolution..................... 0.02 pH, 1 mV ORP, 0.3 ºC

Specifications

Chemical CompatibilityWarranty Information

Product Registration

1. Depressurize and vent system prior to installation or removal.

2. Confirm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifications.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. When using chemicals or solvents care should be taken

and appropriate eye, face, hand, body, and/or respiratory

protection should be used.

The retaining nuts of pH and ORP sensors are not designed

for prolonged contact with aggressive substances.

Strong acids, caustic substances and solvents

or their vapor may lead to failure of the retaining

nut, ejection of the sensor and loss of the process

fluid with possibly serious consequences, such as

damage to equipment and serious personal injury.

Retaining nuts that may have been in contact with

such substances e.g. due to leakage or spilling,

must be replaced.