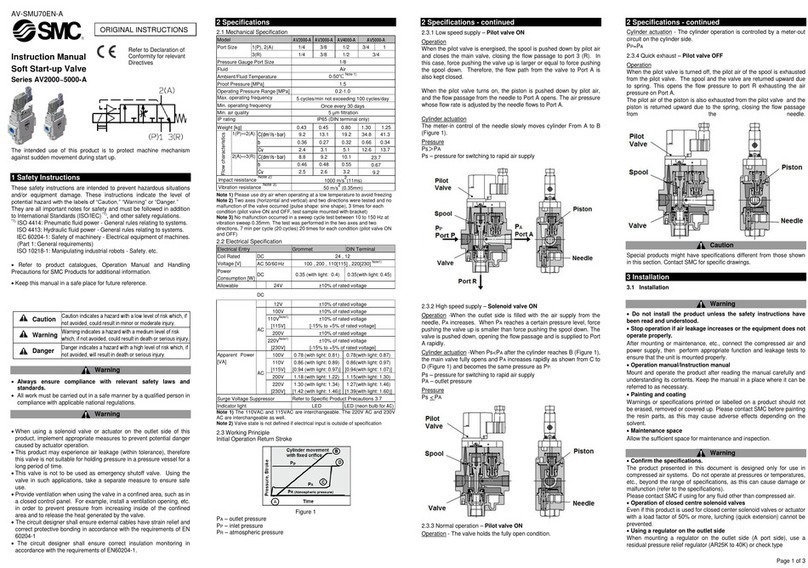

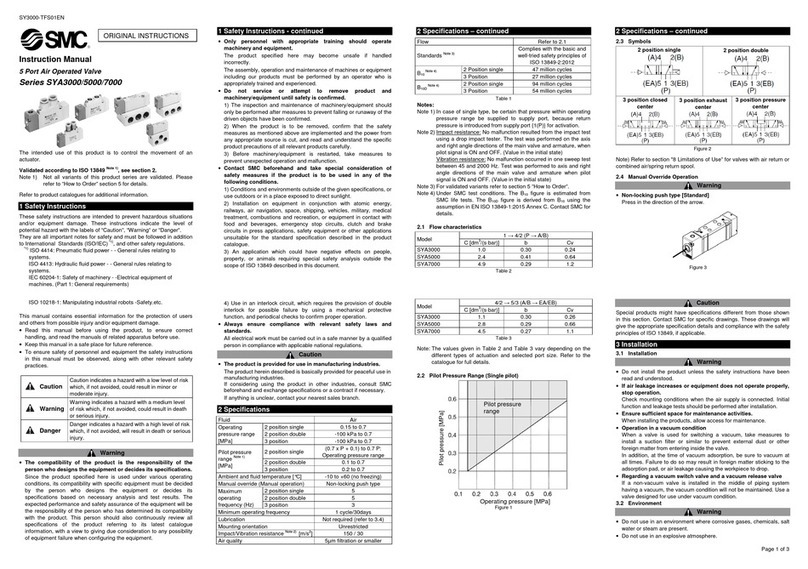

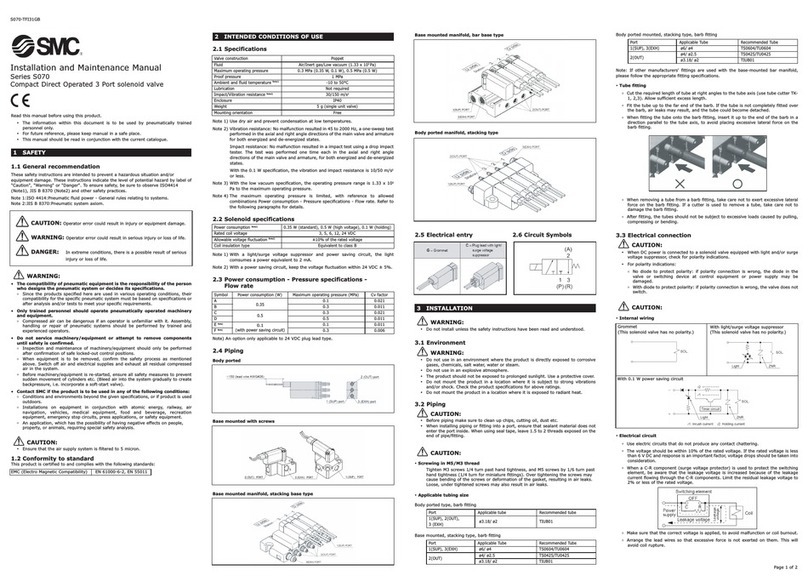

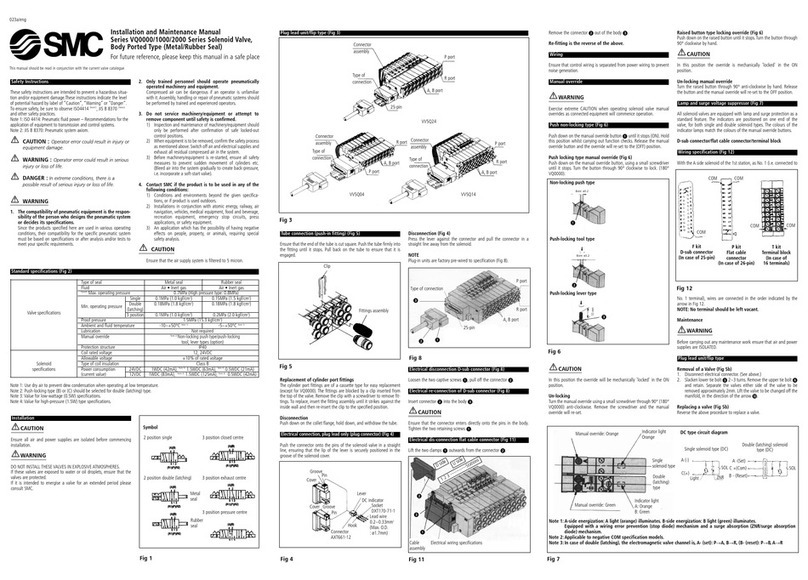

3.3 Electrical connection

CAUTION

When DC power is connected to a solenoid valve equipped with light and/or surge voltage suppressor, check

for polarity indications.

For polarity indications:

No diode to protect polarity: if polarity connection is wrong, the diode in the valve or switching device at

control equipment or power supply may be damaged.

With diode to protect polarity: if polarity connection is wrong, the valve does not switch.

CAUTION: Light/surge CAUTION: Connection of 24V

voltage suppressor or more DC

For the grommet type, connect the positive (+) side to the red

lead wire and connect the negative (-) side to the black lead wire.

For the DIN terminal, connect the positive (+) side to the

connector’s No.1 terminal and connect the negative (-) side to the

No.2 terminal.

(See the markings on the terminal block.)

For 12V or less DC, positive (+) and negative (-) can be

connected in either direction.

CAUTION: Use of DIN Connector

Connection procedure

Loosen the holding screw, and pull the connector out of the solenoid valve terminal block.

After removing the holding screw, insert the flat head screw driver, etc. into the notch on the bottom of

the terminal block and pry it up, separating the

terminal block and the housing.

Loosen the terminal screws (slotted screws) on

the terminal block, insert the core of the lead

wire into the terminal in accordance with the

prescribed connection method, and attach

securely with the terminal screws.

Fasten the cord by screwing in the gland nut.

Cord entry changing procedure

After separating the terminal block and housing,

the cord entry direction can be changed by

attaching the housing in the desired direction

(4 directions in 90° increments).

*When equipped with light, handle with care so

that the light is not damaged by the cord’s lead

wires, etc.

Precautions

The connector should be inserted and pulled out in a straight line without tilting diagonally.

Compatible cables

Cord outside diameter: ø4 to ø6.5 (Reference)

0.5mm2equivalent to JISC3306, 2 wire or 3 wire

Connector part no.: VK300-37-1

Part No. for connector with light Circuit diagram for connector with light

Rated voltage Rating symbol Part No.

100VAC A1 VK300-37-2-01

200VAC A2 VK300-37-2-02

240VAC A3 VK300-37-2-07

6VDC LW06 VK300-37-4-51

12VDC LW2 VK300-37-4-06

24VDC LD4 VK300-37-3-05

48VDC LD8 VK300-37-3-53

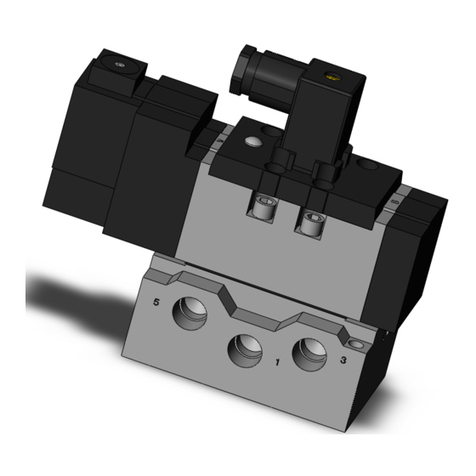

3.4 Mounting

CAUTION

After confirming the installation of the

gaskets, securely tighten the screws to the

tightening torque shown in the table below:

The bushing may be damaged if the tightening

torque of 0.8Nm is exceeded. In the event that

damage does occur, be sure to replace the

bushing.

2 sets per unit are required.

3.5 Lubrication

CAUTION

SMC products have been lubricated for life at manufacturer, and do not require lubrication in

service.

If a lubricant is used in the system, use turbine oil Class 1(no additive), ISO VG32. Once lubricant

is used in the system, lubrication must be continued because the original lubricant applied during

manufacturing will be washed away.

4 SETTINGS AND PROGRAMMING

4.1 Manual override operation

WARNING

When the manual override is operated, connected equipment will be actuated.

Confirm safety before operating.

Non-locking push type (tool required)

There are manual overrides in 2 directions, on

the top and on the side (solenoid side).

By pressing either of the manual overrides in

the direction of the arrow (→) until it stops

(approx. 1mm), it will turn ON, and it turns

OFF when released.

5 MAINTENANCE

WARNING

Not following proper procedures could cause the product to malfunction and could lead to damage

to the equipment or machine.

If handled improperly, compressed air can be dangerous. Assembly, handling and repair of

pneumatic system should be performed by qualified personnel only.

Drain: remove condensate from the filter bowl on a regular basis.

Shut-down before maintenance: before attempting any kind of maintenance make sure the supply

pressure is shut off and all residual air pressure is released from the system to be worked on.

Start-up after maintenance: apply operating pressure and power to the equipment and check for

proper operation and possible air leaks. If operation is abnormal, please verify product set-up

parameters.

Do not make any modification to the product

Do not disassemble the product, unless required by installation or maintenance instructions.

5.1 Manifold mounting

Refer to paragraph 3.4, for mounting valves onto manifolds.

6 LIMITATIONS OF USE

WARNING

Do not exceed any of the specifications laid out in section 2 of this document or the specific product

catalogue.

Long continuous loading time

When power will be applied continuously for extended periods of time, use type VKF33*E. However, it cannot

be used with high frequency. Contact SMC if it will be operated more than once a day.

Be sure to perform switching at least once every 30 days.

CAUTION

Leakage voltage

Particulary when using a resistor in parallel with a switching

element, take note that leakage voltage will increase due to

leakage current flowing through the resistor. Limit the

amount of residual leakage voltage to the following values.

For AC coil: 20% or less of rated voltage

For DC coil: 2% or less of rated voltage

Low temperature operation

Operation is possible to -10°C, but measures should be taken to avoid solidification or freezing of drainage

and moisture, etc.

Mounting orientation

The mounting orientation is unrestricted.

7 EUROPEAN CONTACT LIST

SMC Corporation

Country Telephone Country Telephone

Austria (43) 2262-62 280 Italy (39) 02-92711

Belgium (32) 3-355 1464 Netherlands (31) 20-531 8888

Czech Republic (420) 5-414 24611 Norway (47) 67 12 90 20

Denmark (45) 70 25 29 00 Poland (48) 22-548 50 85

Finland (358) 9-859 580 Portugal (351) 22 610 89 22

France (33) 1-64 76 1000 Spain (34) 945-18 4100

Germany (49) 6103 4020 Sweden (46) 8-603 0700

Greece (30) 1- 342 6076 Switzerland (41) 52-396 3131

Hungary (36) 1-371 1343 Turkey (90) 212 221 1512

Ireland (351) 1-403 9000 United Kingdom (44) 1908-56 3888

Websites

SMC Corporation www.smcworld.com

SMC Europe www.smceu.com

Bushing assembly part no. VKF300-6A-1

Grommet type DIN terminal

Red (+)

Black (-)

Surge voltage

suppressor * Marking

Light

(built into connector

Surge voltage

suppressor

(built into

terminal block)

* Markings

For 24V or more DC

For AC and 12V or less DC

1

(-) (+)

2

Gland nut

Washer

Grommet

(rubber)

Holding screw

Light mounting location

Terminal block

Notch

Terminal screw

(3 places)

Rating symbol

(see table below)

Housing

Appropriate tightening torque (Nm)

0.6 to 0.8

AC

Circuit diagram

12VDC or less

Circuit diagram

24VDC or more

Circuit diagram

LED

NL

RLED

R

R

2

22

111

NL: Neon light

R: Resistor

LED: Light emitting diode

R: Resistor

D: Protective diode

LED: Light emitting diode

R: Resistor

Mounting screw

Bushing

Switching element

Valve

OFF

Leakage current

Power

supply

Resistor

Leakage

voltage

Hole dia. ø5

ø9

D

VKF300-TFH35GB