daviteq CAP10G User manual

CAP10G-MN-EN-01

OCT-2020

CAP10G is the industrial version of PulseCAP10, designed specifically for generator fuel monitoring applications. The

CAP10 has 240..33 ohms resistor output allowing direct connection to a generator controller. It is compatible with most

popular generator controllers on the market such as DEEPSEA, EMKO, DATAKOM, COM AP, MGS, SMART GEN,

WOODWARD, POWERCOMMAND ... CAP10G with high precision up to 0.5%. Measuring range from 100mm - 3500mm.

The sensor has CE EMC certification according to EN61236-1 standard.

The technicians who install sensor, must be graduated from college of mechanic or electric.

The mechanical installation staff (drill, cut, grind, etc.) must have skills in mechanical engineering.

The electrical installation staff (connect, etc.) must have skills in electrical engineering.

The technician must be trained before using.

CAP10G is intended to use with Diesel Oil, Vegetable Oil.

CAP10G must not be used with other flammable fluid such as Gasoline, Alcohol, Ethanol, Acetone, Toluene or

other solvents.

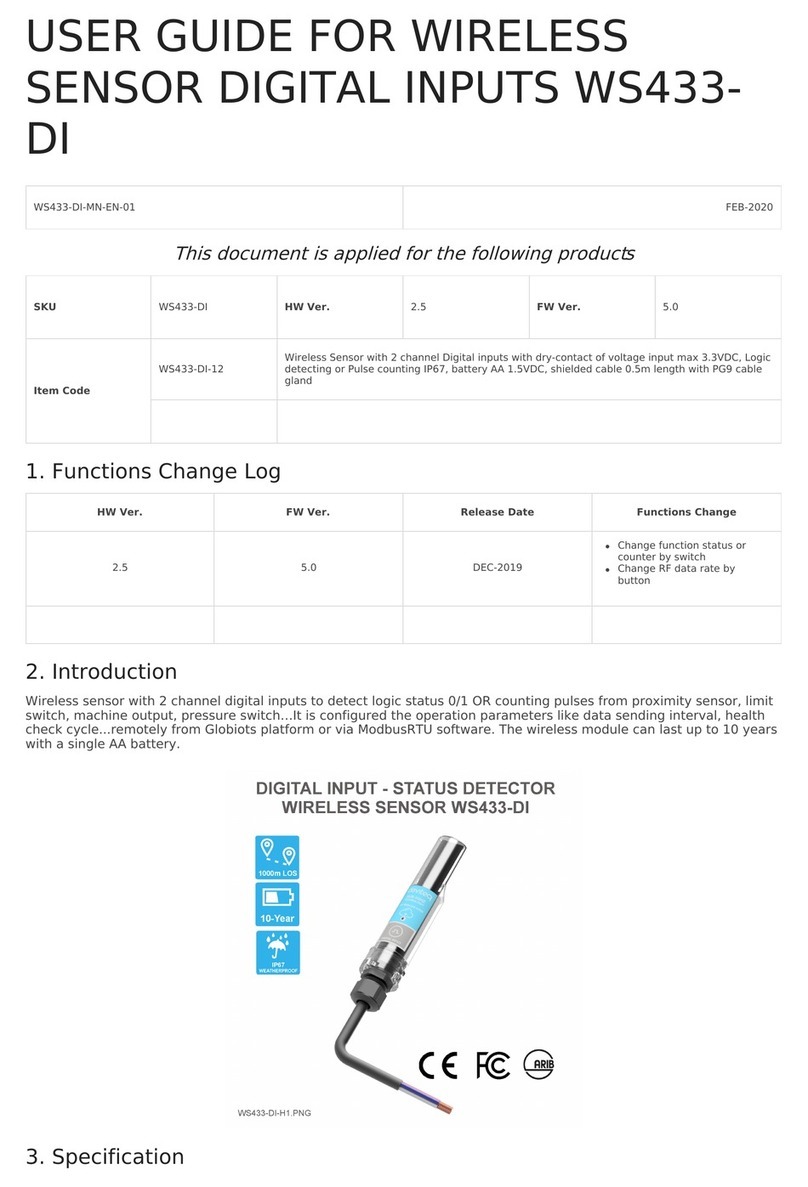

USER GUIDE FOR FUEL LEVEL

SENSOR RESISTIVE OUTPUT

CAP10G

This document is applied for the following products

1. Introduction

2. Notes

3. Safety

Be careful while drilling, cutting, grinding, etc. The fuel tank or other flammable fluid.

Daviteq is not responsible for compensation in case of explosion to bodily injury or property damage.

Read specifications thoroughly and make sure that its output are suitable to reading devices.

Power supply must be in the permitted range.

Do not take out the label and take off the lid as this will lead to the instability of the sensor and manufacturer

could deny warranty. (except cutting of sensor length within the allowed range).

Make sure all the necessary tools are ready before the installation.

CAP10G be equipped with screws. We advise customers should use stainless steel rivets to fasten

the plastic flange onto tank for all type of tanks and only using screws for the thick and hard ones.

Sensor length

Standard 700mm, 1000mm, optional 1200 or 1500mm. Cuttable down to

200mm. Longer than 1500mm, suggest to use Industrial type sensor

CAP10CN

Output

240..33 ohms

Power supply

8..50VDC

Consumption

max 20mA

Working pressure

-1 .. 2 barg

Working temperature

-40 oC .. + 85 oC

Accuracy

+/- 0.5% of span (at 25 oC)

Temperature drift

< + 0.03% of span per 10oC

Resolution

1/1000 of span

Sensor materials

Alloy & Engineering plastic

Electrical connection

3-way connector IP67 from MOLEX with 3m shielded cable as standard

Housing

Cast alumium, IP67 protection

Process connection

Plastic flange

Standard accessories

flange, o-ring, gasket, protection covers, self-tapping screws, twisted

seal, fuse & fuse holder

Certification

CE-Marking per EN61236-1 (with test report)

4. Note Before Installation

5. Specification

6. Full Package

No

Tool Name

No

Tool Name

01

Drilling machine

10

Drill (Φ38)

02

Pump

11

Silicone gasket

03

Rivet clippers

(In case of using stainless steel

rivet)

12

Twist drill 4 mm

(In case of using stainless steel

rivet)

04

Tube cutter

13

Electrical tape

05

Swivel Blade

14

Cutting pliers

06

Hacksaw

15

Phillips screwdriver

07

File

16

Pencil

08

Tape measures

17

Multi Meter

09

Allen key 2 mm

18

Calibration can

7. Tools

Step

Discription

Note

1

Remove fuel: Remove all fuel from the tank.

Some tank have been welded with oil filter and

have float level sensor installed, so it is

necessary to take out the float level sensor

before removing the fuel.

2

Clean the tank

Must clean the tank thoroughly.

3

Central hole locating: The hole will be in the

center of tank's up-per side or closest to

center.

This is an important step as it will directly

affect the stability of the fuel level data.

4

Drilling the central hole:

After determining the center of the oil

tank, we clean the surface and use a 38

mm drill to make a hole on the oil tank.

Remove any burrs from the drilled hole

by a file.

Before drilling, it is vital to check whether the

hole is affected by the internal metal frame or

obstacles at the bottom the tank.

5

Flange installation:

Place the 4 mm rubber gasket at the

center of the tank's upper side.

Place the plastic flange onto the rubber

gasket (4 mm).

Mark 4 points at the bolt hole.

Use screws /rivets to fasten the 4 mm

rubber gasket and the plastic flange

onto tank.

Only using screws for the thick and hard

tanks.

Unplug the screw/ rivet symmetrically.

8. Sensor Installation Guidance

6

Sensor cutting:

After flange installation, we determine the length of the sensor to be installed as picture below:

C = L+20+20-(H+14) => C = L+26-H (mm)

C: Length to be cut.

L: Original length of the sensor.

H: Height of the tank.

*Example:

Sensor length is L = 2000, H = 1700 mm => C = 326 mm => Cut the sensor pipe length of 326

mm.

7

Calibration:

After cutting, make sure the sensor tube is clean.

Re-plug the Filter footer and tighten the screw.

Turn on the sensor in at least 30 seconds in order for the sensor to automatically

recognize its new length.

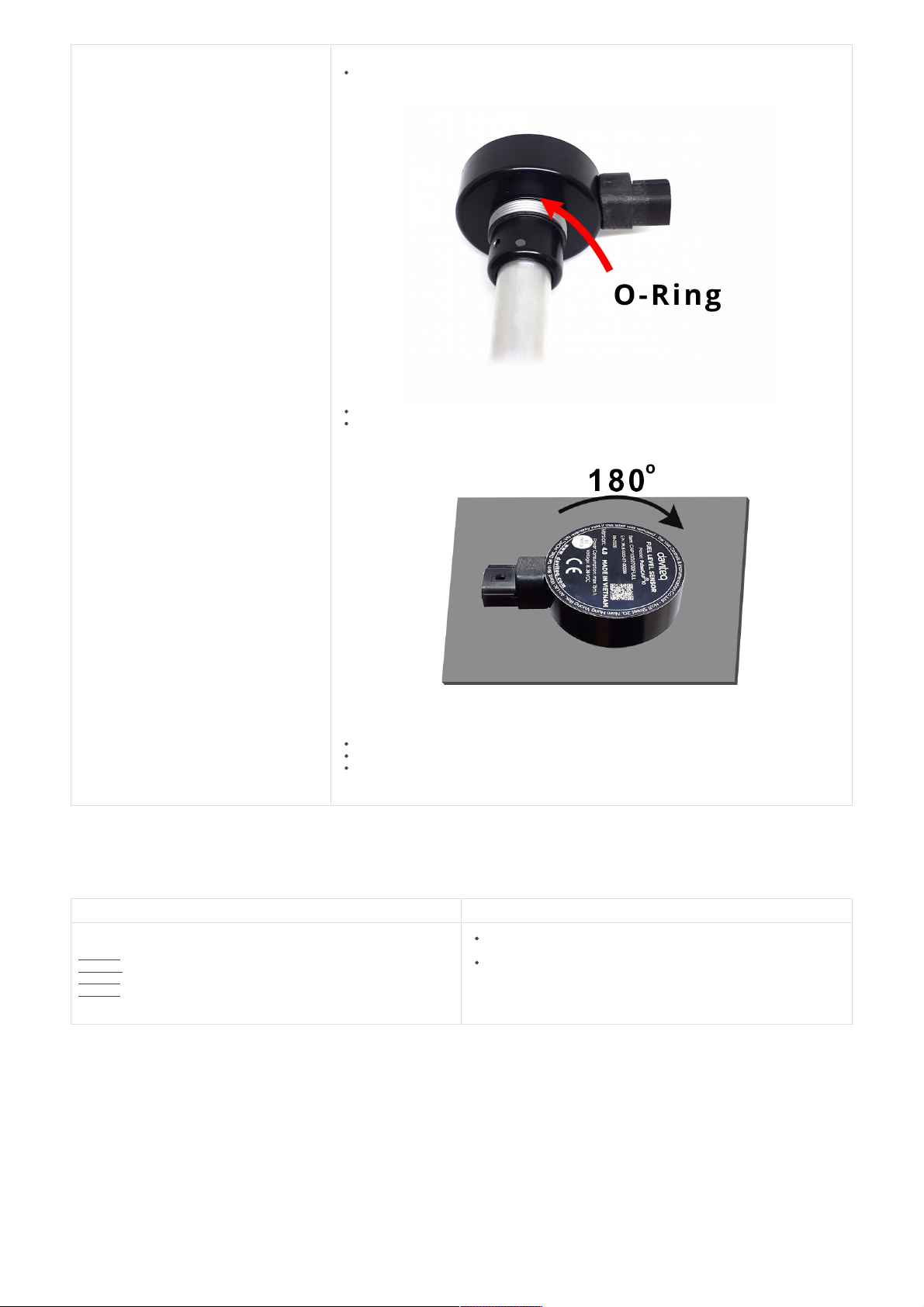

8

Final:

Place the O-ring on the top of the threads, ensure that it can touch the aluminum housing

of the sensor (as below picture):

Install sensor into the threads of flange and turn it in clockwise direction.

Using the O-ring enables to rotate the sensor within 180 degrees from final tighten

position and assuring that the oil will be not spilled (as below picture):

Use the 2mm Allen key to lock the hex bolt to protect the sensor rotate backwards.

Connect the sensor with the cable.

Use sensor head seal to cover the sensor and then use plastic and then use plastic twister

seal to lock the head seal and connector seal to protect the sensor.

Please follow the below steps:

Note

Step 1: Remove the cover

Step 2: Remove the terminal connector

Step 3: Use the 2 mm Allen key to unlock the hex bolt

Step 4: Turn the sensor in counter-clockwise direction

Do not hold the male connector to rotate sensor directly, that

can make the male connector broken.

Do not use locking pliers, pipe wrenches, etc. to twist the sensor

as this cause damages the structure of the sensor such as cast

aluminium housing, label, signal cables (connector), circuit

board, ect. and it will not be covered under warranty.

9. Disassembly Guidance

10. Wiring

Each cable includes wires which are marked labels according to types of connection. (user should not cut these labels

before installation to avoid confusing)

White: PWR+(8...50VDC)

Blue: PWR-(OVDC)

Black: Resistive Output (240.33 Ohm)

Recommend to use 24VDC power.

The signal cable from sensor should be protected by corrugated hose or the Φ16 plastic tube, keep the cable avoid

high temperature areas.

10.1 Follow Labels in Wires:

10.2 Follow Wire Colors:

1. Periodically clean the oil tank 2, 3 or 6 months depending on usage and contamination.

2. Periodically clean the sensor and filter footer 2, 3 or 6 months by:

Cover a sensor's vent before using the air sprayer for another.

Remove and clean the filter footer.

No.

Phenomena

Reasons

Solutions

1

No output

Sensor's powering wire is

damaged

Check out on the sensor's

powering wire

Overpowering has burnt the signal

cable and circuit board

Send to manufacturer

Being tampered

Check the seal again before

sending back to manufacturer

2

Signal interference

Sensor was installed too far from

central hole of tank

Install sensor as closest as

possible to the central hole of tank

(the common point of 02

diagonals)

11. Periodic Cleaning Guidance

12. Troubleshooting

3

Unstable output with many

significant strikes

Accesories burnt or there is liquid

inside of board

Send to manufacturer

Connection to power supply is

loose

Check the connection wire

There are impurities in oil tank,

such as: boil, mud, sand, water,...

Clean tank as well as sensor

Warranty is applied for CAP10G fuel level sensor manufactured by Daviteq Technologies Inc (Daviteq).

CAP10G fuel level sensor will be warranted for a period of eighteen (18) months from date of delivery.

1. Manufacturer undertakes to guarantee within 18 months.

2. Product failed due to defects in material or workmanship.

3. Serial number, label, warranty stamp remains intact (not purged, detected, edited, scraped, tore, blurry,

spotty or pasted on top by certain items).

4. During warranty period, if any problem of damage occurs due to technical manufacturing, please notify our

Service Centre for free warranty consultancy. Unauthorized treatments and modifications are not allowed.

5. Product failed due to the defects from the manufacturer, depending on the actual situation, Daviteq will

consider replacement or repairs.

Notes:

One way was shipping cost to the warranty centre shall be paid by Customers.

1. The warranty period has expired.

2. Product is not manufactured by Daviteq.

3. Product failed due to damage caused by disasters such as fire, flood, lightning or explosion, etc.

4. Product damaged during shipment.

5. Product damaged due to faulty of installation, usage or power supply.

6. Product damaged caused by the customer.

7. Product rusted, stained by effects of the environment or due to vandalism, liquid (acids, chemicals, etc.)

8. Product damaged caused by unauthorized treatments and modifications.

Note:

Customers will be subjected to all repairing expense and shipping cost.

If it arises disagreement with company's determining faults, both parties will have a third party inspection

appraise such damage and its decision be and is final decision.

Warranty service support is available from Monday to Friday (excluding Public Holidays as prescribed)

08:00 AM - 12:00 AM

01:30 PM - 05:00 PM

Hotline: +84.906.885.858

13. Warranty

13.1 Free Warranty Condition:

13.2 Paid Warranty

14. Support contacts

Manufacturer

Daviteq Technologies Inc

No.11 Street 2G, Nam Hung Vuong Res., An Lac Ward, Binh Tan Dist., Ho Chi Minh City, Vietnam.

Tel: +84-28-6268.2523/4 (ext.122)

Email: info@daviteq.com | www.daviteq.com

Revision #2

Created Fri, Oct 16, 2020 6:19 AM by Kiệt Anh Nguyễn

Updated Fri, Oct 16, 2020 7:31 AM by Kiệt Anh Nguyễn

Table of contents

Other daviteq Accessories manuals

daviteq

daviteq WSSFC-ULA-01 User manual

daviteq

daviteq WS433-O2 User manual

daviteq

daviteq WSLRW-AG Series User manual

daviteq

daviteq WS433-AC User manual

daviteq

daviteq WS433-M12F-ATE User manual

daviteq

daviteq A420-FCL User manual

daviteq

daviteq LoRaWAN User manual

daviteq

daviteq WSSFC-AC User manual

daviteq

daviteq CAP10 User manual

daviteq

daviteq WSSFC-V1A-025 User manual

Popular Accessories manuals by other brands

WHISPER KOOL

WHISPER KOOL WK 2500 owner's manual

ICON

ICON Mobile Umini VST user manual

Heath Zenith

Heath Zenith Motion Sensor Entryway Light SL-5610/15 quick start guide

MasterChef

MasterChef EH-380-16 instruction manual

HOMEDEPOT

HOMEDEPOT L-BC205PST Use and care guide

In-situ

In-situ Aqua TROLL 500 overview