daviteq WSLRW-AG Series User manual

Thank you very much for choosing Daviteq Wireless Sensors. We are the leading wireless sensor manufacturer in the

World. We have a wide range of wireless sensors which support different connectivity like LoRaWAN, Sigfox, Sub-GHz,

NB-IoT...Please find out more information at this link.

This manual is applied to the following products

Item code

HW Version

Firmware Version

Remarks

WSLRW-AG-...

1

2

Information Changes in this version v.s previous version

Item

Changes

Changed by

Changed Date

Approved by

Approved Date

2

Improve accuracy and

resolution on FW 2

P.N.Diep

07-09-2022

N.V.Loc

07-09-2022

1

Initial version FW 1

P.N.Diep

01-06-2022

N.V.Loc

02-06-2022

To use this product, please refer step by step to the below instructions.

Operating Principle

Uplink Payload

Battery

Connect to the LoRaWAN Gateway

Installation

Troubleshooting

Configuration

Calibration

Specification

Warranty and Support

WSLRW-AG is a LoRaWAN Tilt Sensor that can measure 3 tilt angles X, Y, and Z of any object such as a Tower, Building,

Manual for LoRaWAN AG Tilt Angle

Sensor - WSLRW-AG | FW 2

1. Quick Guide

Reading time: 10 minutes

Finish this part so you can understand and put the sensor in operation with the default configuration from the

factory.

1.1 What is the LoRaWAN AG Tilt Sensor and its principle of

operation?

Tree, Electricity Tower, Telecom Tower, Bridges... The Tilt sensor utilizes the combination of an

advanced Accelerometer and Gyro meter to deliver high accuracy and stable measurement of the Tilt angle of 03 axis

X, Y, and Z. With Ultra-low Power design and smart firmware allows the sensor can last up to 10 years with 02 x AA-

type battery (depends on configuration). The sensor will transmit data in kilo-meters distance to the LoRaWAN

gateway, any brand on the market.

Please refer to this link for the AG Tilt Sensor's principle operation.

Please refer to this link for typical applications.

The device will send uplink messages in the following cases:

Case 1: After power-up in the 60s, the device will send the first message called START_UP. The payload will tell

the user the HW version, FW version, and current configuration of the device;

Case 2: Then, in every interval time (pre-configured), for example, 10 minutes, it will send the message called

CYCLIC_DATA. The payload will tell the user the following data like measured values, battery level, alarm status...

Case 3: During commissioning, testing, or calibration sensor, the user can force the device to send the uplink

message to get the data immediately. This message is called FORCE_DATA. The payload will provide data like

raw measured value, scaled measured values, battery level, alarm status... It can be forced by applying the

magnet key on the reed switch in 1s;

Case 4: If users want to change the configuration immediately, they don't need to wait until the next cyclic data

sending message, instead they can force the device to send a special uplink message so that the device can get

the new downlink message. This uplink message is named PARAMETERS_UPDATE. It can be forced by applying

the magnet key in more than 5s.

The sensor was pre-configured at the factory with default values for configuration parameters that meet most use

cases. However, depending on the specific use case, the customer can adjust those parameters. Please refer to

section 3.2 for more details.

The sensor is powered by 2 x AA 1.5V batteries for many years of operation. We recommend using Energizer L91

battery which is very popular and high performance. This battery has a capacity of up to 3500mAh with a working

temperature range from -40 to +60 oC. The instruction for installing the batteries is in this link.

For Battery life estimation, please refer to this link.

With the default configuration, the device can be connected quickly to the Network Server by the following steps.

Frequency zone

Most of the sensor was configured the frequency zone to suit customer

application before delivery

DevEUI

Get the DevEUI on the product nameplate

1.1.1 What are the typical applications of this sensor?

1.1.2 When does the device send uplink messages?

To change the cycle of data sending, you can change the value of the parameter: CYCLIC_DATA_PERIOD (default

is 600 seconds).

1.1.3 The important configuration parameters

1.1.4 What kind of battery is used for this sensor?

1.2 What's in the package?

The package includes:

01 x Main device

01 x Magnet key

01 x Wall mounting bracket and screws

1.3 Quick Test for LoRaWAN Sensor

Step 1: Prepare the values of communication settings:

AppEUI

Default value: 010203040506070809

AppKey

Default value: 0102030405060708090A0B0C0D0E0F10

Activation Mode

OTAA with local join server

Network Mode

Public

LoraWAN Protocol version

1.0.3

Class

A

Input the above settings on your device registration page of the network server.

Please visit this link to get the instructions for adding the LoRaWAN sensors to some common network servers such as

Actility, TTN...

Refer to this link for details.

Please refer to section 1.4 Uplink Payload and Data Decoding for details of decoding the receiving packet.

For the Uplink Payload structure, please refer to this link.

Note: If the above settings do not match your network server/application, please refer to section 3.2 Sensor

configuration to change the settings

Step 2: Register the device on the LoRaWAN network server.

Note: Different network server software will have different device registration processes. Please refer to the

manual of the network server software used for more details.

Step 3: Install the batteries to the device

After installing the battery in 60 seconds, the first data packet will be sent to the LoRaWAN gateway. After

receiving the first data packet, the time of another packet depends on the value of the parameter:

cycle_send_data. Additionally, you can use a Magnet Key to force the device to send data instantly.

Step 4: Decode the payload of receiving package

1.4 Uplink Payload and Data Decoding

Note: Please select the right Payload document to suit the FW version of the sensor

1.5 Sensor Installation

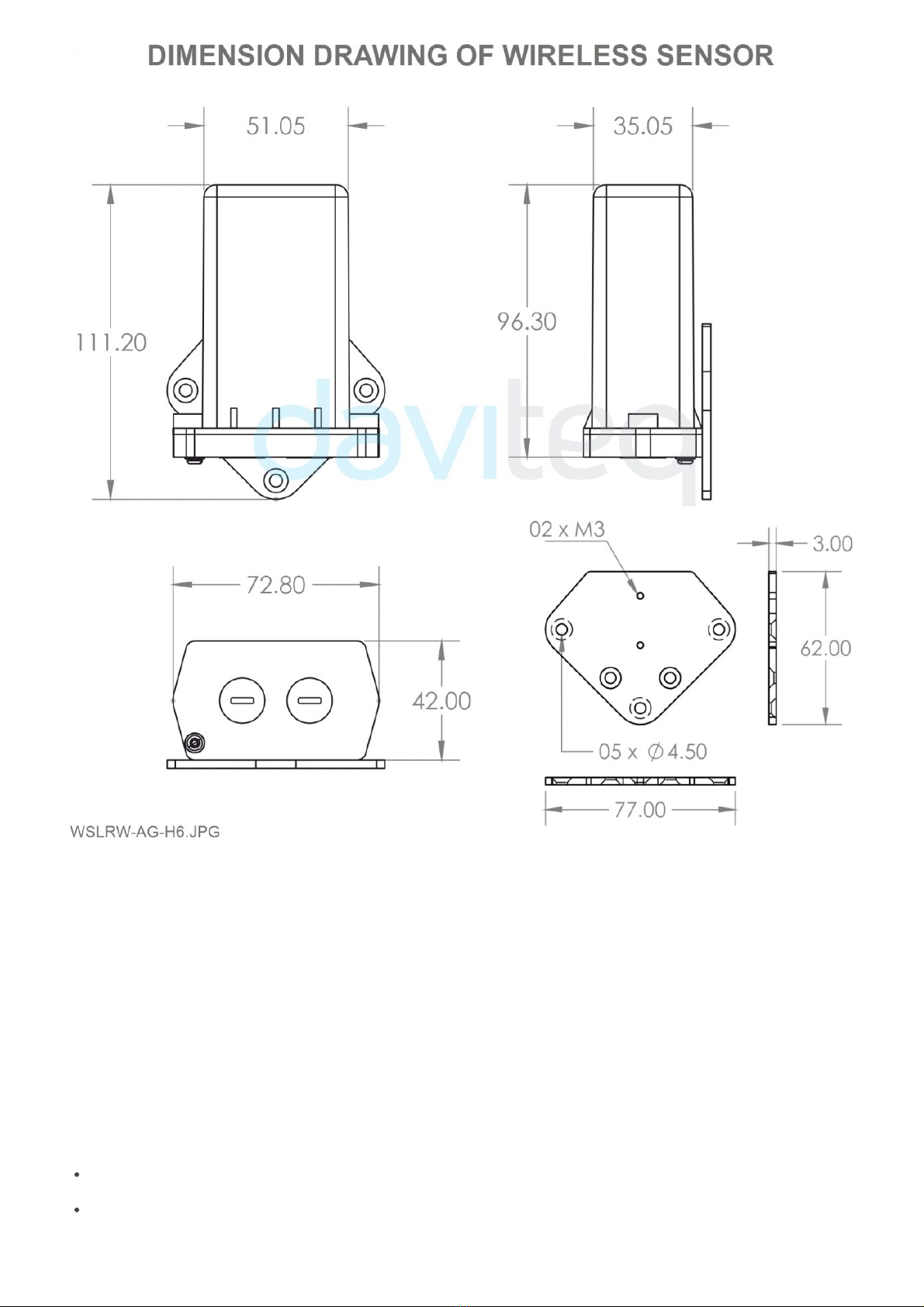

1.5.1 Dimension drawings

Please follow the instructions in this link.

The LoRaWAN AG Tilt sensor is pre-calibrated at the factory. There is no need to re-calibrate it at the field.

Please follow this link.

Problems with LoRaWAN communication like not receiving the packets...please refer to this link to

troubleshoot the device.

Problems with the sensor functions like not measuring or inaccurate measuring....please refer to this link to

troubleshoot the sensor part.

1.5.2 Battery Installation

1.5.3 Sensor calibration and configuration

1.5.4 Sensor mounting on wall or pole

2. Maintenance

2.1 Troubleshooting

Maintenance works

Yes/No

Descriptions

Consumable parts replacement

Yes

The battery is the only part need to check the

lifetime to replace. Check the battery status on

the back-end system.

Cleaning device

No

Re-calibration / Re-validation

No

No calibration is required for the wireless

transmitter.

Please refer to this link.

The Daviteq LoRaWAN AG Tilt Sensor comprises 02 parts linked internally:

- The Daviteq LoRaWAN wireless transmitter;

- The Daviteq AG tilt sensor;

The AG Tilt sensor module measures the Acceleration of the 3-axis.

2.2 Sensor maintenance

2.2.1 Maintenance of Wireless transmitter

2.2.2 Maintenance of the AG Tilt sensor

3. Advanced Guide

3.1 Operating principle of LoRaWAN AG Tilt Sensor

3.1.1 Operating principle of the complete device

The LoRaWAN wireless transmitter is to read the measurement values from the AG sensor and performs the calculation

to deliver the desired output values, then it sends data to the gateway in the following cases:

- Case 1: when the time of the Data sending cycle is reached.

- Case 2: when the device is forced to send data by a Magnet key.

To understand how the AG Tilt sensor work, please refer to this link for a complete understanding of this measuring

technique.

Below are some important configuration parameters which affect the operation of the device.

measure_period | Default = 600s

This is the time period for the wireless transmitter to wake up and take the measurement from the sensor. The

default value is 600s. Users can reduce this value, but smaller value, shorter battery life!

cyclic_data_period | Default = 600s

Interval time to send an uplink message regardless of any conditions

Those configuration parameters can be changed by downlink or offline tools. For more other configuration parameters,

please refer to the next section.

Sensor configuration can be configured in 02 methods:

Method 1: Configuring via Downlink message. Please find the instructions in this link, but please take note of

the FW version of the Document.

Method 2: Configuring via offline cable.

Some parameters are read-only, and some are read and writeable.

To read the parameters, use the off-line cable as above instruction.

To write the parameters, use the off-line cable or downlink as above instructions.

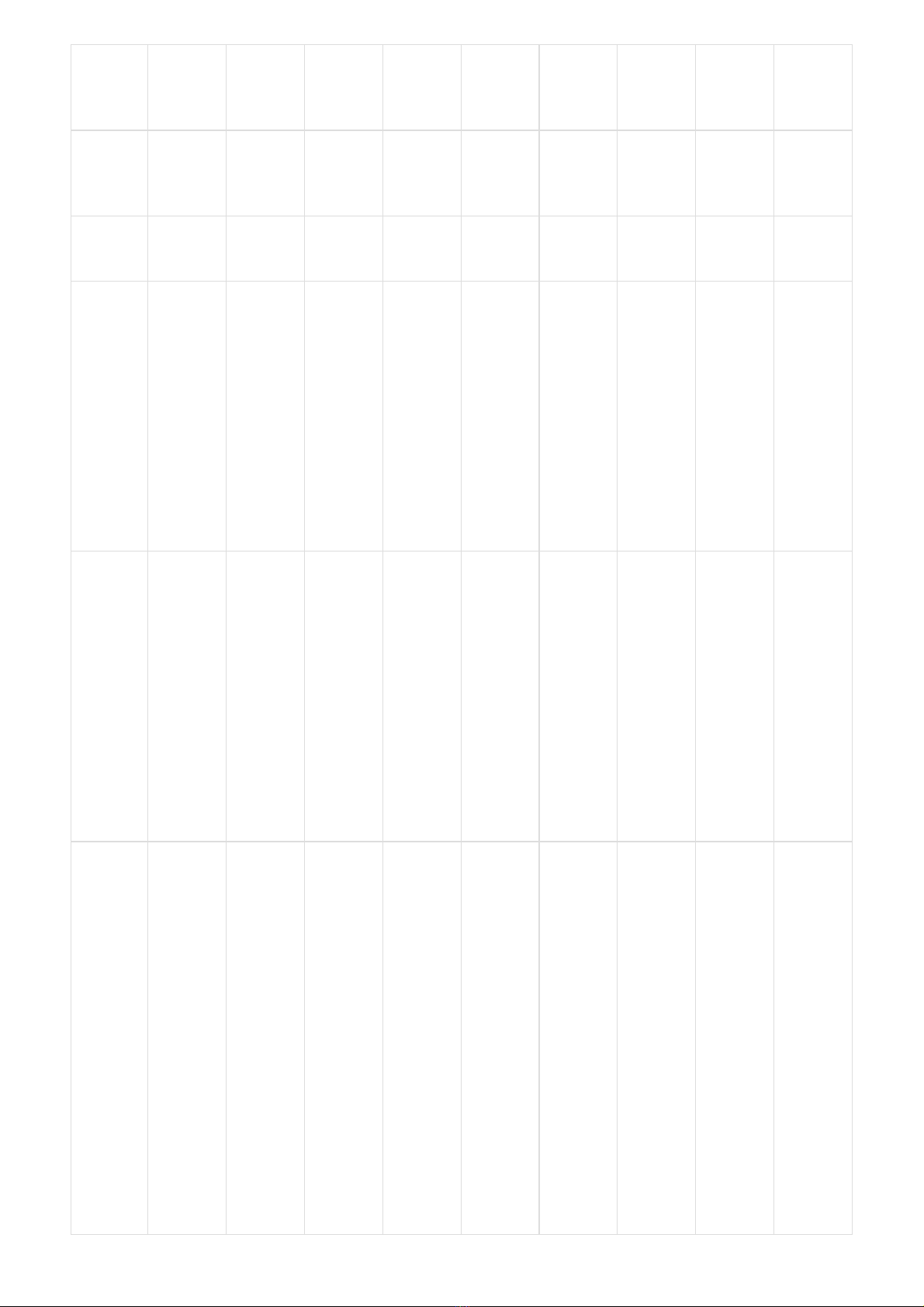

Below tables are the lists of the parameters of the device.

Read-only Parameter Table

Modbus

Register

(Decimal)

Modbus

Register

(Hex)

Function

Code

# of

Registers

Description

Range

Default

Format

Property

Comment

0

0

3

5

device info

string

Read

Wireless

Sensor

LoRaWAN

G4 Gas

Sensor

5

5

3

4

firmware

version

1.00ddmm

string

Read

ddmm =

day / month

9

9

3

2

hardware

version

1.10

string

Read

3.1.2 Operating principle of AG Tilt sensor

3.1.3 Some important configuration parameters

3.2 Sensor Configuration

3.2.1 How to configure the LoRaWAN sensor?

Note: THE SENSOR IS ONLY ACTIVE FOR OFFLINE CONFIGURATION IN THE FIRST 60 SINCE POWER UP

BY BATTERY OR PLUGGING THE CONFIGURATION CABLE.

3.2.2 What parameters of the device are configured?

11

B

3

4

lorawan

protocol

version

01.01.00

string

Read

LoRaWAN

v1.0.3

15

F

3

6

application

version

01.03.00.00

string

Read

application

server

v1.3.0.0

21

15

3

6

mac layer

version

04.04.02.00

string

Read

mac layer

v4.4.2.0

27

1B

3

4

deviceEUI

hex

Read

End

Device's

EUI

number,

used to

register the

product on

the Network

Server by

OTAA

31

1F

3

4

Lora appEUI

hex

Read

Application

server's EUI

number is

used to

register the

product on

the Network

Server by

OTAA

35

23

3

8

Lora

appKey

hex

Read

The number

of keys

used to

create two

security

keys of the

End Device,

used to

register the

product on

the Network

Server by

OTAA

43

2B

3

8

Lora

nwkSkey

hex

Read

key number

encrypts

the

communication

command

of the MAC

layer of the

End Device,

which is

used to

register the

product on

the Network

Server by

ABP

51

33

3

8

Lora

appSkey

hex

Read

End Device

data

encryption

key

number,

used to

register the

product on

the Network

Server by

ABP

59

3B

3

2

device

address

0

uint32

Read

End Device

address

created by

the

Application

server,

used to

register the

product on

the Network

server by

ABP

61

3D

3

2

network ID

0

uint32

Read

Network

server ID

number,

used to

register the

product on

the Network

server by

ABP

63

3F

3

2

join mode

OTAA

string

Read

OTAA:

Over-the-Air

activation,

ABP:

Activation

by

Personalization

65

41

3

4

network

mode

PUBLIC

string

Read

PUBLIC,

PRIVATE

69

45

3

3

region code

AS923

string

Read

1: AS923, 2:

KR920, 3:

AU915, 4:

US915, 5:

EU868, 6:

IN865, 7:

RU864, 8:

CN779, 9:

CN470, 10:

EU433

72

48

3

4

data rate

DR2:980

string

Read

DR0:250,

DR1:440,

DR2:980,

DR3:1760,

DR4:3125,

DR5:5470

76

4C

3

3

bandwidth

BW125

string

Read

BW125,

BW250,

BW500

79

4F

3

2

spread

factor

SF10

string

Read

SF12, SF11,

SF10, SF9,

SF8, SF7

81

51

3

4

activation

of ADR

ADR OFF

string

Read

ADR ON,

ADR OFF

85

55

3

1

class

A

string

Read

103

67

3

1

sensor type

1-255

uint16

Read

1-254:

sensor

type, 255:

no sensor

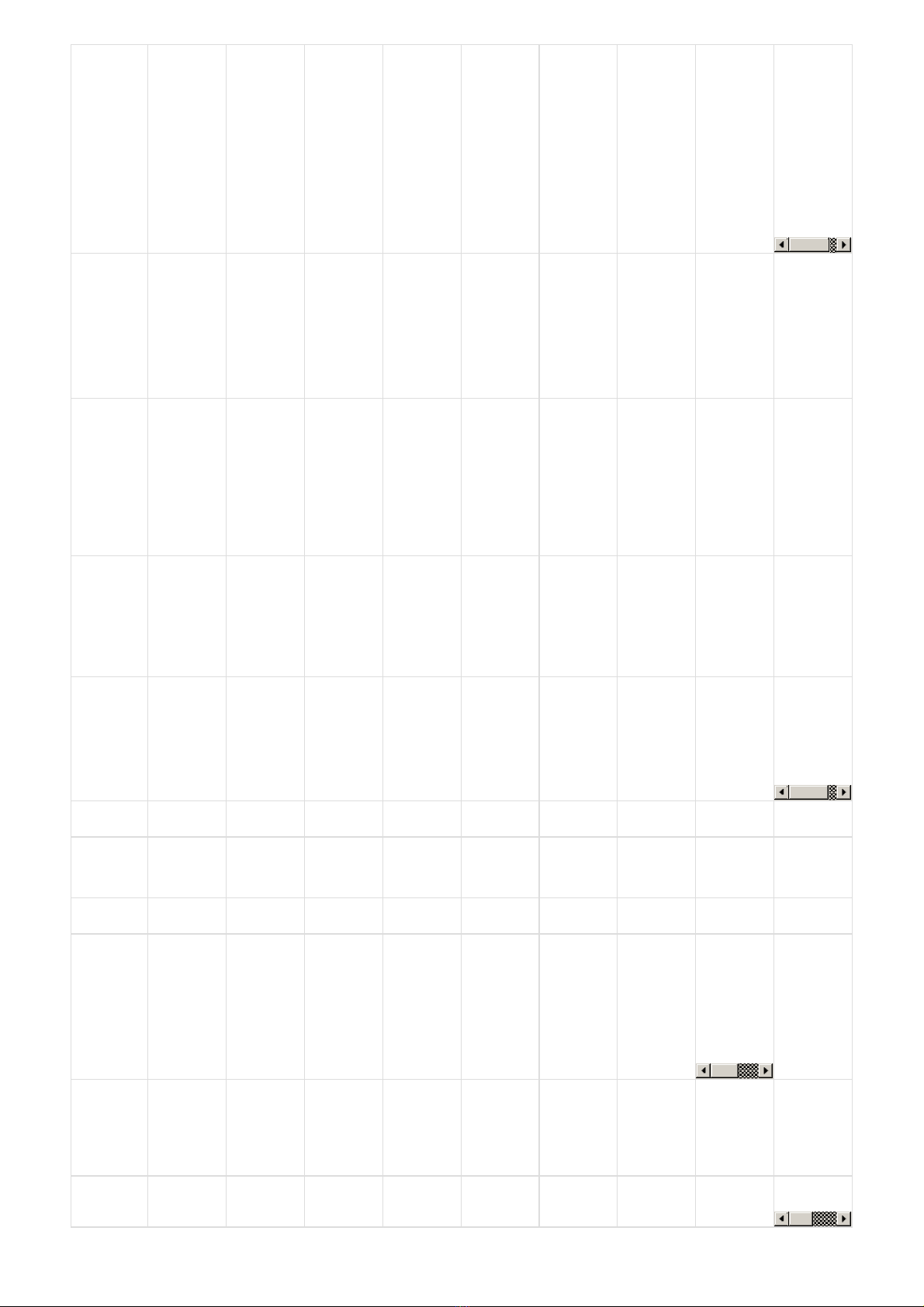

Read/Write Parameter Table

Modbus

Register

(Decimal)

Modbus

Register

(Hex)

Function

Code

# of

Registers

Description

Range

Default

Format

Property

Comment

256

100

3 / 16

1

Modbus

address

1-247

1

uint16

R/W

Modbus

address of

the device

257

101

3 / 16

1

Modbus

baudrate

0-1

0

uint16

R/W

0: 9600, 1:

19200

258

102

3 / 16

1

Modbus

parity

0-2

0

uint16

R/W

0: none, 1:

odd, 2:

even

259

103

3 / 16

9

serial

number

string

R/W

(Password)

268

10C

3 / 16

2

password

for setting

uint32

R/W

(Password)

password

190577

270

10E

3 / 16

4

Lora appEUI

hex

R/W

(Password)

Application

server's EUI

number,

used to

register the

product on

the Network

Server by

OTAA

274

112

3 / 16

8

Lora

appKey

hex

R/W

(Password)

The number

of keys

used to

create two

security

keys of the

End Device,

used to

register the

product on

the Network

server by

OTAA

Note: Please check the column Property to identify which parameter requests a password for writing a new

value. In this case, the user needs to input the password (190577) into the parameter name "password for

setting" at address 268.

282

11A

3 / 16

8

Lora

nwkSkey

hex

R/W

(Password)

key number

encrypts

the

communication

command

of the MAC

layer of the

End Device,

which is

used to

register the

product on

the Network

Server by

ABP

290

122

3 / 16

8

Lora

appSkey

hex

R/W

(Password)

End Device

data

encryption

key

number,

used to

register the

product on

the Network

Server by

ABP

298

12A

3 / 16

2

device

address

uint32

R/W

(Password)

End Device

address

created by

the

Application

server,

used to

register the

product on

the Network

server by

ABP

300

12C

3 / 16

2

network ID

uint32

R/W

(Password)

Network

server ID

number,

used to

register the

product on

the Network

server by

ABP

302

12E

3 / 16

1

activation

mode (join

mode)

0-1

1

uint16

R/W

(Password)

1: OTAA

(Over-the-

Air

Activation),

0: ABP

(Activation

by

Personalization)

303

12F

3/16

1

downlink

flag

0-1

1

unint16

R/W

1: Enable

0: Disable

304

130

3 / 16

1

application

port

1-255

1

uint16

R/W

(Password)

Port 224 is

reserved

for

certification

305

131

3/16

1

network

mode

0-1

1

uint16

R/W

1: Public, 0:

Private

317

13D

3 / 16

1

region

1-7

1

uint16

Read/Write(Password)

1: AS923-1,

2: KR920,

3: AU915,

4: US915,

5: EU868,

6: IN865, 7:

RU864, 8:

AS923-2, 9:

AS923-3,

10: AS923-

1 Japan

318

13E

3 / 16

1

data rate

7

uint16

R/W

(Password)

0: 250 bps,

1: 440 bps,

2: 980 bps,

3: 1760

bps, 4:

3125 bps,

5: 5470 bps

319

13F

3 / 16

1

tx power

2-20

16

uint16

R/W

(Password)

tx power:

2,4,6,8,10,12,14,16,18,20

320

140

3 / 16

1

adaptative

data rate

0-1

0

uint16

R/W

(Password)

Automatically

adjust data

rate, 0:

disable, 1:

enable

330

14A

3/16

4

current_configuration

hex

R/W

current

configuration

code of the

device

Please refer to this link.

Please refer to the detailed specifications in this link.

For warranty terms and support procedures, please refer to this link.

Use-cases:

Case studies:

White-papers:

END.

Revision #3

Created Tue, Sep 20, 2022 1:36 PM by Lộc Vĩnh Nguyễn

Updated Tue, Sep 20, 2022 2:15 PM by Lộc Vĩnh Nguyễn

3.3 Calibration or commissioning for AG Tilt sensor

4. Product specification

5. Warranty and Support

6. References

Table of contents

Other daviteq Accessories manuals

daviteq

daviteq WS433-O2 User manual

daviteq

daviteq WS433-M12F-ATE User manual

daviteq

daviteq WS433-AC User manual

daviteq

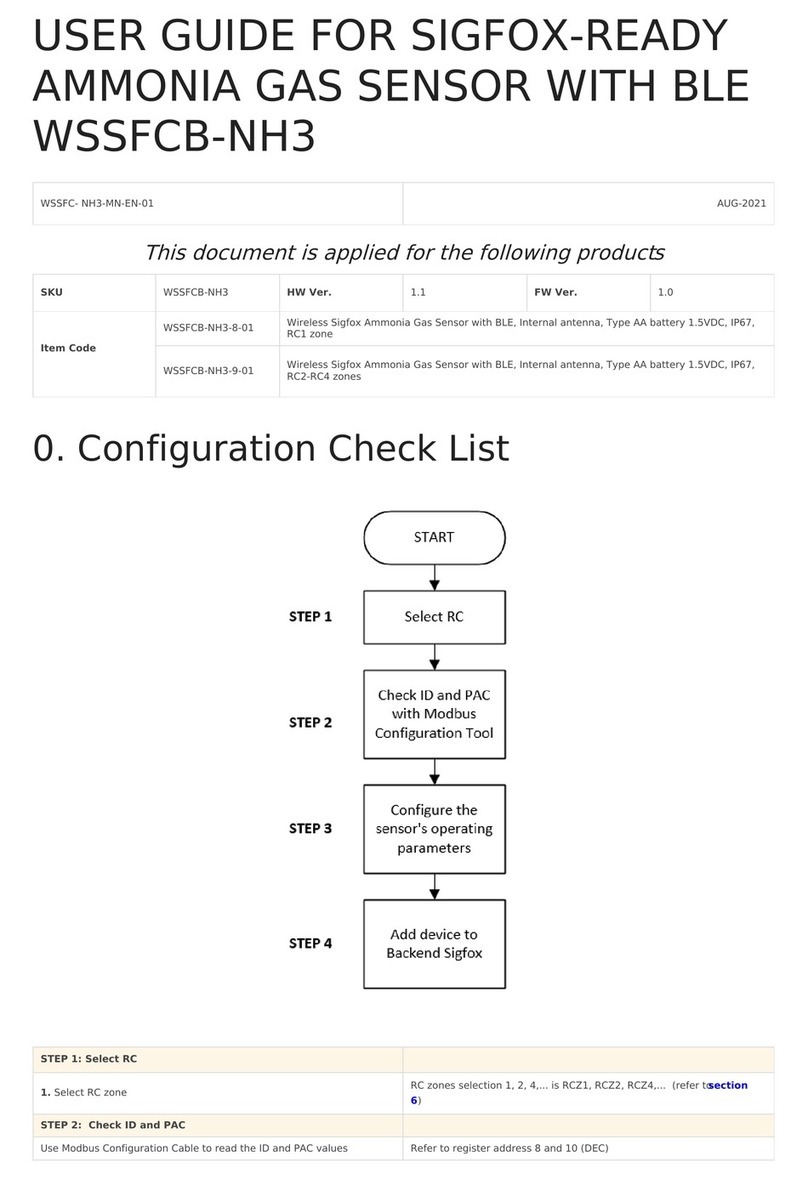

daviteq WSSFCB-NH3 User manual

daviteq

daviteq WSSFC-ULA-01 User manual

daviteq

daviteq WS433-TAG User manual

daviteq

daviteq CAP10 User manual

daviteq

daviteq LoRaWAN User manual

daviteq

daviteq A420-FCL User manual

daviteq

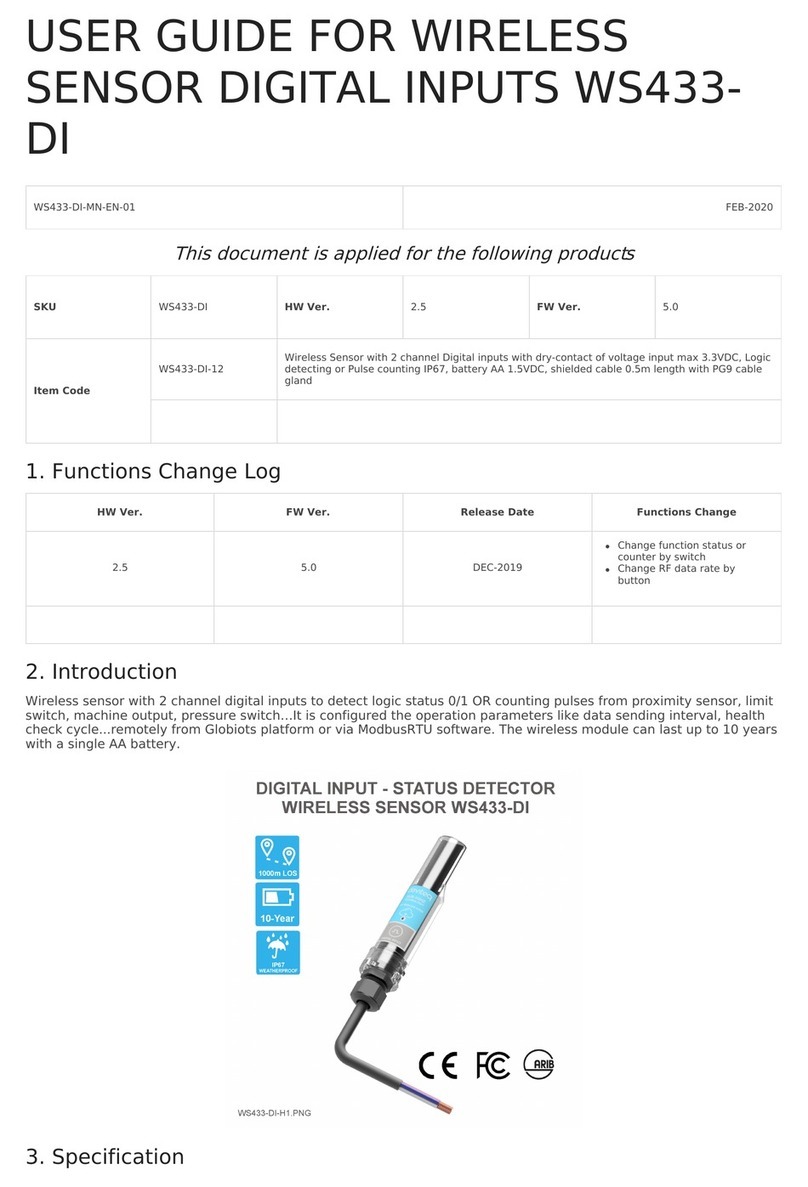

daviteq WS433-DI User manual