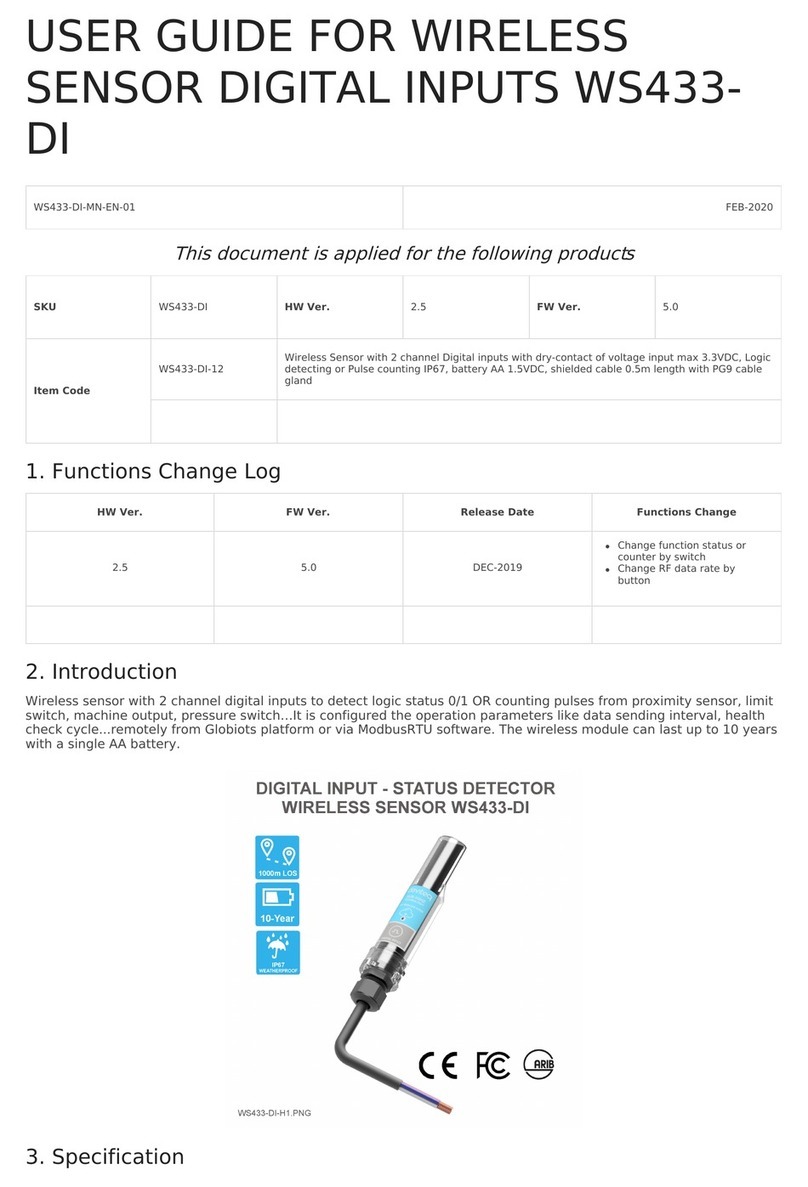

daviteq A420-FCL User manual

A420-FCL-01

JUN-2021

Free Chlorine Sensor with Analog output A420-FCL

The Chlorine Electrode is an amperometric (or polarographic) electrode (or “probe”) used for continuous measurement

of chlorine in drinking water, swimming pools, spas, industrial applications, or dirty/colored samples where colorimetric

methods are inadequate. A 3-electrode system is employed for ensuring good linearity between the output and the

chlorine concentration (up to 50 ppm). The bound membrane sensor cap provides good stability and durability for this

product. In addition, our proprietary Internal Filled Gel (IFG) significantly reduces the electrode measurement’s pH

dependence.

In principle, the chlorine electrode measures the total chlorine of the water sample via the measurement mechanism

described below. However, free chlorine measurement is also feasible when the chloramine concentration is negligible

or constant and calibrated for free chlorine.

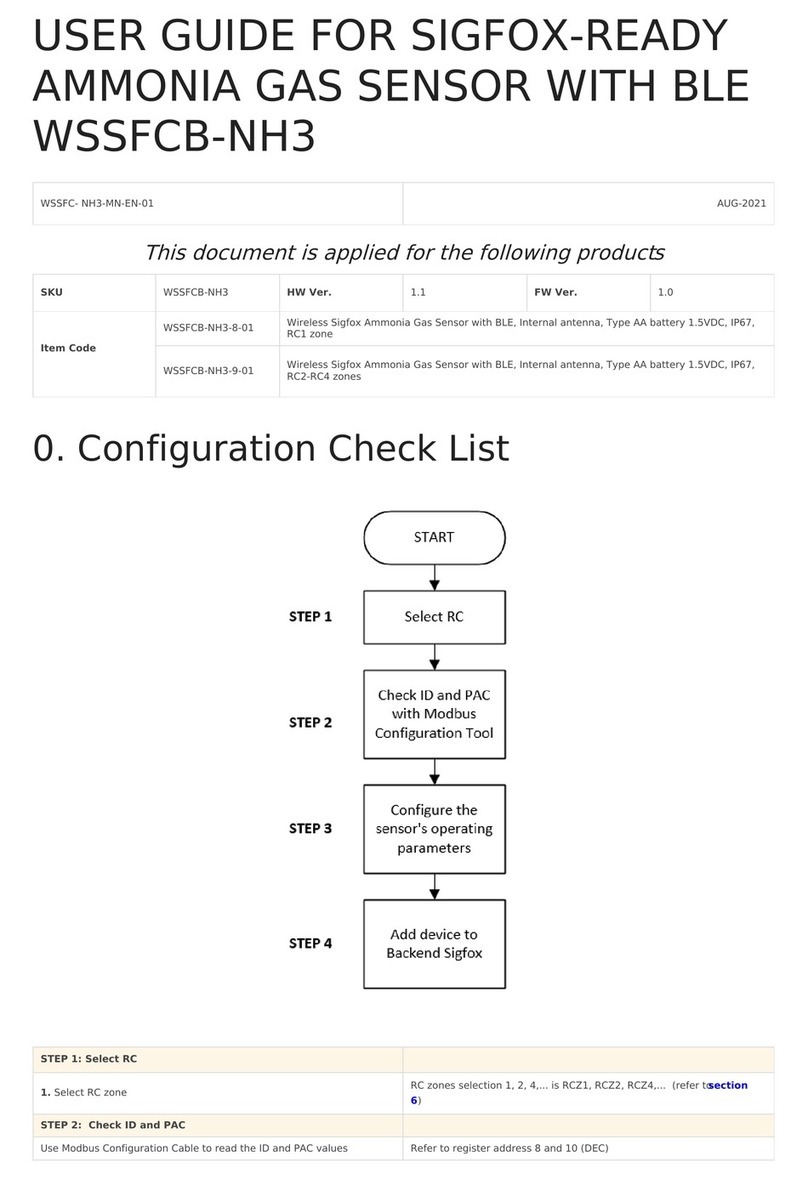

User Guide For Free Chlorine

Sensor with Analog output A420-

FCL

This document is applied for the following products

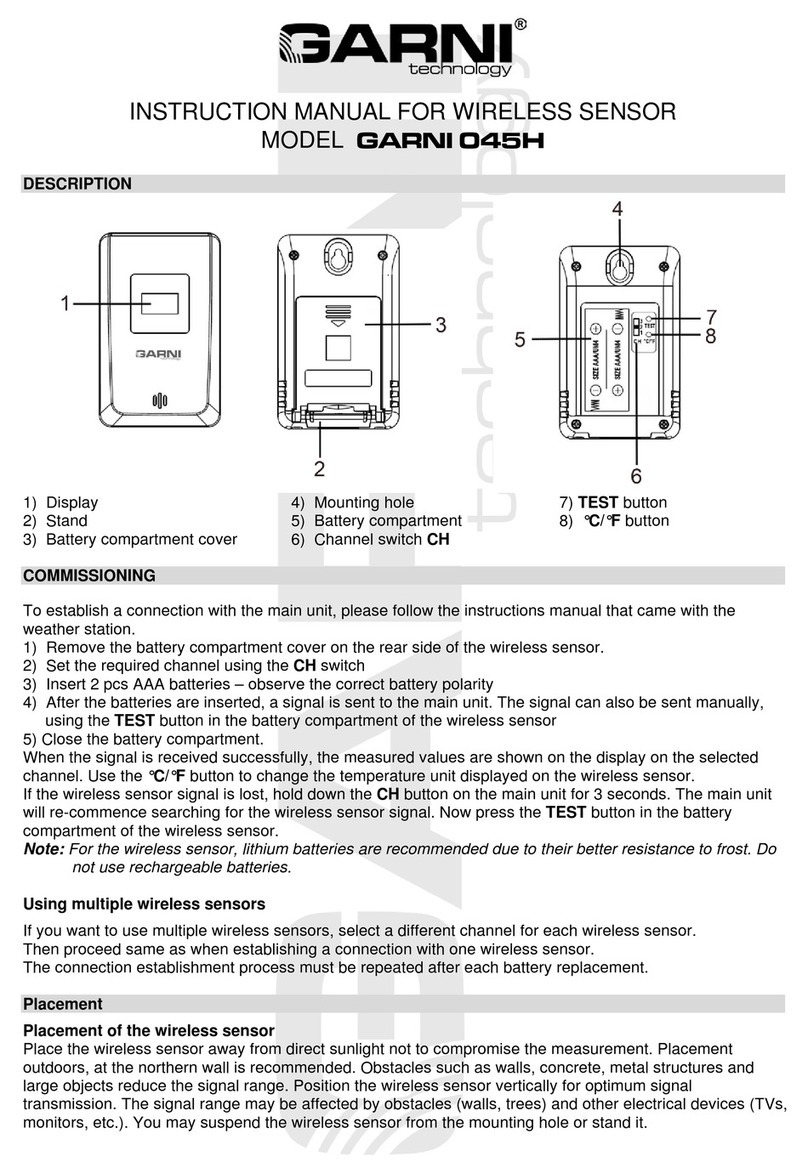

1. Introduction

Sensing Technology

Two-electrode amperometric technology with gas permeable membranes

(replaceable)

Measuring range

0-10mg/L or 0-20mg/L

Accuracy & Resolution

+/- 0.1 mg/L

Repeatability

+/- 0.05 mg/L (25 oC)

Response Time

T90 < 90s (25 oC)

Working Condition

0 .. 50 oC with pH = 5 .. 9

Working Pressure

0 .. 15 psig

Flow range

30 .. 60 L/h or 0.6 .. 1.3 cm/s

Output

4-20mA

Power supply

6..12VDC, avg. < 200mA

Conditioning

New, first start-up: at least 4hours Restart-up: < 30 min.

Calibration

One Point - Manual with DPD

Interferences

ClO2, Ozone, Bromine Cyanuric Acid compatible

Process connection

1/2" NPT

Wetted parts

PVC, Silicone, ABS, PES

Silver-Silver Halide/Platinum

Sensor Cable

6m with BNC connector

Rating

IP68

Sensor Dimension

D21.3 x 219 (mm)

Sensor net weight

< 200 grams

Warranty

1 year for probe, membrane for 03 months

The Chlorine Electrode is designed to operate with 9-24 VDC power. Connecting the electrode to any power outside the

normal range may result in electrode damage and void the warranty.

In addition to complying with the instructions included in this manual, be sure to follow the applicable

analyzer/controller/meter instructions regarding electrode wiring.

The membrane cap needs to be filled with Internal Filled Gel(IFG) before using the electrode.

Safety Data Sheets (SDS) for information on safe handling of chemicals for operating the electrode should be made

available to all personnel involved in installation, testing, and ongoing use, as needed.

2. Specification

3. Installation

IMPORTANT NOTES:

1. Ensure you have the necessary components to assemble the

electrode

Internal Filled Gel (IFG)

Electrode & Membrane Cap

Protection Boot

Electrode polishing strips

2. Remove the protection boot from the electrode or membrane cap

3. Lift the silicone band covering the vent hole. Make sure the vent hole

(see arrow in image) is open to air. Avoid using any sharp tools for this

step. Set the membrane cap aside.

► Note:Avoid damaging the Silver Halide Coating(gray portion)

4. Polish the working electrode (WE) surface (see arrow) with the

polishing strip until it is shiny in appearance.

Polish the gold tip in one direction.

Do not over-polish – this should just take a few strokes on the

polishing strip

Avoid touching the silver halide coating

Rinse the electrode with DI water after polishing

5. Fill the membrane cap with Internal Filled Gel (IFG) to the upper

threads (red arrow).

► Note:DoNOTshaketheInternalFilledGel(IFG) before filling – this may

introduce problematic air bubbles.

3.1. Electrode Assembly steps 1-8

6. Make sure the silicone band is not covering the vent hole and screw

the membrane cap on the electrode until it is finger tight. The vent hole

will allow excess IFG to escape.

► Note:Do this step over a sink with running water to rinse away excess

IFG.

7. Push the silicone vent hole band back into the recess and rinse the

electrode thoroughly before using.

8. Wipe water off the electrode gently. Avoid touching the membrane

after assembly.

The electrode is now ready for polarization and conditioning steps.

Yellow: Vin+

Black: Vin-

Red: 4-20mA Input

Green: Ground, 0VDC

1. The standard cable length is 3 feet. If another cable length is needed, contact your supplier or manufacturer.

The maximum length should be no more than 30 feet to avoid signal loss.

2. The output current of power source should be more than 100 mA.

3. The A420-FCL output can be measured by multimeter or other devices which allow the analogue input and

measurement. The maximum loop resistance of the devices should be less than 400Ω for testing the current

output of A420-FCL (4-20mA version).

3.2. Electrode wiring

NOTE:

To achieve accurate measurements, an appropriate flow rate in the range of 30 to 60 L/hr is required to reach

equilibrium between the electrochemical consumption and the diffusion of chlorine. A beaker with magnetic stirrer can

be used for electrode evaluation or polarization in a lab environment, but for real continuous measurement

applications, a flow cell system is required. A diagram of a flow cell system for the A420-FCL electrode, a pH electrode,

and a flow regulator is shown in picture below.

Make sure the stainless-steel ring on the A420-FCL chlorine electrode is completely submersed in the water

(above the stainless-steel counter electrode).

The flow regulator and 90o elbow tubing is important for the devices to maintain a constant flow rate. An

unstable flow rate will lead to an inaccurate chlorine measurement.

The flow regulator can be installed at INLET side as well.

Avoid bubbles adhering to the center hole of membrane cap. Bubbles in other areas of membrane cap are

acceptable.

Make sure to maintain a clear space of ~25mm (about 1”) between the tip of the sensor cap and the bottom of

the flow cell tube.

The output of A420-FCL is linear with chlorine concentration. As a result, a 2-point calibration determine the final

calculation equation. Usually, the zero and the half-scale points are recommended for calibrating A420-FCL.

For the zero point (1st point), it can be obtained in zero chlorine water during the conditioning processing. Generally,

the zero point of A420-FCL should be within the specification ranges provided in Tables 1 and 2. The zero point drift is

very slow and negligible in most cases. If the zero point of A420-FCL is not within the specification ranges, please

change the internal filled gel, clean the working electrode and polarize the probe in the zero-chlorine water again.

Please check the zero point every quarter or half a year at least for more precision.

For the half-scale point (2nd point), it is usually around the middle point of the measurement range and it is the most

important point for the accuracy of A420-FCL. In most cases, the calibration of A420-FCL is actually a 1-point

calibration while zero point drift can be ignored. Thus, the colorimetric DPD method (colorimeter, photometer or

spectrophotometer) is strongly recommended to standardize the exact concentration of chlorine at this point. There

are primarily two types of DPD Reagents commercially available:

1. DPD Free Chlorine Reagent (DPD Method #1) for measuring free chlorine.

3.3. Installation into a flow cell or similar system

NOTE:

4. Calibration

2. DPD Total Chlorine Reagent (DPD Method #4) for measuring total chlorine.

The operator should review and familiarize themselves with the DPD method, reagents, and devices to make sure

knowing how to perform this important calibration measurement.

PreparetheequipmentandDPDreagentsforafastandefficientmeasurement.

MakesuretheA420-FCLchlorineelectrodeisfullypolarizedandconditionedinzero-chlorinewaterand record the output

of zero point (the 1st point).

Make sure the electrode is installed properly inthe measurement system with a constant flowrate ranging from

30 L/hr to 60 L/hr (0.6 cm/s to 1.3 cm/s).

Add chlorine to the system, and preliminarily measure the chlorine concentration by DPDmethod.

Approximately adjust the chlorine concentration to the middle point of the measurement range by adding water

or chlorine if necessary.

Let the probe output be stable, and then take water samples from the measurement system for DPD

standardization. This sample should be close to the A420-FCL electrode location for best accuracy.

Record the output of A420-FCL (the 2nd point) as well as the chlorine reading from DPD test.

Calculate the slope as follows:

Once the slope is obtained, the electrode output including voltage (0-5V) or current (4-20 mA) can be converted into

“mg/L” or “ppm” in customers’ analyzer/controller/meter. The conversion equation for any of A420-FCL output is

below:

When the zero point of A420-FCL is not within specifications or there is no significant change in the measurement

environment, but the electrode reading is continuously increasing or decreasing (not fluctuating) within an hour, re-

polarization is probably needed. The root cause is that some interfering substances probably were brought to the

working electrode again, such as unsuccessfully polishing the surface of working electrode, changing the IFG, replacing

the membrane or soaking the electrode with the power off (unconnected) in chlorine or other strong oxidant solution

for a long time. The re- polarization process is mandatory until the electrode presents a stable output. If the zero point

of A420-FCL still can not meet the specifications after a reasonable amount of polarization time, changing the IFG or

polishing the working electrode again may be necessary, or adding tiny sodium thiosulfate in testing water for

removing the potential oxidizers.

If the zero point of the A420-FCL does not meet the listed specifications it may be necessary to change the IFG. The IFG

also needs be changed if the stainless-steel ring (counter electrode) is not submersed in the water when the electrode

is powered for more than 5 minutes. Also, when the slope is lower than 50% of the nominal value, changing the IFG

may correct this situation. It is important to disconnect/power off the electrode before removing it from the water.

Instructions for changing the IFG are as follows:

Calibration Preparation and Procedure

5. Maintenance

5.1. Electrode re-polarization

5.2. Changing the Internal Filled Gel (IFG)

1. Lift the vent hole band up and move it to the lower part of the membrane cap.

2. Unscrew the membrane cap from the electrode body.

3. Dump any residual IFG remaining in the cap or on the electrode body.

4. Rinse the membrane cap with DI water, then with 1-2 mL of new IFG.

5. Complete the IFG change as described in the section Electrode Assembly, from step 5 to step 8.

It is recommended to clean the membrane, when the center pore of the membrane cap is discolored (usually yellow or

brown) or if the slope is lower than 50 % of the nominal value after changing the IFG. This is not actually “cleaning”

the membrane, but rather the removal of extra iodine precipitates by Na2S, Na2S2O3 solution or Ethanol. The

recommended process is as follows:

1. Disconnect the electrode and unscrew the membrane capdiscard the IFG, and rinse the membrane cap and

the electrode with clean water.

2. Cover the working electrode (WE) and reference electrode (RE) parts with a paper towel and avoid exposure

to sunlight.

3. Prepare ~ 0.1 M Na2S2O3 or 95% Ethanol and pour ~150 ml in an appropriately sized beaker to allow the

membrane to be submerged.

4. Submerge the membrane cap in the solution completely for overnight. Use parafilm to cover the open of the

beaker during soaking.

5. Clear the cap by DI water and paper, refill IFG and screw onto electrode.

If the membrane cap gets damaged, the electrode reading is fluctuating, or the slope is lower than 30% of the nominal

value after changing the IFG and cleaning the membrane, the membrane cap may need to be replaced. Please make

sure the electrode is not powered during assembly and then follow the instruction below for replacement.

1. Unpack the membrane cap replacement kit and prepare the new membrane cap on a clean surface.

2. Unscrew the old membrane cap and discard it.

3. Rinse the new membrane cap with clean water, then rinse it with 1-2 mL of the IFG.

4. Follow the instructions from step 5 to step 8 as described in the Electrode Assembly section.

If the A420-FCL electrode reading is abnormal or the zero point is not within specifications after a reasonable

polarization time, the working electrode (WE) may not be able to completely polarize. Try to polish the WE again with

the polishing strip. In addition, if a stain or discoloration is visible on the surface of the WE, it should be polished until

the stain is less visible or removed completely. Please refer to Step 4 of Electrode Assembly section to brush the gold

reference electrode (RE) a few times in one direction, and then follow the next steps for electrode assembly.

The A420-FCL electrode can be stored in clean water or stored dry, preferably at normal room temperatures, while not

in use. It is recommended to:

1. Soak the electrode in clean water (IFG in cap) if it will be used within 1 week.

2. Store the electrode dry (IFG in cap) if it will be used within 1 month.

3. Store the electrode dry (without IFG in cap) for longer than 1-month storage.

5.3. Cleaning the Membrane Cap (De-iodine)

5.4. Replacing the Membrane Cap

5.5. Polishing the Working Electrode (WE)

5.6. Storing the Electrode

NOTE: The reference electrode is light sensitive and should be capped or covered during storage

6. Troubleshooting

Problem

Possible Cause

Solution

No reading (1)

Insufficient conditioning.

Reading should appear within 10

mins.

No reading (2)

Electrode connection or power

supply.

Check connection/wiring.

No reading and electrode feels warm

PCB shorted or corrupted.

Replace electrode

Zero point out of specification

1. Water sample is not

chlorine free

2. Insufficient

polarization/conditioning

3. Interfering substances

cannot be cleaned

electrochemically.

1. Replace the zero chlorine

water.

2. Continue polarizing

andconditioning electrode.

3. Brush WE with polishing

strip.

Reading instable or fluctuation

1. Membrane cap fouled or

damaged.

2. Air bubbles on outside of

membranecap – especially

at center pore

3. Air bubbles inside the

membrane cap.

1. Clean or change membrane

cap.

2. Shake the electrode to

remove theair bubbles from

the center pore.

3. Shake electrode or inspect

the cap for air bubbles

Slope too low

1. Membrane cap fouled.

2. IFG deterioration.

3. Insufficient conditioning

4. Flow rate too low.

5. Erroneous DPD

standardization.

1. Clean or change membrane

cap.

2. Refill IFG.

3. Recondition the electrode.

4. Adjust flow rate into

working range.

5. Check the measurement

range of the DPD and

recalibrate.

Reading out of range

1. Chlorine content >

maximum measuring range.

2. Electrode and membrane

cap are unmatched or

improperly attached.

1. Confirm actual sample or

electrode range

specification

2. Reinstall the membrane cap

looser or slightly tighter.

Replace the membrane cap.

7. Package Include:

Manufacturer

Daviteq Technologies Inc

No.11 Street 2G, Nam Hung Vuong Res., An Lac Ward,

Binh Tan Dist., Ho Chi Minh City, Vietnam.

Tel: +84-28-6268.2523/4 (ext.122)

Email: info@daviteq.com | www.daviteq.com

Distributor in Australia and New Zealand

Templogger Pty Ltd

Tel: 1800 LOGGER

Email: contact@templogger.net

8. Support contacts:

Table of contents

Other daviteq Accessories manuals

daviteq

daviteq WS433-M12F-ATE User manual

daviteq

daviteq WS433-DI User manual

daviteq

daviteq WSSFC-V1A-025 User manual

daviteq

daviteq WSSFC-ULA-01 User manual

daviteq

daviteq WS433-O2 User manual

daviteq

daviteq WS433-TAG User manual

daviteq

daviteq CAP10 User manual

daviteq

daviteq WSSFC-AC User manual

daviteq

daviteq CAP10G User manual

daviteq

daviteq WS433-AC User manual