decon Gearwheel GWl0S0 User manual

2020-02

Revision No. 4

User manual

®GEARWHEEL

EC Declaration of Conformity

The undersigned, representing the following manufacture:

Gearwheel

2

Table of Contents

1. Introduction ............................................................................. 3

2. Intended users........................................................................ 3

3. Contact......................................................................................... 3

4. Description................................................................................ 3

5. Warnings..................................................................................... 4

6. Safety precautions ............................................................... 5

Check delivered products

Make sure you have one pair (2 units) of wheels

Check GEARWHEEL’s equipment

Balance and tipping sensitivity

Operating Instructions

Gear lever and finger pinching hazard

Wheel and gear management

7.

Overview - drive wheel...................................................... 6

8. Operation ....................................................................................7

Gear changing

Remove and secure the wheels

9. Settings........................................................................................ 8

10. Maintenance and care ...................................................... 9

Monthly

Information about corrosion

11. Transport in vehicles........................................................... 9

12. Warranty and service life ................................................. 9

13. Waste management and recycling of

materials ...................................................................................10

14. Marking plate ....................................................................... 10

15. Technical Specications................................................. 10

If you are visually impaired,

this document can be viewed in

pdf-format at www.decon.se

16.Information about product safety and recall..... 10

Reuse of the product

3

1. Introduction

GEARWHEEL is very pleased that you have chosen our wheels for

your wheelchair. We are committed to developing a strong

relationship with users based on a positive experience, both in the use

of their wheelchairs and in their dealings with us as a company,

GEARWHEEL`s geared wheelchair wheels are designed to make

propelling easier in widely varying terrains and situations. The

mechanical solution offers a choice of gear ratios with the huge added

benet of an integrated hill-holder. The gearchange is operated with

a shift lever on the outside of the wheels. The wheels incorporate a

quick release, operated by a user-friendly hoop.

We also encourage you to read the operating manual for your

particular wheelchair model where important information is available

regarding proper wheelchair use.

2. Intended users

GEARWHEEL`s geared wheelchair wheels are intended for personal

and everyday use, both indoors and outdoors, for users who have

limited mobility or cannot walk. GEARWHEEL’s wheelchair wheels

are tested for a user weight of up to 125 kg. GEARWHEEL`s geared

wheelchair wheels are intended for use on a range of different

wheelchair models and only in conjunction with the appropriate

GEARWHEEL designed adaptors.

3. Contact

For matter regarding customer

service, delivery, please contact:

DeconWheel AB

Södra Ekeryd 119

314 93 Hyltebruk

www.decon.se

Tel: +46 (0)345-40 880

4. Description

GEARWHEEL has developed a solution with fully mechanically

geared wheelchair wheels that can be mounted on existing

wheelchairs on the market. The patented solution combines the ability

to shift to different gears on the wheelchair within a design that is not

significantly different from ordinary wheelchair wheels.

Gear-changing makes possible a greater self-propelling capability.

The difference can be great for certain user groups and can be

significant where ground level differences, thresholds, carpeting,

lawns or maybe the last incline to ones home is a natural part of

everyday life.

A shifter on each wheel changes gear between two different ratios,

direct drive (1:1) and a lower ratio. Added to this is an integrated hill-

holder. The wheels are supplied with an adaptor, specific to each

wheelchair model, that enables the correct functioning of the gears.

For matter regarding product,

construction and CE-marking,

please contact:

Gearwheel AB

Flottiljgatan 49

721 31 Västerås

www.gearwheel.se

Tel: +46 (0)70-69 59 427

4

5. Warnings

Using GEARWHEEL can affect the chair’s balance and its

tipping sensitivity.

Warning

Read and carefully follow the instructions in the

GEARWHEEL manual as well as the instructions contained

in the wheelchair manufacturer’s User Manual for the

specic wheelchair model.

Warning

Risk of injury in the center of the wheel hub, where there

is a gap between the spoke guard and the center of hub.

Warning

Risk of tipping backwards when the gear is in reverse

lock position, Hill-holder. Never use the chair without

anti-tippers.

Warning

The product is not crash-tested and is therefore not

intended to be used for transport in vehicles.

Warning

5

6. Safety precautions

Check delivered products

• Check the products supplied by GEARWHEEL.

Make sure you have one pair (2 units) of geared wheelchair

wheels.

• Make sure you have one pair of the correct adaptors for your

specic wheelchair model.

• Make sure you have the correct hand rims.

Check GEARWHEEL’s equipment

Ensure the following:

• The wheels’ axles are easy to move in and out of their receivers.

• The wheels are attached properly after assembly on the

wheelchair, both in neutral and shifted position.

• The Quick Release hoop on the outside of the wheel locks the

wheel when not lifted up.

• None of the four wheels on the wheelchair is in the air when the

chair is on a flat surface.

• The rotation lock is in the correct position. This means that the

peg on the inside of each wheel is properly inserted in the hole in

the adaptor when the wheel is attached, see figure 8.7.

Balance and tipping sensitivity

The ability to change gear on the wheelchair and the

engagement of the hill-holder can adversely affect the

balance and tipping sensitivity.

Warning

Operating Instructions

Before using GEARWHEEL: Read and follow the

instructions in the user manual.

Warning

In addition to the instructions that come from the wheelchair

manufacturer, it is important that you practice using your geared

wheelchair wheel. Anti-tip stabilisers MUST be used. Take the proper

time to familiarise yourself with your new wheels so that you are as

comfortable as possible with the various conditions that the gearing

options provide. If you have any questions about using GEARWHEEL

geared wheels on your wheelchair, please feel free to contact us or

your local sales representative.

Gear lever and nger pinching hazard

Risk of nger pinching between the shift lever and

the spoke guard. Never use the wheels without the

spoke guards.

Risk of nger pinching at the center of the wheel hub,

where there is a gap between the spoke guard and the hub.

Warning

Important

6

Wheel and gear management

• To remove the wheels, the gear should preferably be in the direct

drive (1:1) position (the gear lever is in the vertical position).

• It is possible to change gear both when stationary and in motion.

However, the gearbox works more smoothly when the wheelchair

is in motion.

• Check that the wheel is attached by pulling the wheel outwards

and even shifting gears once, and ensure that the wheel does not

slide out from its mounting on the chair.

• Inspect GEARWHEEL’s geared wheelchair wheels once a month

as instructed in Section 8.

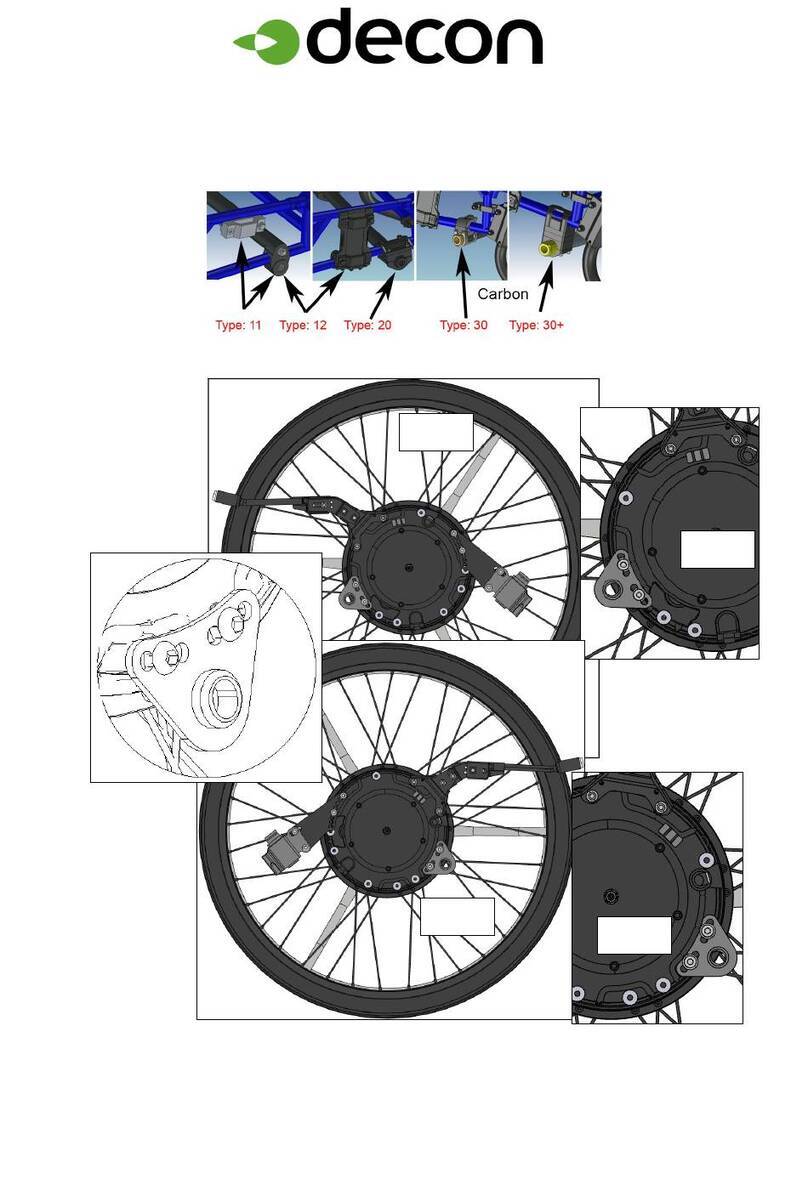

7. Overview - drive wheel

1. Hand rim

2. Gear lever

3. Spoke guard – not visable in

picture

4. Quick release - QR-hoop

1. Hand rim

2. Gear lever

3. Spoke guard

-not visable in picture

4. Quick release

- QR-hoop

7

8. Operation

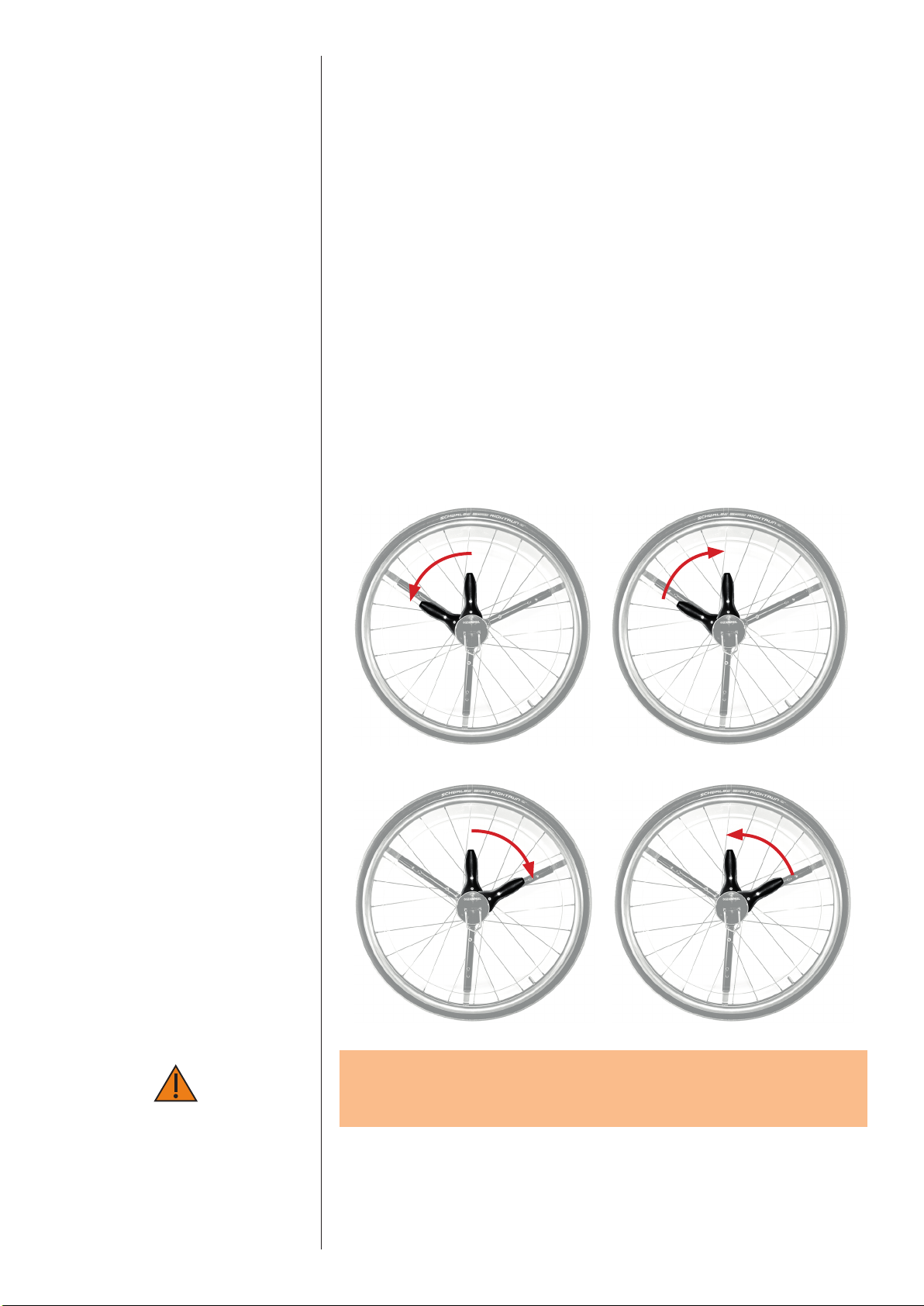

Gear changing

The gearbox has three positions: direct drive (1:1), low gear,

and low gear + hill hold.

•Direct drive (1:1) – As in a regular wheel where the hand rim

rotates at the same speed as the wheel

•Low gear - The hand rim rotates faster than the wheel, reducing

the effort required to push the chair by about 40%.

•Low gear + hill hold - In addition to the lower gear, the wheels are

locked from rolling backwards. Note that this greatly increases the

risk of tipping backwards, since the user cannot control the balance

of the wheelchair in the normal way.

To select low gear, move the shift lever forward as far as it will go

(Figure 8.1) To switch back to direct drive (1:1), move the shift lever

backward until it reaches its vertical position (Figure 8.2). To switch

to reverse lock (hill-holder) mode, move the shift lever backward

(Figure 8.3). To switch back to 1: 1, push the shift lever forward to its

vertical position (Figure 8.4)

Fig 8.1 - Left wheel Fig 8.2 - Left wheel

Fig 8.3 - Left wheel Fig 8.4 - Left wheel

Risk of tipping backwards increases when the gear is in

reverse lock/ hill-holder mode. Tipping protection must

be used.

Warning

•It is possible to shift gears when in stationary position but it is

easier and more convenient to shift when in motion.

•The hill-hold function shall be used regularly, at least once a

week to ensure full functionality.

8

It is possible to shift gears both while stationary and when in motion.

However, the gearbox works more smoothly when the wheelchair is

in motion.

Remove and secure the wheels

Unlock the wheels by lifting the QR–hoop (Figure 8.5) and pull the

wheel straight out (Figure 8.6). To re-x the wheel lift the QR-hoop,

insert the wheel axle in its receiver on the chair whilst at the same

time engaging the peg on the wheel’s rotation arm with the receiver

in the adaptor on the wheelchair (Figure 8.7). The wheel’s QR-hoop

then drops down to its parked position and the wheel is locked

in place (Figure 8.8).

Fig 8.5 Fig 8.6

Fig 8.7 Fig 8.8

• It is preferable to remove the wheel when the gear lever is in the

direct drive (1:1) position.

• Check that the wheel is attached to the chair by pulling it outwards

and even shifting gears once to see that it does not slide out.

• Make sure the rotation lock is properly tted. The peg on the

rotation arm is engaged in the receiver in the adaptor on the

wheelchair.

Important

Important

9. Settings

The wheelchair settings and adjustments are made according to the

wheelchair manufacturer’s instructions. GEARWHEEL wheelchair wheels

provide the user with the unique ability to change gear. Although the

GEARWHEEL gearbox design is designed to require no adjustment, the

user is advised to check the wheelchair and the adaptors if the system is not

operating normally.

9

10. Maintenance and care

GEARWHEEL recommends, in addition to the instructions given by

the wheelchair manufacturer for the wheelchair model, the following

maintenance.

Monthly

•Check the pressure in the tyres. Unscrew the valve cap and

reinflate the tyre. Maximum tyre pressure is 9 bar. Check for any

damage and wear. If solid tyres are used check for cracks due to age or

wear.

• Check that the brakes/wheel locks function normally and

satisfactorily.

•Use a mild detergent to clean the parts of the wheel. Lubricate

moving parts very lightly with suitable lubricant after washing.

(light oil, e.g. 3-in-1)

•Thoroughly clean the quick-release axles and lubricate very lightly.

Rain, sand, salt, debris, or prolonged periods in which the wheels

are not removed mean cleaning and lubrication need to happen

more often.

• Check that the screws and nuts are tightened.

• Check that the shift lever locks in its end positions (Downshift and

downshift + hillhold) and that the gear shift works correctly in each

gear.

• Check the gear system for damage. In case of damage to wheels

and gear mechanism, contact Decon AB, or a Decon appointed.

The product is not crash-tested and is therefore not inten-

ded to be used for transport in vehicles

Warning

12. Warranty and service life

GEARWHEEL provides 2 years of factory warranty on drive wheel

hub, gear assembly, with the exception of gear shift and adaptor

systems. Other items, 12 months, with the exception of wearing parts.

The expected service life of the complete product (not wearing parts) is five

years from the date of sale.

13. Waste management and recycling of

materials

The following is a description of the materials in GEARWHEEL

construction, with regard to possible waste disposal and recycling of

materials.

• Aluminium: Hub, wheel rim, handrim (depending on the model),

brackets

• Rubber: tires, handrim (depending on the model)

Information about corrosion

All gearwheel parts that may be subject to corrosion are made of aluminium,

stainless steel or steel. The materials and the transitions between the materials

have been surface-treated, which is why there is no increased risk of corrosion.

11. Transport in vehicles

10

14. Marking plate

The marking plate is located on the GEARWHEEL wheel. The exact

designation and technical specifications relating to the product are

indicated on the nameplate. When contacting Decon, please quote

the serial number (labeled SN).

Manufacturing date

Serial number

Manufacturing company

Max load

CE mark

Operating instructions

H000309

15. Technical Specifications

Weight without hand rim and without tire: 2551 g

Wheelsizes: 22", 24" and 25"

Chair’s adjustable width increase: approx. 3 cm

Max User Weight: 125 kg

CE marking: 93/42/EEC

Type of tyres: Pneumatic tyres: Dimension 24x1, 25-540, max bar 9.

Tyre punctures: Replace with product that meets the specification.

Contact your medical equipment supplier if needed.

16. Information about product safety and recall issues

Contact the reseller where the product was purchased or the

manufacture of GEARWHEEL for information about product safety or any

recall information.

When GEARWHEEL has reached the end of its service life and needs to be

scrapped, contact the local authority for information on recycling and

follow their instructions. Alternatively, you can contact your retailer to

recycle your used GEARWHEEL.

When GEARWHEEL is to be transferred to a new user, all technical

documents must also be transferred. The product must be cleaned by a

professional, disinfected and serviced.

•Plastic: spoke guard, gear lever, handrim (depending on the

model)

•Steel: screws, springs, front axle in gear system, spokes,

quick release axles, shift handle

EXAMPLE

Gearwheel AB

Flottiljgatan 49

721 31 Västerås

E-mail: [email protected]

www.gearwheel.se

Tel: +46 (0)70-69 59 427

This manual suits for next models

2

Table of contents

Other decon Wheelchair manuals

decon

decon INFM7002 User manual

decon

decon Adventus User manual

decon

decon Infinity User manual

decon

decon ADV5X02 User manual

decon

decon E-Move MEM20 User manual

decon

decon Adventus Footrest Universal User manual

decon

decon JW Smart Tune User manual

decon

decon Gearwheel User manual

decon

decon E-Drive PLUS User manual

decon

decon Adventus Quick start guide

Popular Wheelchair manuals by other brands

Rhythm Healthcare

Rhythm Healthcare B3400F manual

Invacare

Invacare REA Dahlia 30 Service manual

DiscountRamps

DiscountRamps Silver Spring ESC400 instructions

Sunrise Medical

Sunrise Medical Sopur Easy Life RT Directions for use

Invacare

Invacare TDX SC parts list

Maximex

Maximex Secura Premium 23556 Assembly instructions