3

The boiler must be connected by a qualified

professional. Strict compliance with these

usage, electrical connection and start up

instructions is a precondition for the correct

operation of the boiler.

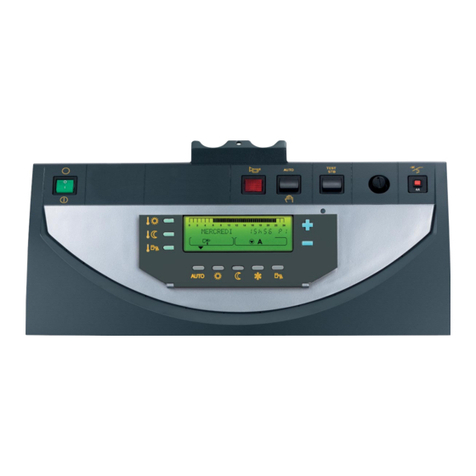

The B control panel is used on the following

De Dietrich boilers:

- GT 120 A and GT 1200 A.

2. GENERAL

Electrical heating control panel, equipped with regula-

tion with priority for domestic hot water production as

original equipment.

The basic delivery for the B control panel compri-

ses:

- 1 B control panel

- 1 boiler sensor to measure the water temperature in

the boiler.

Options

The following options can be connected:

- DHW sensor (package FM 45) for the connection of a

domestic hot water calorifier,

- remote room thermostat.

3. PRESENTATION

4.TECHNICAL CHARACTERISTICS

The B control panel includes a boiler thermostat, a

domestic hot water thermostat, an electronic thermo-

meter and a safety thermostat.

The boiler thermostat

to regulate the boiler operating temperature.

The safety thermostat

with manual reset to make the boiler safe in operation.

If the boiler temperature rises abnormally

(110°C/230°F), the safety thermostat cuts off the

burner electricity power supply.

In this case, you must call your fitter.

The domestic hot water thermostat

for the preparation of domestic hot water (GT 120 A

connected to a calorifier and GT 1200 A), is used to

adjust the average domestic hot water storage tempe-

rature giving priority to preparation of domestic hot

water.

The domestic hot water priority trips the burner and

the DHW load pump and stops the heating pump

whenever a domestic hot water heating request is

received. During summer conditions, the boiler tempe-

rature is not maintained between two hot water

requests. The domestic hot water temperature is

measured by the DHW sensor.

Electrical power supply: 120V - 60 Hz

1. INTRODUCTION

- Value of water sensors (boiler and domestic hot water)

Temperature Resistance

in °C / °F in Ohm

0°C / 32°F 32 014 Ω

10°C / 50°F 19 691 Ω

20°C / 68°F 12 474 Ω

30°C / 86°F 8 080 Ω

40°C / 104°F 5 372 Ω

Temperature Resistance

in °C / °F in Ohm

50°C / 122°F 3 661 Ω

60°C / 140°F 2 535 Ω

70°C / 158°F 1 794 Ω

80°C / 176°F 1 290 Ω

90°C / 194°F 941 Ω