3

The boiler must be connected by a qualified

professional. Strict compliance with these

usage, electrical connection and start up

instructions is a precondition for the correct

operation of the boiler.

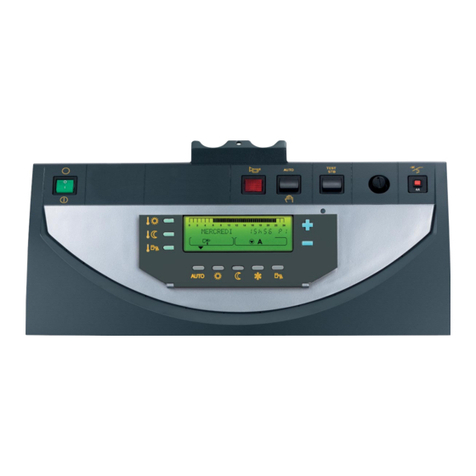

The E control panel is used on the following

De Dietrich boilers:

- GT 120 A and GT 1200 A.

1. GENERAL

1.1 Presentation

The E control panel with an Easymatic regulator to

be fixed to the wall or integrated into the boiler

control panel can be used for:

- automatic operation of heating when the ambient

temperature has been reached

- control of heating as a function of the outside tempe-

rature.

- regulation and programing of domestic hot water pro-

duction (if it is present) with or without priority

- providing a frost free room temperature if the home is

empty. The duration of this period may be programed

up to 99 days.

The basic delivery of the E control panel comprises

- 1 E control panel

- 1 Easymatic regulator with support to be installed in

the chosen room or to be included in the control panel

- 1 boiler sensor measuring the water temperature in

the boiler

- 1 external sensor

Options

The following option can be ordered:

- domestic hot water sensor (package FM 45).

1.3 Technical characteristics

The E control panel can be used to program and regu-

late the room temperature as a function of the outside

temperature by controlling the burner. The boiler

thermostat must be set to a sufficiently high tempera-

ture for automatic regulation to operate correctly (set-

ting between mark 8 and 9).The safety thermostat with

manual reset (adjusted to 110°C/230°F) maintains

operating safety.

In the case of domestic hot water (d.h.w.) production,

domestic hot water is regulated by the regulator acting

on the load pump giving priority to heating of domestic

hot water.

When a request is made for heating domestic hot

water, the domestic hot water priority stops the burner

and the d.h.w. load pump and stops the heating pump.

Under summer conditions, the boiler is not kept hot

between two domestic hot water loads. The domestic

hot water temperature is measured by the d.h.w.

sensor.

The regulator includes the possibility of a "antilegio-

nellosis" protection.

1.2 Operating principle

Temperature Resistance

in °C / °F in Ohm

- 20°C / -4°F 2 392 Ω

- 16°C / 3°F 2 088 Ω

- 12°C / 10°F 1 811 Ω

- 8°C / 18°F 1 562 Ω

4°C / 25°F 1 342 Ω

0°C / 32°F 1 149 Ω

Temperature Resistance

in °C / °F in Ohm

4°C / 39°F 984 Ω

8°C / 46°F 842 Ω

12°C / 54°F 720 Ω

16°C / 61°F 616 Ω

20°C / 68°F 528 Ω

24°C / 75°F 454 Ω

- Electrical power supply: 120V - 60 Hz

- Clock operating capacity: 2 years minimum

- Resistance of the external sensor in Ω (option)- Value of water sensors in Ω

Temperature Resistance

in °C / °F in Ohm

0°C / 32°F 32 014 Ω

10°C / 50°F 19 691 Ω

20°C / 68°F 12 474 Ω

25°C / 77°F 10 000 Ω

30°C / 86°F 8 080 Ω

40°C / 104°F 5 372 Ω

Temperature Resistance

in °C / °F in Ohm

50°C / 122°F 3 661 Ω

60°C / 140°F 2 535 Ω

70°C / 158°F 1 794 Ω

80°C /176°F 1 290 Ω

90°C / 194°F 941 Ω