3

11/13/09 - XXXX-XXXX R0 GT 220A

.

¯ Alaysfollowthe safetyinstruction describedbeloworlabels

ahdered to the boiler. failure to follow such instruction may result in

personal injury, including loss of life or damage to the boiler and

surronding property.

iNSTRUCTIONS & SAFETY WARNING LABELS: These

instructions and labels must never beremoved or covered. Replace

damaged or illegible instructions and labels.

The boiler casing is not designed for structual support DO NOT

STAND ON OR USE THE BOILER AS A LADDER.

IF YOU SMELL GAS OR COMBUSTION RELATED FUMES,

PROCEED AS FOLLOWS:

`Do not smoke or generate fire or sparks

`Do not operate any electrical devices or switches

`Close the gas supply cock to the appliance

`Open doors and windows

`Warn those present to leave the building

`Do not use any phone in the building

`Call your local gas supplier once outside the building, if you

cannot reach them call the local fire department.

DO NOT USE THE BOILER IF ANY PORTION OF THE CONTROL

SYSTEM HAS BEEN SUBJECTED TO WATER, INGESTED WITH

WATER OR SUBMERGED IN WATER.

IMMEDIATELY CALL YOUR SERVICE COMPANY TO INSPECT

AND REPLACE ALL CONTROLS AND GAS COMPONENTS.

Boiler Modification and spare parts:

This boiler use specific original manufactured parts, the boiler must

not be modified or use non OEM parts, without the written approval

from DDR Americas Inc. De Dietrich Boilers.

Installation, servicing & maintenance of this boiler shall be

completed by a licenced and trained individual, experinced in

hot water boiler heating and gas & oil combustion. The

installationmustconformtoallnationalandlocalcodeshaving

jurisdication:

`In Canada CSA B149.1 Gas Code & CSA B139 Oil Code

`InUSA ANSIZ223.1 (NFPA54) GasCode, NFPA31 OilCode

& ASME CSD-1 Automatically fired boilers.

If you have any technical questions or need assistance with

this product, please call us toll free

1.800.943.6275 E.S.T. Monday thru Friday 08:00 - 17:00 EST

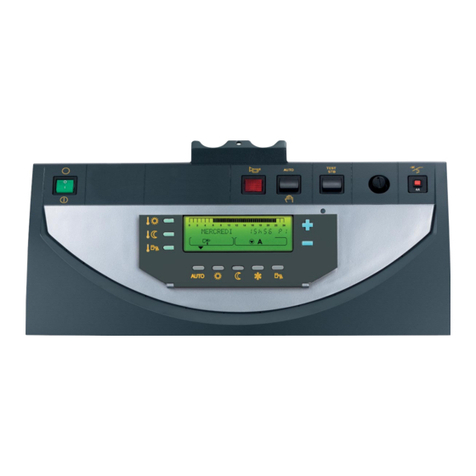

0.2 Description

S2NA control panel is designed specifically for the De Dietrich

GT120-220A series cast iron sectional boilers, they are

approved for use with the above mentioned boiler series, they

are not approved to be used with any other boiler series or

manaufacturers.

The panel is designed for to be used with a power burner

Application(s):

Space heating only

DHW heating possible with seperate control

Single or 2 stage* burners

2 stage

Modulating burner require a seperate control

a single heating circuits non

0.3 Control overview

S2NA Panel overview 1. Wiring terminal strip