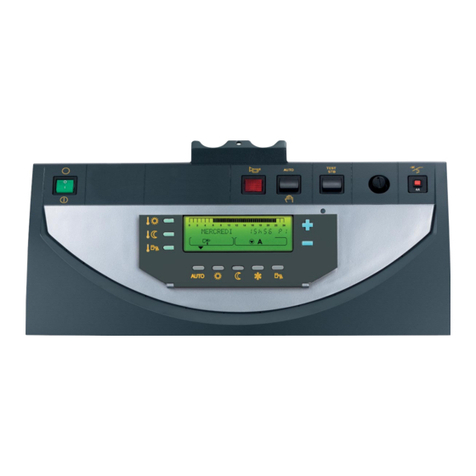

6Control panel S3 23/01/06 - 300008905-001-A

Commissionning

The first start-up is to be performed by your installation

engineer.

Beforestartingtheboiler,checkiftheinstallationis filled with water.

Start the boiler in the following order :

•Boiler temperature regulation by means of the thermostats

`Set the boiler thermostats 3to the desired position. The 2nd

stagethermostatmust be set to avalue at least 5°C lower than

the 1st stage thermostat.

If there is no control unit, we advise you never to set the

boiler thermostat below mark 4 (approx. 40°C) in order to

avoid the risk of combustion products condensing on the

walls of the boiler.

`Ifnecessary, change the position of the maximim temperature.

• Moving the thermostat stop

A factory-set stop limits the maximum temperature to 75 °C.

To move the stop, proceed as follows:

`Pull the thermostat button out carefully (use pliers and a cloth).

`Remove the stop with the pliers.

`Put the stop in the hole of the desired higher temperature

(maximum 85°C).

• Control unit in boiler room electrical cabinet

See the instructions supplied with the control unit and any

remote control unit used.

•Check that safety thermostat 7 is properly set. To do so,

Unscrew the safety thermostat cover and press the reset button

using a screwdriver.

•Set the On/Off switch to 1.

9

8

7

6

5

M000154