Content

For your safety .................................................................................................................................................................................. 2

Technical data and information ........................................................................................................................................................ 3

Operational conditions ..................................................................................................................................................................... 4

Terminolo y ...................................................................................................................................................................................... 4

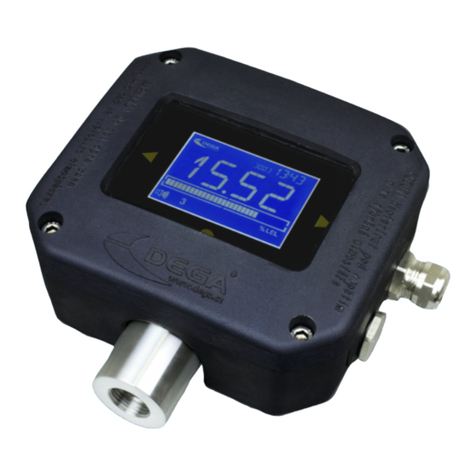

Product desciption ............................................................................................................................................................................ 5

Instalation, assembly and disassembly of the transmitter ............................................................................................................... 6

1. Assembly of the transmitter ................................................................................................................................................. 6

2. Replacement of the sensor module ...................................................................................................................................... 6

3. Replacement of the battery .................................................................................................................................................. 6

4. Connectin the transmitter via current loop to the controler DEGA UPA II/DEGA UPA III .................................................. 7

5. Connectin the sensor via RS485 to the controller DEGA UKA III/DEGA UPA III/DEGA UDA III ........................................... 7

6. Installation of wirin for RS485 ............................................................................................................................................. 7

7. Settin the RS485 adress of the transmitter......................................................................................................................... 7

8. Terminatin resistor .............................................................................................................................................................. 7

9. Communication protocol switch DEGA/MODBUS ................................................................................................................ 7

Transmitter functions ....................................................................................................................................................................... 8

1. Turnin on the transmitter ................................................................................................................................................... 8

2. Gas detection ........................................................................................................................................................................ 8

3. Malfunction ........................................................................................................................................................................... 8

4. Monitorin the calibration periods ....................................................................................................................................... 8

5. Readin the record of measured concentrations and alarms .............................................................................................. 8

Operation, maintenance, inspection and service of the transmitter ............................................................................................... 8

1. Usa e limits ........................................................................................................................................................................... 8

2. Operation .............................................................................................................................................................................. 9

3. Operation/Maintenance ....................................................................................................................................................... 9

Accessories and basic types of transmitters ..................................................................................................................................... 9

1. Calibration adapter/connection to the as pump DEGA GAS INLET .................................................................................... 9

2. Cover a ainst splashin water DEGA WATER CAP ................................................................................................................ 9

3. Funnel for as collection DEGA COLLECT CAP .................................................................................................................... 10

4. Additional Ex „d“ cable land .............................................................................................................................................. 10

Basic types of transmitters ............................................................................................................................................................. 10

1. Transmitters with a catalytic sensor NSx-CL III ................................................................................................................... 10

2. Transmitters with an electrochemical sensor NSx-EL III ..................................................................................................... 10

3. Transmitters with an infrared sensor NSx-IL III................................................................................................................... 12

4. Transmitters with a semiconductor sensor NSx-SL III ......................................................................................................... 13

5. Transmitters with a PID sensor NSx-PL III PID ..................................................................................................................... 13

Add-on modules .............................................................................................................................................................................. 14

Attachments .................................................................................................................................................................................... 14

1. Chart for settin the transmitter adress ............................................................................................................................. 14

2. Si nalization transmitted by the current loop 4-20 mA ..................................................................................................... 14

3. Conversion between volume concentration and lower explosive limit of methane ......................................................... 14

4. Packa e contents ................................................................................................................................................................ 14

General warranty terms and conditions ......................................................................................................................................... 15

For your safety

Beware of static electricity

Electronic components are sensitive to static electricity. Do not touch them directly - they may et daman ed.

T e device is intended to be installed by a trained person

The product is desi ned for installation only by a certified technician. The manufacturer is not liable for dama es resultin

from incorrect or improper handlin .

In case of malfunction, immediately unplug from t e power supply

If you notice an unusual smell or smoke emittin from the product, unplu it from the power supply, battery backup and all

other attachments. Continued operation could result in injury or property dama e. After disconnectin , have the device

inspected at an authorized dealer or manufacturer.