AX-Series Motion Controller Instructions Manual TOC

TOC

TOC 1

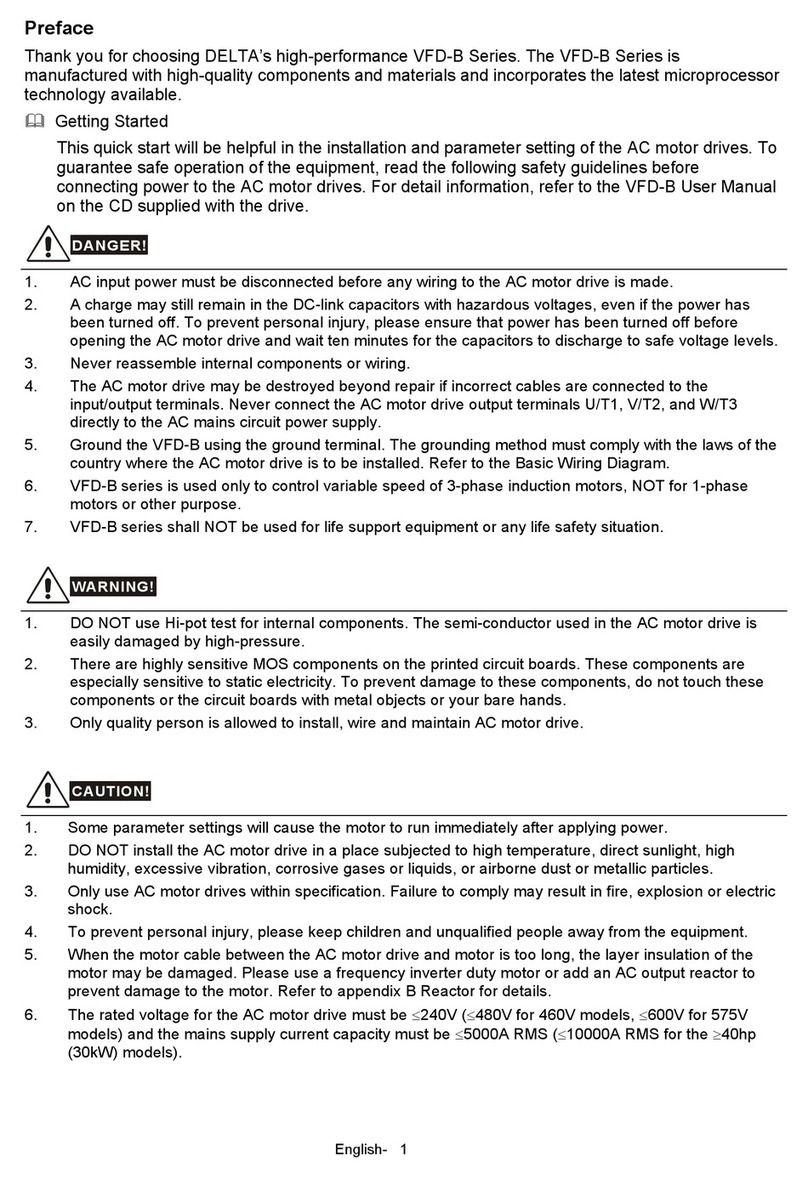

Preface 1

P.1Introduction .................................................................................................. ......................................1

P.1.1 Applicable Products .................................................................................................................... 1

P. 1 . 2 Associated Manuals.................................................................................................................... 1

Introduction to Motion Control......................................................................................................2

1.1 Introductions of Motion Control...............................................................................................3

1.1.1 Basic Knowledge of Motion Control Instructions ..................................................................... 3

1.2 Categories of Motion Control Instructions ..................................................... .......................6

1.3 Overview of Delta Motion Instructions Library ............................................... .....................7

Motion Control Instruction ..........................................................................................................8

2.1 Motion Control Instructions .................................................................................................... 9

2.1.1 MC_Home ............................................................................................................................ 9

2.1.2 MC_Stop............................................................................................................................. 13

2.1.3 MC_Halt ............................................................................................................................. 16

2.1.4 MC_MoveAbsolute.............................................................................................................. 20

2.1.5 MC_MoveRelative............................................................................................................... 26

2.1.6 MC_MoveAdditive ............................................................................................................... 30

2.1.7 MC_MoveSuperImposed ..................................................................................................... 34

2.1.8 MC_CamIn ......................................................................................................................... 38

2.1.9 MC_CamOut....................................................................................................................... 55

2.1.10 MC_MoveVelocity ............................................................................................................... 59

2.1.11 MC_PositionProfile.............................................................................................................. 64

2.1.12 MC_VelocityProfile.............................................................................................................. 68

2.1.13 MC_AccelerationProfile ....................................................................................................... 72

2.1.14 MC_Jog .............................................................................................................................. 76

2.1.15 MC_GearIn ......................................................................................................................... 79

2.1.16 MC_GearOut ...................................................................................................................... 83

2.1.17 MC_GearInPos ................................................................................................................... 88

2.1.18 MC_Phasing ....................................................................................................................... 94

2.2 Administrative Motion Control Instructions........................................................................99

2.2.1 MC_Power .......................................................................................................................... 99

2.2.2 MC_SetPosition ................................................................................................................ 104

2.2.3 MC_ReadParameter ......................................................................................................... 109

2.2.4 MC_WriteParameter.......................................................................................................... 112

2.2.5MC_ReadBoolParameter................................................................................................... 115

2.2.6 MC_WriteBoolParameter ................................................................................................... 118

2.2.7 MC_ReadActualPosition.................................................................................................... 121

2.2.8 MC_ReadActualVelocity .................................................................................................... 124

2.2.9 MC_ReadActualTorque ..................................................................................................... 127

2.2.10 MC_Reset......................................................................................................................... 128

2.2.11 MC_ReadStatus................................................................................................................ 131