Damper Mounting and Installation

• Place the actuator on the damper shaft so that the front of the actuator is accessible. (The label and the manual override button

are on the front side.)

• The minimum damper drive shaft is 3/4-inches (20mm). The shaft length determines whether the shaft adapter will be

mounted on the front or back of the actuator.

• Refer to Specifications for minimum and maximum damper shaft dimensions.

• Set auxiliary switches, DIP switches, and Offset/Span as required by your application. (See following sections for details.)

• The position indicator can be mounted to show either the clockwise or counterclockwise 0 to 90 scale.

• A mounting bracket is included with the actuator.

• The shaft adapter and mounting parts are shipped in a separate container with the actuator.

• The actuator is shipped from the factory with a 5° pre-load to ensure tight damper close off.

• Detailed mounting instructions are included with each actuator.

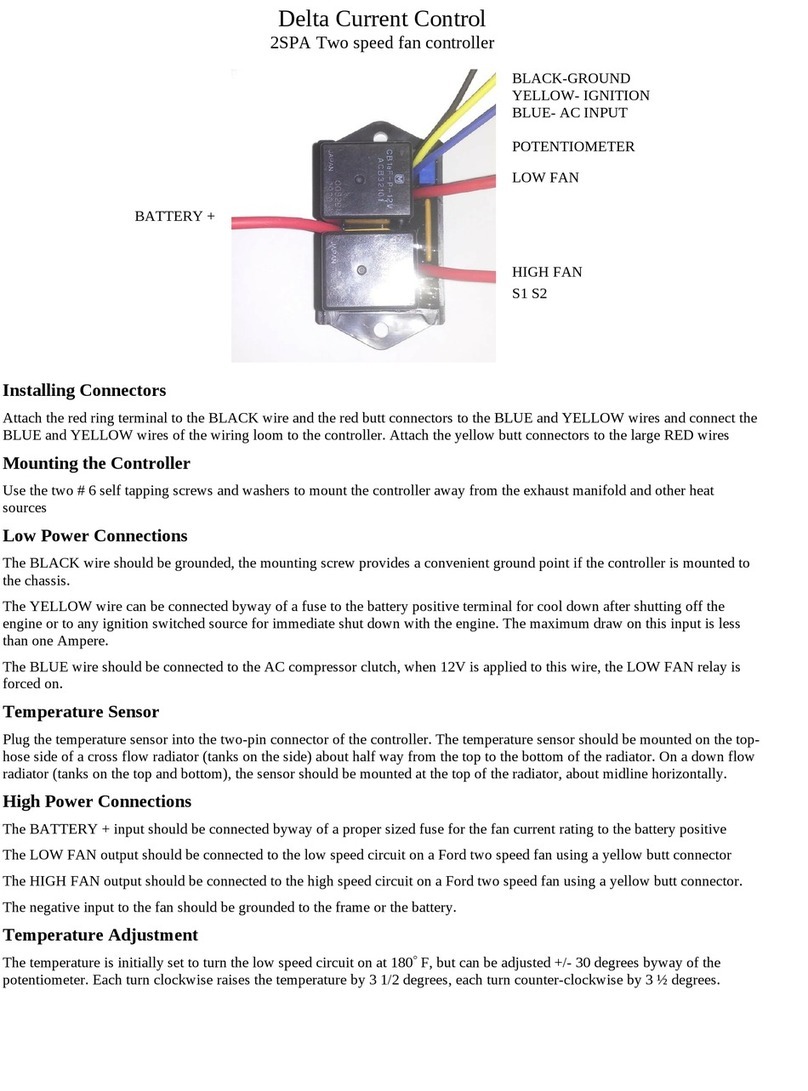

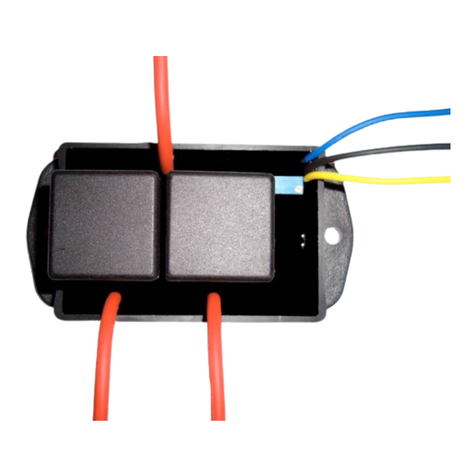

Manual Override

Mechanical Range Adjustment

1

3

2

PUSH

L > 3 in.

77mm

L < 2-3/8 in.

60mm

3

2

PUSH

To move the damper blades

and lock the position with no

power present:

1. Hold down the PUSH

button.

2. Make adjustments to the

damper position.

3. Release the PUSH button.

Once power is restored, the

actuator returns to automated

control.

1

2

Figure 2.

90

5

4

Figure 3.

90

45

Figure 4.

90

45

Figure 5.

The angular rotation is adjustable between 0 and 90° at 5-degree intervals. The range of shaft movement is limited by mounting the

shaft adapter:

1. Loosen the shaft adapter from the damper shaft and remove the actuator from the damper shaft.

2. Remove the clip and shaft adapter from the actuator.

3. Return the actuator gear train to the “0” position using the steps that follow for the clockwise or counterclock wise damper

shaft rotation.

Clockwise to open:

a. Insert the shaft adapter to the right as close as possible to the raised stop. See Figure 3.

b. Hold down the PUSH button and rotate the shaft adapter to the left until it stops. See Figure 4.

c. Release the PUSH button.

d. If the shaft adapter is not resting against the left raised stop, remove the adapter and insert it against the left stop.

e. Place the position indicator to the “0” position on the outside scale. See Figure 5.

Counterclockwise to open:

a. Insert the shaft adapter to the left as close as possible to the raised stop.

b. Hold down the PUSH button and rotate the shaft adapter to the right until it stops.

c. Release the PUSH button.

d. If the shaft adapter is not resting against the right raised stop, remove the adapter and insert it against the right stop.

e. Place the position indicator to “0” on the inside scale.

4. Determine the angle of rotation for the damper blade shaft. Subtract that amount from 90°.

5. Remove the shaft adapter and insert it with the position indicator pointing to the mark on the scale calculated in the

previous step. See Figure 4.

6. Attach the clip.

7. Rotate the damper blade shaft to its “0” position.

8. Return the actuator to the damper shaft and tighten the shaft adapter to the damper shaft.

PAGE 4