Table of contents

1. Version.........................................................................................................1

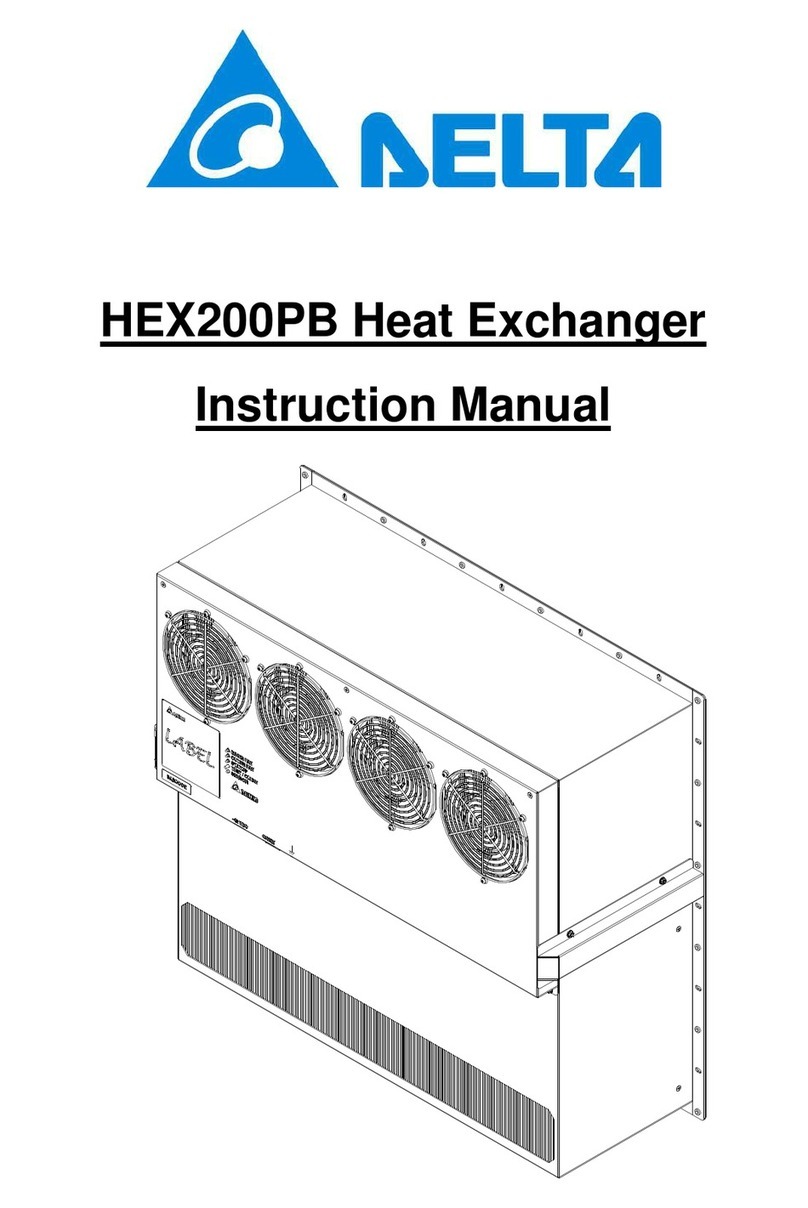

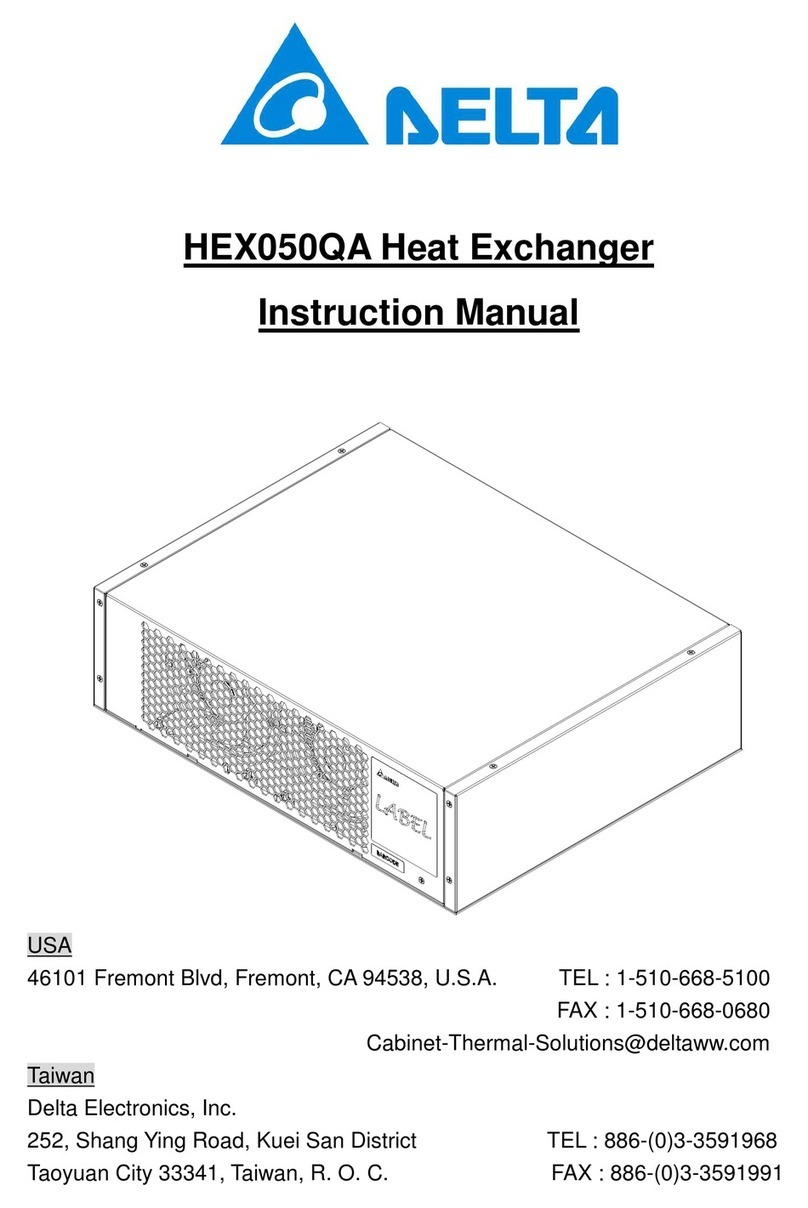

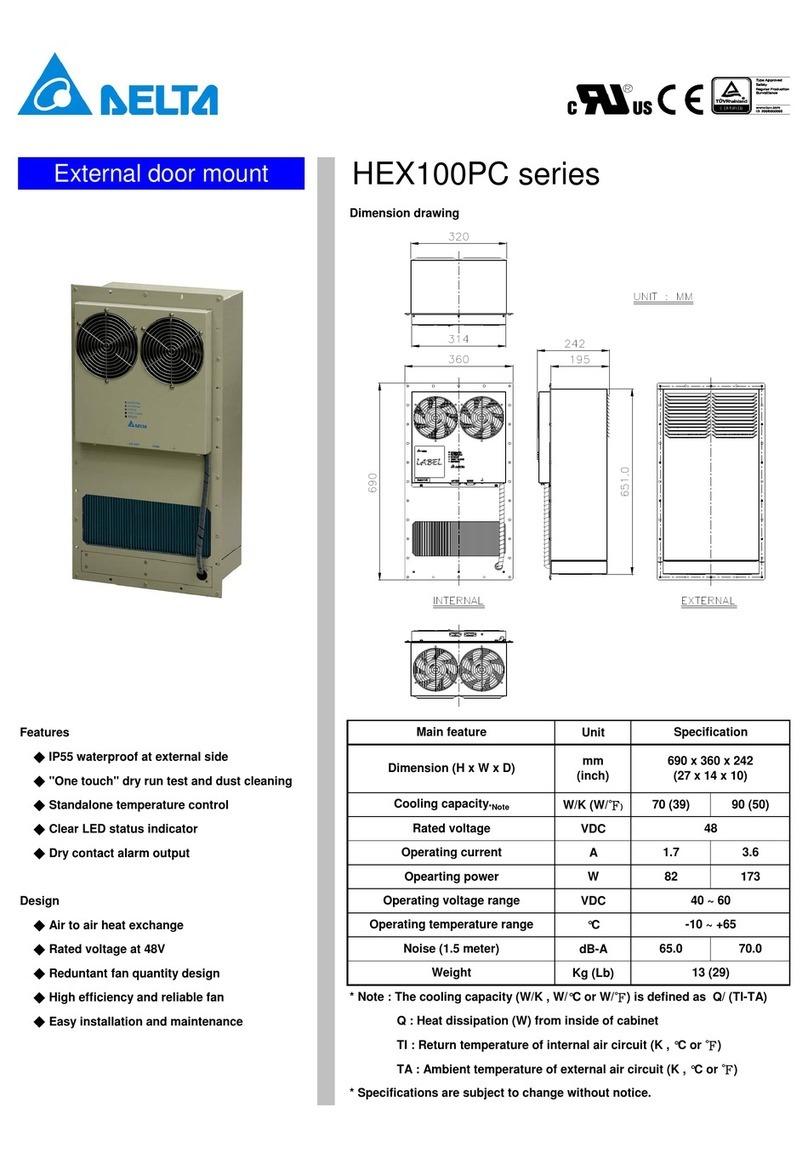

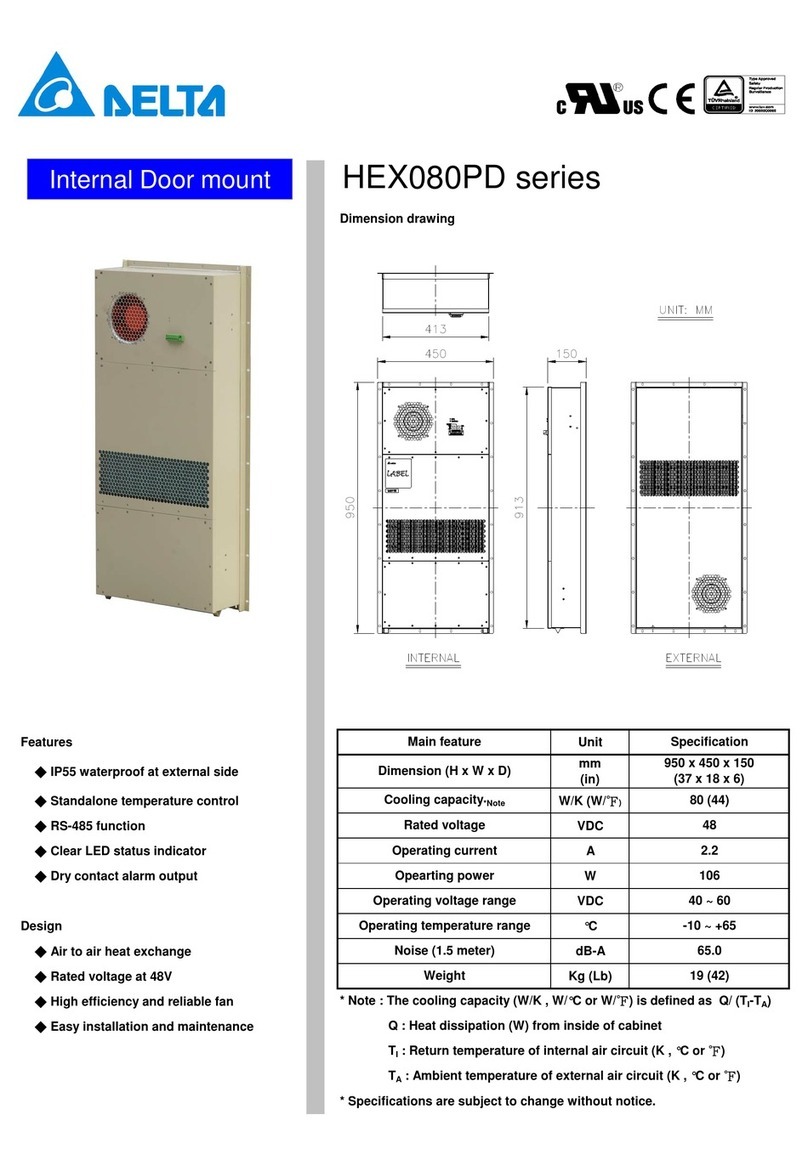

2. Description...................................................................................................1

2-1 . General...............................................................................................1

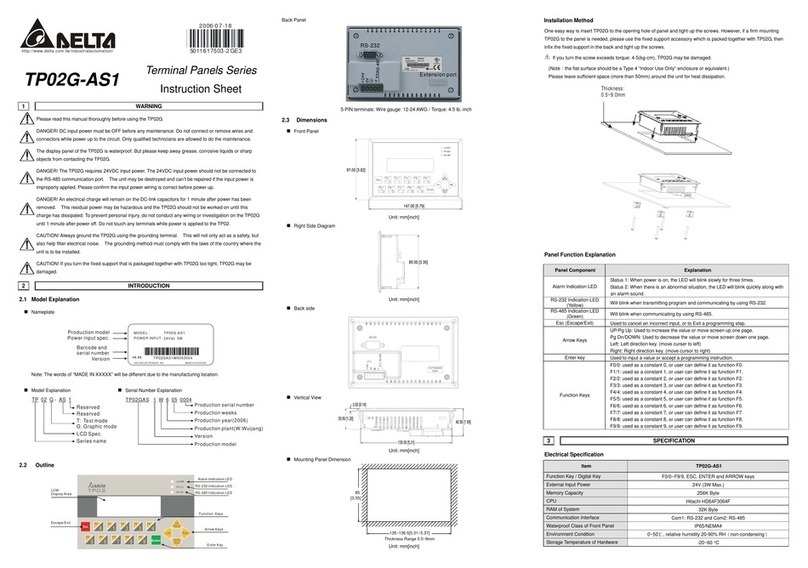

2-2 . Specification......................................................................................1

2-3. Environmental condition...................................................................2

3. Installation ...................................................................................................2

3-1 . Outline drawing.................................................................................2

3-2 . Mounting panel cutout and waterproof foam sticking ...................3

4. Electrical specification................................................................................3

4-1.Connection and LED indicator (on HEX panel).................................3

4-2.Standalone control mode....................................................................5

5. Mechanical feature......................................................................................6

5-1. Thermal path and Airflow baffle.......................................................6

5-2. Configuration.....................................................................................6

6. Maintenance and Replacement..................................................................7

6-1. Maintenance.......................................................................................7

6-2. Replacement......................................................................................8

7. MTBF and Reliability...................................................................................8

7-1. MTBF...................................................................................................8

7-2. Relibability .........................................................................................8

8. Safety............................................................................................................9

9. Accessory....................................................................................................9

9-1. Power cable........................................................................................9

9-2. Function cable...................................................................................9

10. General Safety and Warnings ..................................................................9