Preface

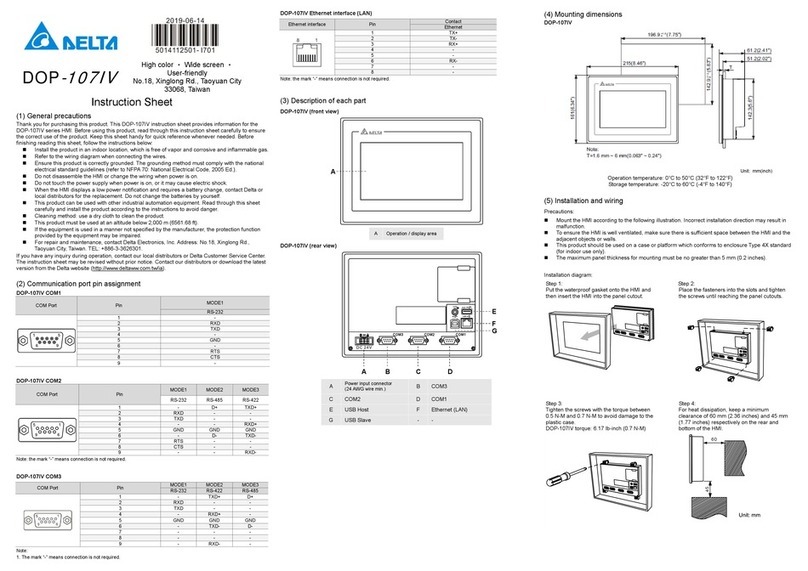

Thank you for purchasing DELTA’s DOP-B series. This quick start will be helpful in the installation,

wiring and inspection of Delta HMI. Before using the product, please read this quick start to ensure

correct use. You should thoroughly understand all safety precautions before proceeding with the

installation, wiring and operation. Place this quick start in a safe location for future reference. Please

observe the following precautions:

Install the product in a clean and dry location free from corrosive and inflammable gases or

liquids.

Ensure that all wiring instructions and recommendations are followed.

Ensure that HMI is correctly connected to a ground. The grounding method must comply with

the electrical standard of the country (Please refer to NFPA 70: National Electrical Code, 2005

Ed.).

Do not modify or remove wiring when power is applied to HMI.

Do not touch the power supply during operation. Otherwise, it may cause electric shock.

For the information of HMI software operation, and software installation, please refer to the

HMI software manual.

If you have any questions during operation, please contact our local distributors or Delta sales

representative.

The content of this quick start may be revised without prior notice. Please consult our distributors or

download the most updated version at http://www.delta.com.tw/ia/.

Safety Precautions

Carefully note and observe the following safety precautions when receiving, inspecting, installing,

operating, maintaining and troubleshooting. The following words, DANGER, WARNING and STOP are

used to mark safety precautions when using the Delta’s HMI product. Failure to observe these

precautions may void the warranty!

Installation

damage.

Do not install the product in a location that is outside the stated specification for

the HMI. Failure to observe this caution may result in electric shock, fire, or

explosion.

Do not install the product in a location where temperatures will exceed

specification for the HMI. Failure to observe this caution may result in abnormal

operation or damage the product.

Please note that this equipment has obtained EMC registration for commercial

use. In the event that it has been mistakenly sold or purchased, please exchange

it for equipment certified for home use.

Do not use this product as an alarm device for disaster early warning that may