3

LT-2 027

EN Tab le o f C o n te n ts

1. General Information ......................................... 4

A. Safeguards............................................................ 4

B. Initial Inspection ................................................... 4

C. T ravel ................................................................... 5

D. DC Power ........................................................... 5

E. Setting Pressures and Features ............................ 5

F. Images: DeVilbiss DV54 PAP................................. 5

2. Description of Normal Operation .................... 6

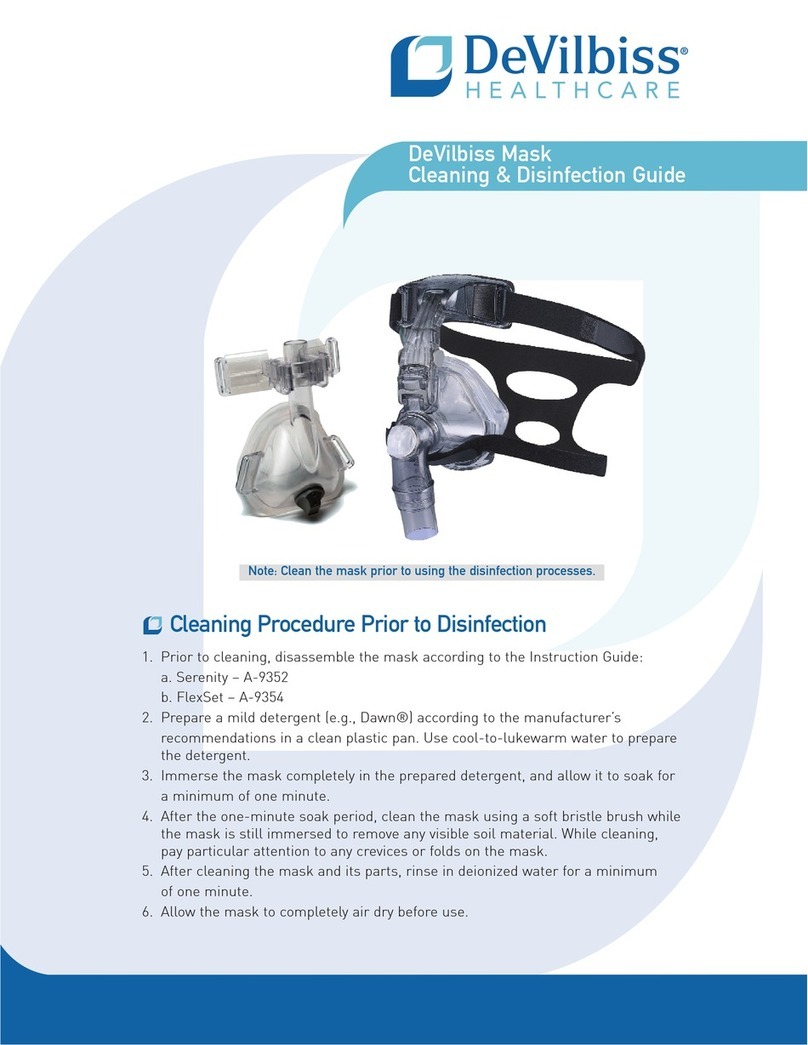

3. Cleaning and Disinfecting ................................. 7

A. R outine Cleaning--Patient .................................... 7

B. Disinfecting .......................................................... 7

4. Maintenance...................................................... 10

A. Initial Inspection—Equipment Provider .............. 10

B. R outine Maintenance—Patient ............................ 10

C. R equired 2-year Maintenance—

Equipment Provider ......................................... 10

5. Testing ............................................................... 11

A. Pressure Accuracy T est ........................................ 11

B. Flow Accuracy T est .............................................. 11

C. K eypad T est ......................................................... 12

D. Auto-ON / Auto-OFF T est.................................. 12

E. Backlight T est for LCD and K eypad ..................... 12

6. Alerts and Device Faults................................... 13

A. Alerts Visible to Patients ...................................... 13

B. Device Faults Visible to Patients ......................... 13

C. R eading and Clearing the Last Device Fault Code 13

7. Calibration......................................................... 14

A. Manual Calibration............................................... 14

B. Calibration Errors ................................................ 15

C. Auto-Calibration ................................................. 15

D. Details on T c Serial Command............................ 15

8. Troubleshooting ................................................ 16

9. Service Instructions .......................................... 18

A. Cover R emoval ................................................... 18

B. Cover R eplacement ............................................. 18

C. Control PC Board R emoval................................. 18

D. Control PC Board R eplacement.......................... 19

E. Power Supply Board R emoval.............................. 20

F. Power Supply Board R eplacement........................ 20

G. Blower R emoval .................................................. 21

H. Blower R eplacement ........................................... 21

I. K eyPad & LCD Display R emoval and R eplacement......... 22

J. Firmware installation............................................. 22

10. Unit Specifications ............................................ 23

11. General Information- DV5HH .......................... 24

A. Safeguards............................................................ 24

B. T ravel.................................................................... 24

C. DC Power ........................................................... 24

D. Product Description ............................................ 24

12. Description of Normal Operation- DV5HH..... 25

13. Maintenance and Testing- DV5HH................... 26

A. Cleaning and Disinfection .................................... 26

B. Maintenance......................................................... 26

C. T esting.................................................................. 26

14. Troubleshooting- DV5HH.................................. 27

15. Service Instructions- DV5HH........................... 28

A. R emoving the DV5HH base cover....................... 28

B. R eplacing the DV5HH base cover........................ 28

C. R emoving and replacing silicone manifold................ 29

D. R emoving and replacing the latch........................ 29

16. Unit Specifications- DV5HH............................. 30

17. Ordering and R eturning Parts.......................... 31

A. Ordering Non-W arranty R eplacement Parts ....... 31

B. Ordering W arranty R eplacement Parts ............... 31

C. R eturning W arranty Defective Parts .................... 31

D. Placing orders...................................................... 31

18. Parts List ........................................................... 32

19. W arranties......................................................... 33