INSTALLATION

1.

The air supplied to spray gun must be cleaned air which any water, oil and solid material

removed.To setupthe Mist Separator and AirTransformernearthe gun is recommended. The

use of airnot cleaned may cause coating troubles.

2.

Connect fluid cup and air hoses tightly. If tightened loosely, hoses can be removed which may

result in damaging the human body, objects to be coated and other equipment used together.

3.

Adjust Needle Packing(19) before start using new gun. Tighten the Needle Packing kit(18)

gradually and then to adjust the needle moving smoothly, untighten until the Needle(15)is not well

pulled back.

OPERATION

1.

The recommended pressure of air supplied to gun inlet is in a range of 0.15MPa-0.25MPa.

Do not supply to gun the air pressure in excess of the gun’s maximum working pressure

(0.69MPa).

2.

Try with the pressure starting from 0.15MPa –0.25MPa or around as the spraying pressure

variesdependingupontheinnerdiameterofgun,triggeringdistance, materialsetc.

3.

The recommended spray distance is 150-200mm. If the spray distance is too far, good result

does notappear.

4.

Inorder togetuniformfinishing,the spray gunshouldbehold vertically toward thepainting

surface.

PREVENTIVE MAINTENANCE

1.

Daily lubrication and cleaning isnecessary tomaintain the best condition ofthe gun.

2.

Toclean the gun body, wipe exterior with solvent dampened cloth. Do not submerge the gun

bodyinsolvent as anysolids may getinto the air passage and cause troubles.

3.

Clean the spray gun after used with clean solvent and empty the inside of the hose.

To clean the fluid passage, after removing extra paint, through the appropriate solvent and flush

down the residual paint.

4.

The Air Cap can be immersed in solvent and brushed down for cleaning. If orifices are

clogged, use a toothpick toremove obstruction. Neveruse a steel wire orhardinstrument. This

willdamage air cap andresult ina distorted spray pattern.

5.

Do not immerse any plastic parts insolvent for long time.

6.

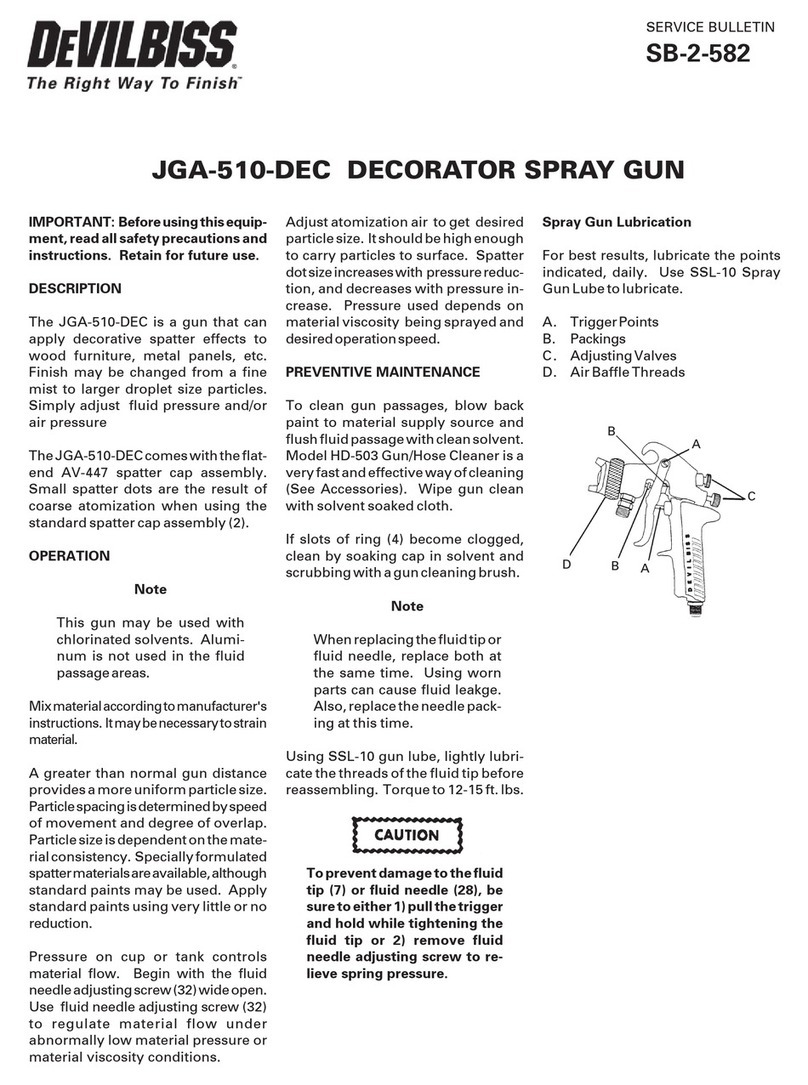

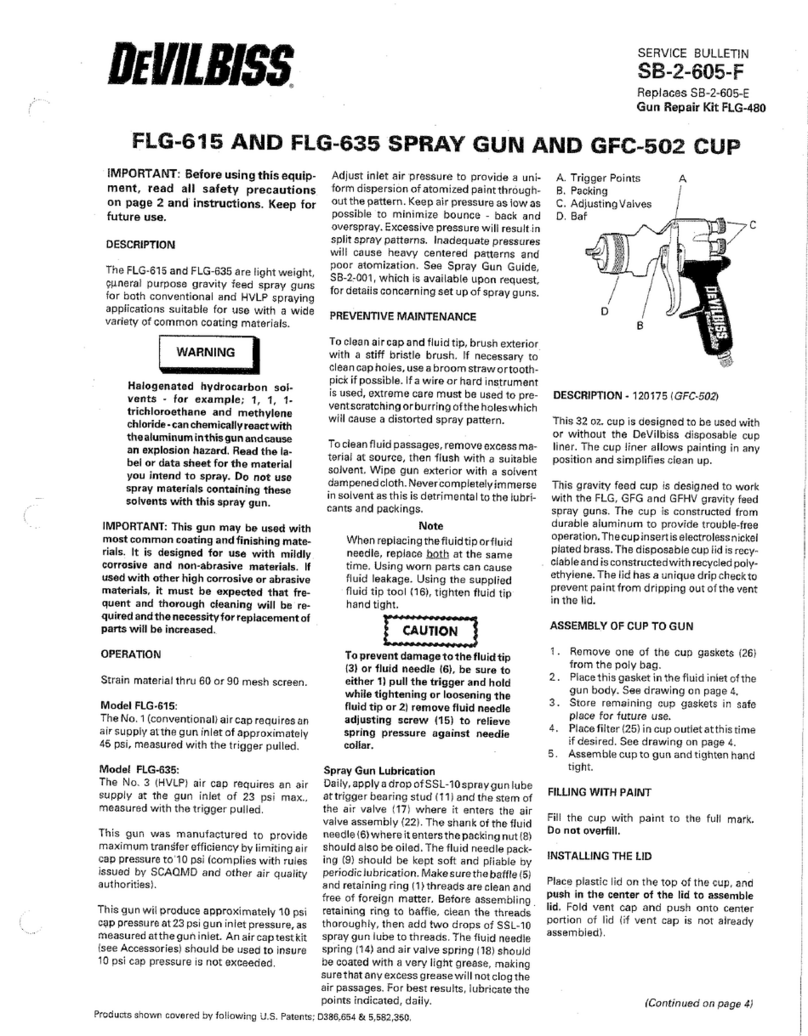

Certain portions of gun should be lubricated. Do not lubricate to any portion where not

instructed. For lubrication, SSL-10 Gun Lube* is recommended (*sold separately, vegetable

notrepellingmaterials).

7.

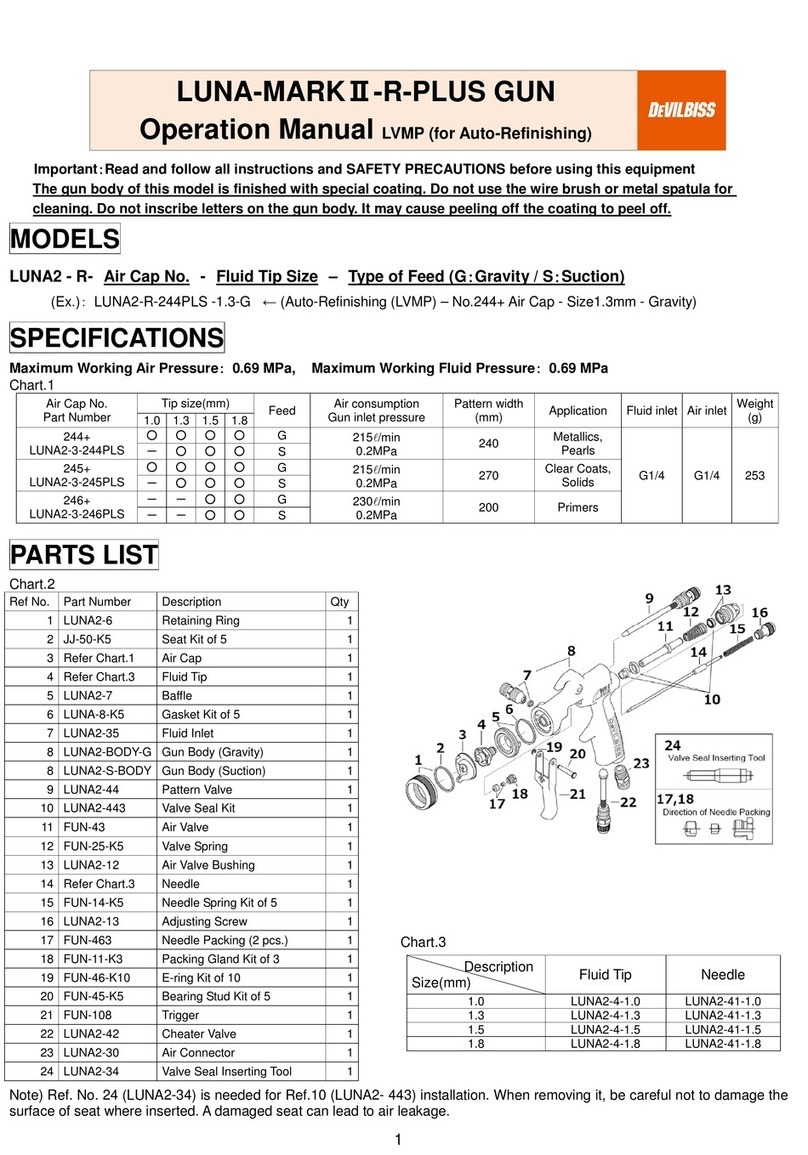

The following portions should be lubricated regularly; Bearing Stud (20), Pattern Valve (10),

and Needle Adjusting Knob (17),Air Valve(12) stem, portion of PackingGland(18)hereNeedle

(15)comes in andout.

8.

When installing Air Cap (4), make sure no foreign materials adhered on Retaining Ring (1) and

thread of body and then oil one drop of Gun Lube SSL-10.

9.

Apply non-silicone grease lightly on Needle Spring (16)and Air ValveSpring (13).Do not apply

too much grease as it may clog the air passage.