DeVilbiss JGA-510-DEC Reference manual

Other DeVilbiss Paint Sprayer manuals

DeVilbiss

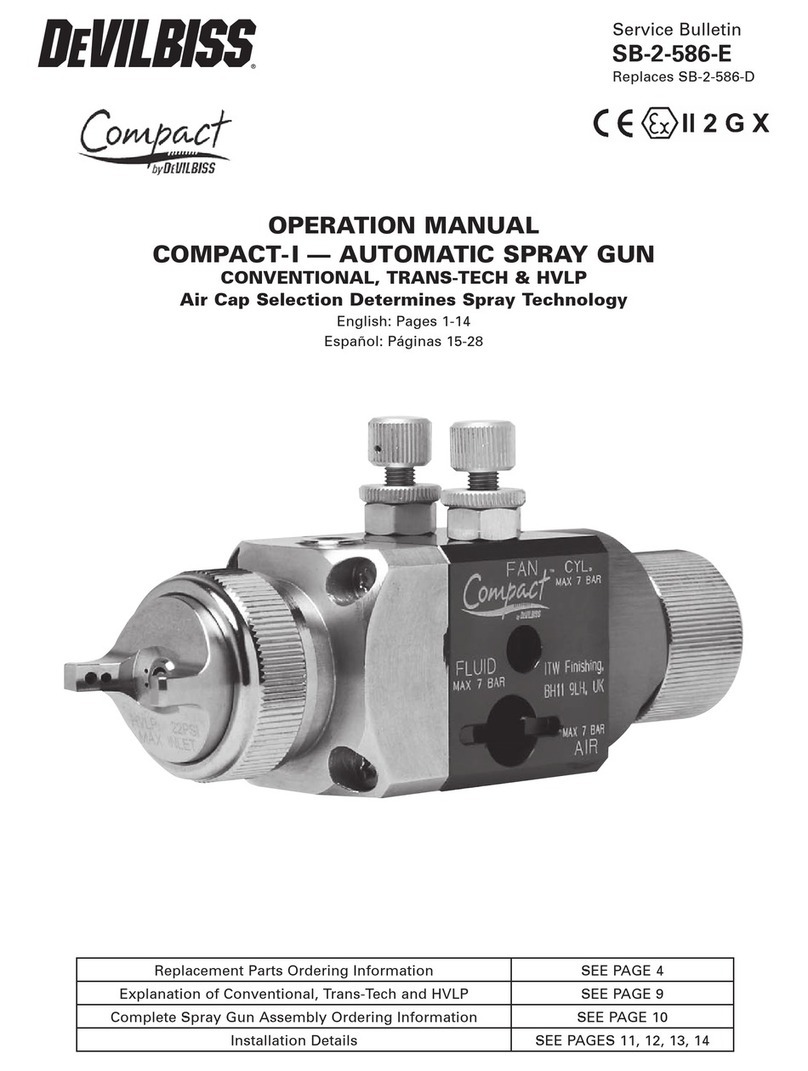

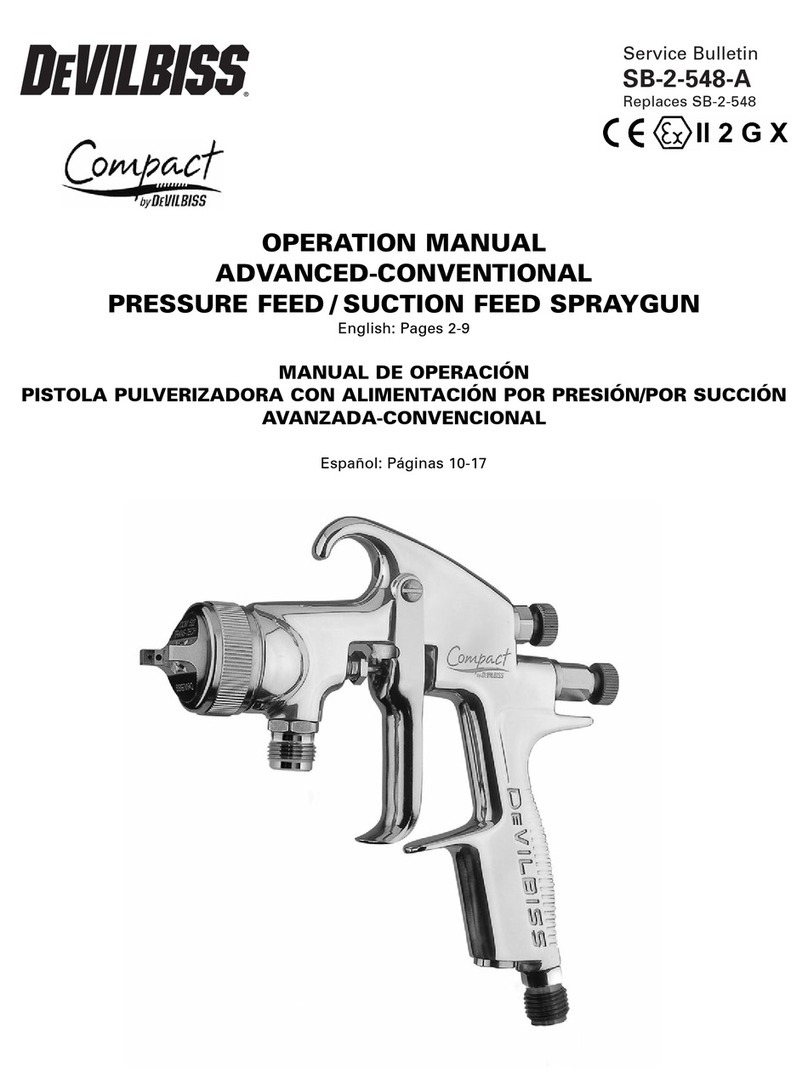

DeVilbiss Compact-I User manual

DeVilbiss

DeVilbiss Viper User manual

DeVilbiss

DeVilbiss Compact COM-PS430-18-01 User manual

DeVilbiss

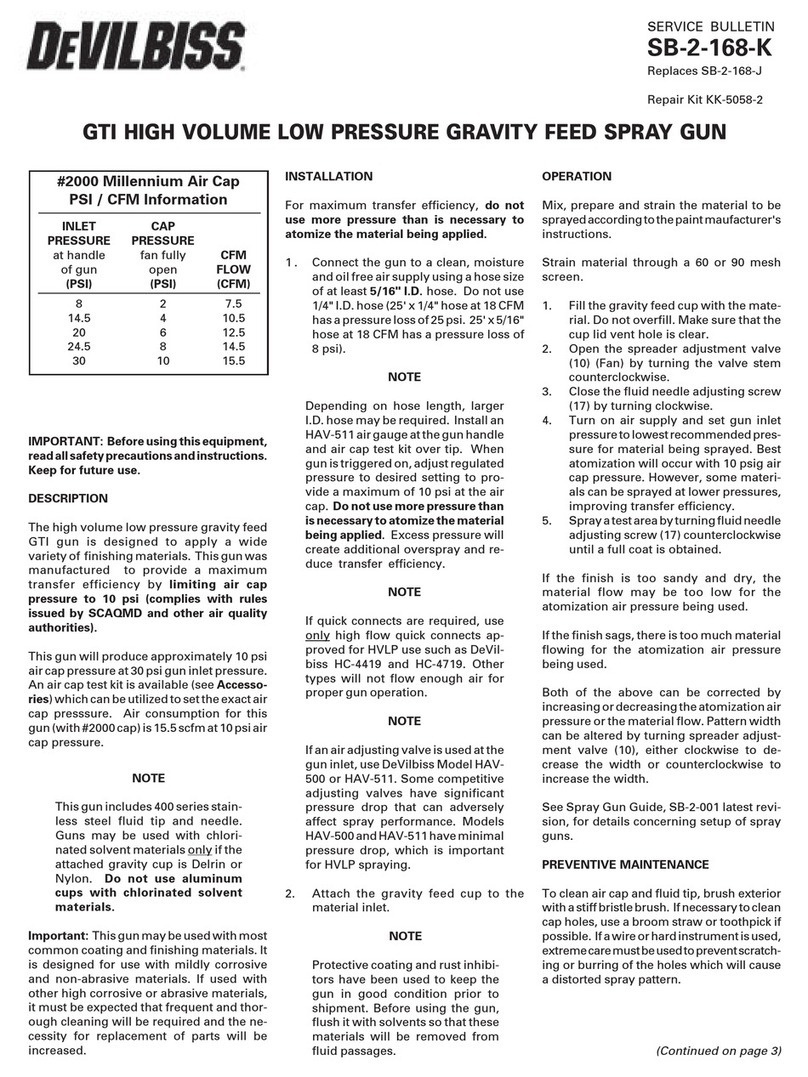

DeVilbiss SB-2-168-K User manual

DeVilbiss

DeVilbiss Compact Series User manual

DeVilbiss

DeVilbiss SRi User manual

DeVilbiss

DeVilbiss FinishLine FLG-611-114 Installation manual

DeVilbiss

DeVilbiss GTI User manual

DeVilbiss

DeVilbiss Compact MINI Service manual

DeVilbiss

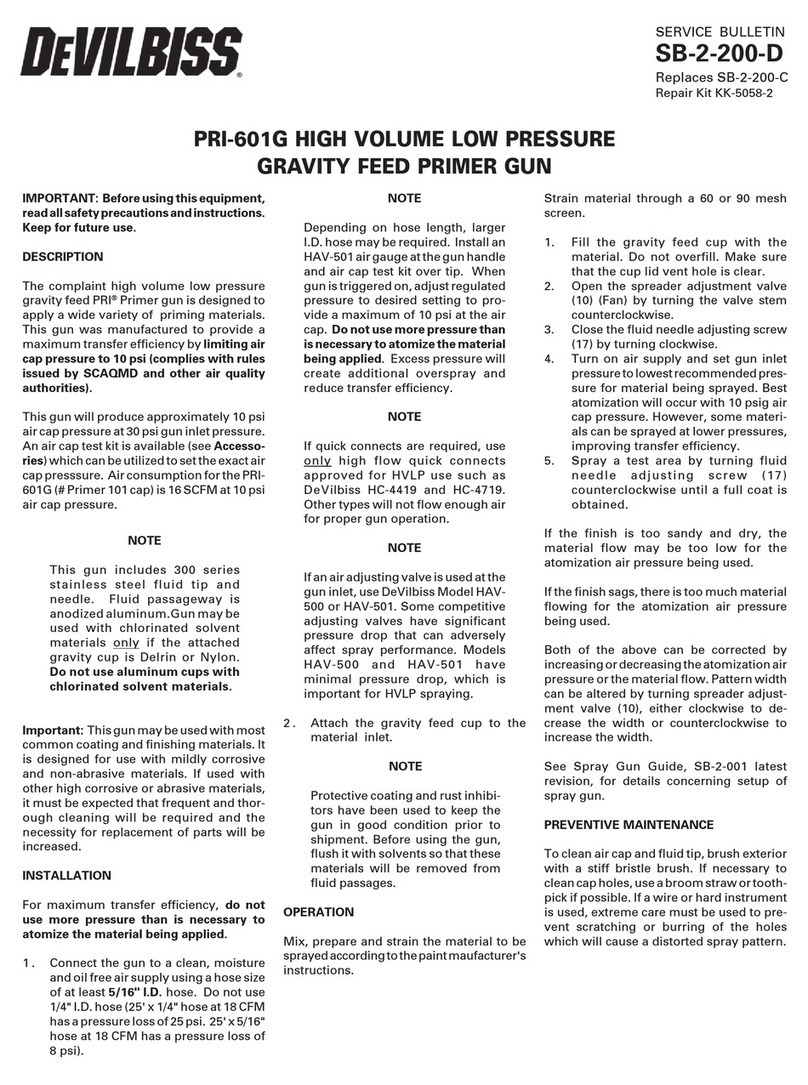

DeVilbiss PRI-601G Reference manual

DeVilbiss

DeVilbiss JGX-502 User manual

DeVilbiss

DeVilbiss GTI User manual

DeVilbiss

DeVilbiss ADVANCE HD Series User manual

DeVilbiss

DeVilbiss HD-503 User manual

DeVilbiss

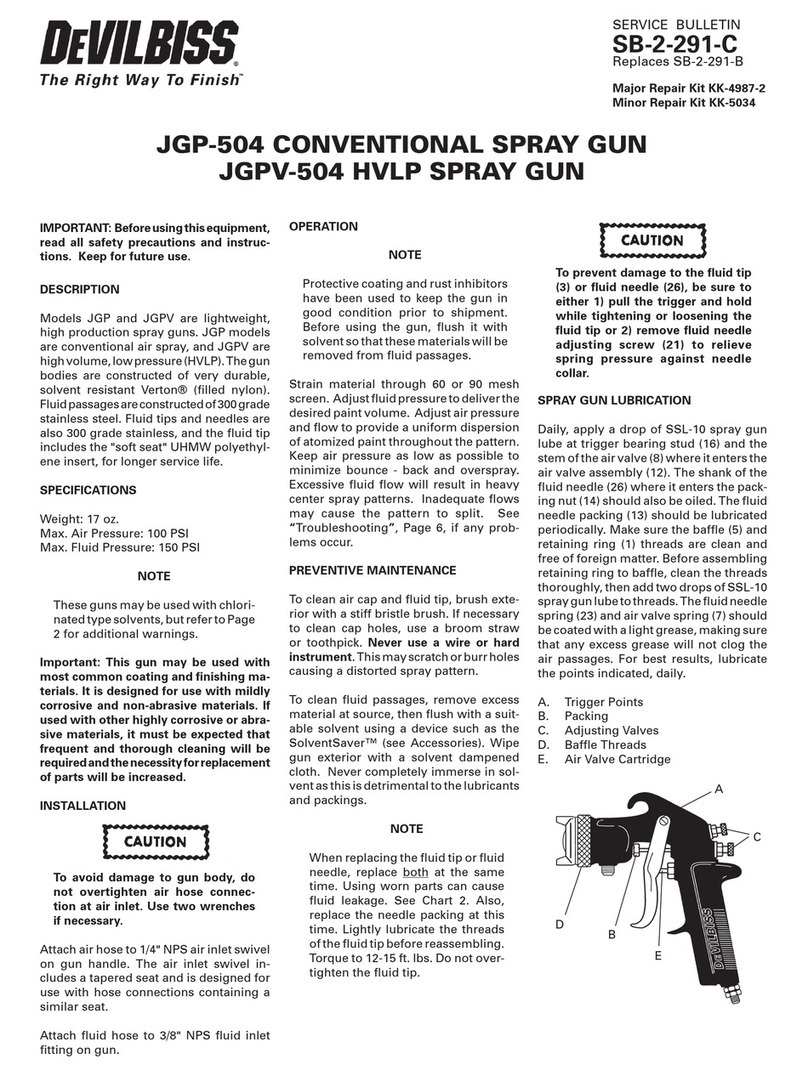

DeVilbiss JGP-504 User manual

DeVilbiss

DeVilbiss TGC-536 User manual

DeVilbiss

DeVilbiss FLG-CNG-115 User manual

DeVilbiss

DeVilbiss NEPTUNE Series User manual

DeVilbiss

DeVilbiss JGA Operating instructions

DeVilbiss

DeVilbiss SB-2-001-F Operating manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual