d. Controlling positive pressure with flow restrictors

Inhibiting the flow with the constrictors is helpful in two ways:

The amount of gas used is minimized as compared to a

system with no inhibitors.

The pressure remains high in the wells or cartridges

containing liquid as compared to the empty or dry wells

or cartridges.

e. Adjusting the extraction flow

The Waters Positive Pressure-96 Processor has a two-level gas

delivery system used to pressurize the SPE plate. One part of the

system is controlled by the rotometer located on the left side of

the instrument panel. By switching the “SPE Flow Rate” selector

to the left, “Adjust Flow” setting, the gas is delivered to the

Manifold through the adjustable flow regulator and then through

the rotometer controlled by the needle valve located at its base.

The rotometer provides a very precise and slow flow through

the plate wells or the cartridges by limiting the gas flow to the

manifold from 0 to 2.5 SCFH.

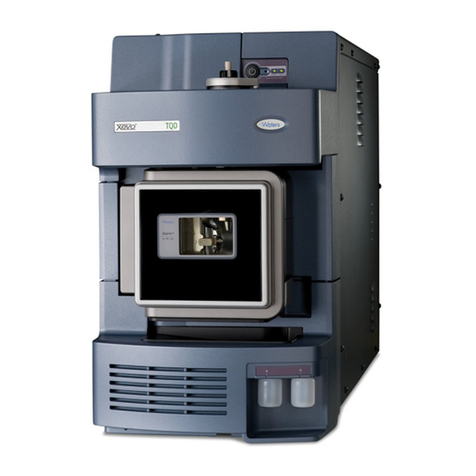

A. Manifold Head

B. Toggle Switches

Raise and lower manifold head

(1 on each side)

C. Rotometer

Sets the gas flow for the

low flow setting

D. Low Flow Regulator

E. Max Flow Regulator

F. Selector Valve

Used to select LOW or MAX

gas flow through the device.

Key Features.

Tip: The rotometer needle valve is for adjustment only and must

never be used as an on off valve. Use the selector valve to turn off

the gas flow.

The second part of the gas delivery system provides for rapid

gas flow to the manifold. This flow is controlled by adjusting the

regulator located below the pressure gauge labeled “Max Flow”.

The pressure range is 0 to 80 psig and is used to maximize

flow through the plate wells or the cartridges for processing

highly viscous samples or to dry the well or cartridge in situ.

By switching the “SPE Flow Rate” selector to “Max Flow”, gas is

introduced to the manifold at the pressure set on the “Max Flow”

regulator as indicated by the gauge located directly above it. By

turning the “SPE Flow Rate” selector to off, no gas will flow to the

manifold. It should be in the off position during the compression

and decompression cycles and when not in use.

IV. MAINTAINING THE WATERS POSITIVE

PRESSURE-96 PROCESSOR

a. Maintenance considerations

Safety and handling

Observe these warning and caution advisories when you perform

maintenance operations on your system.

Warning: To prevent injury, always observe Good Laboratory

Practices when you handle solvents, change tubing, or operate the

Waters Positive Pressure-96 Processor. Consult the Material Safety

Data Sheets regarding the solvents you use.

Caution:The Waters Positive Pressure-96 Processor device is constructed

of anodized aluminum, stainless steel, and plastics. To prevent

damage to the device, clean solvent spills and overflow immediately.

b. Replacing the 96-place sealing gasket

Required materials

96-place sealing gasket

3/16-inch hex key

To replace the 96-place sealing gasket:

1. Using the enclosed hex key, remove the two 1/4-20 screws

that fasten the manifold to the unit.

2. Lift the manifold off the standoffs and place it upside down on

the table.

Rationale: Removing the manifold helps you accurately align

the replacement 96-place sealing gasket.

3. Remove the old 96-place sealing gasket from the manifold.

4. Attach the enclosed screws to the threaded holes on each

corner on the bottom of the manifold.

5. Remove the backing of the replacement 96-place sealing

gasket. Use the screws for aligning and adhere the replacement

96-place sealing gasket.

6. Once the sealing gasket is attached, remove the four screws.

7. Carefully set the manifold on the standoffs. Fasten the

manifold with the screws.

8. Using the 3/16 hex key, tighten the screws.

4

[ OPERATOR’S GUIDE ]

Waters Positive Pressure-96 Processor