3

CONTENTS

Chapter 1 - Wire Myograph overview .................................................................................................................................................................................... 3

Chapter 2 - setting up the wire myograph - 620M............................................................................................................................................................ 4

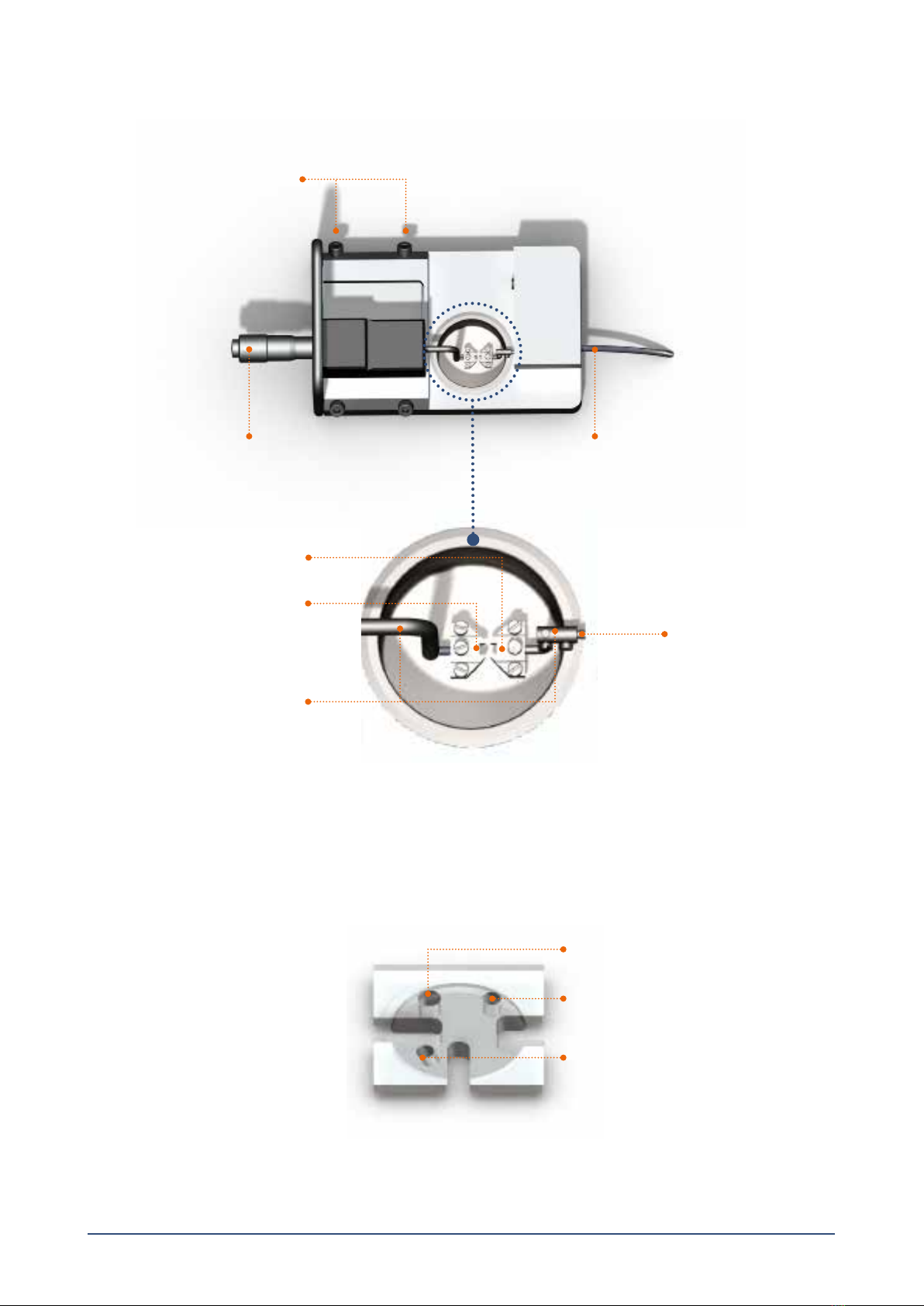

2.1 Changing and adjusting the mounting supports ...................................................................................................................................................... 4

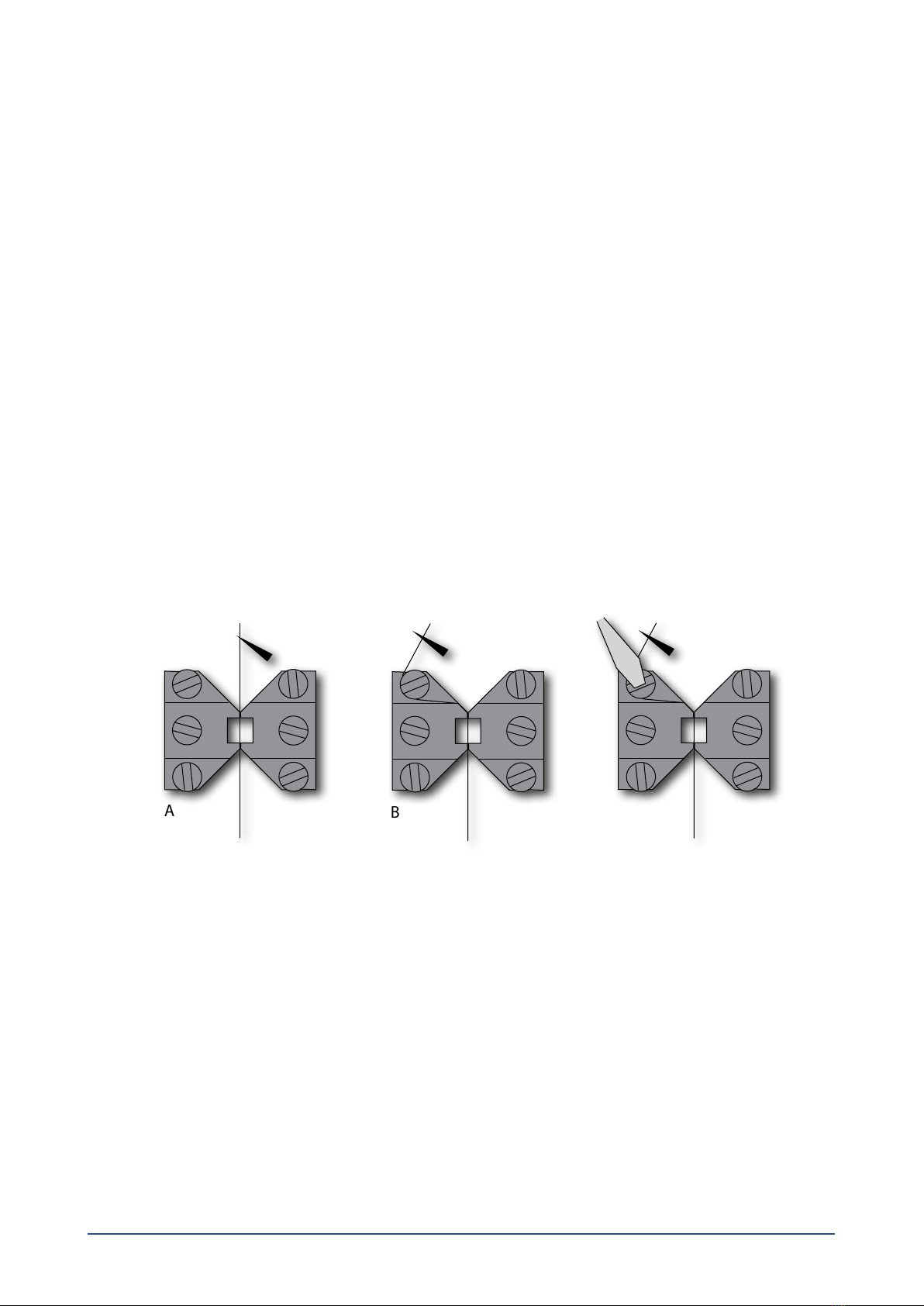

2.1.1 Changing the mounting supports (gure 2.1)......................................................................................................................................................... 4

2.1.2 Coarse adjusting the jaws for small vessels (gure 2.1)........................................................................................................................................ 4

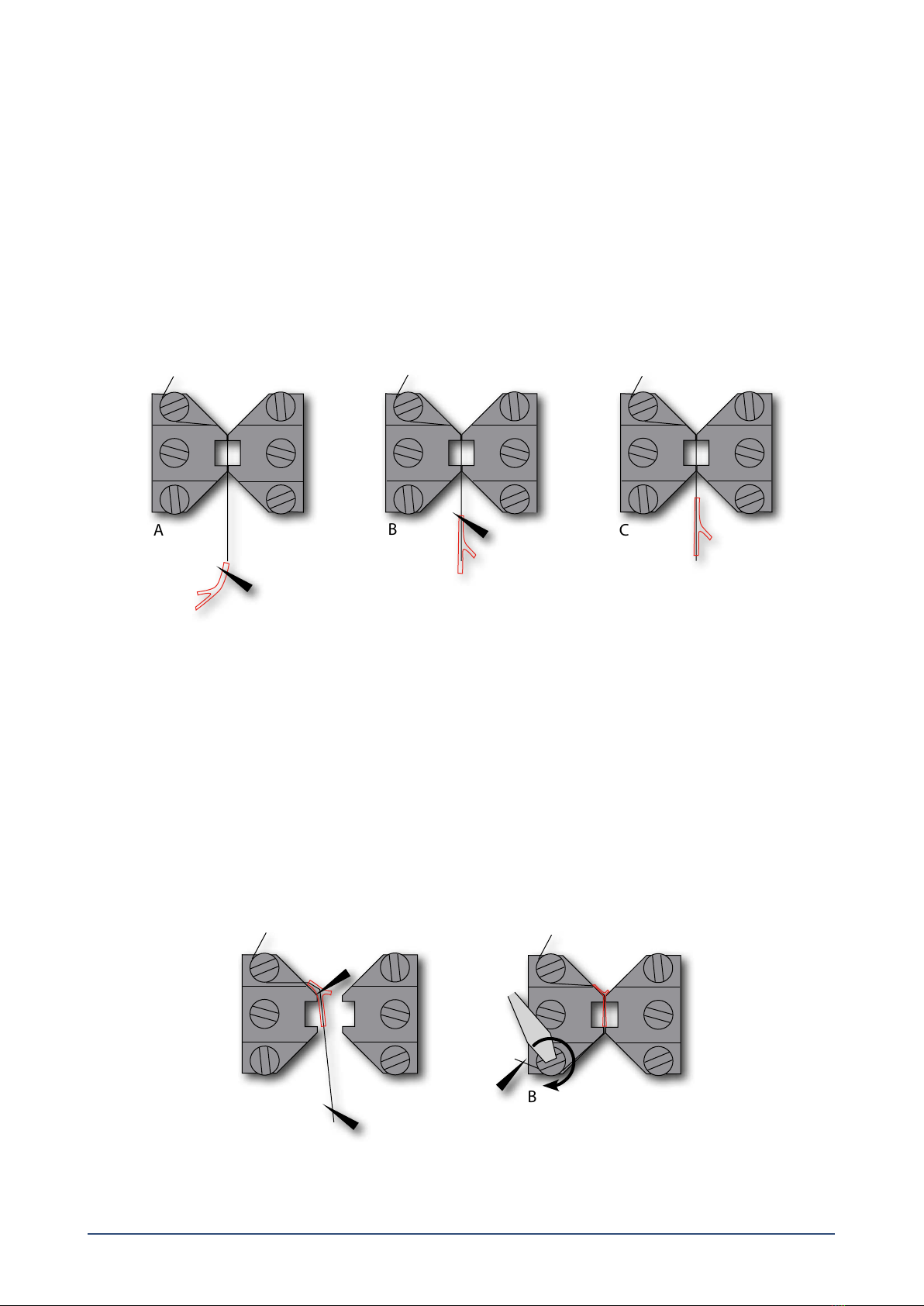

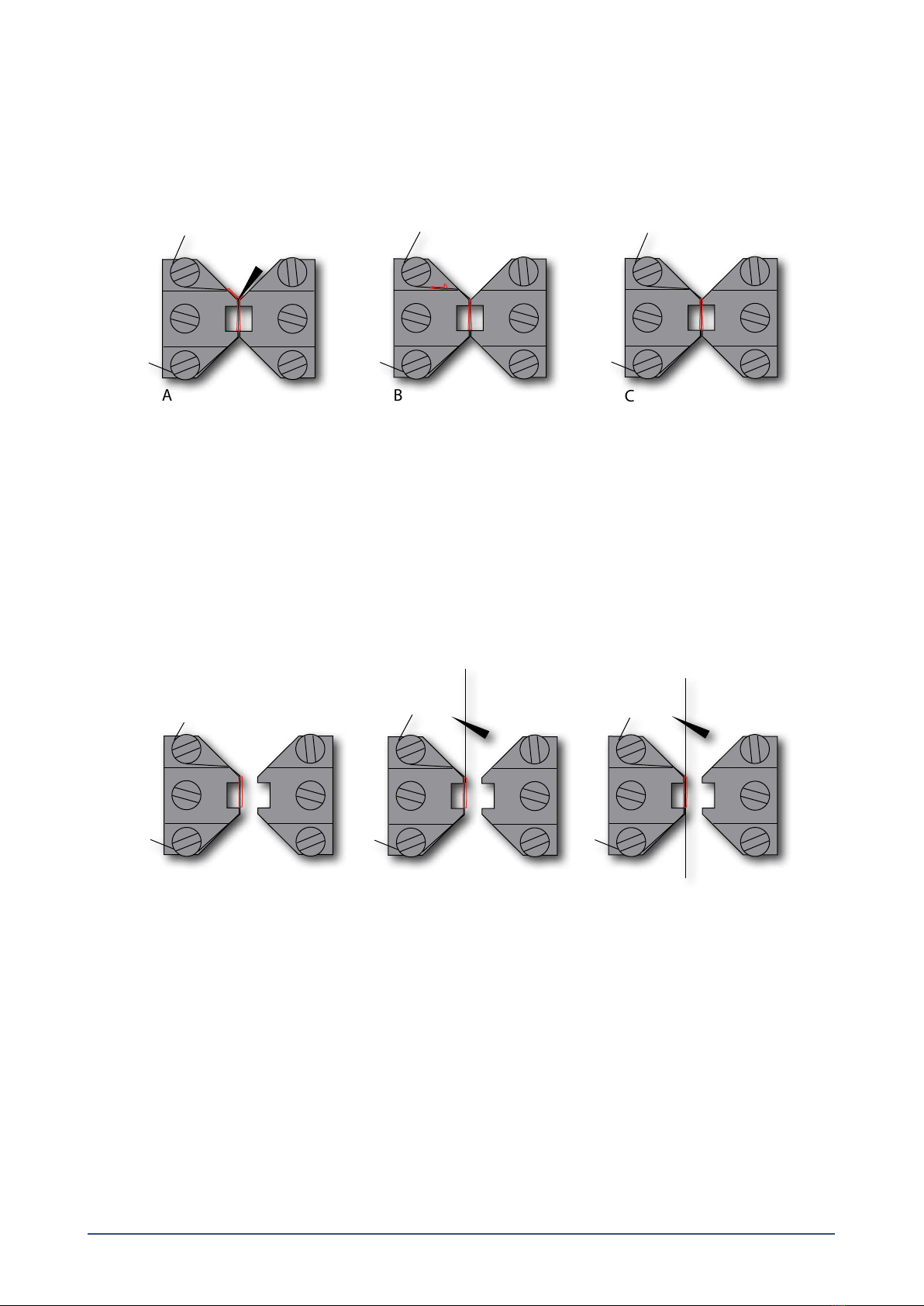

2.1.3 Fine adjusting the jaws for small vessels (gure 2.2 and gure 2.3)................................................................................................................. 5

2.1.4 Fine adjusting the pins for larger vessels (gure 2.4 and gure 2.5):............................................................................................................... 6

2.2 Calibration of the force transducer.................................................................................................................................................................................. 6

Chapter 3 - Experimental set-up ............................................................................................................................................................................................. 7

3.1 Mounting protocol for small arteries .............................................................................................................................................................................. 7

3.1.1 Mounting step one............................................................................................................................................................................................................. 7

3.1.2 Mounting step two............................................................................................................................................................................................................. 8

3.1.3 Mounting step three.......................................................................................................................................................................................................... 8

3.1.4 Mounting step four............................................................................................................................................................................................................ 9

3.1.5 Mounting step ve............................................................................................................................................................................................................. 9

3.1.6 Mounting step six.............................................................................................................................................................................................................10

3.1.7 Mounting step seven.......................................................................................................................................................................................................10

3.2 Normalization........................................................................................................................................................................................................................10

3.2.1 Principles of the normalization procedure..............................................................................................................................................................11

3.3 Standard start ........................................................................................................................................................................................................................11

3.3.1 Principles of the standard start procedure..............................................................................................................................................................11

3.4 Endothelium function ........................................................................................................................................................................................................12

3.4.1 Principles of checking endothelium function........................................................................................................................................................12

3.5 In vitro experiment 1: Noradrenaline contractile response..................................................................................................................................13

3.5.1 Background.........................................................................................................................................................................................................................13

3.5.2 Protocol ................................................................................................................................................................................................................................13

3.6 In vitro experiment 2: Acetylcholine relaxation curve............................................................................................................................................14

3.6.1 Background.........................................................................................................................................................................................................................14

3.6.2 Protocol ................................................................................................................................................................................................................................14

Chapter 4 - Cleaning and maintenance ..............................................................................................................................................................................15

4.1 Cleaning the Wire Myograph ..........................................................................................................................................................................................15

4.2 Maintenance of the force transducer............................................................................................................................................................................16

4.2.1 Checking the force transducer.....................................................................................................................................................................................16

4.2.2 Force Transducer Replacement....................................................................................................................................................................................17

4.3 Maintenance of the linear slides.....................................................................................................................................................................................18

Appendix 1 - Buer recipes .....................................................................................................................................................................................................19

Appendix 2 - Normalization theory ......................................................................................................................................................................................21

Appendix 3 - Reading a millimetre micrometer...............................................................................................................................................................23