206.05.21 en / 393A

The device is supplied with DC auxiliary voltage via terminals A1(+) / A2.

Switching on the auxiliary voltage (Power-On) is followed by an internal

self-test for 12 s (see „Device test functions“). The test process is visible

with the status LED. After this, measurement of the insulation resistance

in the measuring circuits begins and the status LED changes into green.

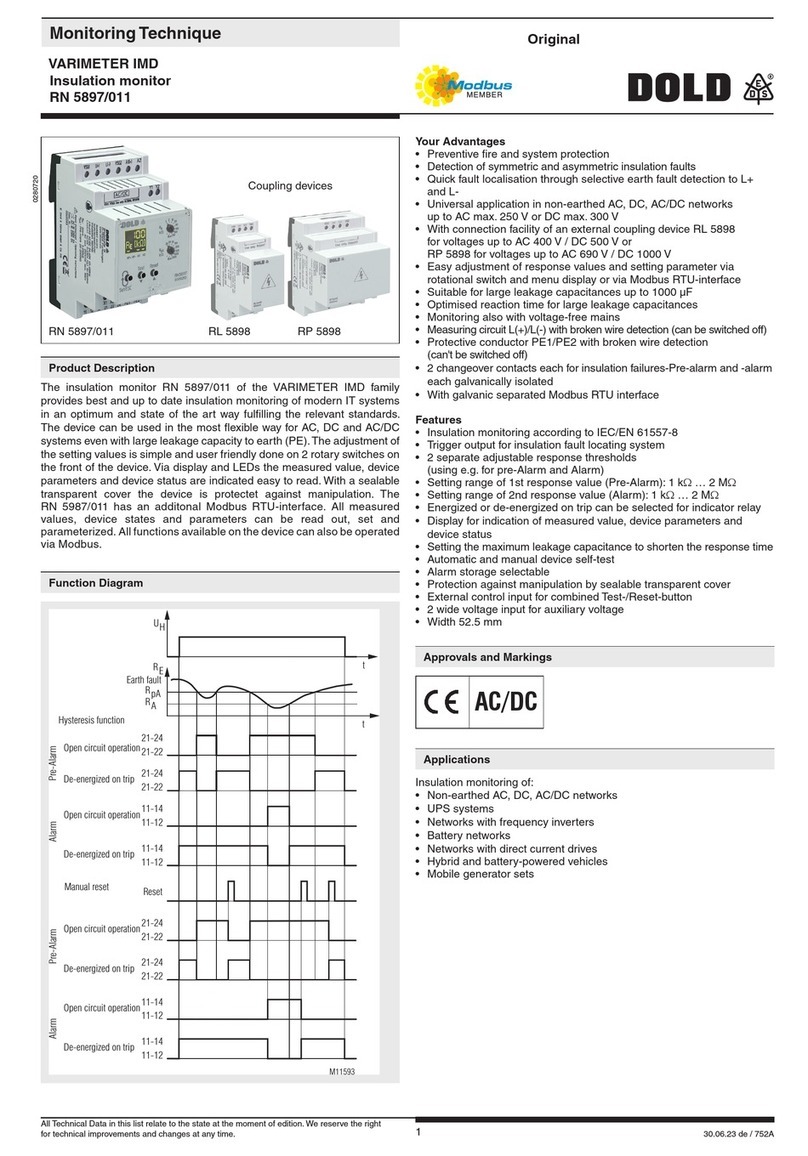

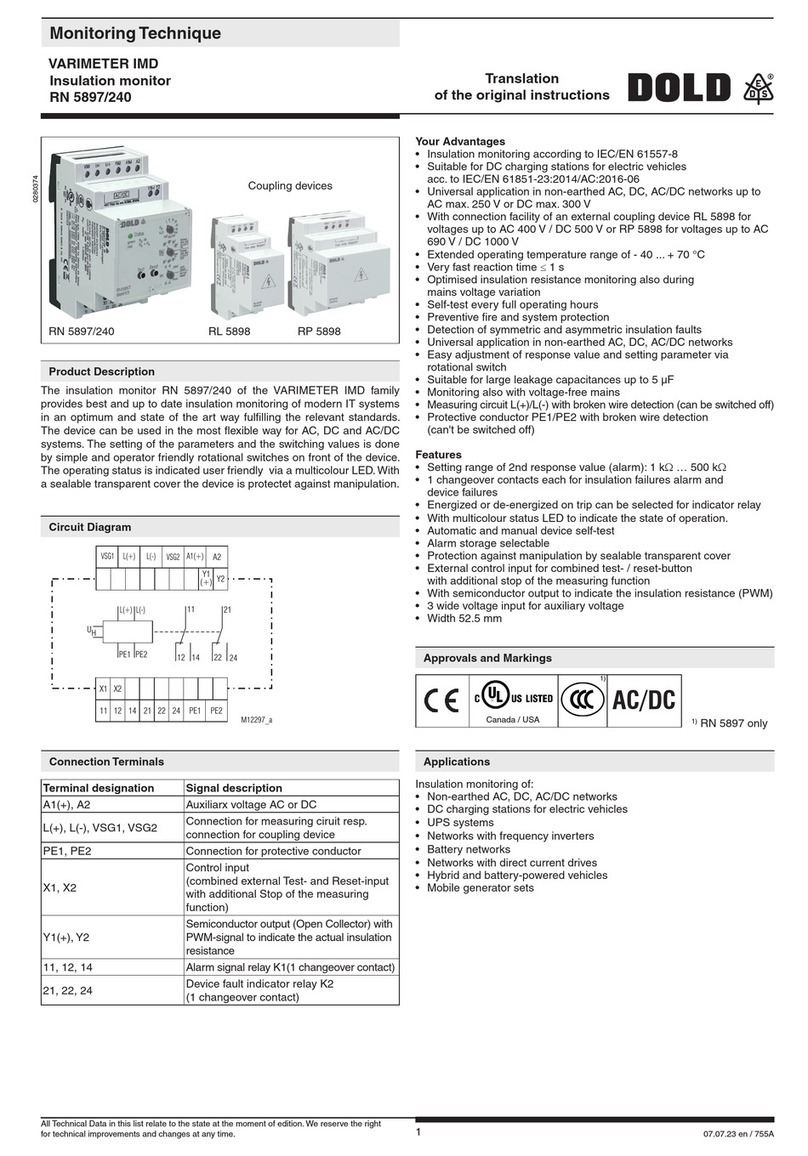

Measuring circuit

(Insulation measurement between terminals L1(+) / L2(-) on the

coupling device and PE1/PE2 on the insulation monitor)

The insulation monitor RN 5897/320 can only be used with a coupling

device. Max. mains voltage and connection diagrams have to be observed!

To connect the insulation Monitor RN5897/320 to a coupling device the

terminals with identical designations are connected (VSG1, VSG2, L(+),

L(-)) .The votage system to be monitored is connected to L1(+) und L2(-)

of the coupling device.

A broken wire detection that can be disabled provides a fault signal if

both terminals L1(+) and L2(-) are not linked by the connected network.

Broken wire between coupling device and insulation monitor cannot be

directly detected but the the measured value of the insulation resistance

when one or more connections are interrupted, is much lower then the real

insulation value which will cause a tripping of the alarm relays.

The type of the voltage system or the connection method (AC, DC, 3NAC)

has to be correctly adjusted on the rotational switch "UN"

Also the terminals PE1 and PE2 have to be connected with 2 separate

wires to the protective earth. An interruption of a wire also causes a fault

signal (see section ”Behavior on faulty connection”). The monitoring of

the PE connection cannot be de-activated.

To measure the insulation resistance an active measuring voltage with

changing polarity is connected between L1(+) and L2(-) and PE1/PE2.

The duration of the positive and negative measuring phase depends on

the actual leakage capacity of the monitored system and in DC systems

also on the level and duration of possible voltage variations. This allows

a correct and fast measurement in different network conditions.

At the end of a measuring cycle the actual insulation resistance is produced

and indicated. The relays for alarm K1 and pre-alarm K2 switch when

dropping under the adjusted response values. In addition the status LED

changes to orange color on pre-alarm or to red color on alarm.

Manual reset of fault message

With the 2-section rotational switch "UN", manual or auto reset of the alarm

can be selected. If manual reset is activated the insulation fault signals

of the measuring circuit are stored when dropping under the adjusted

response values also if the insulation resistance goes back to healthy

state. Pressing the „Reset“ button on the front side for 2 s, the alarm signal

is reset if the actual insulation resistance is in healthy state.

Indicator relay for insulation fault signal

The function of the relays K1 (contacts 11-12-14 for alarm) and K2 (contacts

21-22-24) can be altered between energised on trip (relay n.o.) or de-

energized on trip (relay n.c.). When energised on trip the relays energize

when the value drops below the setting, when de-energised on trip, the

relays de-energize when the value drops below the setting.

Disable the measuring function

Using the external control input X1/X2 the measuring function of the

RN 5897/320 can be disabled. This could be used when several isolated

voltage systems with individual insulation monitors need to be coupled.

The measuring voltage is set to -90V (negative measuring phase) and

the evaluation of the measurement is stopped. The status of the output

relays is frozen and not changed any more. If the measurement is disabled

the status LED flashes continuously orange. Please be aware, only the

evaluation of the measurement is stopped and the measuring pulse is

interrupted! A high resistive disconnection to PE does not take place

(see internal resistance).

Broken wire detection

As described in section "Measuring circut", the measuring circuits L(1+)/

L2(-) and the protective conductors PE1/PE2 are constantly monitored for

wire breaks – not only at Power-On or a manual or occasional automatic

test. The response time of PE1/PE2 monitoring is only a few seconds.

The response time of monitoring of L1(+)/L2(-) can be up to approx.

2 min. Broken wire detection between L1(+) and L2(-) is performed via

coupled alternating voltage. This alternating voltage is short-circuited if

the terminals are connected to the connected mains at low-resistance.

The device detects that the mains to be monitored is properly connected.

Since this broken wire detection is carried out with alternating voltage, large

capacitances should be avoided between L1(+) and L2(-), since the

capacitive reactance of these capacitances also short-circuits this

alternating voltage. The device would no longer detect a connection fault

on L1(+)/L2(-).

Especially parallel lines should be prevented over larger distances.

If larger capacitances between L1(+)/L2(-) cannot be avoided or if the coupled

alternating voltage interferes with the system, the broken wire detection

can be de-activated on the 2-section rotational switch for alarm "RA". It

can be altered between continuously disabled (Broken Wire Detect OFF),

or continuously enabled (Broken Wire Detect ON) for 10 seconds every

2 minutes. If the broken wire detection on L1(+)/L2(-) is de-activated no

AC voltage is injected. The broken wire detection on PE1/PE2 cannot be

de-activated.

Device test functions

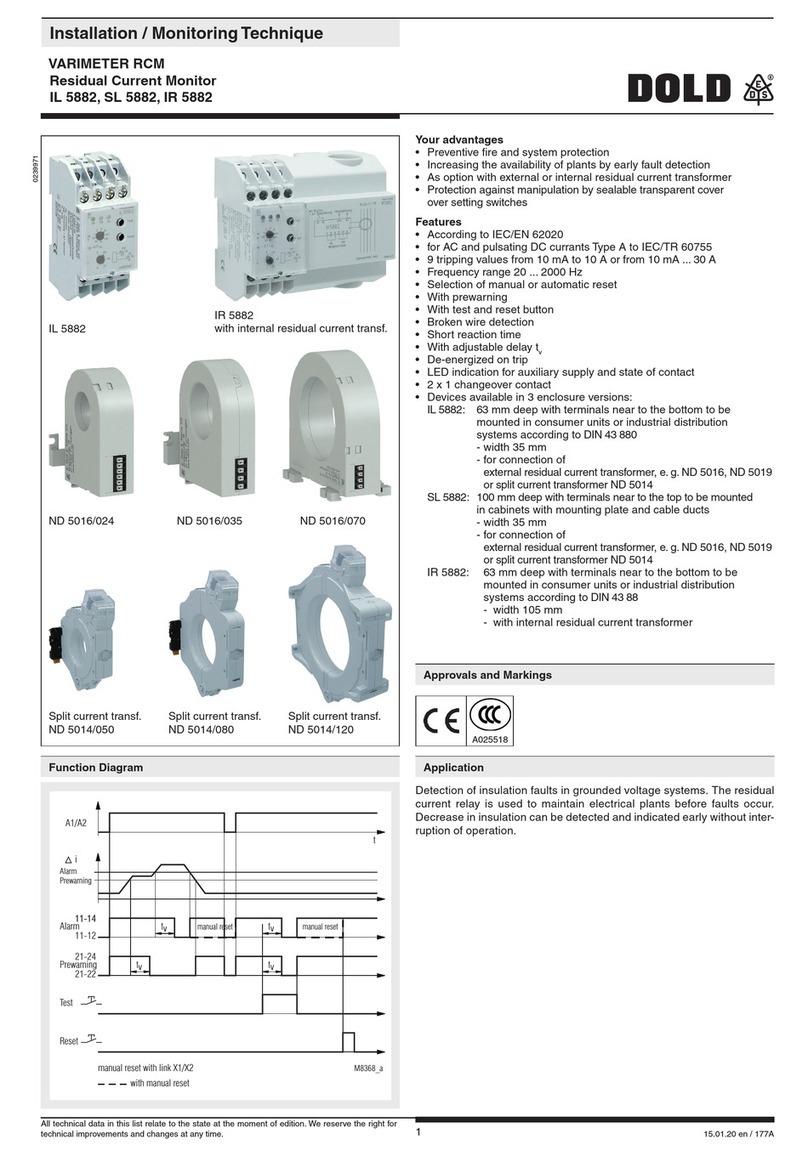

Principally, 2 different test functions are implemented: The "self-test" and

the "expanded test":

The self-test of the device is performed automatically after Power-On and

every full operating hours. It can also be triggered manually at any time by

pressing the "Test" button at the device front for 2 s.

With the self-test, contrary to the expanded test, the status of the Indicator

relays is not affected; the sequence is as follows:

The self test is indicated by the status LED with flash code 1 in orange colour.

First the negative measuring pules is activated for about 5 s and the internal

measuring circuit is checked on failures. Then the positive measuring pulse

is activated for about 5 s and more internal tests are performed. If no failures

are detected, the normal measurement continuous. The extended test is

started, when during or at the end of above procedure (12 s) the button

"Test" is pressed again for 2 s.

The procedure is the same as above (2 measuring phases with 5 sec

each) but in addition the output relays K1 and K2 go into alarm state. The

Status LED shows flash code 2 in orange colour. The test phases will be

continuously repeated. The extended test can be finished after the first

complete sequence (approx. 10 sec) by pressing the "reset" button for 2

seconds. The device starts the insulation monitoring again.

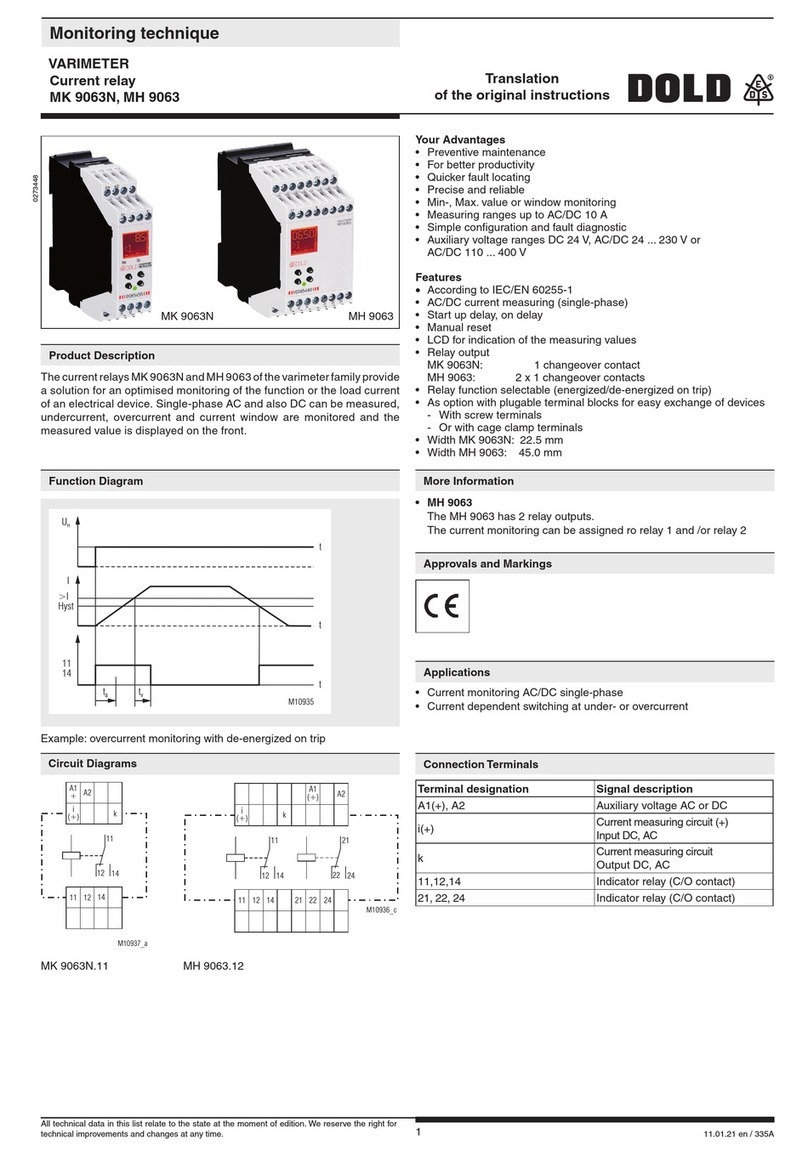

Test signal 1)

Reset signal 2)

Relay state K1 and K2

Measuring voltage

Positive

Alarm

No Alarm

Insulation

measurement Insulation

measurement

Insulation

measurement

3)

4)

Self test (Test 1)

Duration: approx. 12s

Self test (Test 1)

Duration: approx. 12s

Duration: approx. 10s

Continuous extended

test (Test 2)

Negative

U

t

1) Test signal: Button Test > 2 s oder X1/X2 > 1,5 s und < 10 s

2) Reset signal: Button Reset > 2 s oder X1/X2 < 1,5 s

3) To initiate the extended test (Test 2) the test signal must be operated

within the self test (Test 1) again..

4) The reset signal has here no function, as the first complete sequence

of extended test (Test 2) is not finished.

FunctionFunction