1

Table of Contents

Table of Contents.......................................................................................1

Introduction................................................................................................3

Quick Start User's Guide...........................................................................4

Fig. 1: Model 4100XL Front Panel Layout.................................................................4

Power Up: ....................................................................................................................4

Basic Weighing Operation:...........................................................................................4

Controls and Display Operation: ..................................................................................5

Zero:.............................................................................................................................5

Units: (Optional) ...........................................................................................................5

Print: (Optional)............................................................................................................5

Installation:...................................................................................................................5

Electrical Connections:.................................................................................................5

Quick Setup Guide.....................................................................................6

Load Cell and Power Connections:..............................................................................6

Fig. 2: Load Cell / Power connections.......................................................................6

Option Connections:.....................................................................................................6

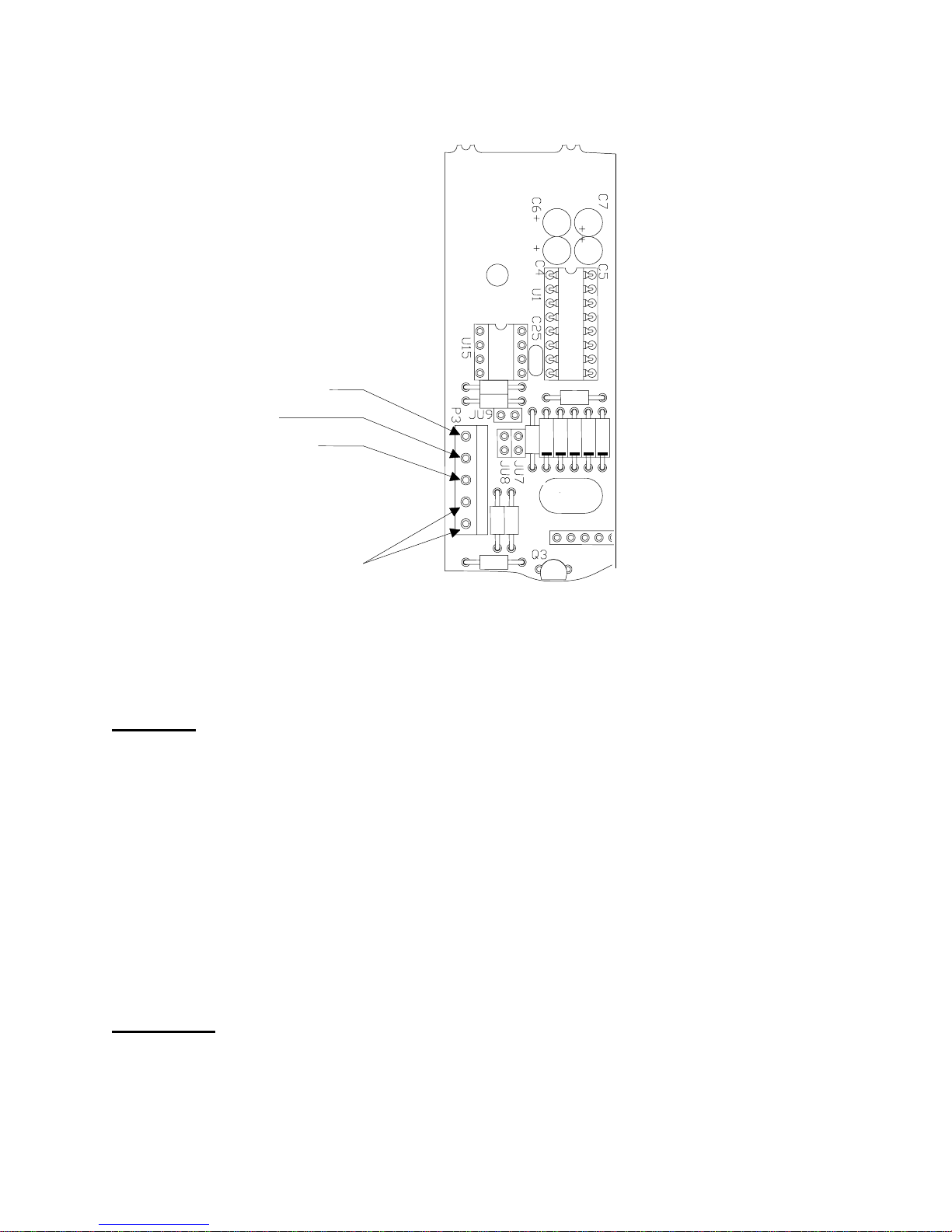

Fig. 3: Remote Push Button Connections .................................................................7

Detailed Parameter Setup........................................................................10

Entering and Exiting the Calibration Setup Menu:.....................................................10

Fig. 4: Quick Access Panel .....................................................................................10

Stepping through the menu parameters:....................................................................10

Changing a Parameter:..............................................................................................11

Quick Review of Setup Parameters:...........................................................................11

Legal for Trade Restrictions:......................................................................................11

Setup Menus Explained...........................................................................12

Capacity Setup Menu..............................................................................................13

Calibration Menu.....................................................................................................13

Over and Under Setup Menu ..................................................................................14

Digital Filter Setup Menu.........................................................................................14

Automatic Zero Tracking Setup Menu.....................................................................15

Motion Aperture Setup Menu ..................................................................................15

Start Up Zero Setup Menu ......................................................................................15

Latching Zero Request Setup Menu........................................................................15

Latching Print Request Setup Menu........................................................................16

Printer Data Output Setup Menu.............................................................................16

Output Formats .......................................................................................................16

Baud Rate Setup Menu...........................................................................................16

Serial Data Handshaking Setup Menu ....................................................................17

Units Conversion Setup Menu.................................................................................17

Start Up Units Selection Menu ................................................................................17

Remote Push-button Configuration Menu...............................................................18

Legal For Trade Setup Menu ..................................................................................18

Scale Resolution Setup Menu.................................................................................18

Raw Counts Display Mode......................................................................................18