MN196-00.DOC 7 of 22

Section 4. Parameter Setup

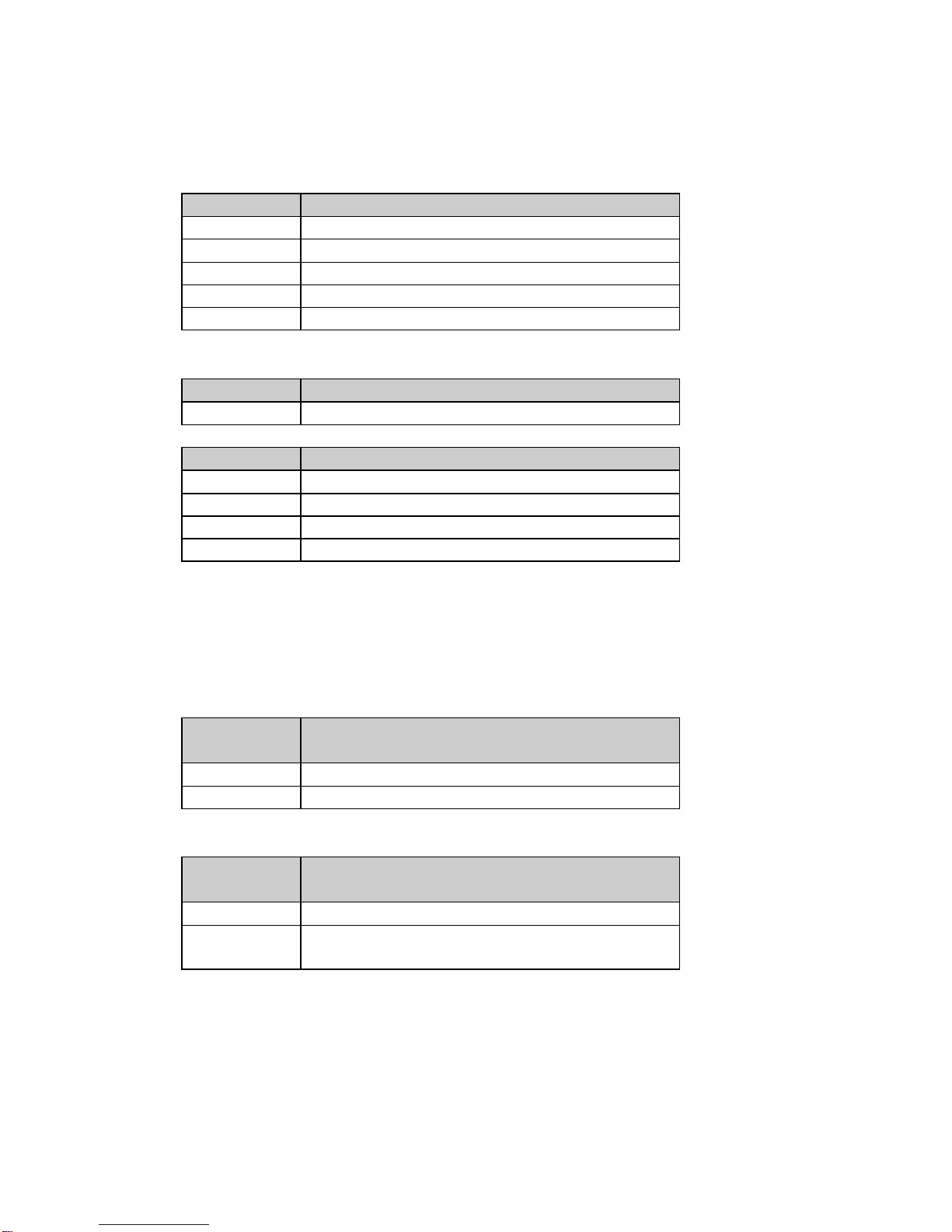

The PC200 has eighteen setup and calibration parameters which can be changed

(sixteen in the Legal for Trade mode). This flexibility makes these scales versatile

weighing instruments capable of meeting almost all common weighing needs.

Entering and Exiting Setup Mode:

To enter the setup menu, apply power to the PC200, turn the scale

over and remove the screw located next to the RS-232 connector.

Place a thin blunt object through the hole and press straight down.

The scale should enter the Setup/Calibration mode, and the scale

should display “CAP 5”, “CAP 2” (1000g), or “CAP 10”, (depending on

capacity).

The parameters are accessed by pressing a hidden button located 3/4”

to the right of the “ZERO” button. Pressing this button will cause the

scale to step to the next parameter on the list.

To exit the setup mode, press and release the hidden button until the

menu prompt “donE n” appears on the display. Then press the “ZERO”

button so that “donE Y” is displayed. Press the hidden button once

more and the scale will leave the setup mode.

NOTE: No setup information is saved until the PC200 exits the setup

mode. In the event of a power failure while in the Setup Mode,

any changes that have been made will be lost. This includes

calibration parameters generated during calibration.

After all setup changes have been completed and the scale is in it’s

normal operating mode, replace the screw on the bottom of the scale.

If it is necessary to seal the scale, run a lead and wire seal through the

screw on the bottom and a cross drilled screw on the side of the scale.

Changing a Parameter:

Once the desired parameter has been found, it may be necessary to

change the option associated with that parameter. Press and release

“ZERO” to step through the individual options. When you have stepped

through all of the choices, the scale will return to the top of the list and

start over.