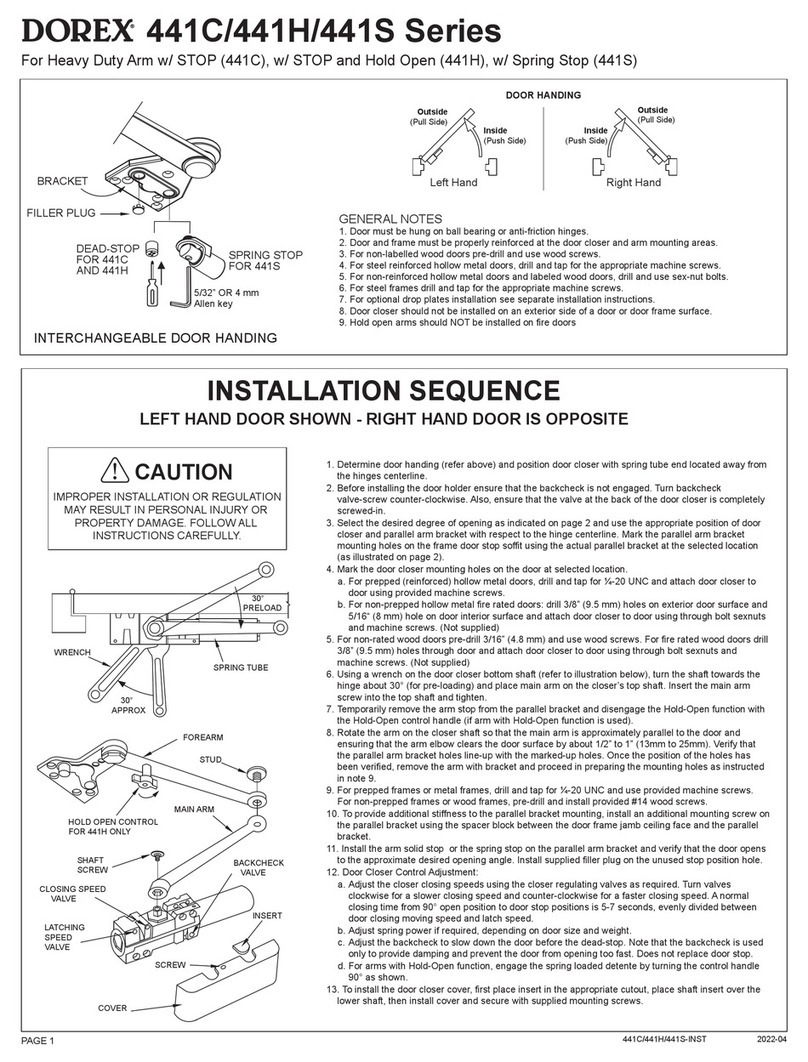

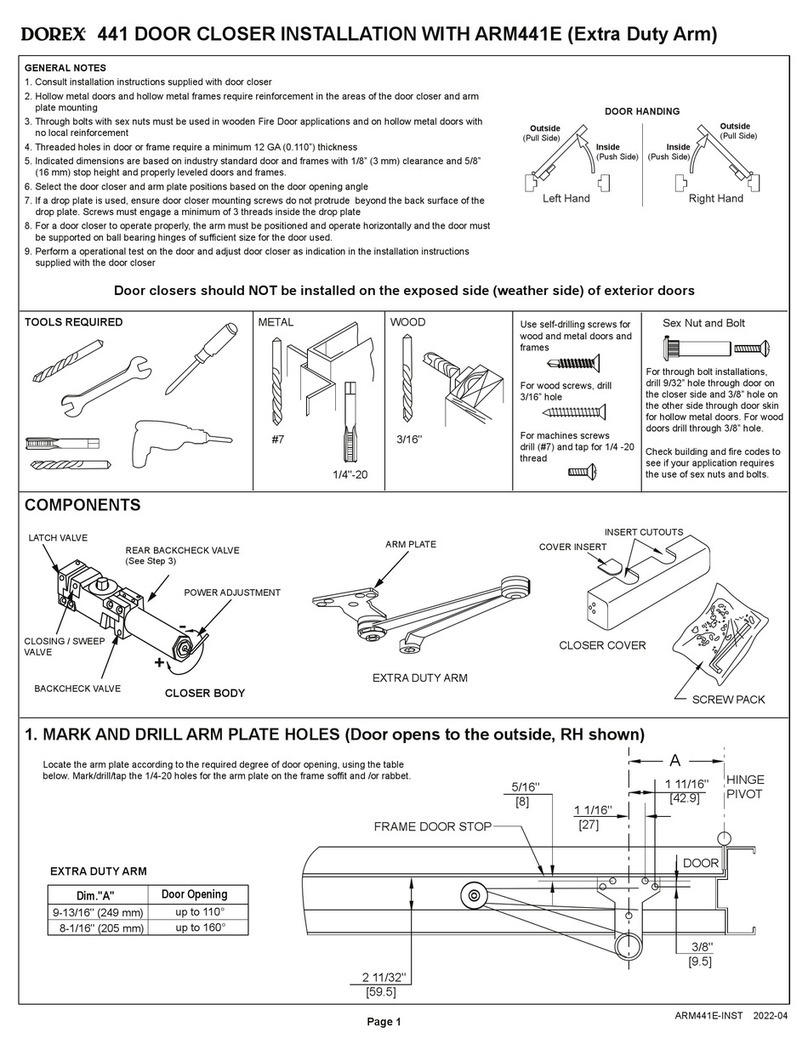

PULL SIDE – REGULAR OR STANDARD INSTALLATION

(MAXIMUM 120° DOOR OPENING)

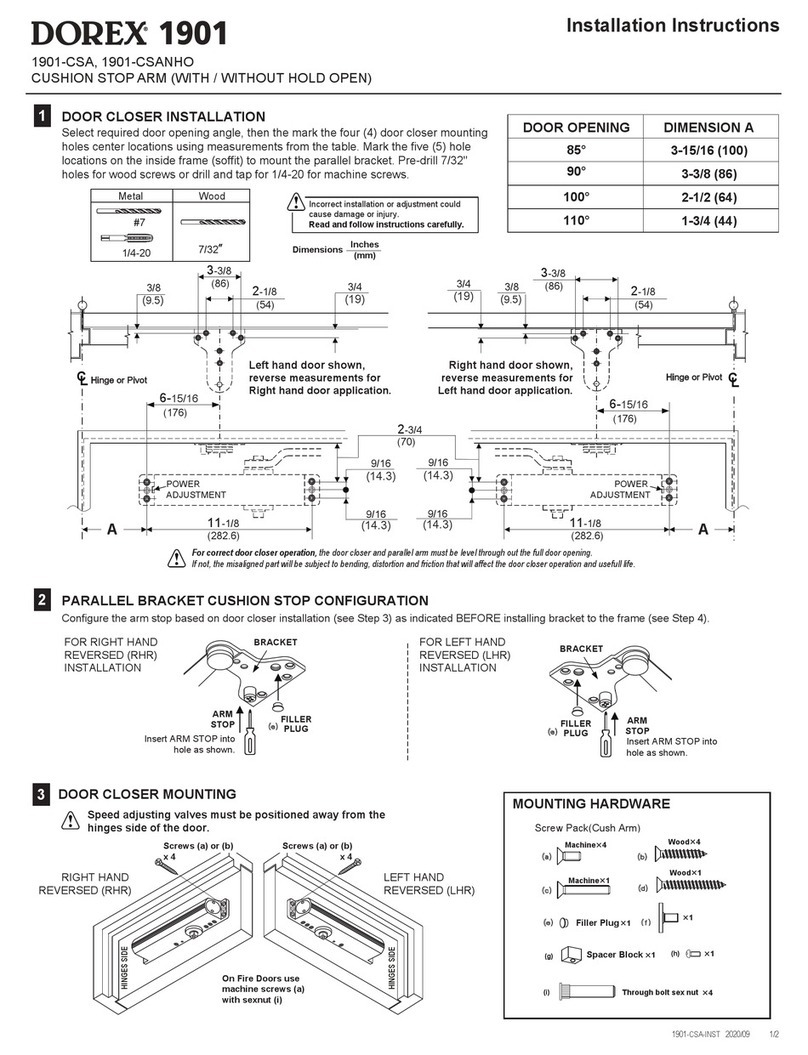

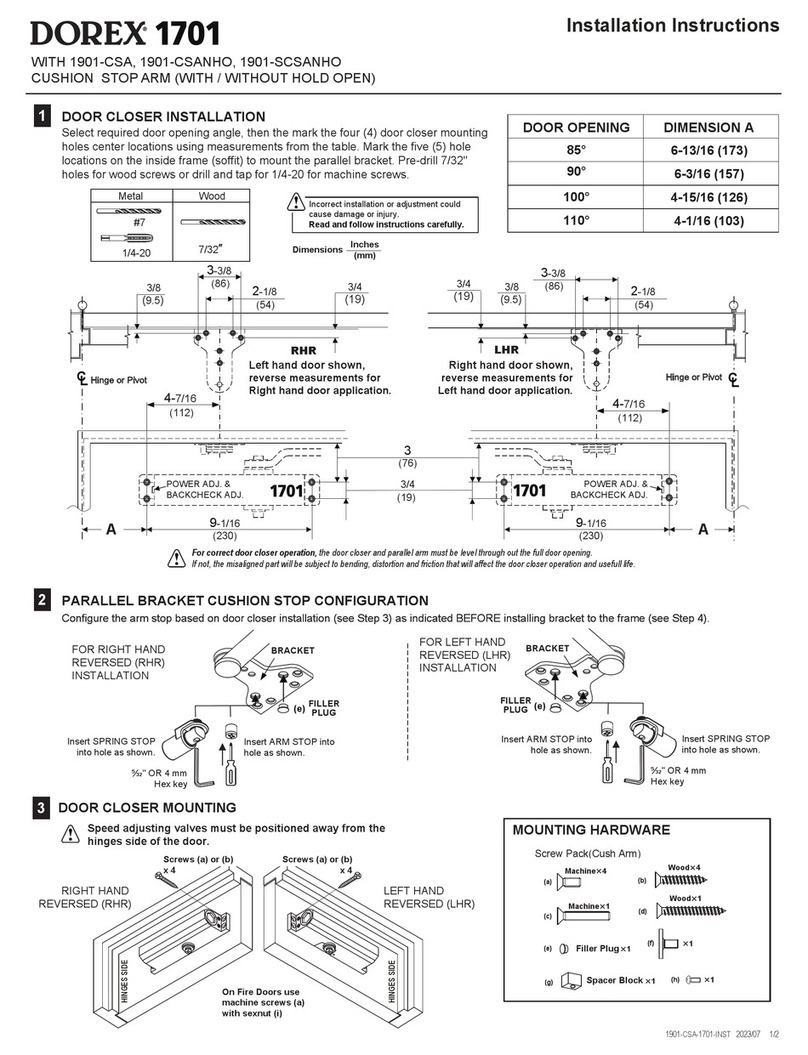

Installation Instructions

1701 SERIES DOOR CLOSER WITH SLIDE TRACK ARM (SA1901)

SA1901-1701-INS 2023/12 1/3

AN INCORRECTLY INSTALLED OR IMPROPERLY

ADJUSTED DOOR CLOSER CAN CAUSE PROPERTY

DAMAGE OR PERSONAL INJURY.

THESE INSTALLATION INSTRUCTIONS SHOULD BE

FOLLOWED TO AVOID THE POSSIBILTY OF

MISAPPLICATION OR MISADJUSTEMENT

CAUTION

HINGES SIDE

HINGE

CENTERLINE

5 5/8

(143)

4 7/8

(123.8)

9 1/6

(230)

19 7/8

(504.8)

INCH

(MM)

3/4

(19)

1 1/8 (28.5)

2 3/6

(55.5)

1 1/16 (27)

B

A (2x) : Drill ¹⁄8" (3 mm) pilot hole for wood screws or drill & tap for #10-32 machine screws

B (4x) : Drill ³⁄16" (4.75 mm) pilot hole for wood or drill & tap for 1/4-20 UNC machine screws.

DOOR EDGE

INTERIOR

RIGHT HAND

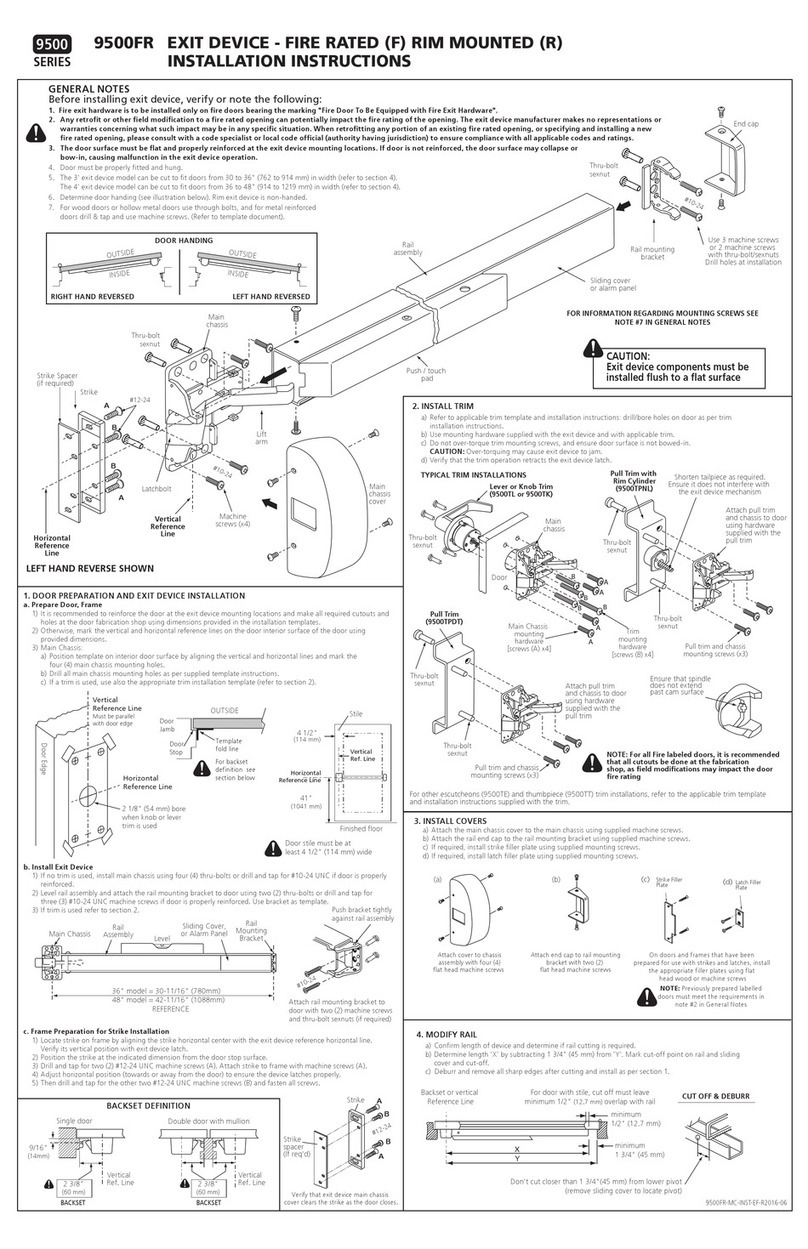

1. Locate door closer and track position using the Figure 1 above.

2. Mark hole positions and drill holes as indicated above.

3. Install door closer to the door using the appropriate fasteners as per supplied instructions with door closer.

The POWER ADJUSTMENT valve of the door closer should be facing AWAY from the hinges.

4. Assemble track stopper (or holder) and slide insert in sequences as indicated above, then fasten to the door frame using supplied screws.

5. Place arm on door closer top pinion at pre-load postion (45°) as shown in Figure 2. Then secure with included arm spring washer and socket bolt.

6. Rotate arm until parallel with the door surface, then secure arm end to the slide insert in the track with supplied screw.

7. Open the door to the desired opening angle then slide the stopper (or holder) against the slider insert. Secure the stopper (or holder) into position by

tightening the set screw.

8. Release the door and verify operation. Adjust door closer power and closing speeds as indicated on the door closer’s installation instructions.

FIGURE 1

Main Arm

45°

FIGURE 2

Right hand door installation shown.

For left hand installation, reverse illustrations.

Document provided as-is, manufacturer reserves the right to make technical changes

without prior notice.

This document describes a recommended installation based on common product and

industry standards. It is customer's responsibility to the determine the validity or suitability

of these recommendations for a particular purpose or installation.

Always ensure to properly mount the product using the appropriate mounting hardware for

the proper surface material.

The execution and installation of this product must be done by qualified personnel and

follow any and all local regulations which relate to this product.

Slider Insert

Arm Connection

Stopper

Track

End Cap

Stopper

Fixing Screw

Stopper

Fixing Screw

Mounting screw passes

through BOTH the

Track and the End Cap

The direction, orientation, and order in which the track is assembled is important.

Ensure that the assembled track matches the installation.

The hold-open function should not be installed on fire-rated openings.

HOLD-OPEN CONFIGURATION

INSTALLATION IN CONJUCTION WITH INSTALLATION

INSTRUCTIONS PROVIDED WITH DOOR CLOSERS

STOP CONFIGURATION

The stopper can be removed

if not required.

FIXING

SCREW

TO ADJUST THE HOLD OPEN

OR STOP POSITION:

1. Loosen the fixing screw of the stopper.

2. Open the door to the require angle.

3. Slide the stopper to engage or butt against

the Slider Insert.

4. Tighten fixing screw.

STOPPER SLIDER INSERT

STOPPER SLIDER INSERT

POWER

ADJUST

EXTERIOR

DRAWING IS NOT TO SCALE.

DO NOT USE AS TEMPLATE.

DOOR CLOSER AND TRACK MUST BE LEVELED HORIZONTALLY.

3/4

(19)

1 1/8 (28.5)

A (2x) : Drill ¹⁄8" (3 mm) pilot hole for wood screws or drill & tap for #10-32 machine screws

B (4x) : Drill ³⁄16" (4.75 mm) pilot hole for wood or drill & tap for 1/4-20 UNC machine screws.

A

DOREX 1701

SA1901