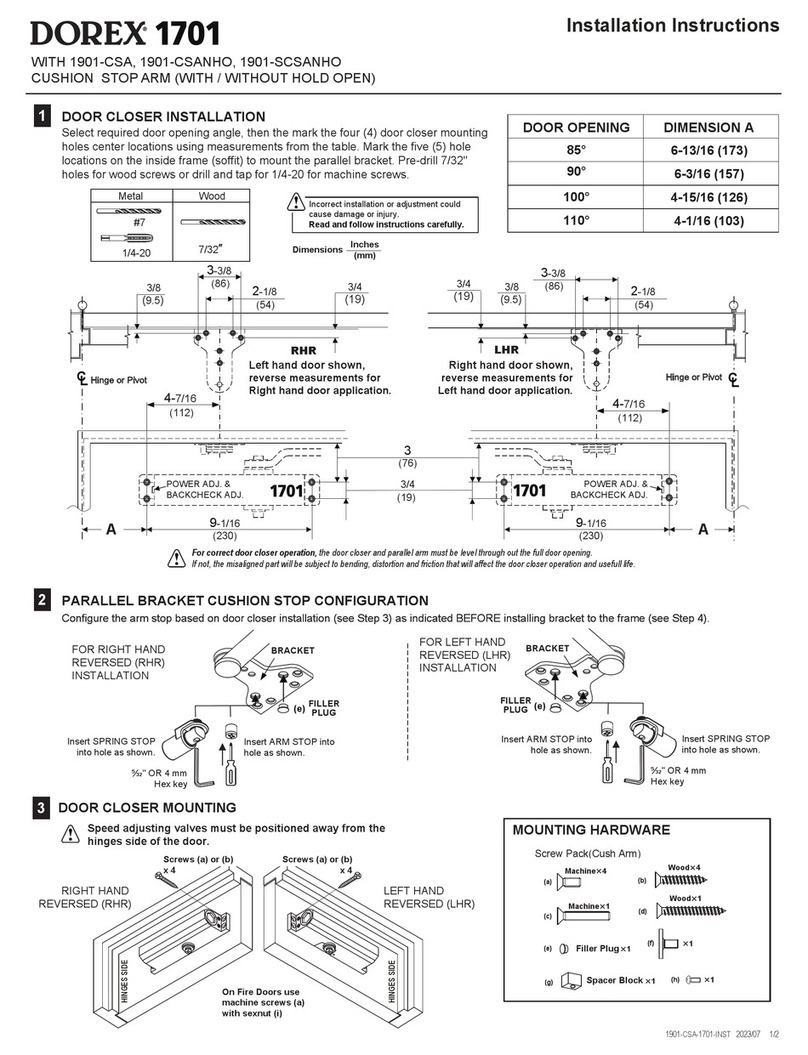

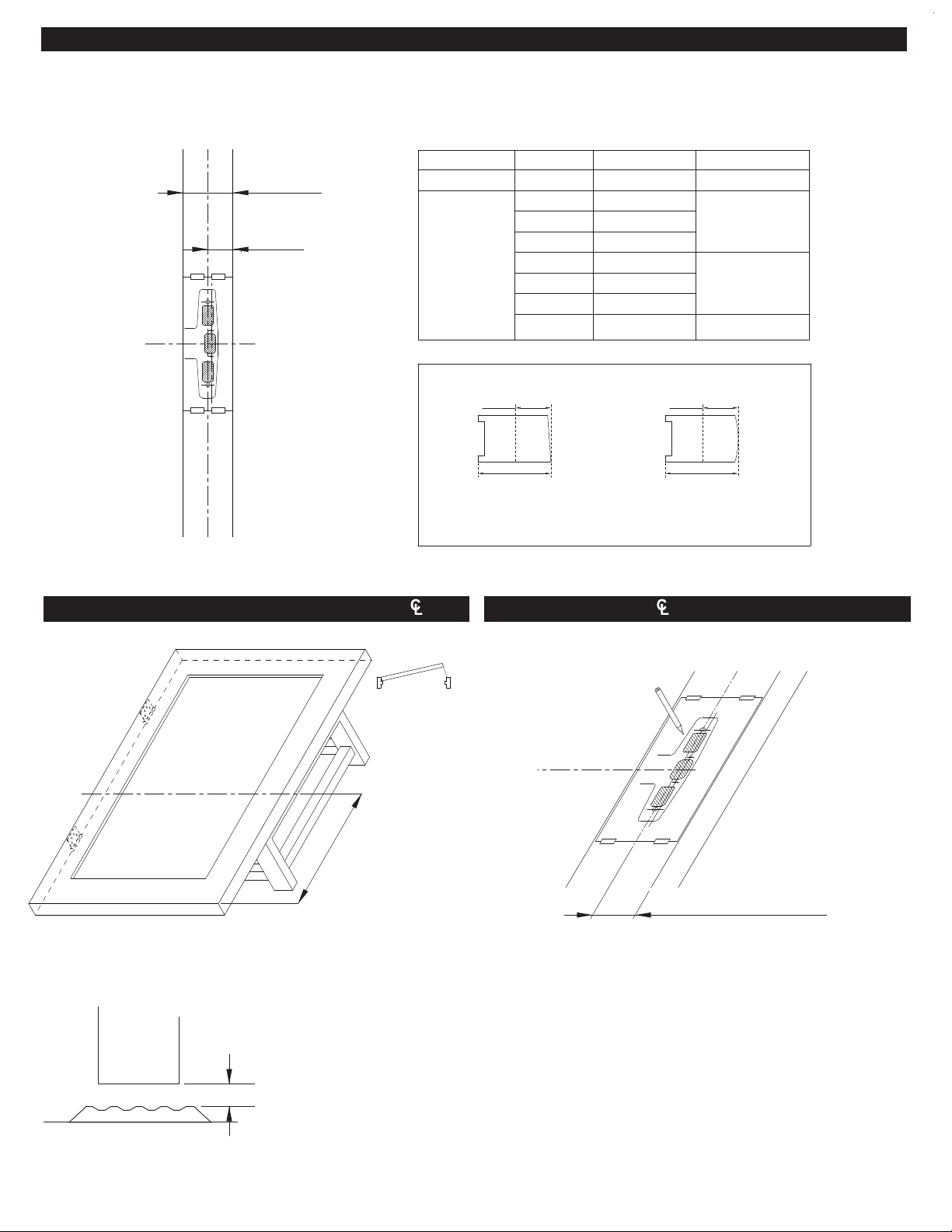

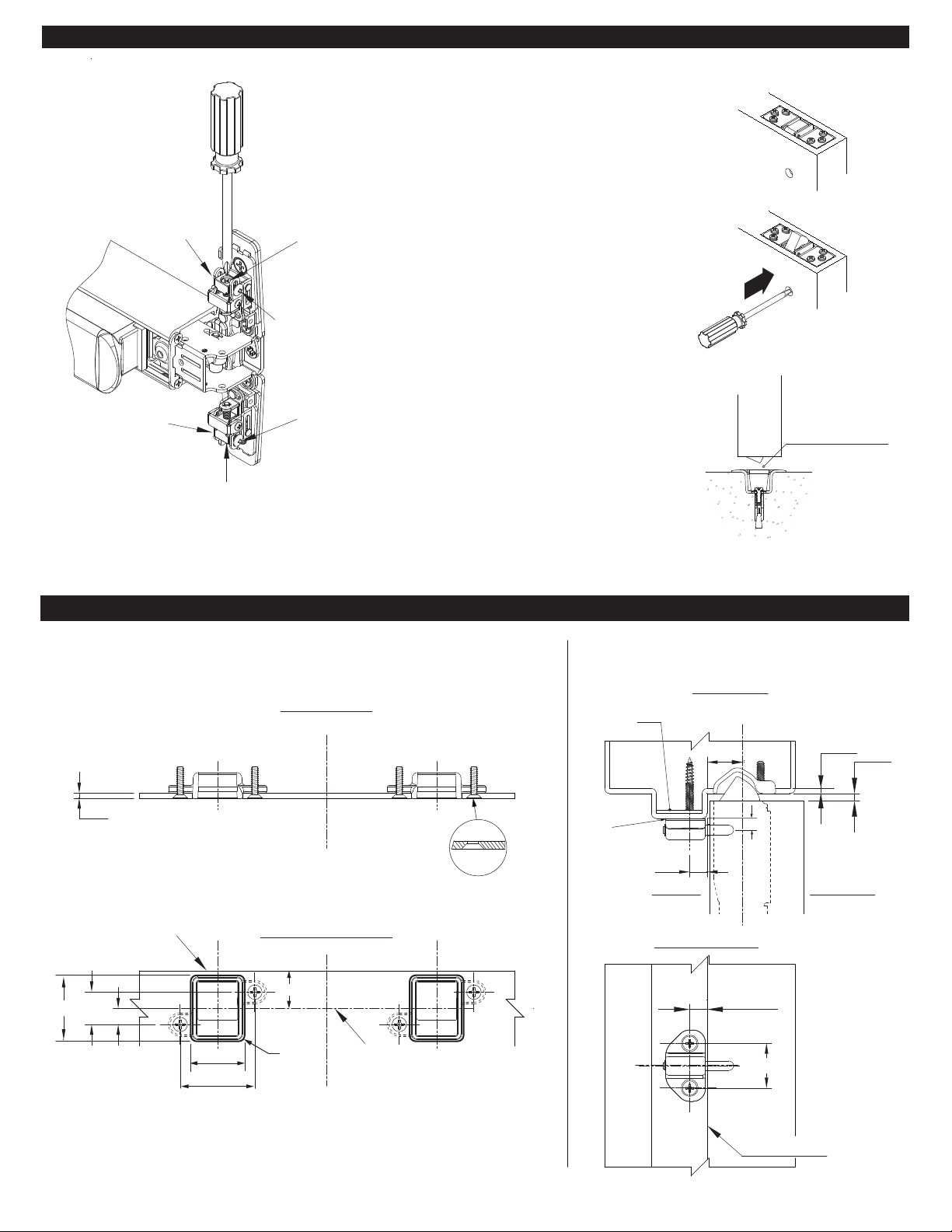

DOOR PREPARATION REFERENCE CHART

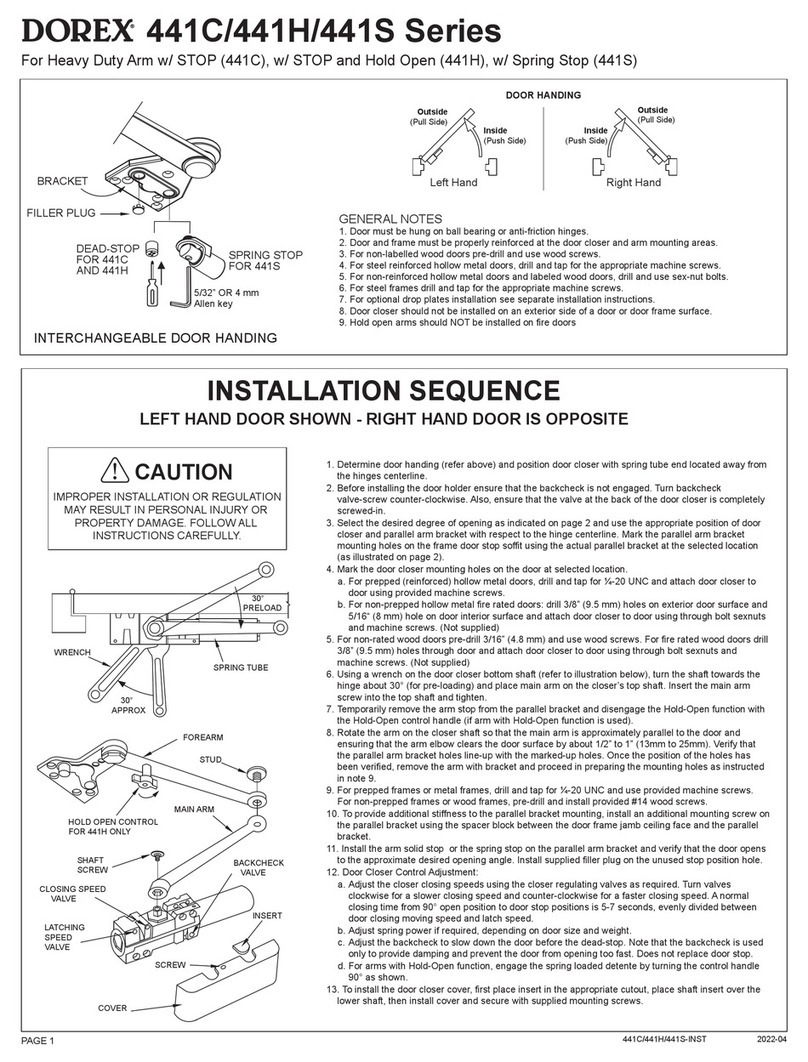

TOP & BOTTOM LATCH PREPARATION

BOTTOM STRIKE

SEE PAGE 10

*PREPARE HOLES AFTER LOCK SIDE

OF DEVICE IS MOUNTED AND HINGE

SIDE OF DEVICE IS LEVELED

METAL

#25 DRILL

#10-24 TAP

END CAP BRKT. - 2 HOLES

SURFACE MOUNT

WOOD

¹/8" DRILL

PILOT 1" DEEP

¹³/32"

DRILL THRU

⁵⁄16" DRILL

(DEVICE SIDE)

¹³⁄32" DRILL

(OPPOSITE SIDE)

METAL

WOOD

SEX BOLTS

INSIDE

OUTSIDE

RHR LHR

LATCHES

RHR shown (LHR opposite)

of Device

L

C

#25 DRILL

#10-24 TAP

METAL

WOOD

¹/8" DRILL

PILOT 1" DEEP

Vertical

LATCH RELEASE

PLUNGER HOLE

SEE PAGES 6 & 9

L

C

L

C

X

X

1⁵⁄8"

1⁹⁄32"

⁷⁄8"⁷⁄8"

1¹⁄2"1¹⁄2"

⁷⁄8"⁷⁄8"

1⁵⁄8"

1⁹⁄32"

1⁵⁄8"

1⁹⁄32"

Cut Out for Latchbolt 1¹⁄2"

METALMETAL

#7 DRILL

#¹/4"-20 TAP

WOOD

¹³/32" DRILL THRU (FOR SEX BOLTS)

¹/2" DRILL THRU (FOR TRIM)

⁵⁄16" DRILL INSIDE

¹³/32" DRILL (FOR SEX BOLTS)

¹/2" DRILL OUTSIDE (FOR TRIM)

SURFACE MOUNT

CENTER CASE - 2 HOLES

SEX BOLTS

OR WITH TRIM

CENTER CASE

2 HOLES

#25 DRILL

#10-24 TAP

WOOD

¹/8" DRILL

PILOT 1" DEEP

METAL

SURFACE MOUNT

N/A

of Device

L

C

Vertical

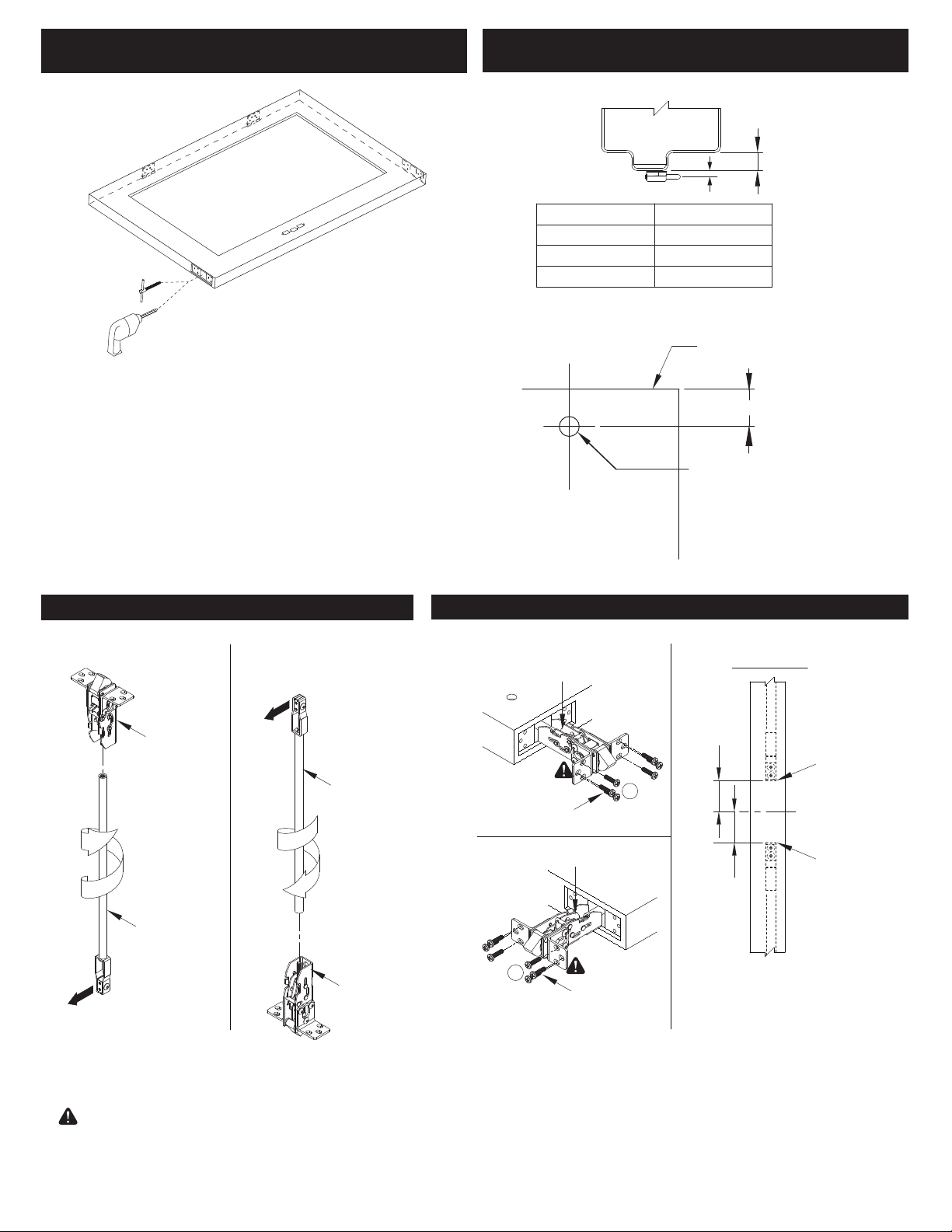

FOR DOOR PREPARATION REFERENCE ONLY.

Verify that this is the latest version of this document.

We recommend samples be used to verify

preparation before door / frame manufacturing.

Cut Out for Brackets

⁹⁄32" deep

Cut Out for Bracket

⁹⁄32" deep

4" 2"

SEE TRIM INSTALLATION INSTRUCTIONS,

TEMPLATES, OR DOOR PREPARATION

DOCUMENTS FOR DETAILS.

Fire Exit Hardware is to be installed on Fire Doors

bearing the marking “Fire Door to be equipped with Fire

Exit Hardware” Any retrofit or other field modification to

a Fire Rated opening can potentially impact the Fire

Rating of the opening.

IMPORTANT:

• Use supplied templates for field installations.

• Use door preparation documents for door/frame manufacturing.

• Door must be properly reinforced where the exit device chassis

and latches are mounted. The surface must be flush and flat

within ¹⁄16" (1.5 mm).

• Prepare the door and top and bottom door edges using the exit

device templates or door preparation and instructions.

• Prepare the exterior of door using the trim template or door

preparation and installation instructions.

• All threaded holes require a minimum metal material thickness

of 0.125" (3 mm).

• We recommend samples be used to verify preparation before

mass door or frame manufacturing.

• NOT RESPONSIBLE for any physical or property damage due to

incorrect / improper preparation or installation.

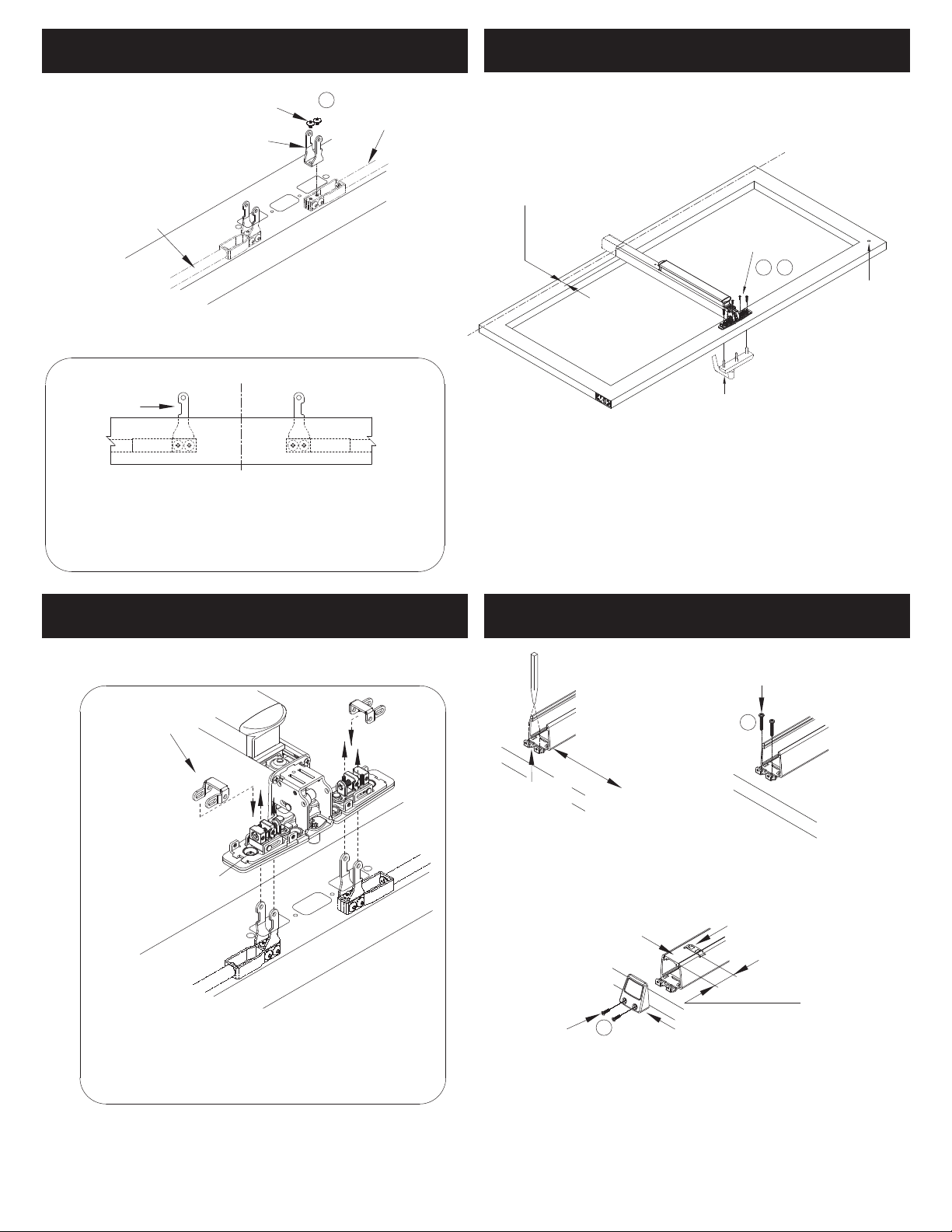

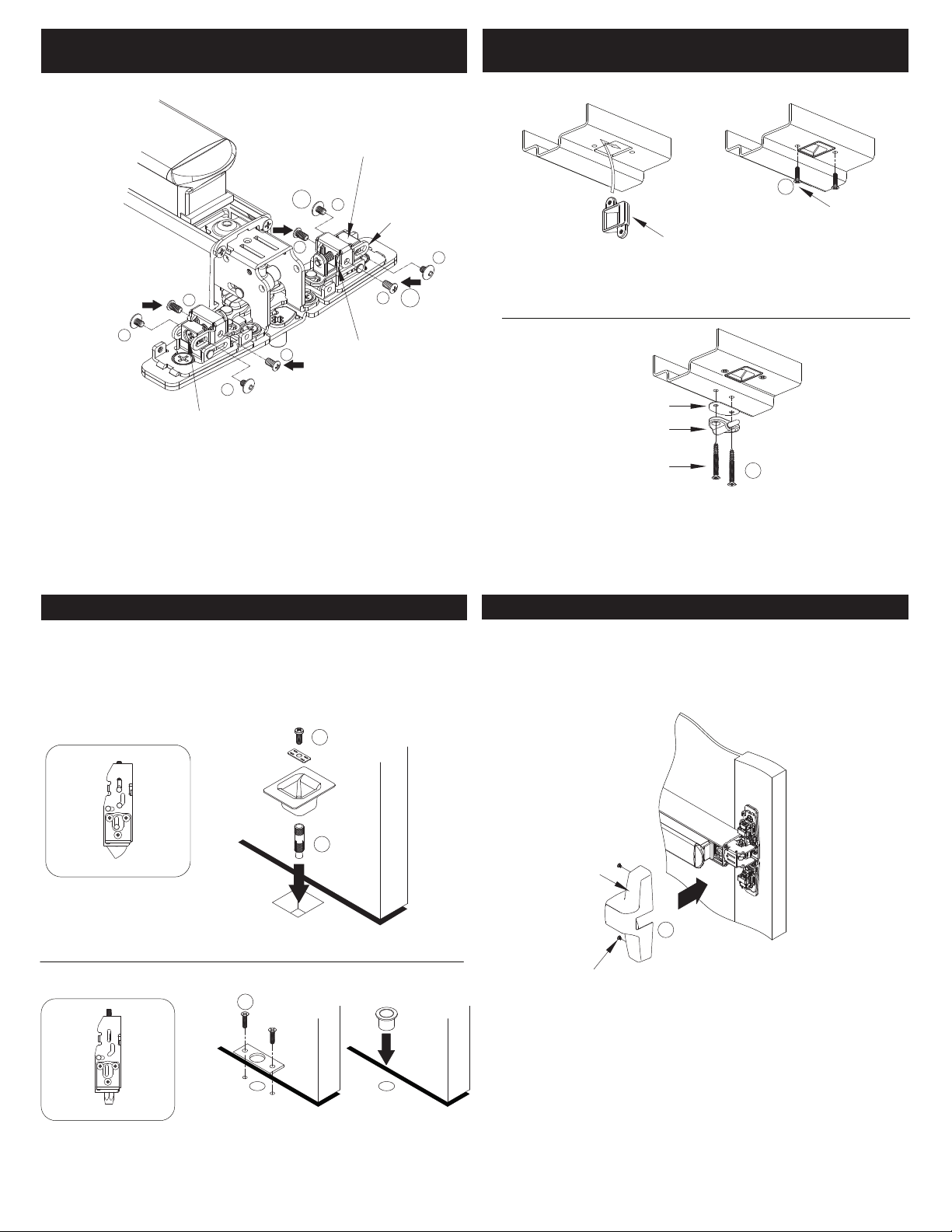

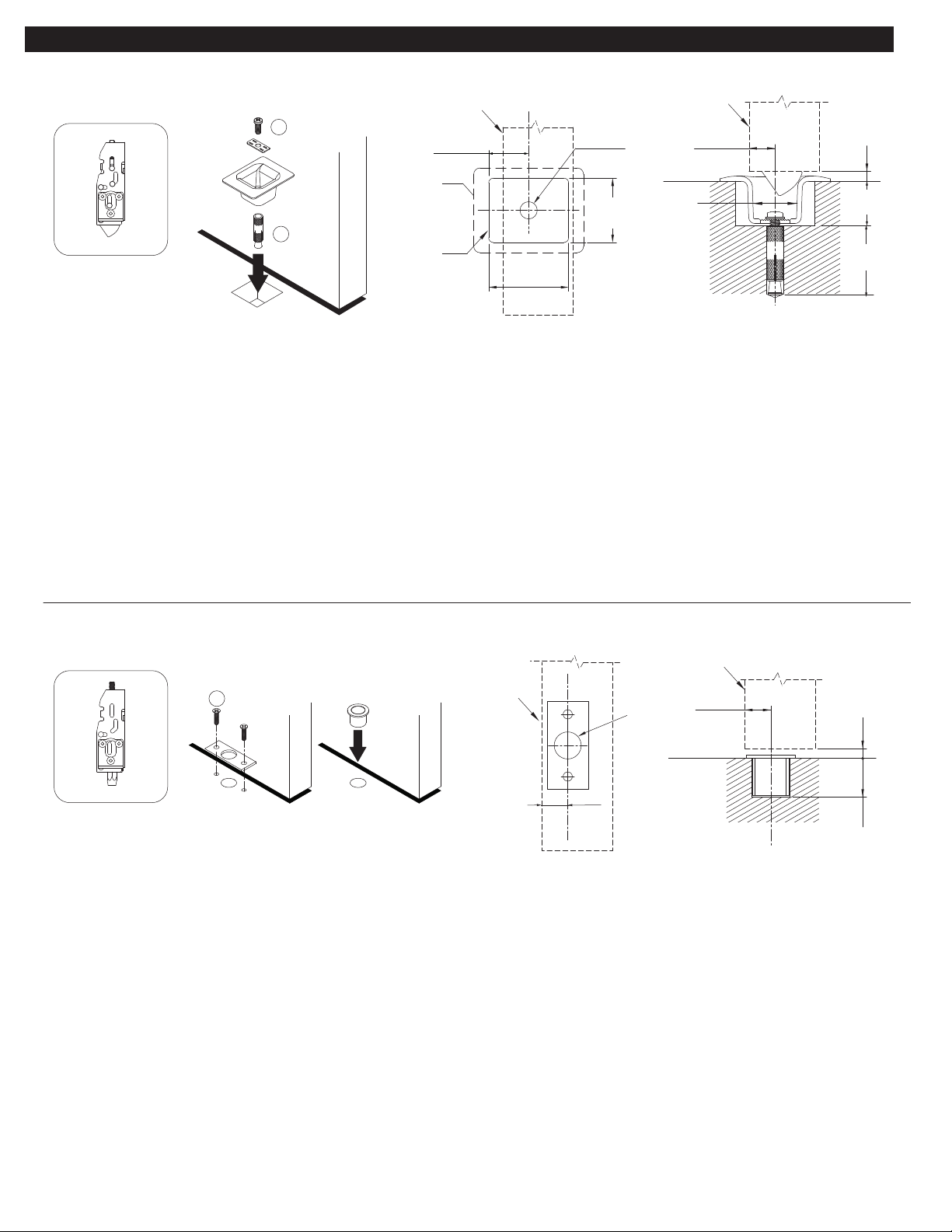

TOP STRIKE

SEE PAGE 9

1" Dia.

Prepare door bottom and top edge to accomodate required latch (see below) and vertical rods. Use the same backset (vertical centerline) used for the exit device center chassis.

It is recommended to install top and bottom latches using both pre-installed brackets as supplied.

Fire or Panic Exit Device

Both Brackets Installed

Panic Exit Device Only (optional)

One Bracket Installed

4 / 12

4¹⁄2" height from

door top edge

For vertical

rod passage

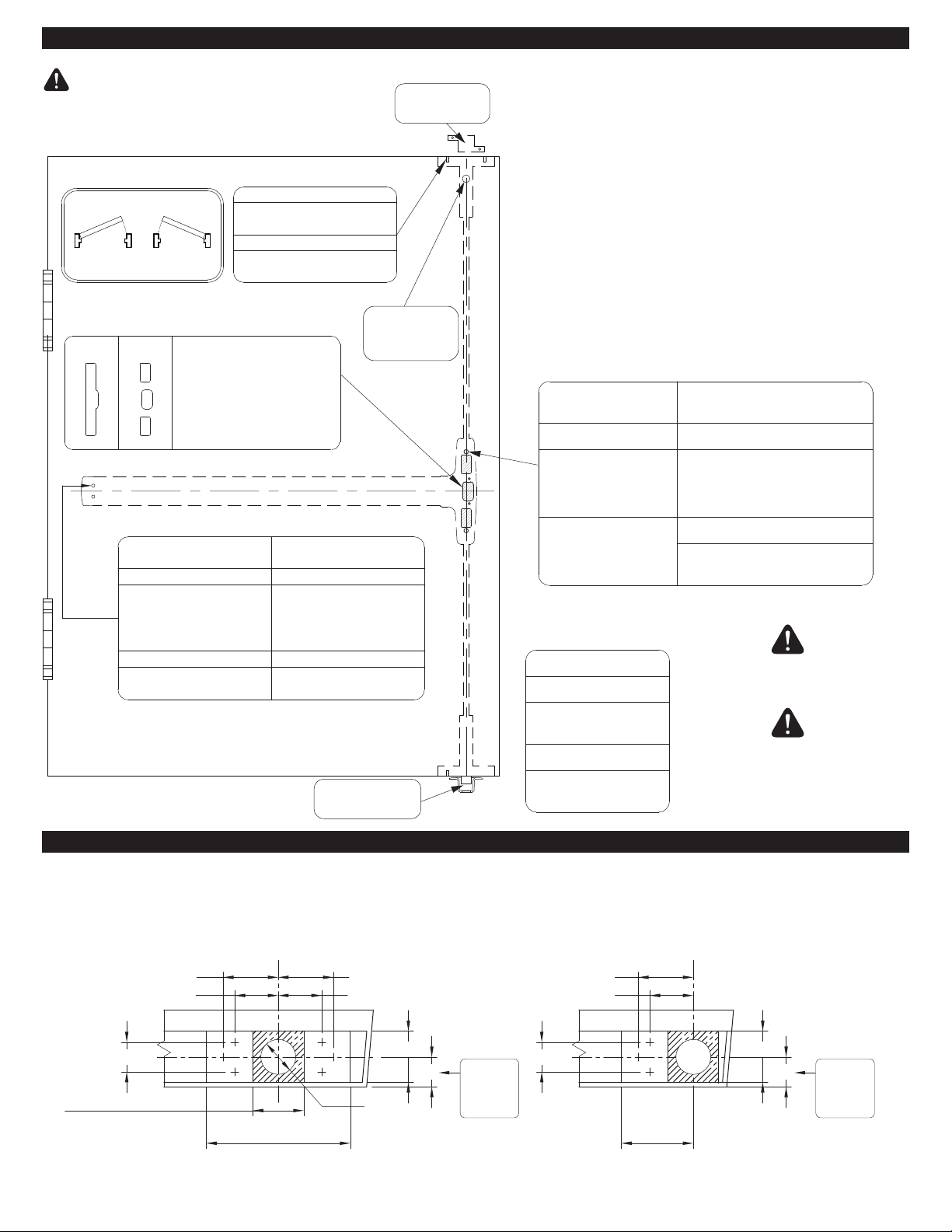

DOOR CUT-OUTS

CUT-OUT ON DEVICE

SIDE ONLY. 1³⁄8" DEEP

.

Consult template or

door preparation for:

- Metal door

- Wood Door

WOOD METAL

Constant

dimension

for all door

thicknesses.

Constant

dimension

for all door

thicknesses.