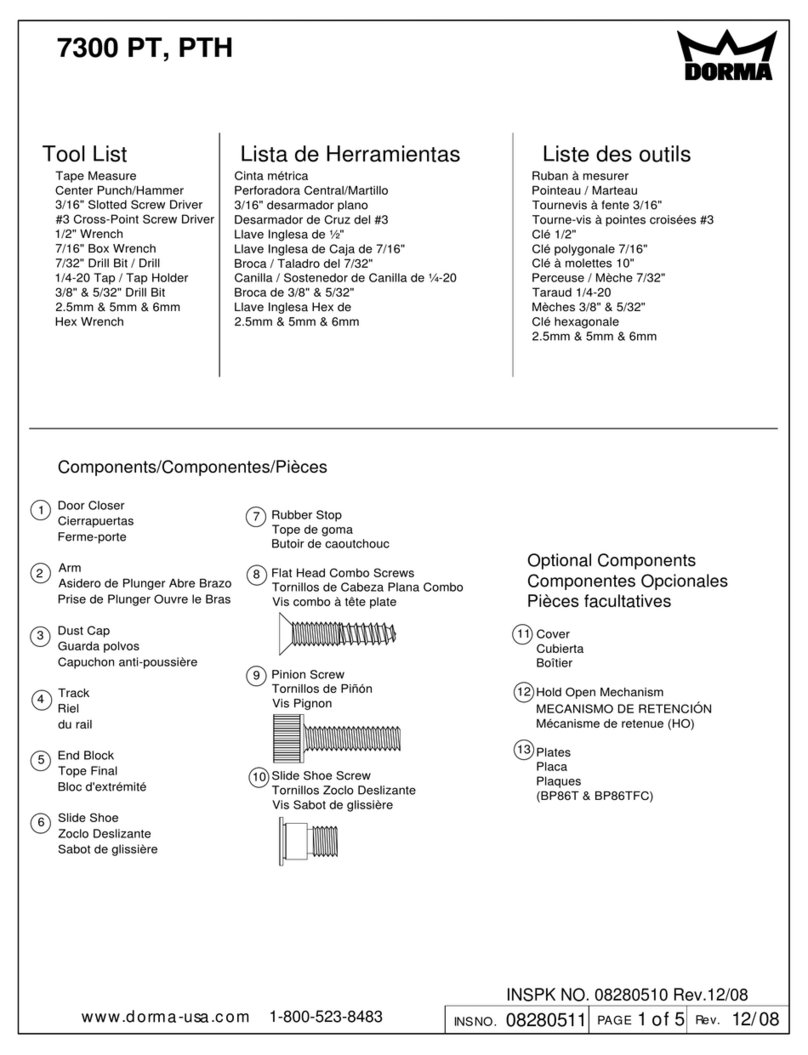

Adjusting bolt

7

5/8"

*

*

Top latch

& rod

assembly.

Inner rod

assembly

1/2"

2"

Top and bottom rods and latches are shipped

unassembled and are adjustable for door opening

heights ranging from 6' 8" to 8' 0" and will fit up to

a 10' 0" door opening with the addition of a 2 foot

top rod extension (ETR). Follow instructions on

page to assemble the latch and rod assemblies.

"Standard" (NS) Narrow stile brackets are pre-

assembled in the top and bottom latch cases.

Optional: Angle brackets are available for steel

and wood door application, and are "required"

for all fire rated applications, install as shown

with proper fasteners.

Holes in outer rod are at 1/2" intervals and holes

in inner rod are at 2" intervals for door openings

under or over 7' (instructions are for 7' door

opening and standard mounting height).

For all other door sizes, see rod ajustment chart.

Slide inner rod assemblies into outer rods, locate

proper holes and insert rod retainer clip by;

inserting through both rods, rotating it and locking

it in place as shown.

For "LBR" less bottom rod device skip bottom rod

and latch assembly instructions.

Additional "Popper" required for "LBR" fire

rated openings. See details to left.

Standard (NS)

Narrow stile

aluminum door

mounting bracket

(installed at

factory).

Optional:"WD" "L" shaped mounting

brackets for steel and wood door

applications and all fire doors.

NOTE: requires a new top fire latch

assembly as well. Secure to latch

using (6) 8-32 x 1/4" F.H.P.M.S.

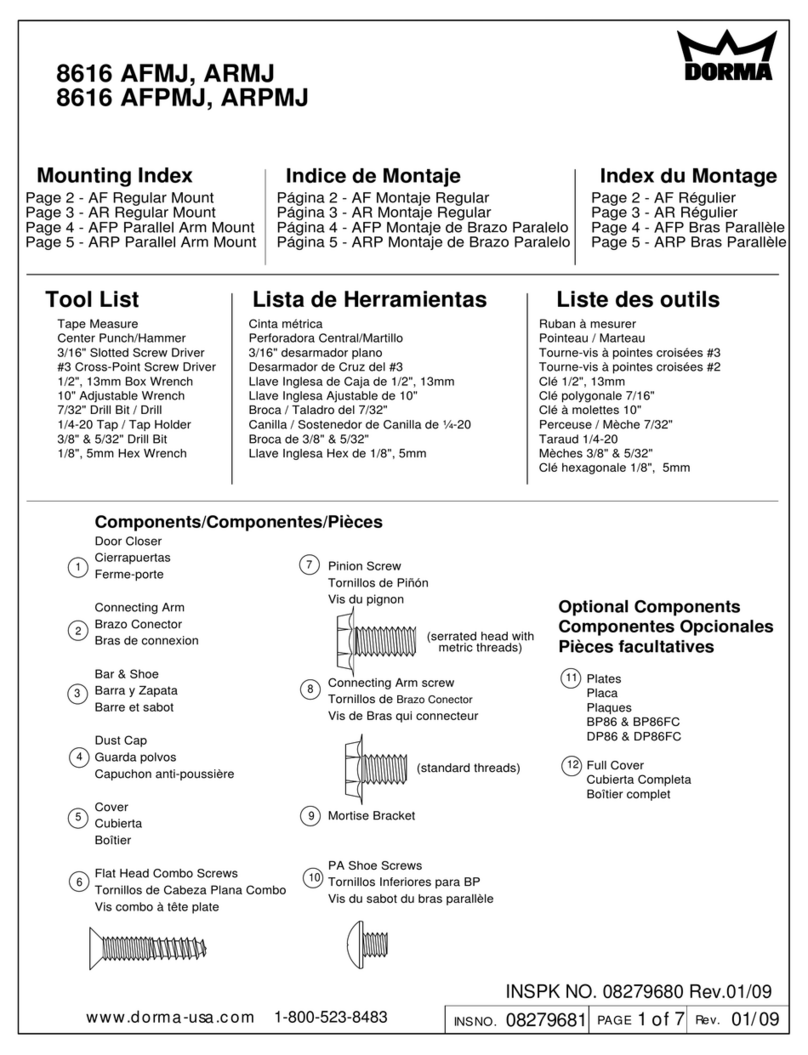

Bottom

latch

& rod

assembly.

Inner rod

assembly

Optional:

Pullman

latch.

Thread on

Optional: "WD" "L" shaped mounting

brackets for steel and wood door

applications and all fire doors.

NOTE: requires a new bottom fire

latch assembly as well. Secure to

latch using (6) 8-32 x 1/4" F.H.P.M.S.

Optional: "ALD" bracket

Optional: "ALD" bracket

12"

Finished floor

"POPPER"

Cap plug

Rod

retaining

clip.

5

Assemble rods, latches and adjust to preliminary length.

Outer

rod

4th hole

for top rod

on 7' door

opening.

Insert pin

through

proper holes,

flip over and

lock in place.

Top latch

assembly

Outer

rod

*

2nd hole

from link

on 7' door

opening.

*

Middle

hole for

bottom

outer rod

on 7' door

opening.

Insert pin

through

proper holes,

flip over and

lock in place.

Thread on

leave aprox.

1/8" of thread

showing.

See additional instructions

packaged with "Popper" for

details.

Required for; "LBR"

(less bottom rod)

fire rated exit devices.

4th hole

for top rod

on 7' door

opening.

Thread on

leave aprox.

1/2" of thread

showing with

pullman latch.

"Use 4th

hole using

pullman

latch".