©DOSATRON INTERNATIONAL / 15

©DOSATRON INTERNATIONAL / 14

1 - GENERAL REMARKS(cont...)

Follow the instructions in this

manual and take additional safety

measures appropriate to the liquid

being pumped and the temperature

of the water that powers the

DOSATRON.

Be extremely careful in the presence

of hazardous substances (e.g.

corrosives, toxins, solvents, acids,

caustic, flammables, etc.).

- Before applying any aggressive

chemicals, please consult your

distributor to confirm compatibility

with the dosing pump.

- When installing the DOSATRON

on a hot water system (140°F/

60°C max.), a dosing unit with

“T”-option is required. High

temperature increases the risk

and the dangerousness of the

substances mentioned above. It is

strongly recommended to identify

and label the dosing unit and the

complete hot water installation

as such, and to respect the

corresponding regulations in force.

IMPORTANT !

It is the responsibility of the

owner/operator to check that

the flow and pressure of the

installation do not exceed the

DOSATRON characteristics.

- Adjustmentmust be made when

there is no pressure in the Dosatron.

-Turn off the water supply and allow

the pressure to drop to zero.

- It is the responsibility of the

owner/operator of the DOSATRON,

to determine the correct amount of

solution and injection ratio to obtain

the desired result.

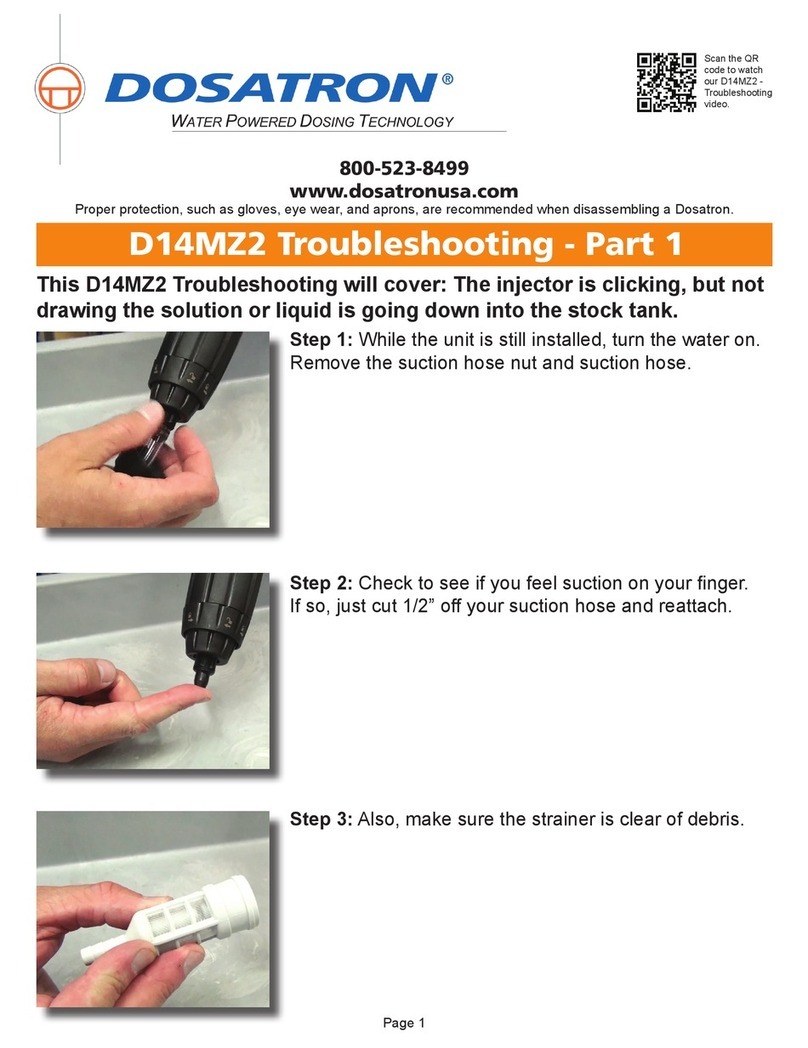

- An air inlet, an impurity or

a chemical attack on seal can

interrupt the dosing function. It is

recommended to periodically check

that the solution is being correctly

drawn up into the DOSATRON.

- Change the suction tube as soon as

it seems damaged by the chemical.

- Relieve the pressure after use

(advised).

- Rinsing of the DOSATRON is

required :

. when changing chemicals,

. before handling the DOSATRON, to

avoidany contact with the chemical.

- All assembly should be done

without tools, hand tighten only.

2 - WATER WITH HIGH PARTICLE

CONTENT

- A (ex.: 50 mesh - 300 microns

depending on your water quality)

water filter must be installed

upstream from the DOSATRON

(see accessories), if a filter is not

installed abrasive substances will

cause the DOSATRON to deteriorate

prematurely.

PRECAUTIONS (cont...)

US

3 - WATER-HAMMER /

EXCESSIVE FLOW

- For installations subject to water

hammer a protection device such

as a check valve or union ball check

must be fitted (pressure/flow

control system).

- For automatic installations, slow

opening and closing solenoid valves

are preferable.

- In an installation where a

DOSATRON serves several sectors,

the closing of one sector and the

opening of another sector must be

done at the same time (simultaneous

operation of the solenoid valves).

4 - INSTALLATION LOCATION

- The location of the DOSATRON

and concentrate container should

be accessible, but should never

present a risk of pollution or

contamination.

- It is recommended to label all

water lines with a warning about

the injected solution i.e.

IMPORTANT ! Not For Human

Consumption.

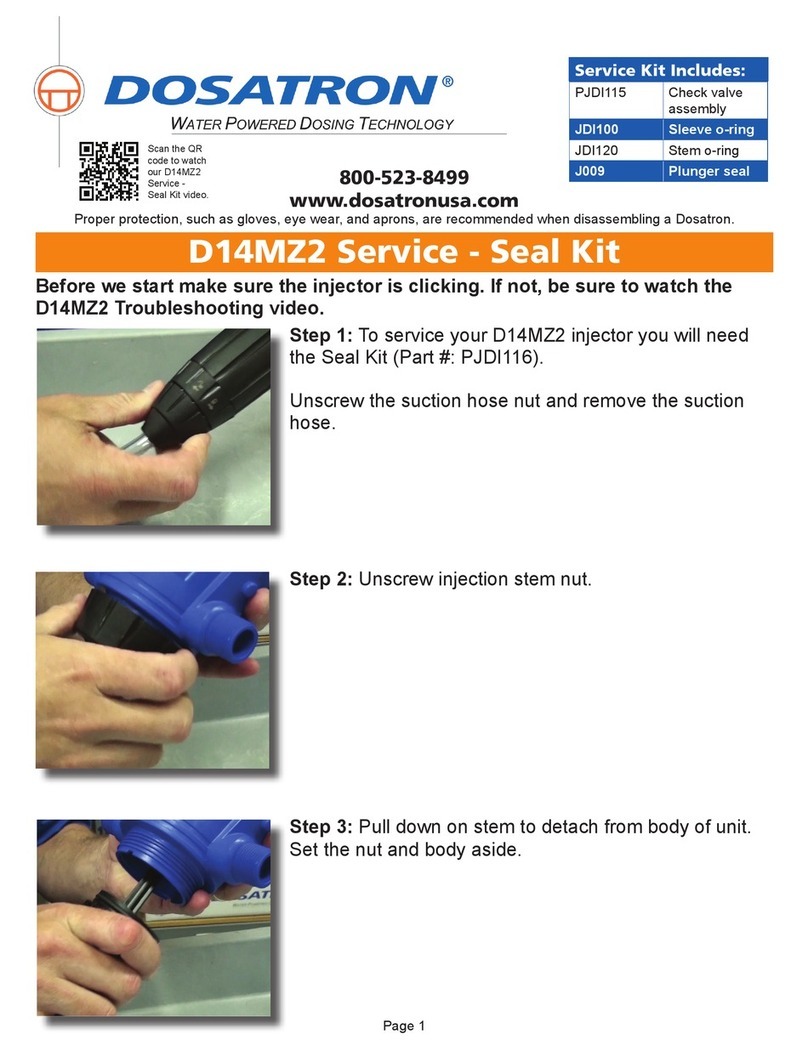

5 - MAINTENANCE

- Rinse the injection areas after using

the DOSATRON. To do this, insert

suction tube into a container of clean

water and inject about 1/4 liter

[8 1/2 US Fl.oz].

- Routine maintenance once a

year will add to the life of your

DOSATRON. Replace the injection

seals as well as the suction hose

annually to ensure proper injection.

6 - SERVICE

- This DOSATRON was tested prior

to packaging.

- Complete maintenance and seal

kits are available.

- Call your DOSATRON distributor

for service or parts.